A beginner who is first thinking about how to build a brick fireplace with his own hands will need a masonry diagram first of all. It is called ordering and allows even amateurs to solve this complex problem without going into calculations or delving into regulatory documents. There is no point in “inventing” a fireplace on your own without being an expert in this matter. But in addition to the ready-made order, the home craftsman will also need theoretical knowledge about the basic elements of the fireplace, the principles of its efficient and safe operation. All the necessary information is in front of you.

The warmth of a home cannot be compared with anything Source n1s1.hsmedia.ru

What parts does the fireplace consist of?

To better understand how to build a fireplace with your own hands, you need to understand what parts it consists of and how it works.

- Foundation.

The weight of a brick fireplace with the same chimney can reach up to a ton, so it needs a reliable foundation.

- Portal.

This is the decorative front part of the hearth, framing the firebox.

- Firebox.

One of the main elements representing a fuel combustion chamber. The firebox can be open (without a door) or closed, lined with refractory bricks or made of cast iron. Quite often, when building fireplaces, they buy a ready-made metal firebox and line it with brick.

On a note! The interior finishing of the firebox with refractory materials is called lining.

- Ash pan.

Chamber under the firebox for collecting ash. This is not a necessary element of the home. It is equipped if the firebox is equipped with grates - a cast-iron grate on which firewood is stacked. After their combustion, the ash and coals fall into the ash pit, from where they are periodically cleaned out.

Diagram of the design and operation of the fireplace Source ibb.co

- Smoke collector.

This is the upper tapering part of the firebox through which smoke is thrown into the chimney. To narrow it, the rear part of the firebox is laid out with a forward slope and the formation of a fireplace tooth, which, during gusts of wind, prevents smoke from flowing back and being released into the room.

- Chimney.

A vertical channel through which smoke is discharged outside. Equipped with a valve for manual draft control.

- Pre-furnace sheet or platform.

The area in front of the firebox, made of fire-resistant material - steel sheet, ceramic tiles, brickwork. Provides safety by preventing fire or damage to the floor when burning coals fall out of the firebox.

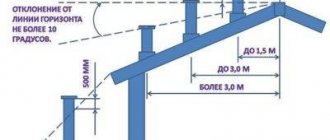

Chimney

If the chimney structure is made of brick, it is necessary to consider a foundation or a steel frame for it, which will rest against the main foundation. The chimney itself is located on the outside of the firebox and wrapped in thermally insulated material. The top of the chimney is sheathed with a sheet of steel or aluminum.

Bracket for fastening the chimney pipe

Using ready-made pipe sections for the chimney, special clamps are used as fastenings, with the help of which the structure is fixed to the floors of buildings. This chimney option can do without a foundation.

Choosing the shape and size of the fireplace

Before you make a fireplace in your house, you need to decide on its location, shape and size. It is advisable to resolve these issues at the stage of designing a house, since in an already constructed building this will be much more difficult: you will have to dismantle the floors for the foundation and ceilings for the chimney outlet, take into account the existing roof truss system so that the chimney does not disturb it and is separated from the load-bearing elements at a safe distance.

When passing pipes through floors and roofs, it is important to isolate them from the hot surface Source ytimg.com

Depending on the shape and location of installation, home fireplaces can be island, wall, corner, or built into the wall. For self-construction, it is better to choose fireplaces attached to a wall or an inner corner of the room. And fireplaces built into interior walls can heat two rooms at once. At the same time, they should be positioned so that they do not stand in the way of drafts from an open door or window.

It is very important to determine the optimal size of the fireplace, which depends on the area of the room in which it is installed. If it is too large, there will not be enough air flow for smoke draft, and smoke will escape into the room, or, with the doors open, draw heat from other rooms. A small fireplace will not be able to heat the entire volume.

When choosing dimensions, you need to focus on the following recommendations:

- area of the firebox should be about 1/50 of the area of the room;

- the depth of the combustion chamber should be 1.5-2 times less than its height in the opening;

- the cross-section of the chimney is made 9-10 times smaller than the cross-section of the portal opening.

Table indicating the optimal ratios of fireplace dimensions Source ibb.co

Types of fireplaces depending on the design features of the firebox

The main design features of the firebox primarily affect the number of sides to which heat is transferred from the fireplace. In most cases, this is only one direction; corner fireplaces most often become exceptions. However, it is imperative to consider all possible options.

