The next article in the section is “apartment consumption”. So, as the heating season has already begun, many are interested in the power of their batteries. After all, the heat in the room and in the apartment as a whole depends on the power (you need to know this when calculating heating radiators at the level of designing a heating system). Today I will talk about the power of 1 section of a cast iron radiator...

Cast iron radiators come in various brands, but there are not so many of them and they can be listed on one hand. Everything else is just a variation of them. Today the most basic ones.

Indicators influencing the calculation of the number of sections

When choosing a radiator for a particular room, you need to take into account technical features. For example, the calculation will be different for a corner and non-corner room, for a room with different ceiling heights and different window sizes, etc. The most important parameters that are taken into account when determining the required radiator power are:

- the area of your premises;

- floor;

- ceiling height (above or below three meters);

- location (corner or non-corner room, room in a private house);.

- will the radiator be the main heating device;

- There is a fireplace and air conditioning in the room.

There are other important features that need to be taken into account. How many windows are there in the room? What size are they, and what kind of windows are they (wooden; double-glazed windows for 1, 2 or 3 glasses)? Was additional insulation of the walls done and what kind of insulation (internal, external)? In a private house, what matters is the presence of an attic and how insulated it is - and so on.

Cast iron radiators Conner (China)

According to SNIP, 41 W of thermal energy is required per 1 cubic meter of space. You can take into account not the volume, but the area of the room. For a 10 sq.m standard room with one door and one window, one door and an outer wall, the following heat output of the radiator will be required:

- 1 kW for a room with one window and an outer wall;

- 1.2 kW if it has one window and two external walls (corner room);

- 1.3 kW for corner rooms with two windows.

In reality, one kilowatt of thermal energy heats:

- In houses made of brick with a wall thickness of one and a half to two bricks, or made of timber and log houses (window and door area up to 15%; insulation of walls, roof and attic) - 20-25 sq. m

- In corner rooms with walls made of timber or brick of at least one brick (area of windows and doors up to 25%; insulation) - 14-18 sq. m

- In the premises of panel houses with internal cladding and a thermally insulated roof (as well as in the rooms of an insulated dacha) - 8-12 sq. m

- In a “living trailer” (wooden or panel house with minimal insulation) – 5-7 sq. m.

Heat transfer of modern cast iron devices

very efficient in terms of heat transfer .

These devices for heating houses of different sizes have a section that produces 0.14 kW. The heating device Viadrus STYL 500 has this power. Its segment is almost twice as light and smaller than the section of the devices described above. One particle of such a cast iron device holds 0.8 liters of coolant.

Radiator sections of some Russian manufacturers have a similar volume. They are capable of delivering heat at 0.102 kW. According to this indicator, they lag behind Czech products, but are better than MS-140.

The simplest calculation of battery power

To calculate the power of the device required to heat a room with an area of 25 m2 , you need:

- Determine the volume of the room. To do this, 25 m2 must be multiplied by the height of the room, for example, 2.5 m. The resulting figure is 62.5 cubic meters.

- The result obtained must be multiplied by a special coefficient. It depends on the type of room. If this is a panel house, then it is 0.041 kW per 1 cubic meter: 62.5 x 0.041 = 2.562 kW - the total power of the device for a room with an area of 25 m2.

Next, you need to divide the total heat transfer by the power of the segment: 2.562/0.14 = 18.3 – the number of battery sections required to heat a room with an area of 25 m2. The resulting figure must be rounded up. You need to buy a battery with 19 sections. You can purchase two batteries with the number of segments that add up to 19.

The coefficient specified in the second step depends on the type of house. This indicator could be like this:

- 0.034 kW/m – for houses built of brick;

- 0.02 kW/m – for houses whose construction was carried out in compliance with modern standards.

More complicated way

It involves the use of two indicators:

- Total heat demand.

- Heat transfer from one radiator fin (this value can be taken from the technical documentation).

When determining the first indicator, it is necessary to take into account:

- Room area.

- Floor.

- Ceiling height (whether it exceeds 3 m or not).

- Availability of air conditioning and fireplace.

- Number and area of windows.

- Availability of insulation of walls, floor and ceiling.

The heat requirement is determined in the following sequence:

- Calculate the volume of the room (area multiplied by height).

- The volume is multiplied by the figure 41 W (according to SNIP, 41 W of heat should be created per 1 cubic meter).

- The resulting figure is adjusted by various coefficients:

- if the ceiling is less than 3 m, then the height is divided by 3 and the result obtained is multiplied by the calculated heat requirement. If more, then they do the same;

- if the room is corner, then the resulting figure is multiplied by 1.8;

- if there is one large window or several windows, then the result is again multiplied by 1.8. In the case of plastic double-glazed windows, a correction factor of 0.8 is used;

- if the battery is connected to the bottom, then take a correction factor of 1.1;

At the end, the resulting figure is divided by the heat transfer of the section and the number of fins is determined.

poluchi-teplo.ru

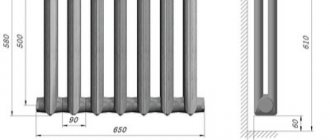

Dimensions and weight of cast iron heating radiators

The parameters of cast iron radiators using the example of the domestic product MS-140 are as follows:

- height – 59 centimeters;

- section width – 9.3 centimeters;

- section depth – 14 centimeters;

- section capacity – 1.4 liters;

- weight – 7 kilograms;

- section power 160 watts.

You can hear complaints from property owners that it is quite difficult to move and install radiators consisting of 10 sections, the weight of which reaches 70 kilograms, but the good news is that such work in an apartment or house is done only once, so the dimensions of cast iron heating radiators must be correctly calculated.

Since the amount of coolant in such a battery is only 14 liters, when thermal energy comes from the boiler of an autonomous heating system, then you will have to pay for the extra kilowatts of electricity or cubic meters of gas.

The difference between imported batteries and domestic ones

New type radiators give off more energy than old ones with the same dimensions.

