A beginner who is first thinking about how to build a brick fireplace with his own hands will need a masonry diagram first of all. It is called ordering and allows even amateurs to solve this complex problem without going into calculations or delving into regulatory documents. There is no point in “inventing” a fireplace on your own without being an expert in this matter. But in addition to the ready-made order, the home craftsman will also need theoretical knowledge about the basic elements of the fireplace, the principles of its efficient and safe operation. All the necessary information is in front of you.

The warmth of a home cannot be compared with anything Source n1s1.hsmedia.ru

What parts does the fireplace consist of?

To better understand how to build a fireplace with your own hands, you need to understand what parts it consists of and how it works.

- Foundation.

The weight of a brick fireplace with the same chimney can reach up to a ton, so it needs a reliable foundation.

- Portal.

This is the decorative front part of the hearth, framing the firebox.

- Firebox.

One of the main elements representing a fuel combustion chamber. The firebox can be open (without a door) or closed, lined with refractory bricks or made of cast iron. Quite often, when building fireplaces, they buy a ready-made metal firebox and line it with brick.

On a note! The interior finishing of the firebox with refractory materials is called lining.

- Ash pan.

Chamber under the firebox for collecting ash. This is not a necessary element of the home. It is equipped if the firebox is equipped with grates - a cast-iron grate on which firewood is stacked. After their combustion, the ash and coals fall into the ash pit, from where they are periodically cleaned out.

Diagram of the design and operation of the fireplace Source ibb.co

- Smoke collector.

This is the upper tapering part of the firebox through which smoke is thrown into the chimney. To narrow it, the rear part of the firebox is laid out with a forward slope and the formation of a fireplace tooth, which, during gusts of wind, prevents smoke from flowing back and being released into the room.

- Chimney.

A vertical channel through which smoke is discharged outside. Equipped with a valve for manual draft control.

- Pre-furnace sheet or platform.

The area in front of the firebox, made of fire-resistant material - steel sheet, ceramic tiles, brickwork. Provides safety by preventing fire or damage to the floor when burning coals fall out of the firebox.

Cast iron option

Pursuing the goal of maximizing efficiency, not paying attention to the classic look of the fireplace, gave rise to the idea of creating cast iron devices. They have the same operating principle as a wood-burning fireplace, but some subtleties radically change the heat transfer parameters.

Cast iron firebox built into the system

- The firebox is made in the form of a separate cassette, which is mounted in the fireplace body. A space is created between the firebox and the body for air circulation. Thus, intense heating of air masses occurs, which then fill the entire space of the room.

- The walls of the firebox are made of cast iron. It is able to quickly absorb heat and transfer it to convection air flows. Despite the fact that such a fireplace stops heating the room after burning the fuel, during its operation it has a high (up to 80%) efficiency.

- The chimney is made of metal pipes, which greatly facilitates the independent installation of a fireplace.

Choosing the shape and size of the fireplace

Before you make a fireplace in your house, you need to decide on its location, shape and size. It is advisable to resolve these issues at the stage of designing a house, since in an already constructed building this will be much more difficult: you will have to dismantle the floors for the foundation and ceilings for the chimney outlet, take into account the existing roof truss system so that the chimney does not disturb it and is separated from the load-bearing elements at a safe distance.

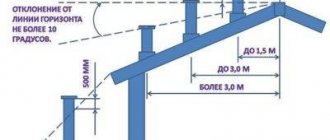

When passing pipes through floors and roofs, it is important to isolate them from the hot surface Source ytimg.com

Depending on the shape and location of installation, home fireplaces can be island, wall, corner, or built into the wall. For self-construction, it is better to choose fireplaces attached to a wall or an inner corner of the room. And fireplaces built into interior walls can heat two rooms at once. At the same time, they should be positioned so that they do not stand in the way of drafts from an open door or window.

It is very important to determine the optimal size of the fireplace, which depends on the area of the room in which it is installed. If it is too large, there will not be enough air flow for smoke draft, and smoke will escape into the room, or, with the doors open, draw heat from other rooms. A small fireplace will not be able to heat the entire volume.

When choosing dimensions, you need to focus on the following recommendations:

- area of the firebox should be about 1/50 of the area of the room;

- the depth of the combustion chamber should be 1.5-2 times less than its height in the opening;

- the cross-section of the chimney is made 9-10 times smaller than the cross-section of the portal opening.

Table indicating the optimal ratios of fireplace dimensions Source ibb.co

Design principle

The fireplace structure consists of two main parts - the firebox and the chimney. In addition, there are other components:

Fireplace design

- heating device,

- smoke collector,

- valve,

- ash pan,

- grate bars,

- lining,

- forced convection system,

- fire cutter,

- protective doors.

As for the external device, it consists of a cladding and a portal. The portal performs decorative functions, supporting a particular style of the room.

Instructions for building a fireplace

Before building a fireplace, you need to choose a design with a description (diagram) of the masonry of each row - the order. This will simplify your task and will guarantee that the fireplace will work properly. Only after this can a suitable place be determined for it and the construction of the base begin.

See also: Catalog of companies that specialize in the installation of fireplaces and stoves.