Single sided fireplaces

The simplest and most common type of fireplace design is a one-sided firebox. They are distinguished primarily by their positive quality, such as a high degree of heat transfer. This is achieved due to the presence of inclined walls that direct heated air in a specific direction. This work occurs due to the fact that heat is reflected from the internal surfaces of the firebox in the desired direction. It is discharged through the main window, thereby warming the room.

Single-sided fireplaces are the easiest to install due to their relative simplicity of design. In addition, most often such devices are quite cheap in comparison with others. That is why the owners of the premises do not have to spend significant financial resources to install them.

Double-sided fireplaces

Among the two-sided fireplaces, we can distinguish both corner and island. So are some models of wall-mounted devices. The latter are distinguished by the presence of two transparent sides - both adjacent and opposite.

Double-sided fireplaces are distinguished by their unusual appearance, which is why they are often chosen for installation in an apartment or house. However, before you begin the purchase and construction process, you should pay attention to several significant disadvantages of these devices, such as:

- The chimney must have high draft. This is due to the fact that the fuel in the firebox of a double-sided fireplace will burn quite quickly. As a result, the ventilation of the room must be of sufficient quality and functionality.

- The amount of heat emitted by the fire will be small. This is due to the fact that double-sided fireplaces do not have inclined firebox surfaces. That is why the energy is distributed from the device in all directions, not completely spent on heating the room.

- Increased level of danger. This is due to the fact that in double-sided fireplaces there is not one side from which smoldering embers of wood can fall out, but two. That is why the owner of the premises will have to protect a large area of the room from possible unpredictable events.

Despite all the shortcomings, double-sided fireplaces are popular because they have a very attractive appearance.

Three-sided fireplaces

The main advantage of three-sided fireplaces is their unusual design. Such devices are quite stylish, original and in a certain sense unique, since they are extremely rare. This is due to three important factors:

- quite significant cost;

- significant complexity of arrangement;

- the need to have a large room area.

The three-sided fireplace really looks very beautiful. That is why it is mainly used only as a decorative element of the room. First of all, this applies to premises made in modern interior styles that have appeared in recent decades.

There is no need to talk about the high energy efficiency of three-sided fireplaces. This is due to the fact that the heat from them spreads in all directions. That is why the room does not warm up.

Due to the presence of three open firebox windows, these fireplace models have quite a significant danger in their operation. Therefore, fire-resistant glass is most often used in them, protecting the rooms from accidental fall of hot wood coals.

Instructions for building a fireplace

Before building a fireplace, you need to choose a design with a description (diagram) of the masonry of each row - the order. This will simplify your task and will guarantee that the fireplace will work properly. Only after this can a suitable place be determined for it and the construction of the base begin.

See also: Catalog of companies that specialize in the installation of fireplaces and stoves.

Foundation structure

You can do without a base for a fireplace only in one case: if the house is built on a solid foundation slab. In all other cases it is necessary, otherwise the heavy structure will break the floor or will sag and become deformed.

When laying the foundation, it is important not to violate the integrity of the load-bearing structures - floor joists, floor beams, rafters. If this cannot be avoided, they must be strengthened.

Another mandatory requirement is that the foundations of the house and hearth should not be connected or cast in the same formwork. Due to different loads from the walls and the design of the fireplace, the degree of shrinkage will be different, which will lead to deformations, cracks in the masonry and other unpleasant consequences.

The base for the fireplace must be separate from the foundation of the house Source ibb.co

Having decided how to build a brick fireplace for your home with your own hands and what size it will be, you can begin marking the foundation. Its depth should be at least half a meter, and its plan dimensions should exceed the dimensions of the fireplace by 10-15 cm in all directions.

It is set up like this:

- the foundation pit comes off;

- its bottom is covered with a 10-centimeter layer of sand, which must be spilled with water and compacted;

- a cushion of crushed stone 20-30 cm thick is laid on the sand;

- formwork is installed in the pit with a height just below the floor level, its walls are covered from the inside with roofing felt or thick film;

- then a reinforcement cage is installed in the formwork and filled with concrete.

For reference! You can lay brick walls around the perimeter of the pit and fill them with rubble concrete.