Cast iron radiators, produced back in Soviet times, had a wide range of parameters and sizes. Regardless of this, the thermal power was approximately the same, which made it possible to install them in rooms of different sizes. Foreign cast iron batteries have smaller dimensions with the same thermal output.

When considering the cast iron material used in both cases, there is a slight difference in the chemical composition and structure of the working surfaces. In domestic batteries it is very rough, which creates significant resistance to the movement of coolant and reduces thermal efficiency. Foreign analogues have an absolutely smooth wall surface, guaranteeing the unhindered movement of liquid through the internal cavities. Therefore, imported devices pass a larger volume of heated water per unit time and release more thermal energy. As a result, the power indicator increases, which allows their use in rooms with a large area (up to 30 m2 or more).

Selection, installation and operation of cast iron heating batteries

Stages of installing a radiator to a heating system.

If the choice (lightweight radiators or cast iron) is made in favor of the latter, then you need to calculate the number of batteries in the room and the number of radiators in each of them. To do this, you need to know the technical characteristics of a particular model, first of all, the amount of heat generated. Another important task is to determine the location for installing the batteries and the method of mounting: wall or floor. Based on this, a specific sample is selected. Photos of almost most cast iron heating radiators can be found on the Internet. Cast iron radiators have different external volumes, including being quite voluminous or completely flat, and having different heights and widths.

A common place in a living room where you can install a battery is a niche located under the window sill. Its parameters dictate the size of the battery. The technical characteristics of this battery should provide 1 kW of heat per 10 m² of room area. Moreover, if the volume of the room is larger than usual due to the high ceiling, or there is a second window, then 1.2 kW of heat is needed for the same area. If the room occupies a corner position, it makes sense to add a few more extra sections, since there is more heat loss there.

The mounting method dictates both the weight of the battery and the strength of the wall near which it is placed. If it is hung on the wall, then it is worth remembering that at least three brackets are needed for each battery. Today, cast iron batteries often use floor mounts, and many models have ready-made legs. If the wall is made of wood, then you should use corner fasteners. Next, you need to carefully install the pipes supplying the coolant and screw them on, ensuring the tightness of the threads as much as possible. At the same time, do not overdo it in applying force so as not to tear it off, otherwise water will leak.

https://youtube.com/watch?v=8l2cyQIMvMQ

Repairing a cast iron battery most often consists of eliminating leaks at the connection points with the pipes. The question arises: how to wash the radiator from the inside? It also has a simple, albeit time-consuming solution. It is disconnected from the battery, and then with the help of a flexible brush and a hose with high water pressure, all accumulated dirt is easily washed out. Like repairs, this procedure is best left to a specialist. Independent steps can be quite successful, but they can also lead to damage.

Cast iron batteries will become an uninterrupted and reliable source of heat for you, your children and grandchildren.

We count batteries by volume

SNiP also has standards for heating one cubic meter of premises. They are given for different types of buildings:

- for brick, 1 m3 requires 34 W of heat;

- for panel - 41 W

This calculation of radiator sections is similar to the previous one, only now we need not an area, but a different volume and standards. We multiply the volume by the norm, divide the resulting figure by the power of one section of the radiator (aluminum, bimetallic or cast iron).

Example of calculation by volume

For example, let’s calculate how many sections are needed for a room with an area of 16 m2 and a ceiling height of 3 meters. The building is made of brick. Let's take radiators of the same power: 140 W:

- Finding the volume. 16 m2 * 3 m = 48 m3

- We calculate the required amount of heat (the norm for brick buildings is 34 W). 48 m3 * 34 W = 1632 W.

- We determine how many sections are needed. 1632 W / 140 W = 11.66 pcs. Round up, we get 12 pieces.

Now you know two ways to calculate the number of radiators per room.

Aluminum radiators

Aluminum devices have higher heat transfer than other types of heating batteries. They also have a large flow area. Thanks to these features, they provide quick heating of the room and make it possible to regulate the temperature. They are also light in weight.

These radiators are made of aluminum alloy and coated with powder enamel. Most often they are used in private homes with an autonomous heating system, since they last a long time only with low operating pressure and clean coolant. For houses connected to a central main line, aluminum batteries are not suitable due to the fact that sudden pressure changes occur in such systems. Aluminum is a lightweight material, so it may not withstand high pressure and simply burst.

But for private buildings such radiators are ideal. To make your home cozy and warm, and for your heating appliances to last a long time, you just need to monitor the cleanliness of the coolant and the pressure in the system. To maintain a comfortable temperature, it is recommended to install special thermostats.

If water is used as a coolant, then aluminum radiators must be washed once a year with running water under pressure. This does not pose a problem if the heating system was created from plastic pipes with quick-release connections. In this case, the radiator can be easily removed, washed and then installed back in its place. Aluminum batteries have a beautiful appearance. The front appears flawless, smooth and beautiful. Despite the fact that unevenness always occurs during the casting of sections, they are not visible on the finished product. Judging by their appearance, the batteries may appear to be made of plastic. The sides of the sections are also evenly painted. The back and interior are coated in one thin layer, but since the composition is of high quality, the paint does not flake or peel off.

The main difference between these two types of aluminum radiators is their appearance; the performance characteristics are almost identical.

Thermal power

In the room, heating devices are placed against the outer wall under the window opening. As a result, the heat emitted by the device is distributed optimally. The cold air coming from the windows is blocked by the heated air flowing upward from the radiator.

Cast iron batteries

Cast iron analogues have the following advantages:

- have a long service life;

- have a high level of strength;

- they are resistant to corrosion;

- Excellent for use in utility systems operating on low-quality coolant.

- Now manufacturers produce cast iron batteries (their price is higher than conventional analogues), which have an improved appearance thanks to the use of new technologies for casting their housings.

Disadvantages of products: large mass and thermal inertia.

