In most cases, the majority of people think about the reliability and efficiency of the heating system after a certain failure has occurred in it. It is extremely important that no significant mistakes are made at all stages of the design, selection and installation of such a system. To avoid serious heating errors, the installation of a heating system in a house must be approached with the utmost responsibility.

1-Selection of boiler

What causes the most trouble for a person is the wrong choice of heating boiler. Moreover, its selection is determined not only by the spaciousness of the apartment. If the boiler power is higher than required, the monthly costs for heating equipment will greatly increase. But it will be much worse if the boiler power is too small compared to what is needed. Then there will be a catastrophic lack of heating during the cold season.

It is important to study not only the boiler power, but also the efficiency. This indicator is as significant as the previous one.

DIY installation

Following simple rules will allow you to install a 2-pipe heating system yourself:

- A circuit is placed on top that supplies heated coolant from the boiler to the radiator. Bottom - to return waste liquid back to the boiler.

- The highways are laid parallel to each other.

- The heating circuit must have a slope away from the heating element towards the outer radiator.

- To reduce heat loss, the central riser must be insulated.

- To allow repair of individual sections of the heating network, blocking valves are installed.

- It is advisable to minimize the number of angles that reduce the speed of coolant movement.

- It is necessary to accurately select circuit elements for the cross-section of the pipes used.

- Every 1 - 1.2 m the pipeline must be supported by a system of fasteners (especially when using metal pipes).

Installation should be performed in the following sequence:

- A central riser is connected to the installed heating boiler.

- The central riser is connected to the expansion tank.

- From the tank there is a branching pipeline with a phased installation of heating devices.

- The installation of a parallel waste liquid return line begins from the bottom of the boiler.

- A pump is mounted at the inlet or outlet of the boiler (less often) (if necessary).

How to connect radiators

There are 3 ways to connect radiators:

- One-sided (lateral). Heat transfer is about 95%. Recommended when connecting radiators with up to 15 sections.

- Diagonal (cross). Heat transfer is about 100%. Suitable for batteries with 15 sections or more.

- Lower. Heat transfer is about 85%. Most often used with a hidden pipeline laying concept.

How to balance the system

Without balancing, radiators farthest from the boiler will warm up according to the residual principle, even at maximum boiler operation.

- Method 1. Electronic flow meter based on calculated data.

The most correct method, however, is impossible to carry out without a design and hydraulic calculations. In addition you will need:

- control valves on each riser;

- balancing valve with fittings for connecting electronics;

- special equipment connected to the control valves.

An electronic device for precise temperature control is connected to the valve fittings and measures the actual coolant flow. Then, by turning the spindle, the target values are set.

Important. Currently, you can purchase a special balance valve equipped with a flow meter bulb. This device makes it possible to balance the system by analogy with the method described above.

- Method 2. Balancing each radiator by temperature.

To do this, each battery must have a control valve installed at its output. You will also need a special thermometer to measure the temperature of the metal valve body.

- The valve on the outermost battery of the circuit opens completely.

- The rest in the row are unscrewed several turns according to the principle of increasing from the boiler. For example, the first radiator from the boiler is 1 turn, the second is 2 turns, etc.

- The temperature is measured at each valve of the circuit until it is equalized at all.

How much would it cost to install such a system?

The cost of installing double-circuit heating depends on a number of factors:

- room area;

- the cost of the equipment and materials used;

- type of heating (warm floors, convector radiators, etc.) and, accordingly, the complexity of the work;

- type of temperature control (manual or automatic);

- the need to connect hot water supply and much more. etc.

For example, a house with an area of 100 m² at average rates will be about 260,000 rubles. The minimum level is about 160,000 rubles.

By doing the work yourself, you can reduce these costs by almost 2 times.

2-Pipe selection

The pipes must be the same diameter. Otherwise, hydraulic losses begin to increase due to the fact that the pressure at the joints will differ. An error will occur in the functioning of the heating system.

Important!

When choosing pipes, you need to pay attention to the reinforcing layer. If it is missing, then the line will not have enough rigidity to resist the influence of hot water.

3-Selection of heating scheme

Developing the right diagram is one of the most important elements when installing a heating system. There is no scheme that would be equally suitable for different rooms. Each is calculated and selected based on the individual characteristics and features of the room.

This scheme is being developed by plumbers. It is recommended to hire designers to compare the results. This will slightly increase the accuracy of the calculations. You should be careful with information on the Internet, since the most common options are presented very briefly there. Sites on this topic are sometimes full of shortcomings.

It would be more advisable to spend time calculating the heating circuit at the very beginning of work than to correct them later. Adjusting the system after installation will take much longer and require more financial costs. It is better to entrust the calculations to experienced specialists in advance.

Clogged radiator

Sometimes the reason that the radiator does not heat can be a simple blockage. When determining the causes of blockage, let’s highlight the symptoms:

- It only warms around the perimeter.

- Only the top part.

- The bottom is heated, the top is not.

