A heating structure project is a drawing of a future fireplace design on paper. Before starting masonry, you need to carefully think through all the points and draw up a sketch correctly.

When studying designs of houses with a fireplace, you should know the following parameters:

- what size of foundation to pour under the fireplace;

- room height;

- the strength of a tall brick structure;

- compliance with fire safety measures;

- the appearance of the attractiveness of the fireplace.

A correctly drawn up diagram of a brick fireplace will save time and effort, and will make it possible to carry out the planned construction in the best possible way, as well as avoid difficulties during operation. Brick fireplace projects

Corner fireplace and its uniqueness

Let's look at a detailed drawing of the masonry of a corner brick fireplace and the order with a description. Today, there are a huge variety of fireplace designs, but at the moment we offer you a convenient fireplace built into the corner, which can be installed in a small room of at least 12 m2, since there will not be enough oxygen to heat it. To create it, you should find a mason of the 4th - 5th category, so that he has the intricacies of constructing this structure or delve into the intricacies of this process on his own.

It should be remembered that the internal structure of fireplaces is created almost identically, and the combustion of fire in the firebox is the same.

Corner fireplaces have their advantages:

Its peculiarity is that it is not located in the center of the building, but in the corner, and has small dimensions. In addition, it evenly transfers heat energy throughout the room.

Folded neatly, with the smallest deviations and tolerances in construction, the corner fireplace is a heating equipment, carries a certain decorative beauty and shows the status of the owner of this building.

Its disadvantage is the expensive, decorative finishing.

The brick for the construction of this structure needs a high grade; of course, you can lay it out with grade 100, but you should remember that this material is of poor quality for laying it out. In this case, if you build a fireplace from this brick, then, according to fire safety regulations, it should be plastered.

This brand of brick is used for laying out the outer part of the building and for constructing the pipe. And the inside of the firebox is made of refractory bricks.

Necessary materials

Brick finishing of fireplaces and stoves

To make a small fireplace you will need:

- Brick. When calculating the amount of material, do not forget to take into account 10% waste and waste;

- Coarse sand. Before use, the sand is sieved and washed to remove small debris;

- Clay. To build a quality fireplace you will need a blue type of clay;

- Several buckets of crushed stone;

- Reinforcement 1 m long and 10 mm in diameter in the amount of 10 pieces.

Tip: before starting construction, draw a masonry diagram on paper. Try to strictly adhere to the dimensions of the brick and room in the drawing. Also, do not forget to take into account the layout of the dacha.

Rectangular fireplace diagram and drawing

Its size is 5x2.5 brickwork order consists of 33 rows

This structure is used without a door on the firebox. The designer, when creating this drawing, used a smoke exhaust through channel, which provides good draft. In this regard, its heat capacity decreases in order to increase the efficiency of this structure. To do this, you should use standard methods, such as laying empty channels along the firebox and chimney.

- The inside of the firebox should be made of refractory bricks that can withstand temperatures of 1100 degrees.

The main massive part of the fireplace is laid out with high-quality solid ceramic bricks, it must correspond to grade 125 and higher, its heating temperature is 750 degrees.

You should remember that refractory and ceramic bricks are prohibited from being tied, but they can be tied using 3 mm wire placed in the seam between the bricks.

Order diagram of a rectangular fireplace 5×2.5 made of brick

When laying out this structure, you should maintain the same thickness between bricks, equal to 5-7 mm. If the material contains flaws, for example oblique corners, then they should be trimmed apart from each other, this way you will achieve the desired thickness of the seam.

*

Rows should be checked with a level or plumb line to achieve the correct geometric shape of the structure.

This drawing is used by master stove makers, and even with extensive experience, they consult it.

Options

What parameters do different heating systems work with?

For central heating, typical pressures at the entrance to the elevator unit are 5 - 7 kgf/cm2 in the supply and 3 - 4 kgf/cm2 in the return pipeline. The coolant temperature varies depending on the outside temperature.

In most cases, a temperature schedule of 150/70 is used: during the peak of cold weather, the supply temperature rises to 150C, and the return temperature to 70C.

Temperature chart 150/70.

The temperature of the mixture (water after mixing the supply and return in the elevator, entering the batteries) is limited to 95 degrees in residential and industrial buildings and 37 degrees in preschool institutions.

Under a number of force majeure circumstances, the standard pressure and temperature parameters may be significantly exceeded.

Here are examples of such scenarios:

If you quickly fill an empty circuit or abruptly stop the circulation in it, an area of high pressure will form at the flow front. During water hammer, its values can reach 25 - 30 atmospheres;

The consequences are not difficult to predict.