The lower table states how many kW is in a cast iron radiator, based on its model.

| Radiator model | Thermal power of one section in Watts |

| MS-140/M-2 | 160 |

| MS-140/M-300 | 117 |

| MS-90 | 130 |

| T-90/M | 127 |

Note! To heat a room with an area of 15 m², the power, that is, kW of a cast iron radiator, must be at least 1.5. In other words, the battery should consist of 10-12 sections.

Aluminum radiators

Aluminum products have greater thermal power than cast iron counterparts. When asked how many kW is in one section of an aluminum radiator, experts answer that it reaches 0.185-0.2 kW. As a result, for the standard level of heating of a fifteen-meter room, 9-10 sections of aluminum sections will be sufficient.

The advantages of such devices:

- a light weight;

- aesthetic design;

- high level of heat transfer;

- You can control the temperature yourself using thermostatic valves.

But aluminum products do not have the same strength as their cast iron counterparts, for example a 2 kW oil radiator. Therefore, they are sensitive to surges in operating pressure in the system, water hammer, and excessively high temperature of the coolant.

Note! When water has a high pH (acidity) level, aluminum releases a lot of hydrogen. This negatively affects our health. Based on this, it is advisable to use such devices in a heating system in which the coolant is neutrally acidic.

Bimetallic products

Before you find out how many kW are in 1 section of a bimetallic radiator, you should take into account that such batteries have similar operational parameters to their aluminum counterparts. However, they do not have any inherent disadvantages.

This circumstance was determined by the design of the devices.

- They consist of copper or steel pipes through which coolant flows.

- The tubes are hidden in an aluminum plate housing. As a result, the water circulating inside does not interact with the aluminum of the case.

- Based on this, the acidic and mechanical characteristics of the coolant do not in any way affect the operation and condition of the device.

Thanks to the steel pipes, the device has high strength. Increased heat transfer is ensured by external aluminum fins. When trying to find out how many kW is in a steel radiator, keep in mind that bimetal has the highest heat transfer - about 0.2 kW per fin.

What is heat transfer and power of radiators

The power of cast iron heating radiators and their heat output are among the main characteristics of any device that provides room heating. Typically, manufacturers of equipment for heating structures indicate this parameter for one section of the battery, and the required number is calculated based on the size of the room and the required heat transfer of cast iron radiators.

In addition, other factors are taken into account, such as the volume of the room, the presence of windows and doors, the degree of insulation, climatic conditions, etc. The heat output of heating radiators depends on the material they are made of. It should be noted that cast iron is inferior to aluminum and steel in this matter. The thermal conductivity of this material is 2 times lower than that of aluminum. But this drawback is compensated by the low inertia of cast iron, which gains heat and releases it for a long time.

In closed heating systems with forced circulation, the efficiency of aluminum batteries will be much greater, but subject to the presence of an intense coolant flow. As for open structures, cast iron has more advantages with natural circulation. The approximate power of one section of a cast iron radiator is 160 watts, while for aluminum and bimetallic devices the same parameter is within 200 watts. Therefore, under equal operating conditions, a cast iron battery should have a large number of sections.

Calculation specifics

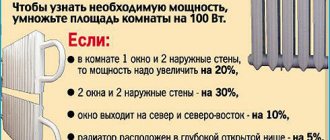

When calculating, corrections are made for the number of windows and doors.

Modern manufacturers of cast iron trim offer their customers batteries with various operating parameters that determine a wide range of specific powers. There are several methods for carrying out technical calculations related to determining the performance characteristics of radiators. Simple and more complex algorithms allow you to find the necessary indicators with a given degree of accuracy (error) and, if necessary, adjust them.

When introducing correction factors, many factors are taken into account, including the number of doors and windows in the room. When increasing the specified structural elements by at least one, in the general case one section is added to the result obtained. The same correction must be introduced when taking into account the material from which the window or doorway is made.

Coolant for cast iron radiators

One of the significant advantages of cast iron models is their insensitivity to various coolants. There is no need to monitor the acidity levels of the circulating fluid. The width of the channel makes it possible to freely pass through and not allow impurities to accumulate inside, of which there are a huge number in central heating systems.

Cast iron radiators do not enter into chemical reactions with antifreeze, water or other liquids containing anti-freezing additives. However, this does not mean that you can forget about water treatment. Indeed, in addition to the batteries, the coolant flows through pipe lines, inside the boiler and other installed equipment.

Working and testing pressure

Among the technical characteristics, in addition to the fact that the power of cast iron heating radiators is important, mention should be made of pressure indicators. Typically, the operating pressure of the coolant liquid is 6-9 atmospheres. Any type of battery can cope with this pressure parameter without problems. The standard pressure for cast iron products is considered to be exactly 9 atmospheres. In addition to the working one, the concept of “pressure testing” is used, reflecting its maximum permissible value that occurs during the initial start-up of the heating system. For the cast iron model MS-140 it is equal to 15 atmospheres.

According to the regulations, during the process of starting the heating system, it is necessary to check the ability to smoothly start centrifugal pumps, which should operate in automatic mode, but in reality everything is far from as it should be.

Unfortunately, in most homes, automation is either absent or faulty. But the instructions for carrying out this type of work stipulate that the initial start-up should be performed with the valve closed. It is allowed to open smoothly only after equalizing the pressure in the coolant supply line.

But utility workers do not always follow instructions. As a result, in case of violation of the regulations, water hammer occurs. With it, a significant pressure surge leads to exceeding the permissible pressure value and one of the batteries located along the path of the coolant is unable to withstand such a load. As a result, the service life of the device is significantly reduced.

Technical characteristics of cast iron radiators ms 140

At the moment, in our country, cast iron heating radiators MS 140 can be called the most common model of heating devices. These devices are manufactured in accordance with GOST 8690–94. Depending on the distance between the axles, there are five standard sizes of MS 140 batteries: 300, 400, 500, 600 and 800 mm.

