The rules for storing food in the autumn-winter period differ from the features of their preservation in the summer. Extending the shelf life of fresh vegetables and canned goods is possible due to special basement and semi-basement premises with a controlled microclimate. The main condition for their storage is proper air circulation and control over humidity levels. Cellar ventilation with one and two pipes makes it possible to achieve optimal environmental parameters and ensure the safety of all products until the onset of the next season.

Consequences of poor ventilation

Operating principle and purpose of the system

Organizing a microclimate is a complex task, to achieve which a whole range of means, materials and techniques are used. One of the stages of designing a cellar is the selection and installation of a ventilation system. Lack of air circulation is considered a serious problem that can negate all efforts to harvest and prepare crops for the winter. In a room with insufficiently functioning or completely absent ventilation, the following phenomena develop:

- air stagnation;

- increase in humidity;

- increase in indoor temperature;

- acceleration of decay processes;

- the appearance of condensation;

- development of mold fungi;

- activation of corrosion processes.

As a result of such factors, food and all other attributes in the room suffer. Racks quickly rust, shelves rot and collapse, lids oxidize, vegetables and fruits rot, and the air becomes unbreathable. Effective ventilation guarantees the storage of products, increasing the service life of shelving and all related equipment.

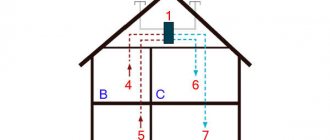

There are several ways to achieve complete circulation of air masses inside the cellar. However, the most effective among them is the design of a natural supply and exhaust system with two pipes. The principle of its operation is determined by the temperature difference between the environment and the cellar. From a school physics course it follows that heated air evaporates, rising to the ceiling. At the same time, its place is taken by cooled masses, providing the necessary circulation of flows. A similar effect can be achieved indoors by using a simple system consisting of two pipes.

Supply and exhaust ventilation diagram

Scheme of the ventilation system and its features

Arrangement of natural aeration is possible only in small areas without partitions and large-sized racks. The presence of obstructions reduces the rate of circulation, making ventilation less effective. The same rule applies to the area of the room, since the larger it is, the more difficult it is for air flow to move through it. Therefore, to organize adequate ventilation in such buildings, forced-type systems based on the action of electrical energy are used.

Air flow pattern

*

- The creation of a working model of ventilation of a natural type room is carried out according to clearly established rules regulated by SNiP. The influx of fresh air and the removal of exhaust air is carried out using 2 channels. The supply air duct is installed 10-15 cm above the floor level, and the second one is right under the ceiling, retreating from it by 5-10 cm. This arrangement of pipes ensures the outflow of waste masses and allows fresh air to flow freely into the room.

- From the outside, the supply air duct is mounted above the ground 30-40 cm above its level. The exhaust pipe is installed above the inlet pipe by 25 cm or more. A similar arrangement makes it possible to achieve the required pressure difference and ensure full aeration inside the cellar.

- Important! The higher the outlet pipe is installed, the greater the difference in pressure inside the room. Consequently, air masses will begin to replace each other more often, removing excess moisture and preventing the spread of mold.

Natural ventilation in the cellar

Equipment and materials

The natural supply and exhaust system is simple in its implementation compared to forced-type structures. The main part is considered to be the air duct, and the remaining parts are classified as auxiliary equipment. In addition to pipes, to create complete natural aeration you need:

- pipe connectors;

- fasteners;

- protective nets;

- deflectors or umbrellas.

Deflector

*

No other devices, fixtures or parts are included in the design of supply and exhaust aeration models. Thanks to this, the cost of their construction is reduced, and the effectiveness (subject to compliance with the requirements) increases.

The only criterion that directly affects the cost of the project is the pipe material. The following types of ducts are used:

- plastic;

- asbestos-cement;

- galvanized.

Each of these materials has features, characteristics and positive qualities. In this case, the choice of a specific type of product is made not based on economic indicators, but solely on the basis of technical features and operating conditions of the future model.