- After the end of the heating season, heating mains are tested for density. During tests, the pressure in them increases to 12 atmospheres or more. In this case, the input valves of the elevator unit must be closed, but the human factor or malfunction of the shut-off valves may well lead to the fact that not only the route will be tested;

- During extremely severe frosts and with a large number of complaints about the cold in apartments in the northern regions, it is practiced to operate an elevator without a nozzle. The suction is suppressed by a steel pancake, and water enters the heating circuit directly from the supply line of the route. And its temperature at the peak of cold weather, as we remember, can reach 150C.

Water from the heating main supply directly enters the heating circuit.

In an autonomous heating system, a typical pressure is 1.5-2.5 kgf/cm2 at a temperature of 70-75C on the supply side and 50-55C on the return side. If the heating system is correctly calculated, these parameters are stable and do not depend on external factors.

Mini fireplace drawing

It is recommended to install this heating device in a room of at least 16 m2. It is built into a partition to heat two rooms. To increase heat transfer, the firebox is laid out without refractory bricks. Thus, ceramic brick heats up much faster because it retains less heat capacity of the mass than refractory brick.

- In this case, to protect the firebox from high temperatures, the stove maker uses a metal sheet 3 millimeters thick instead of a stone tooth.

A drawing of a brick fireplace is attached below in the description. If the master has little qualifications in this direction, then instead of the portal arch, you can build a horizontal ceiling. To do this you will need 2 metal corners of the required length.

A positive characteristic of this fireplace is that when purchasing materials for its construction, you spend minimal money.

For construction you will need:

- ceramic bricks 235 pieces;

- clay – 0.12 m3;

- sand – 0.3m3;

- cleaning door – 1 piece;

- stove valve – 1 piece;

- grate – 1 piece;

- choke tubes – 2 pieces;

- steel sheet thickness - 3 mm and size 0.25 m2;

- roofing felt – 1.5 m2;

- cement - 15 kilograms.

“Mini” fireplace and its sequential masonry scheme

*

To maximize the efficiency of this structure, the side walls of the firebox are laid out at an angle of 25 degrees.

The back wall is laid out in 10 rows in the usual way, that is, horizontally. Starting from the 11th row, the brick extends a quarter at an angle of 30 degrees into the inside of the firebox. With this action, a chimney tooth pass is formed, metal pins are then inserted into the seams between the bricks, and a sheet of metal will be attached to them.

Below is a metal drawing for a firebox.

Due to the absence of fireclay bricks in this building, the space in the room heats up much faster, since side air channels are laid out.

In the lower part there are holes through which cold air enters, and the hot air heated from the fireplace insert through the “ventilators” located in the 13th and 14th rows exits into the room as hot air. Thus, its efficiency increases by 15, 20%

We carry out calculations

The main thing is to make a detailed drawing before starting work. The choice of product scale will depend on the area of the room. It is necessary to strictly adhere to the recommended standards when drawing up a project in order to obtain a high-quality result.

Fire hole

The first step is to determine the dimensions of the firebox. To accurately calculate them, you should measure the area of the room. The proportion of the hole in relation to the room is recommended 1 to 50. Consider a specific example:

- The area of housing where the fireplace will be installed is 40 sq.m.

- We divide this parameter by 50 (40/50 = 0.8 sq.m.).

- The result obtained is 0.8 sq.m or 8000 sq.cm - the required hole area.

This needs to be recorded in the drawing. We will tell you how to determine the aspect ratio below.

Firebox width and height

The proportion by which experts determine the length of the sides is 2 to 3. In our case, it turns out 73 * 109.5 cm. If you want to check the correctness of the calculations, simply multiply 73 and 109.5, the result will be 7993.5 (almost 8000 sq. cm ). This indicator practically coincides with the requirements.

Depth

Correctly chosen, it significantly affects traction, so you cannot make a mistake with this parameter. Inaccuracy may result in smoke and poor heating. Calculating the required value is very simple - it is in proportion to ⅔ to the height. This means: (73/3)*2 = slightly less than 49 cm. If this parameter is exceeded in the finished product, then the heat will simply go into the chimney pipe. If, on the contrary, then smoke will inevitably appear in the room.