Previously, all standard sizes were used quite widely, and they could be seen not only in residential apartments, but also in administrative and industrial buildings. At the moment, the most commonly used cast iron radiators are MS 140 500 and 300. Other modifications are extremely rare and, as a rule, they are made to order.

In view of the popularity of ms 140 500 batteries, you should consider the technical parameters of this model. For heating cast iron radiators brand MS 140, the characteristics are given for one section, since this is a purely sectional model. By selecting the required number of sections, you can create the optimal temperature regime in the room.

The main characteristics of heating radiators MS 140 500 are as follows:

- pressure. Working pressure is up to 9 atmospheres, and pressure testing is up to 15 atmospheres;

- heat transfer is low and equals 175 W;

- each section has two channels;

- section dimensions: height – 50 cm, width – 9.8 cm;

- the capacity of one section is 1.35 liters of water;

- The radiator is able to withstand coolant temperatures up to +130 degrees.

It is worth considering the design of a cast iron heating battery model ms 140 500. Gray cast iron is used for production. Nipples are made of malleable cast iron. Gaskets are installed between the sections. Heat-resistant rubber is used to produce gaskets.

Parameters of some battery samples

Comparative power of 1 section of radiators by imported and domestic manufacturers

In distant Soviet times, MS-140 batteries could be found in almost every apartment, but today they are perceived by many as a relic of the past. However, some users still prefer them to all other well-known models. Their admirers usually choose the following two modifications:

- in the first model, the power of 1 section of a cast iron radiator in kW is 0.120 units;

- for the second sample this figure is 0.190 kilowatts.

The latter are much larger in size and much heavier - the height and width of the sections are 0.588 and 0.121 meters, respectively. The volume of the internal cavities of one such segment is 1.5 liters.

Calculating the power of a cast iron radiator

You can calculate the number of sections for cast iron heating devices using a variety of methods. In specialized books there are methods that include a large number of factors, including the area of the room, the location of windows and doorways, the material and structure of the walls, technical indicators of batteries, etc.

However, you can obtain the desired value using a simpler formula: multiply the area of the room by 100 and divide by the power of one section.

The result obtained should be corrected as follows:

- In rooms with a height of more than 3 m, 1-2 sections are added to compensate for heat losses

- Adding several sections is necessary for rooms where two walls border the street

- In rooms with two window openings, radiators are installed under each of them, dividing the found number of sections equally. This is necessary so that air barriers are formed under the windows for cold through flows from outside.

- The fractional value is always increased in a positive direction

Classic cast iron radiators are not much different in appearance. However, the development of the heating appliance market and the constant change in the style of the interior forced manufacturers to come up with something new, more elegant and extravagant.

Today, the market offers models of various color palettes (gold plated, silver, copper, bronze, etc.). There are radiators with artistic castings on which ornaments are applied.

However, external design significantly affects the cost. Decorative models are much more expensive than classic, modern aluminum, steel or bimetallic ones.

Video instructions for assembling sections

Having examined in more detail the features and technical characteristics of cast iron heating radiators, you can get your own idea about these heating devices. However, it is impossible to claim their great superiority over other models. The reason is that each of the proposed options has its pros and cons.

Due attention should be paid to cast iron models when designing a heating system. You can purchase them in a maintained condition to save money and not have to worry about them breaking down soon.

How do foreign radiators differ from domestic ones?

The products of both groups of manufacturers are made from almost the same cast iron. The difference lies in the surface characteristics of the cast iron.

Foreign versions have a smooth inner surface . The coolant circulation easily slides along it without “feeling” much hydraulic resistance. Therefore, smaller sections of foreign heating devices are able to pass more water per unit of internal area and absorb more heat. As a result, their power increases. They need to be installed in rooms with a large area (30 or more sq. m.).

Advantages compared to other batteries

- The undeniable advantage of a cast iron radiator over modern aluminum, steel, and bimetallic batteries is its durability. The half-century anniversary of the cast iron battery is a ubiquitous phenomenon. In some cities, the batteries that were cast in the century before last have survived to this day and continue to work properly.

- The cost of a cast iron product can only please the future owner - European prices for trendy aluminum or bimetallic batteries are not affordable for everyone. In addition, purchasing a large number of sections promises significant benefits.

- Another advantage of cast iron is the absence of any coolant requirements. Water of any quality is poured into the heating system.

- The thickness of the cast iron sections allows them to withstand the highest operating pressures. starting from 9 Atm and above. In addition, cast iron withstands water hammer very well, which is why it is preferred in centralized heating systems.

“Calculation taking into account” the characteristics of the room

This is the most complex method, but it will give almost accurate figures due to the large number of different coefficients. They do not relate to the heating system, but only to the features of the room, to the methods of installing the batteries. The same formula is used:

To obtain the required heat transfer, which will then have to be divided by the thermal power of one section, the footage (not volume!) of the room is first multiplied by the average power rate for 1 m2. It does not depend on the region and is 100 W. Then the result is multiplied in turn with coefficients A, B, C, D, E, F, G, H, I and J.

“A” is the number of external walls of the room

To a greater extent, heat loss strongly depends on their quantity:

- external wall - only one: 1.0;

- two external walls - 1.2;

- external walls - three: 1.3;

- four walls - 1.4.

“B” - room orientation

A minimum of heat is retained in rooms with windows facing where there is always little sunlight: to the north or east, where the sun’s rays are “noted” only in the morning:

- windows face east or north - 1.1;

- the room is located on the west or south side - 1.0.

“C” - degree of insulation

High-quality thermal insulation gives a chance to retain heat in the room as much as possible:

- masonry with 2 bricks or insulated external walls - 1.0;

- no insulation on the outside - 1.27;

- very high level of insulation (if thermal calculations have been carried out) - 0.85.

"D" - climate in the region

SNiP also takes these conditions into account; without taking them into account, no capital construction is possible. Here they use the average temperature of December, its coldest ten-day period. This data must be obtained from the hydrometeorological service of the city (district):

- up to -10° - 0.7;

- up to -15° - 0.9;

- not lower than -20° - 1.1;

- from -25° to -35° - 1.3;

- from -35° or below - 1.5.