Galvanized pipes

Pros and cons of ventilation pipes

Plastic pipes are considered the most popular material used for the construction of natural aeration structures. Their main advantage is their relatively low cost, which reduces the overall costs of the project. In addition, the positive aspects of plastic include low weight, high ductility, flexibility and resistance to temperature changes. However, despite obvious advantages, they also have obvious disadvantages associated with low strength and instability to mechanical stress.

Asbestos-cement pipes are considered no less popular among builders. Their strength exceeds that of plastic products, which expands the scope of application of the material. In addition, its cost is also quite economical, which makes it possible to get an effective model for relatively little money. However, this is where the advantages of asbestos cement end. Its negative aspects include weight and bulkiness, lack of adapters, the need for additional reinforcement of fasteners and sealing of joints.

Galvanization is the most popular material for the construction of ventilation systems made of two pipes. The material is not subject to corrosion, is durable, accessible, does not deform, is resistant to thermal influences and has a wide range of products. Highways of various shapes, lengths and directions are created from galvanized metal, without worrying about their tightness and functionality. A relative disadvantage of the material is the cost, which exceeds other products, affecting the cost-effectiveness of the project.

Calculation of the diameter of air ducts

Calculating the diameter of the pipe for cellar ventilation is a difficult task, on which the functionality of the ventilation depends. Too small a cross-section of pipes does not allow air to circulate fully, and exceeding the size leads to a lack of the required pressure drop. To determine the size of the inlet and outlet channels, you need to know the following parameters:

- room area;

- wind load in a specific climate zone;

- location on the ground;

- temperature characteristics of the region.

Based on these criteria, making ventilation will not be difficult. According to the technical documentation for utility rooms (cellars and basements), the norm is the circulation of air masses in the amount of 120 cubic meters per hour. As a rule, to obtain complete air exchange in a room with an area of up to 25 square meters, installing pipes with a diameter of 100 mm is enough.

To improve natural circulation, special deflectors are used, which are installed at the outlet of the exhaust ducts. Thanks to the design details, these devices increase the speed of air movement, promoting renovation inside the room.

How to dry a damp cellar in summer

With the advent of warming, climatic conditions change - the street temperature becomes higher, warm light air does not want to sink into the cellar on its own. Accordingly, cold air masses do not leave the room, the natural ventilation of the basement does not work, and moisture is not removed.

How to dry a cellar:

- Force the air mass to move. Connect a small axial fan to the exhaust duct through a flexible corrugated pipe.

- Option for a cellar with a separate entrance: open the door wide, install a large household fan inside and direct the flow towards the doorway (hatch).

- Resume the natural circulation of flows by raising the temperature inside the basement. Install a brazier with coals, a diesel heat gun, or a homemade wood-burning stove indoors. After 2-3 days of heating, the dampness will go away.

- Use moisture-absorbing materials - sawdust, lime, corrugated cardboard. After they are saturated with moisture, they need to be changed (at least once a day) and dried outside.

Advice. To prevent fungus from appearing on concrete walls, after drying, treat the surfaces with a solution of slaked lime or another antiseptic.

For summer ventilation of the cellar, owners often use the traditional method - they simply open all the hatches and doors to the basement. The method is ineffective, because heavy cold air does not tend to come out. This drying will take 1-2 weeks depending on the humidity inside the room.

Installation stages

*

Installation of a ventilation system from the design stage of a future structure. This part plays an important role, as it makes it possible to assess the scale and focus of the work, as well as determine the amount of material required. To assess the complexity of a project, a simple diagram drawn with an ordinary pencil on a sheet of paper is suitable. Having estimated and purchased all the parts, we proceed to the direct installation of ventilation from 2 pipes with our own hands, which consists of the following steps:

- collection and preparation of equipment;

- formation of holes for laying air ducts;

- distributing and fixing pipes;

- sealing connections;

- installation of protective umbrellas.