Foundation structure

You can do without a base for a fireplace only in one case: if the house is built on a solid foundation slab. In all other cases it is necessary, otherwise the heavy structure will break the floor or will sag and become deformed.

When laying the foundation, it is important not to violate the integrity of the load-bearing structures - floor joists, floor beams, rafters. If this cannot be avoided, they must be strengthened.

Another mandatory requirement is that the foundations of the house and hearth should not be connected or cast in the same formwork. Due to different loads from the walls and the design of the fireplace, the degree of shrinkage will be different, which will lead to deformations, cracks in the masonry and other unpleasant consequences.

The base for the fireplace must be separate from the foundation of the house Source ibb.co

Having decided how to build a brick fireplace for your home with your own hands and what size it will be, you can begin marking the foundation. Its depth should be at least half a meter, and its plan dimensions should exceed the dimensions of the fireplace by 10-15 cm in all directions.

It is set up like this:

- the foundation pit comes off;

- its bottom is covered with a 10-centimeter layer of sand, which must be spilled with water and compacted;

- a cushion of crushed stone 20-30 cm thick is laid on the sand;

- formwork is installed in the pit with a height just below the floor level, its walls are covered from the inside with roofing felt or thick film;

- then a reinforcement cage is installed in the formwork and filled with concrete.

For reference! You can lay brick walls around the perimeter of the pit and fill them with rubble concrete.

Video description

The process of preparing a pit and pouring a foundation for a fireplace is shown in the video:

The concrete must dry and gain strength, which will take 10-14 days. This time can be devoted to selecting and purchasing materials.

Selection of materials

It’s not enough to know how to properly build a brick fireplace with your own hands; you also need to do it from high-quality materials. The brick for the main masonry needs red ceramic, preferably solid. If the hearth is not intended to be faced with tiles or stones, it is better to buy facing bricks for laying the front rows. And the combustion chamber is lined with fireproof fireclay.

The exact number of each type is easy to count in order. And add 10-15% for the battle and various flaws.

Order for a wall-mounted fireplace with a metal chimney Source wp.com

Test kindling

The solution continues to dry from 10 to 14 days, after which the first kindling can be performed.

It is important that the temperature of the masonry increases gradually to avoid cracking. To do this, set fire to wood chips or a small bundle of brushwood with the damper open.

Note!

Insulate the foundation with your own hands - a step-by-step description of the use of the best materials and technologies (90 photos)

- Do-it-yourself pergola on a summer cottage: step-by-step instructions with photos and descriptions

Laying laminate flooring with your own hands: a detailed description of how to lay laminate flooring. Laminate calculation, step-by-step description and installation secrets (105 photos and videos)

Firewood must be added little by little, and at the same time watch out for cracking of the walls, as well as the fireplace chimney. Any cracks that appear are sealed with the same solution.

Video description

The following video shows one of the options for how to lay out a brick fireplace step by step in pictures:

You can choose any other design with a ready-made arrangement. In any case, general recommendations can be given for the construction of a fireplace.

- The first row is always made as a continuous sheet.

- The following rows are laid out in exact accordance with the order; it is advisable to first try on without mortar.

- If the bricks need trimming, they are trimmed for the entire row, adjusted dry and set on mortar.

- To highlight the portal, its laying begins from the 3-4th row, moving the bricks out relative to the lower rows by 2-3 cm.

- After each row, their vertical and horizontal levels should be checked.

Advice! Since it is difficult to build a brick fireplace yourself for the first time, and it is difficult to do it smoothly and accurately, after laying the first rows, pull cords along its corners between the ceiling and floor or install metal guides and guide the next rows along them. This will speed up the process and allow you to act more confidently.

- Before laying, bricks must be kept in water to release air from the pores. Dense fireclay brick can simply be wiped off with a damp cloth to remove dust.

The photo shows air bubbles escaping from the stone Source yandex.net

Briefly about the main thing

In order for a home hearth to effectively heat the room and not smoke, its dimensions must correspond to the area of the room, and the design must not disturb the main load-bearing elements of the house.

Before building a fireplace, a separate foundation is poured for it, which should be slightly larger in area than the area of the hearth itself.

It is recommended to build yourself according to ready-made order schemes, which take into account all the nuances of masonry.

The fireplace is built from ceramic bricks with clay mortar.

Materials

Directly affect the operation of the fireplace, its reliability and not causing discomfort during use. The quality of the brick determines how long it will last.

When choosing, take into account the following indicators:

- brand not lower than M200;

- absence of damage – cracks, lumps, broken parts and others;

- laying the outer contour with pink, solid brick;

- purchasing the required volume of one batch;

- making payments in advance;

- purchase for the boiler and chimney exclusively material that is resistant to high temperatures - heat-resistant fireclay or clinker type.

To successfully complete the task, you must know the amount of refractory bricks. In addition to this, the following should be available:

- oven clay;

- cement category M 300, M 400;

- purified and sifted sand with a fraction of up to 1.5 mm;

- crushed stone;

- smoke damper.

In addition, they stock up on reinforcing bars 70 cm in diameter, 1 cm in diameter, with a round profile, transverse protrusions and a pair of longitudinal ribs.