"E" - ceiling height

As already noted, both SNiP standards (from 60 to 200 W per 1 m2) and the average value (100 W) used in this case imply a standard ceiling height of 2700 mm. If they do not “reach” this figure, then they choose a coefficient of 1.0. When the height exceeds it, then another is taken for multiplication:

- 1.05 if the height is in the range of 2800-3000 mm;

- 1.1 for 3100-3500 mm;

- 1.15 for 3600-4000 mm;

- 1.2 if the ceiling height is more than 4100 mm.

"F" - the room located above

Since rising warm air more readily escapes through the ceiling of a room, in this case the upper floor is of great importance. These coefficients look like this:

- on top of an attic or other unheated room - 1.0;

- insulated attic and roof - 0.9;

- heated room - 0.8.

“G” – quality of window structures

Different plastic windows have different characteristics. Ordinary window designs stand apart, greatly increasing the coefficient:

- old-style wooden frames with double glazing - 1.27;

- single-chamber double-glazed window with two glasses - 1.0;

- double-glazed window or single-chamber, but with argan coating - 0.85.

“H” - room glazing area

Regardless of the quality of window structures, more heat loss occurs due to the impressive window area. This coefficient depends on the ratio of the area of window openings and the total footage of the room:

- less than 0.1 - 0.8;

- from 0.11 to 0.2 - 0.9;

- 0,31-0,4 — 1,1;

- from 0.41 to 0.5 - 1.2.

“I” - radiator connection diagram

Heating efficiency depends on how the batteries are connected to the pipes - both supply and return. The best option is a diagonal connection: the first from above, the second from below. It (indicated by the letter A in the figure) corresponds to a coefficient of 1.0.

- B - 1.03;

- B - 1.13;

- G - 1.25;

- D, E - 1.28.

“J” - degree of openness of batteries

Any artificial (or existing) barrier can slightly affect heat transfer. In this case, the radiator located under the window sill “deserves” a coefficient of 1.0. Other heating devices with an “obstacle”:

- located on the wall without any “limiters” - 0.9;

- niches covered from above with a ledge - 1.07;

- having fencing from a window sill and from a decorative casing, but only from the front side - 1.12;

- batteries completely covered with a decorative element - 1.2.

All coefficients are first written down on paper, then, multiplying the footage by the average rate (100 W), they begin to multiply by the coefficients in order. The resulting result is divided by the heat transfer of 1 section (for the model you like), obtaining the required number of sections. If such calculations do not inspire “feats”, then you can use online calculators. However, this work only seems difficult; in reality there is nothing complicated.

Also, you can use our online calculator to calculate heating.

Which method to choose depends only on the strength of the owners’ desire to thoroughly understand the issue. More detailed information can be found in this video:

Recommendations for choosing heating batteries

Externally, bimetallic radiators resemble aluminum ones; it is difficult to distinguish them. Without specific knowledge, visual differences are not easy to see. However, when it comes to performance characteristics, bimetallic batteries are much better than aluminum ones.

The best radiator currently is bimetallic. It is durable and can withstand high pressure, so it can also be installed in multi-storey buildings with a centralized heating system. As for aluminum products, they cannot always be used.

It is not recommended to use them in cases where:

- There is high pressure in the heating system

. Since aluminum is a brittle metal, if the maximum permissible pressure is exceeded, the product may not withstand and leak. For this reason, aluminum radiators are not used in multi-storey buildings connected to a central highway. - Non-freezing liquids, which are incompatible with aluminum, are used as coolants

. If such a coolant comes into contact with this metal, a chemical reaction occurs, leading to the destruction of the heating device. - The boiler has a copper heat exchanger

. Copper and aluminum are incompatible materials, since they form a galvanic couple, between which an electric current arises, destroying both elements. Aluminum suffers the most because its ions are attracted to copper. As a result, over time, the walls of the heating device will become thinner and may leak. However, such a problem will not arise if metal-plastic or polypropylene pipes were used to create the heating system - in this case, galvanic couples are not formed.

Panel steel radiators are used exclusively in autonomous heating systems. These batteries can be used with any coolant and even with copper heat exchangers. Steel radiators are quite durable, but they are susceptible to rust.

All types of heating radiators have certain advantages and disadvantages, so the choice depends on the specific situation. As for the characteristics and operating conditions, bimetallic radiators are the best, but not every family can afford to buy them.

Details about the types of heating batteries in the video:

How many kilowatts are in one section of a bimetallic radiator

Bimetallic radiators are difficult to distinguish from aluminum ones in appearance. They can also be equipped with air cutoffs, and the level of heat transfer mainly depends on the height.

As with aluminum, manufacturers' specifications differ from those in reality. Therefore, we provide information for the water temperature in the circuit of 65-70 degrees.

Thermal power of a section of a bimetallic heating radiator without air cutoffs:

- 200 mm – 0.5-0.6 kW;

- 350 mm – 0.1-0.11 kW;

- 500 mm – 0.14-0.155 kW.

How many kW of one section of a bimetallic radiator with air cutoffs:

- 200 mm – 0.6-0.7 kW;

- 350 mm – 0.115-0.125 kW;

- 500 mm – 0.17-0.19 kW.

Recommendations for selection and installation

The selection of this type of battery comes down to determining the required number of sections for heating a particular room and the appropriate standard size. To do this, you should know the required thermal power or approximately calculate it by quadrature, and take the heating radiators with some margin. If we take as a basis that for each m2 of area you need 100 W of thermal energy, then for a room of 10 m2 you will need 1 kW of heat, and sections of the MS device 140 500 - 1000 / 160 = 6.25, 7 pieces are taken.

For northern regions, an increasing coefficient of 1.5 to 2 must be applied to the value of thermal power, and for southern regions, a decreasing index of 0.7 must be applied.