- Only a few sections out of all possible provide heat (if the bypass location is correct)

Could it be just the old battery that is clogged? Not at all. New systems (modern and ultra-modern, aluminum and cast iron) suffer from this just as often. The problem may lie in the general contamination of the system:

- From long-term use.

- Due to installation errors.

- Sediments with high water hardness.

- Erosion of system elements (oxide, rust).

How to get rid of it?

Modern heating devices with properly installed shut-off valves include an “American” valve, by turning off which the non-working part can be easily dismantled and cleaned, purged, and washed under pressure.

It’s harder where the equipment is “countless years old.” To disassemble, you may have to turn to specialists, emptying (preliminarily or with their help) the entire volume (usually just water).

Cast iron radiators can be cleaned. It is recommended to replace steel flat flow welded radiators with new ones of other models. But it is they, ironically, that are most often susceptible to rusting and clogging of channels - due to the design features and materials used. Therefore, they often do not heat properly. An additional reason not to clean this type of heating device is the risk of leakage of the eroded wall due to its thinning in the process of peeling off oxidized metal flakes. A leak can be costly (even if you forget about the cost of repairing the “junk”). This is the same case when the stingy one has every chance to pay twice, or even three times.

Interesting fact: cast iron radiators clog 3-5 times less often than aluminum or stamped ones.

5-Selection of circulation pump

There are programs that allow you to calculate hydraulics. The resistance that pipes and various devices provide is determined, and it is demonstrated how much the pressure can drop under the influence of a particular pump.

Then you can select a pump. Its pressure must overcome the created resistance. If the pump pressure is not enough for resistance, then the heating system will malfunction.

Note!

When selecting a pump, it is also important to pay attention to what noise it will make, what size it reaches, what are the features of its maintenance, etc.

How to make a calculation

Without a preliminary calculation of the power of the future heating system, it is quite difficult to achieve comfortable heat in the house. Thermal calculation helps to choose:

- heating boiler of optimal power;

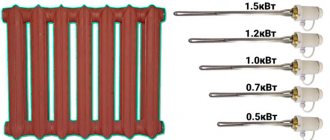

- radiators with the required number of sections;

- pipes, shut-off valves, etc.

For thermal calculation you will need the following data:

- The total area of the building and each room separately, ceiling height.

- The purpose of each room (bedroom, living room, kitchen, utility room, etc.).

- The presence of buildings adjacent to the building.

- The material from which the building is constructed (walls and ceiling, floor and ceilings, roof).

- Type of insulation used.

- Number, type and sizes of windows and external doors.

- The duration of the heating season and the “wind rose” of the area, average temperature minimums in a given period.

- Desired temperature in the house.

- Connection points to communications (gas, electricity, water supply).

Power and heat dissipation

Calculation of the required thermal power will allow you to select the exact model of the heating boiler and radiators.

Method 1. Calculation of heating power by area:

Q=S×A×k, where:

- Q – Thermal power (watt).

- S – Internal area of the building (m²).

- A - The number of watts of the total power of the heating system per 1 m² (usually 100 - 150 watts).

- k – Power reserve factor in case of severe frosts (1.2 or 1.25).

Important: Sometimes it is not practical to calculate the power of a room in a single field. It is better to divide the area into residential and technical. For the first, the indicator is A=100 or 150 watts, for the second, A=50 or 75 watts.

This method is simple, but is not always the optimal solution, because... does not take into account the climatic characteristics of the region, nor the height indicators of the premises, nor the characteristics of the materials from which the house is built, etc.

Method 2. Calculation of heating power based on the volume of the room and the climatic characteristics of the region.

Q= (S×B×C×X) + (E×200+F×100), where:

- Q – Thermal power (watt).

- S – Internal area of the building (m²).

- B – Wall height (m).

- C – Correction coefficient of heat loss (for detached buildings, for example, it is equal to 60).

- X – Regional coefficient.

- E – Number of doors.

- F – Number of windows.

| Winter type | Region | Regional coefficient |

| Warm winter | South, Black Sea coast | 0,7 — 0,9 |

| Moderate winter | Central Russia, North-West | 1,2 |

| Harsh winter | Siberia | 1,5 |

| Extremely cold winter | Chukotka, Yakutia, Far North | 2 |

Hydraulic calculation

The coolant pressure created in the system is not a constant value. It is constantly influenced by the friction force created in the pipeline, adjustment of temperature indicators, etc. This can lead to unbalancing of the heating circuit.

This can be avoided by hydraulic calculation, which ensures that each radiator receives the coolant in the amount necessary to maintain the specified parameters. During the calculation, the following are determined:

- pipe diameter and capacity;

- potential pressure loss locations;

- optimal volume of coolant;

- hydraulic linkage conditions.

We calculate the volume of coolant based on the boiler power:

V= 13.5×Q, where:

- V – Volume of water mass of the heating main.

- 13.5 – Wed. volume of coolant per unit of boiler power.

- Q – Boiler power (kW).

The volume of coolant can also be calculated based on the actual capacity of the circuit, when all the volumes of the constituent elements of the circuit (pipes, radiators, etc.) are summed up.