Solution

Composition of the solution

Conventional cement mortar is completely unsuitable for constructing structures that experience high thermal loads. The mixture for laying a fireplace is made on the basis of clay and sand, and their percentage depends on the fat content of the clay.

Cement may also be present in such a solution, but in a very small amount.

This solution is not suitable for masonry

- The solution must be homogeneous , without lumps, and have normal plasticity. Only in this case will it firmly bind the brickwork, will not crack when drying and will shrink slightly.

- A too plastic mortar based on fatty clay is perfectly smoothed over the brick, allowing you to make a beautiful and thin seam, but it is not suitable for kiln work, since it shrinks a lot during use.

- A low-plasticity mortar based on lean clay practically does not shrink, but does not provide good masonry strength; it cracks and spills out of the joints when dry.

Requirements for the quality of sand and clay for mortar

The sand should be clean and fine. It is best to use mountain or river sand, sifted through a fine sieve to remove large inclusions and vegetation. This procedure will create a high-quality, homogeneous solution and obtain a thin and even masonry joint.

Only experienced stove makers can determine the quality of clay by touch. But there are many ways, both folk and laboratory, to check whether clay is suitable for preparing stove mortar and to determine the optimal ratio of clay and sand. Here are some of the simplest ways:

- Place the clay in a bucket, add water and mix well - you should get a solution the consistency of sour cream. Dip a long planed board into it, and then take it out and evaluate the thickness of the clay adhering to it. A thin layer of up to 1 mm indicates that the solution is low-plastic; it is necessary to add fatty clay to it. A layer that is too thick indicates the need to add sand. If the clay layer on the board is about 2 mm thick and adheres unevenly to it, the clay has normal plasticity.

- This is the longest method, but also one of the most reliable. You will need five 1 liter portions of clay. The first portion is simply mixed with water. Add a tenth of a liter jar of sand to the second, a quarter of the jar to the third, three quarters to the fourth, and a jar full to the brim to the fifth. A solution that does not stick to your hands is prepared from all the mixtures, and then small (5 mm) balls are molded from each portion. Some of the balls are flattened into flat cakes 2–3 mm thick. All these products must be dried in a dry, draft-free room for 8–10 days. The solution suitable for masonry is the one from which the cakes almost do not crack, and the balls do not break when falling to the floor from a meter height. Squeezing clay balls

- If you don't have time to wait that long, you can check the fireplace mortar differently. The same balls are placed on a planed board and with a little effort they are pressed on with a second similar board. If the ball immediately crumbles, the solution is thin; if cracks appear only when the ball is compressed to half its diameter, the solution is too greasy. A normal solution is the one the balls of which begin to become covered with thin cracks when compressed by about a third of the diameter.

How to prepare the solution?

Having determined experimentally the ratio of sand and clay, measure out the required amount of materials and sift them. Sand - in the usual way, and clay is pre-soaked with water, mixed thoroughly and filtered through a sieve with fine mesh.

Ready clay solution

After mixing the clay and sand, the solution is filtered again through a larger sieve so that it is homogeneous, without clots. The finished mixture should not spread over the shovel, but slide off it well. This solution produces ideal seams with a thickness of 3–5 mm.

To increase the strength of the mortar, you can add cement ( ¾ liter per bucket of mortar) or table salt ( 150–250 g ). Before adding, cement is diluted with water to the consistency of sour cream, salt is also dissolved in water.

How much mortar is needed for laying fireplaces?

To lay 100 bricks flat, making 5 mm , you will need two buckets of mortar. When laying a Russian stove, this amount increases by 20%.

Attention! It is very important to prepare a solution of the required plasticity and thickness! Only such a solution will fill all the unevenness, ensure density and gas-tightness of the seams and strong adhesion of the bricks.

Video description

The process of preparing a pit and pouring a foundation for a fireplace is shown in the video:

The concrete must dry and gain strength, which will take 10-14 days. This time can be devoted to selecting and purchasing materials.

Selection of materials

It’s not enough to know how to properly build a brick fireplace with your own hands; you also need to do it from high-quality materials. The brick for the main masonry needs red ceramic, preferably solid. If the hearth is not intended to be faced with tiles or stones, it is better to buy facing bricks for laying the front rows. And the combustion chamber is lined with fireproof fireclay.

The exact number of each type is easy to count in order. And add 10-15% for the battle and various flaws.