Radiators are installed to an external wall in accordance with the diagram.

To fasten MC 140 batteries, 2 types of brackets are used: steel and cast iron.

There are paired brackets welded with a strip, which are best used when mounting on a wall made of porous materials. They can be attached to the surface at several points.

Right choice

- The performance of heating devices should be 10% of the area of the room if its ceiling height is less than 3 m.

- If it is higher, then 30% is added.

- For the end room you need to add another 30%.

Necessary calculations

After determining the heat losses, you need to determine the performance of the device (how many kW should be in a steel radiator or other devices).

- For example, you need to heat a room with an area of 15 m² and a ceiling height of 3 m.

- We find its volume: 15∙3=45 m³.

- The instructions say that to heat 1 m³ in the conditions of central Russia you need 41 W of thermal output.

- This means that we multiply the volume of the room by this figure: 45∙41=1845 W. The heating radiator must have this power.

Note! If the home is located in a region with severe winters, the resulting figure must be multiplied by 1.2 (heat loss coefficient). The final figure will be 2214 watts.

Number of ribs

Next, you need to calculate the number of sections in the battery. The instructions for the products indicate the parameter of each edge.

From it you will find out how many kW are in one section of a bimetallic radiator and an aluminum analogue - this is 150-200 W. Let's take the maximum parameter and divide the total required power in our example by it: 2214:200=11.07. This means that to heat the room you need a battery of 11 sections.

External design features

Cast iron radiators are produced only in factory conditions; mostly gray cast iron is used for these purposes. The radiator is made up of separate sections or “teeth”, each containing a round or oval shaped channel through which the coolant will move. Sections can be single-channel or double-channel. Next, the sections are assembled into a single battery, they are joined together, and heat-resistant gaskets are laid for tightness. The size of the battery will depend on the number of sections.

The size of heating radiators made of cast iron can be different; various models with different section parameters are now produced. The size is selected individually depending on the area of the room, insulation and the number of window and door openings in the house. The size of radiators can vary from 50 to 140 centimeters in depth, from 35 to 150 centimeters in height, the width is chosen based on the number of sections.

Batteries are manufactured using the casting method. Therefore, the design is sealed and reliable. Cast iron perfectly accumulates and releases heat, suitable for autonomous and centralized heating systems. Cast iron batteries have a high wear resistance and service life. They withstand pressure surges well; the operating pressure in the battery is nine atmospheres. They are also not picky about the coolant; fine sand and scale when hot water moves cannot cause significant damage to the channels inside the sections. For central heating systems, where the coolant “acquires” a good supply of chemical elements during its journey, cast iron is also suitable, since the metal does not react and does not rust.

Heat transfer of one section

Today there is a wide range of radiators. While most are similar in appearance, thermal performance may differ significantly. They depend on the material from which they are made, on the dimensions, wall thickness, internal cross-section and on how well the design is thought out.

Therefore, it is possible to say exactly how many kW in 1 section of an aluminum (cast-iron bimetallic) radiator only in relation to each model. This data is provided by the manufacturer. After all, there is a significant difference in size: some of them are tall and narrow, others are low and deep. The power of a section of the same height from the same manufacturer, but of different models, may differ by 15-25 W (see the table below STYLE 500 and STYLE PLUS 500). There may be even more noticeable differences between different manufacturers.

However, for a preliminary assessment of how many battery sections are needed for space heating, we calculated the average thermal power value for each type of radiator. They can be used for approximate calculations (data are given for batteries with an interaxial distance of 50 cm):

- Bimetallic - one section produces 185 W (0.185 kW).

- Aluminum - 190 W (0.19 kW).

- Cast iron - 120 W (0.120 kW).

More precisely, how many kW can you have in one section of a bimetallic, aluminum or cast iron radiator when you choose a model and decide on the dimensions. The difference in cast iron batteries can be very big. They are available with thin or thick walls, which causes their thermal output to change significantly. Above are the average values for batteries of the usual shape (accordion) and those close to it. Retro-style radiators have significantly lower thermal output.

Based on these values and average standards in SNiP, the average number of radiator sections per 1 m2 was calculated:

- the bimetallic section will heat 1.8 m2;

- aluminum - 1.9-2.0 m2;

- cast iron - 1.4-1.5 m2;

How to calculate the number of radiator sections using this data? It's still simpler. If you know the area of the room, divide it by the coefficient. For example, a room of 16 m2, to heat it you will need approximately:

- bimetallic 16 m2 / 1.8 m2 = 8.88 pcs, rounded - 9 pcs.

- aluminum 16 m2 / 2 m2 = 8 pcs.

- cast iron 16 m2 / 1.4 m2 = 11.4 pcs, rounded up - 12 pcs.

These calculations are only approximate. Using them, you can roughly estimate the costs of purchasing heating appliances. You can accurately calculate the number of radiators per room by choosing a model, and then recalculating the number depending on the temperature of the coolant in your system.

Heat transfer calculation

First of all, it is recommended to pay attention to the existing data sheet, which is attached to each product of this type. In it you can find the necessary information regarding the thermal power of one section of the product

These figures need significant correction. The heat transfer of bimetallic heating radiators, like aluminum ones, have excellent power ratings, and the judgment is based on the well-known fact that copper products have an excellent level of heat transfer, as well as aluminum ones. They have a high thermal conductivity, while heat transfer depends on many other factors.

Heat transfer from the heating radiator is multiplied by a correction factor taken depending on the DT value

The figure indicated in the passport is correct only if the difference between the supply and processing temperatures is 70°C.

Using the formula, calculations are made as follows:

The instructions may have different symbols. Often only a difference of 70°C is mentioned and nothing more.

Calculation by area

This is the simplest method that allows you to roughly estimate the number of sections required to heat a room. Based on many calculations, standards for the average heating power of one square area have been derived. To take into account the climatic features of the region, two standards were prescribed in SNiP:

- for regions of central Russia, from 60 W to 100 W are required;

- for areas above 60°, the heating rate per square meter is 150-200 W.