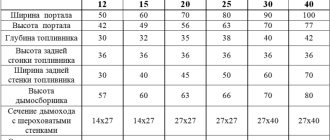

Fireplaces: height, width, depth (table to simplify the procedure):

| Room (sq.m) | Portal (mm) | Firebox (mm) | Chimney cross-section (mm*mm) | ||||

| Square | cubic capacity | Width | Height | Depth | Neck | Rear width | |

| 12 | 42 | 500 | 450 | 300 | 120 | 300 | 140*140 |

| 16 | 50 | 600 | 500-520 | 320 | 120 | 400 | 140*270 |

| 22 | 60 | 700 | 560-580 | 350 | 120 | 450 | 140*270 |

| 30 | 80 | 800 | 600-650 | 370-380 | 130 | 500 | 270*270 |

| 35 | 100 | 900 | 700 | 400-420 | 130 | 600 | 270*270 |

| 40 | 120 | 1000 | 750 | 450 | 140 | 700 | 270*270 |

Medium sized English fireplace

A DIY English brick fireplace is one of the oldest ever built. It is also called a classic open-type brick fireplace.

The parameters include the following features:

- protruding tooth;

- open firebox;

- rear wall of an inclined fracture.

The internal recess of the firebox or hearth is lined with refractory bricks in a mortar containing clay and fireclay chips, as well as a little cement. The external contour of the structure is created from ceramic, solid material.

Equipment installation

How to calculate the dimensions of the fireplace

After finishing the construction work, you need to install the main components of the fireplace with your own hands. The following are installed in the heating system:

- Fireplace insert. It can be purchased on the market or created with your own hands. Practice has shown that it is still better to insert a branded firebox into a homemade fireplace, since it is a key element in the functioning of the entire heating system.

Installation and operation of a fireplace insert - The pipe for connecting the chimney is a metal base that allows you to hermetically connect the pipe and the fireplace insert. For maximum protection of the interior of the dacha, the pipe must be lined with fire-resistant materials.

- A chimney vent is mounted on top of the fireplace insert. It is better to choose a metal pipe as a chimney for two reasons: firstly, it is easier to install, and secondly, it does not require additional sealing. The metal pipe must be covered with a thick layer of heat-insulating materials - glass wool, foam glass or aluminum tape. This is done so that the walls of the chimney do not become heated from the hot pipe and do not lead to the destruction of the masonry.

- Pressure equalization grid. You don’t have to buy this small device on the market; you can make it yourself from scrap materials. Take a piece of ordinary stainless steel and cut a small door out of it, measuring 5x5 cm. The blank is inserted into the side of the fireplace at a distance of 10 cm from the ceiling. With its help you will control the pressure in the fireplace. For example, when the pressure is weak, the window must be closed, and when the pressure is strong, on the contrary, it must be opened.

At this stage, the manufacture of a country fireplace can be considered completed. All that remains is to add decorative elements for the dacha and build a small shed where firewood for the fire will be stored.

Examples of small woodsheds

As for the decorative design of the fireplace, almost any style is suitable for a country house. The main requirement for a fireplace design is its simplicity. Heating equipment can be decorated with ceramic silhouettes and other items made from fire-resistant materials. [ads-pc-2][ads-mob-2]

Elements and diagram of an English-type fireplace

This scheme is relevant for most English-type models.

* This English-type circuit is complex, but it pays off in that it has stable thrust and good efficiency. Drawing of a fireplace made of English type 5x3 bricks and its order diagram.

To build it you will need:

- solid ceramic brick – 350 pieces;

- fireclay bricks – 125 pieces;

- sand-clay solution – 215 kg;

- fireproof mortar – 155 kg.

Below is a detailed drawing of an English heating device 5x3 made of brick

The first four rows of the base are laid out of ceramic bricks of grade 100, then higher quality material of grade 150 and higher is used.

This structure is installed in a room with at least 80 m3 of total space. Having studied its order, the following points should be noted; note that there is no blower and grate.

If a small room has hermetically sealed windows on all sides, you should install an oxygen supply from the street to the firebox for better combustion.

To create a ceiling for the firebox, a corner of steel and 2 strips of the same material are laid on the twelfth row.

In this design, a cleaning door is provided on rows 16–17, which is installed on the rear wall. This hole limits the placement of the fireplace against a load-bearing wall or wall. In this case, this heating device will not be able to warm the second room.

To maintain the elasticity of the mortar and its natural setting, ceramic bricks should be soaked in a container of water for 5 minutes before laying the masonry structure. Heat-resistant bricks are wiped with a damp cloth to remove dust.

After completing the construction of an English fireplace, you should gradually heat and dry it for 3 weeks, and only after this time has passed, you can fill the firebox up to half. After another month, you can turn on the heating device at full power.

By following this rule, you will allow the solution to set naturally; if it is violated, then you expose your structure to a limited service life. The decision is yours.