Calculation of coolant movement speed:

V= (Q×L×0.86):(K-Ko), where:

- V – Coolant movement speed (m/s).

- Q – Boiler power (watt).

- L – boiler efficiency.

- K – Coolant temperature at the boiler outlet.

- Ko – Return coolant temperature.

The optimal speed of fluid movement is considered to be in the range from 0.3 to 0.7 m/s. Deviation from the established standard threatens either airing of the circuit or excessive noise.

Pipe diameter

The determination of the pipe cross-section is based on the results of thermal and hydraulic calculations.

D= √354×(0.86×Q):(K-Ko):V, where:

- D – Pipe cross-section (cm).

- Q – Boiler power (watt).

- K – Coolant temperature at the boiler outlet.

- Ko – Return coolant temperature.

- V – Coolant movement speed (m/s).

The calculation is quite complex, so it is easier to use ready-made tables or special online calculators, widely available on the Internet.

As a result of all calculations, a plan for individual heating of a private house (apartment) is drawn, indicating the diagrams and data of each element of the system.

6-Selection of expansion tank

A tank is an element of the heating system, which is a container that can be used to compensate for the expansion of the liquid during heating. When selecting a tank, it is important to first carefully study each parameter of the system, otherwise there is a risk of making a significant mistake. It threatens a complete failure of the heating system.

The volume of the tank should be equal to 15% of the coolant. Therefore, when choosing, it is better to give preference to those models that are larger in volume than required. Large tank sizes do not affect the heating process in any way, while a lack of size results in problems.

Starting the system

- Before starting, visual inspection of the integrity and tightness of the boiler, radiators, pipes and connecting elements, the functioning of air vents and drain valves is carried out. The draft and integrity of the chimney is also checked. If necessary, it is cleaned and repaired.

- Closed heating circuits require preliminary hydrodynamic flushing, carried out by a special filter pump.

- For pressure testing, a closed system is filled with an increased volume of coolant (sometimes air) through a make-up unit located at the lowest point of the circuit.

- A special antifreeze (preferably propylene glycol, which is safe for human health) or ordinary distilled water is used as a coolant.

- By means of Mayevsky taps (pipe pipes or valves), the air in the main is released until liquid flows.

- The boiler is started according to the manufacturer's recommendations.

- Upon heating of the coolant on the boiler, the make-up valve opens, supplying liquid to the circuit. Boiler pressure gauges are used to check pressure. The pressure indicator should not exceed 3 atmospheres.

- The pressure of the air chamber of the expansion tank should be 5 - 7% higher than the system pressure.

As a result, the heating should stably maintain the set temperature without pressure surges.

7-Purchase of a thermal head

Recently, thermal heads used for radiators have become popular. They allow you to manually adjust the heating temperature inside the room itself. But they cannot always be used. Thermal heads cannot be used when there is a solid fuel boiler in the room. The fact is that it heats the air in the room to the desired level, and then each thermal valve of the radiators closes immediately. Then the boiler temperature rises to boiling. This is where an emergency is likely to occur.

Installing a heating system is by no means as simple as it seems at first glance. It is preferable to entrust the calculation work to experienced specialists. This will help eliminate the possibility of emergency situations and system failures.

To avoid such troubles, you need to ensure that during installation of the heating system at least some of the radiators are left without the manual control function.

Get a quote

Types of circulation

Natural circulation design. The system works according to this scheme.

- The boiler heats the coolant to the required temperature, its volume increases, and its density becomes less.

- Thanks to this, cooled water replaces heated water. It, in turn, rises to the highest point of the boiler, cools down and goes to the radiators itself.

- The entire way the substance moves without help from the environment, it takes a lot of time.

- In this regard, the displaced air has time to reach the top point of the heater, which reduces the risk of excessive airing.

Heating systems with natural circulation remain operational for a long time.

Disadvantages of the system:

- Small radius of the heated room. (No more than 30m)

- A long period of time between turning on the boiler and stabilizing the temperature in the room.

- The pipes through which the heat exchanger moves must be at a special angle.

- Uneven heating. The further away the battery, the colder the liquid.

Wiring with forced circulation of coolant

The driving force of such a heating apparatus is the circulation pump.

Advantages:

- Fast heating of the room.

- Even heat distribution.

- Possibility of using a membrane boiler.

- Simple repair. (The broken section is disconnected from the general system).

- Convenient installation of a two-pipe heating system.

- The amplitude of fuel temperatures at the inlet and outlet is small.

- Lack of air route.

Flaws:

- Energy dependence.

- Large financial costs.

Based on the type of structure, systems are divided into groups: horizontal and vertical type of layout.

The first layout option is possible in a one-story room. The advantage of this type of connection is the low cost of the system itself. The downside is a high probability of strangulation. But it can be eliminated by installing Mayevsky cranes.

The vertical type of layout differs from the horizontal one in that it has a larger number of highways. This option for pipe arrangement is more profitable to use in multi-story buildings. The advantage is the absence of air pockets. But this option will cost much more.