Why are the standards given such a wide range? In order to take into account the wall materials and the degree of insulation. For houses made of concrete, the maximum values are taken; for brick houses, average values can be used. For insulated houses - minimal. Another important detail: these standards are calculated for the average ceiling height - no higher than 2.7 meters.

Knowing the area of the room, multiply its heat consumption rate, which is most suitable for your conditions. You get the total heat loss of the room. In the technical data for the selected radiator model, find the thermal power of one section. Divide the total heat loss by the power, and you get the amount. It’s not difficult, but to make it clearer, let’s give an example.

An example of calculating the number of radiator sections by room area

Corner room 16 m2, in the middle zone, in a brick house. Batteries with a thermal power of 140 W will be installed.

For a brick house, we take heat loss in the middle of the range. Since the room is corner, it is better to take a larger value. Let it be 95 W. Then it turns out that heating the room requires 16 m2 * 95 W = 1520 W.

Now we count the quantity: 1520 W / 140 W = 10.86 pcs. Round up, it turns out to be 11 pieces. This is how many radiator sections will need to be installed.

The calculation of heating radiators per area is simple, but far from ideal: the height of the ceilings is not taken into account at all. For non-standard heights, a different technique is used: by volume.

How to calculate heat transfer and power of radiators

In order to always maintain a comfortable temperature in the room, it is necessary to correctly calculate the heat transfer of heating devices and select them in accordance with the required characteristics.

This is the only way we can correctly calculate heating radiators so that the room is warm and comfortable in cold weather.

The thermal power of the heating device is indicated in its passport. However, this parameter may vary depending on actual operating conditions. The calculation of heat transfer from a radiator is determined based on the temperature difference - the difference between the average temperature of the coolant and the air in the room:

where Твх – coolant temperature at the inlet;

Тout – temperature of the coolant at the outlet;

Troom – air temperature in a heated room (a value of 20 degrees is considered comfortable).

In the technical specifications, the temperature regime is designated as Tin/Tout/Troom. and the temperature pressure is Tnap. If the heating system has indicators that differ from the values specified in the passport, then the thermal power of the radiator should be calculated using the formula:

where k is the heat transfer coefficient of the heating device (indicated in the passport);

A – area of the heat transfer surface of the radiator (indicated in the passport);

Tnap – temperature pressure.

By calculating the power of the heating battery, you can determine the required number of batteries or select a specific type of heating device that has sufficient heat output to heat a particular room.

What to consider when calculating a radiator

Radiator installation examples

When planning to perform a calculation, first of all you need to calculate the level of heat loss that your home has.

According to statistics, the level of heat loss in different areas of the house is as follows:

- chimney – 10%;

- roof – 20%;

- walls of the home – 30%;

- windows – 30%;

- basement – 10%.

Tip : When choosing a place to install cast iron radiators, it is best to give preference to the space under the window.

Why under the window? Everything is extremely simple - during the heating process, cast iron emits 80% of thermal energy by convection and only 20% as infrared radiation. Thus, installation in a section under the window will allow for uniform circulation of heated air throughout the room.

The formula for calculating power is:

K = S x 100 : P

Of what:

- K – number of sections that will be needed;

- S – area of the room for which the calculation is performed;

- P is the power of your radiator.

Now let's look at an example. Let's assume that the calculation is carried out for a room of 30 square meters, with a radiator power of 150 W. Then you get:

K = 30 x 100 : 150 = 20

To meet the needs of this room, its owner will need the power of a 20-section cast iron radiator. It can be divided into 2 batteries of 10 sections each or into 4 batteries, but 5 each, you decide for yourself. Now let's move on to how to carry out independent calculations for your premises.

Explanations of comparative values of heating appliances

From the data presented above, it is clear that the bimetallic heating device has the highest heat transfer rate. Structurally, such a device is presented by RIFAR in a ribbed aluminum housing. in which metal tubes are located, the entire structure is secured by a welded frame. This type of battery is installed in high-rise buildings, as well as in cottages and private houses. The disadvantage of this type of heating device is its high cost.

Important! When this type of battery is installed in houses with a large number of floors, it is recommended to have its own boiler station, which has a water treatment unit. This condition for the preliminary preparation of the coolant is associated with the properties of aluminum batteries

they can be subject to galvanic corrosion when it is supplied in poor quality through the central heating network. For this reason, it is recommended to install aluminum heating devices in separate heating systems.

Cast iron batteries are significantly inferior in this comparative system of parameters; they have low heat transfer and a large weight of the heating device. But, despite these indicators, MS-140 radiators are in demand among the population, the reason for which is the following factors:

Duration of trouble-free operation, which is important in heating systems. Resistance to the negative effects (corrosion) of the thermal fluid. Thermal inertia of cast iron.

This type of heating device has been operating for more than 50 years; for it there is no difference in the quality of the preparation of the thermal fluid. They cannot be installed in houses where the operating pressure of the heating network may be high; cast iron is not a durable material.

Calculation of radiator sections depending on real conditions

Once again, please note that the thermal power of one battery section is indicated for ideal conditions. This is how much heat the battery will produce if its coolant temperature at the inlet is +90°C, at the outlet +70°C, and the room is maintained at +20°C. That is, the temperature pressure of the system (also called “delta system”) will be 70°C. What to do if your system does not exceed +70°C at the inlet? or do you need a room temperature of +23°C? Recalculate the declared power.

To do this, you need to calculate the temperature pressure of your heating system. For example, at your supply you have +70°C, at your outlet 60°C, and in the room you need a temperature of +23°C. Find the delta of your system: this is the arithmetic average of the inlet and outlet temperatures, minus the room temperature.

For our case it turns out: (70°C+ 60°C)/2 - 23°C = 42°C. The delta for such conditions is 42°C. Next, we find this value in the conversion table (located below) and multiply the declared power by this coefficient. Let's learn the power that this section can produce for your conditions.