When erecting a structure, it is better to do without connections and turns; a bend or a weak joint affects the pressure inside the channels. As a result, there is a decrease in the level of circulation of air masses, which leads to a decrease in the performance of the model. Another condition for the effective operation of the system is the tightness of the room. In addition to the supply and exhaust pipes, there should be no other sources of air in the cellar. Additional openings, cracks and holes also affect the movement of masses inside the room, reducing the intensity of circulation.

Supply channel

Briefly about the main thing

Ventilation is as important a part of the cellar arrangement as hydro- and thermal insulation. A poorly designed ventilation system will not cope with the job, which will result in spoilage of supplies. Air circulation for underground ventilation is organized in two ways: natural and forced (mechanical).

The choice of a suitable system (pipe diameter) largely depends on the area of the room. You should not install one pipe in a spacious cellar (or basement); two channels will provide the required level of air circulation. If natural circulation is weak, it is made combined or completely forced, installing one or two fans.

Cellar ventilation with one pipe: differences and features

The principle of ventilating a cellar with one pipe is based on the same principle as the previous design. The role of the exit channel is played by the entrance door and the natural cracks of the room. In this case, the supply pipe is installed according to the general principle, i.e. 10-15 cm above the floor level. Thanks to this, fresh air enters the cellar, ensuring normal circulation. The only drawback of this design is installation only in a small area of up to 12-15 square meters. Exceeding such values does not allow achieving effective aeration.

Important! The design features of the room also play a significant role. The presence of high racks, turns, uneven walls, ceilings and floors inevitably affects air movement. As a result, the natural ventilation system becomes less efficient even when the area is within acceptable limits. For complete air exchange in such cellars, it is necessary to construct a project with 2 pipes.

Cellar ventilation with one pipe

General requirements for the premises

Full temperature stability is achieved at a depth of about 3 m. The north-eastern location of the entrance also helps to maintain the desired parameters. Reliable waterproofing of walls, floors, and ceiling insulation is an axiom.

Wooden shelves, containers or shelving are the norm because wood conducts heat and cold very slowly and does not condense. When used in underground storage facilities, it is not impregnated with protective compounds, but covered with drying oil.

Air circulation is crucial in the fight against mold growth, so shelves and containers should be located 3-8 cm from the walls and floor.

For free-standing underground cellars, the preferred floor is compacted soil, a natural source of constant temperature and humidity. Concrete works well and is practical for basements under living spaces. And also at high groundwater levels, in areas where there is an increased release of radon gas.

Every cellar needs a thermometer and a hygrometer to measure temperature and humidity. It is mounted in the middle of the height of the room. Readings should be monitored daily, if possible.

Adjusting the system in winter

*

The penetration of frosty air into the cellar causes the temperature to drop below 0 degrees. Similar values have a negative impact on the safety of fresh products and preservation. Maintaining an optimal temperature of +2+6 degrees and preventing it from decreasing is an important task, which can be solved with the help of ventilation. However, if the cellar freezes due to insufficient thermal insulation, it will not be possible to solve the problem by restricting the incoming air. It is possible to increase the temperature inside the cellar by reducing the intensity of circulation. To do this, special plugs are installed at the inlet, allowing you to regulate the flow of incoming air or completely limit them.

Pipe freezing in winter

Ventilation care

To ensure quality ventilation, it is necessary to regularly monitor the operation of the system. The easiest way is with a lit match. If there is little oxygen and the air contains excess carbon dioxide, it will quickly go out. This is a signal - it's time to start cleaning your air ducts.

Dust, debris, cobwebs, ice or frost can accumulate in the gaps of pipes. Sometimes foreign objects are found in the ventilation ducts, and often rodents or other small animals.

To clean, you need to remove valves and electrical appliances from the pipe. Place a container underneath to collect debris and use a thin, strong wire with a brush at the end to move along the entire air path.

In winter, condensation collects in the air ducts. When it freezes, it turns into ice. It is quite difficult to remove the solid mass without damaging the pipe. This is done by heating with hot water or warm air. If traction is restored, the cleaning was successful.