Order for a wall-mounted fireplace with a metal chimney Source wp.com

Materials

Table of necessary materials for building a fireplace

The manufacture of fireplaces begins with the selection of materials. For construction we will need:

- Red ceramic brick. Its quantity is calculated based on the prepared drawing, while all incomplete bricks must be taken into account as whole.

- River sand. Be sure to sift and clear of dirt and debris. The grain size of the material should be within the normal range (0.2–1.5 mm).

- Crushed stone for making a foundation. The acceptable fraction should be from 2 to 6 cm.

- Blue Cambrian clay or regular red.

- Cement (M 200 or M 300).

- Smoke damper.

- Fittings.

Video description

The following video shows one of the options for how to lay out a brick fireplace step by step in pictures:

You can choose any other design with a ready-made arrangement. In any case, general recommendations can be given for the construction of a fireplace.

- The first row is always made as a continuous sheet.

- The following rows are laid out in exact accordance with the order; it is advisable to first try on without mortar.

- If the bricks need trimming, they are trimmed for the entire row, adjusted dry and set on mortar.

- To highlight the portal, its laying begins from the 3-4th row, moving the bricks out relative to the lower rows by 2-3 cm.

- After each row, their vertical and horizontal levels should be checked.

Advice! Since it is difficult to build a brick fireplace yourself for the first time, and it is difficult to do it smoothly and accurately, after laying the first rows, pull cords along its corners between the ceiling and floor or install metal guides and guide the next rows along them. This will speed up the process and allow you to act more confidently.

- Before laying, bricks must be kept in water to release air from the pores. Dense fireclay brick can simply be wiped off with a damp cloth to remove dust.

The photo shows air bubbles escaping from the stone Source yandex.net

Open or Alpine (Swiss)

This type of fireplace has become popular only recently. In fact, this is also not a fireplace in its pure form, but for a different reason. Rather, it is simply an open or semi-closed hearth, over which a cap is made that turns into a chimney.

An Alpine or Swiss fireplace has a memorable appearance

It fits perfectly into chalet-style interiors, because that’s where it came to us. The device, in general, is simple, but not very efficient in terms of heating. But it is very decorative.

The option that you see in the photo above is made in a rustic style - made of natural processed stone. Such work costs a lot of money: you have to adjust and trim hard rocks, which requires a high level of skill.

Briefly about the main thing

In order for a home hearth to effectively heat the room and not smoke, its dimensions must correspond to the area of the room, and the design must not disturb the main load-bearing elements of the house.

Before building a fireplace, a separate foundation is poured for it, which should be slightly larger in area than the area of the hearth itself.

It is recommended to build yourself according to ready-made order schemes, which take into account all the nuances of masonry.

The fireplace is built from ceramic bricks with clay mortar.

Classification

Today, all changes are associated with a transformation of appearance, since the main task of fireplaces is becoming a decorative decoration, which can often boast of its functionality. The fireplace cannot go unnoticed, so its design is developed taking into account the stylization of the entire room.

In the classification of devices according to installation method, an island fireplace falls into a separate type. These models arose thanks to modern artistic solutions. There was a need to complement the modern and high-tech styles. Naturally, a classic fireplace could be designed in the same spirit, but it is not able to emphasize the revolutionary nature of ideas, a revolution in the idea of a modern interior.

All island fireplaces can be divided into two categories, which have certain distinctive nuances in installation methods: floor-standing and hanging models. The common properties of these groups is that they are installed in the center of the room and do not have common walls with the walls of the room. The idea of installing an island fireplace is successfully implemented in large rooms, since the occupied space must be fully compensated.

Triangular design

Finishing work

In addition to the fact that the fireplace is a stove, you can decorate it with a colored joint, the brick itself can possibly be repainted in a different color. For these purposes, tempera or gouache is used.

The decoration for the corner version of the fireplace can be tiles or marble tiles, stone or decorative brick. If desired, you can simply plaster the surface or use other decorative elements.

The modern market offers a large number of elements for decoration, including wooden parts. For safety reasons, their use is not recommended.

Table of tile adhesive consumption per 1 meter depending on the choice and inclination of the comb

The decoration is fastened using regular tile adhesive, and the decoration itself should start from the bottom of the fireplace, gradually rising.

If your fireplace or stove already contains marble parts, then it is recommended to cover them with cellophane to avoid scratches.