We find in the columns tinted blue a line with a delta of 42°C. It corresponds to a coefficient of 0.51. Now we calculate the thermal power of 1 radiator section for our case. For example, the declared power is 185 W, applying the found coefficient, we get: 185 W * 0.51 = 94.35 W. Almost twice as much. This is the power that needs to be substituted when calculating the radiator sections. Only taking into account individual parameters will the room be warm.

stroychik.ru

Cast iron radiators are still one of the most common means of heating in domestic apartments. They can deservedly be called veterans of the heating front - after all, this type of heating devices was invented back in 1857 by the French scientist Franz San Galli. Since then, they have been widely used for heating rooms and are still relevant today.

The popularity of cast iron batteries is explained very simply - they are convenient, efficient and low in cost.

Comparative findings

The heat transfer of aluminum radiators is slightly lower, although they are lighter and cheaper than bimetallic ones. In terms of test and operating pressure, aluminum devices can also be installed in buildings of any number of floors, but subject to: the presence of an individual boiler room with a water treatment unit. The fact is that aluminum alloy is susceptible to electrochemical corrosion from low-quality coolant inherent in central networks. It is better to install aluminum radiators in separate systems.

Cast iron radiators differ sharply from others. the heat transfer of which is significantly lower with a large mass and capacity of the sections. It would seem that with such a comparison they would not find application in modern heating systems. Nevertheless, the traditional MS-140 “accordion” continues to be in demand, their main trump card is durability and resistance to corrosion. Indeed, gray cast iron, from which MS-140 is made by casting, can easily serve for up to 50 years or more, and the coolant can be anything.

In addition, a conventional cast iron battery has high thermal inertia due to its massiveness and capacity. This means that when the boiler is turned off, the radiator remains warm for a long time. As for the operating pressure, cast iron heaters cannot boast of high strength. Purchasing them for networks with high water pressure is risky.

Advantages and disadvantages of cast iron batteries

Like any heating devices, cast iron radiators have both advantages and disadvantages. The advantages include:

- Resistance to chemically active components contained in coolants. Unlike materials used in the production of other types of radiators, cast iron practically does not rust.

- Long service life. Some cast iron batteries that have served for 50-60 years are still functioning today.

- There is no need to connect a circulation pump, since cast iron radiators create little hydraulic resistance for the coolant.

- Do not require cleaning for a long time due to the large diameter of the channels;

- Thermal inertia, which acts as an advantage and a disadvantage at the same time. Radiators can retain heat for a long time, but temperature control is not possible.

Flaws:

- Large dimensions, mass of devices, which significantly complicate their installation;

- Difficulty in adjusting temperature conditions;

- Slow warm-up when the system is turned on;

- The intercostal connections are quite complex, which interferes with cleaning and painting the product.

How many kW in the cast iron section of the heating radiator

Cast iron radiators are radiators that have come down to our time from the distant 70s of the last millennium. Today they are more modern, they are almost impossible to distinguish from bimetallic or aluminum radiators coated with enamel. Cast iron radiators are capable of operating with coolant temperatures up to 110 0 C.

The rather large size and impressive weight are compensated by inertia, which allows you to regulate the temperature. They are ideal for any room, reliable and durable, and can be used with any boilers and coolants. Many people are interested in the question - how many kilowatts are in one section of a cast iron radiator? You will find the answer to this question below.

Cast iron heating radiator

Radiators type M-140 have a fairly simple design and are easy to maintain. The material used in their manufacture is cast iron. It is highly resistant to corrosion processes and can be used with any coolant. The low level of hydraulic pressure allows the use of radiators for both gravitational and forced coolant circulation systems. The high threshold of resistance to hydraulic shocks allows them to be used in both two-story and nine-story buildings. The advantages of the M-140 are ease of maintenance, reliability, long service life and low cost.

They are widely used for heating buildings with a coolant temperature within 130 0 C and a pressure of 0.9 MPa. The capacity of one cavity is 1.45 liters, the volume of the heated area is 0.244 square meters. The material used for the manufacture of sections is SCh-10 (gray cast iron).

Radiators used to heat rooms with low window sills and a pressure of 0.9 MPa. Cavity capacity - 1.11 l. The weight of the cavity including components is 5700 g. The strength of the calculated heat flow is 0.120 kW.

Radiators of this model are used for different rooms with a coolant temperature of up to 130 0 C and a pressure of 0.9 MPa. The mass of one cavity is 7100 g. The material used for manufacturing is gray cast iron. S heating with one cavity - 0.244 m 2.

Important! When choosing a radiator for your home, be sure to pay attention to its characteristics and make all kinds of calculations in advance, since it will be almost impossible to exchange the purchased product.

Stylized cast iron radiator

Any heating system that exists today has both pros and cons, let’s look at them.

The rated thermal power of each section is 160W. Approximately 65% of the released heat flux heats the air accumulating in the upper part of the room, and the remaining 35% warms the lower part of the room.

- Long period of use, ranging from 15 to 50 years.

- High level of resistance to corrosion processes.

- Possibility of use in heating systems with gravitational circulation of coolant.

- Low efficiency of heat transfer index correction;

- High level of labor intensity during installation;

Important! In order not to encounter problems during installation, be sure to take into account the above-mentioned pros and cons of cast iron radiators. Their installation is not cheap, and repeated installation work will require a lot of financial resources.

So, how many kW is in 1 section of a cast iron radiator? To calculate the number of sections and their power, it is necessary to determine the V of the room, which will later appear in the calculations. Next, select the value of thermal energy. Its meanings are as follows:

- heating 1 m 3 houses made of panels - 0.041 kW.

- heating 1 m 3 of a brick house with double-glazed windows and insulated walls - 0.034 kW.

- heating 1 m 3 of premises built according to modern building standards - 0.034 kW.