Increasingly, warm floors are being installed in apartments and private houses. It makes it possible to heat the room evenly over the entire area, making the microclimate as comfortable as possible for residents. During the installation of such a system, waterproofing of the heated floor will be mandatory. The need for this measure is explained by the following reasons.

- Waterproofing under a warm water floor is a prerequisite when installing such a heating system, since if the seal of the pipes with the coolant is broken, the base will begin to collapse. This is especially true for an apartment that is not located on the ground floor, since there is a high risk of flooding of neighbors.

- Waterproofing a warm water or electric floor is needed to separate the insulation from the concrete base, since due to changes in low and high temperatures, condensation will occur, which will negatively affect building materials.

- Waterproofing the floor in a private house on the ground floor, between the soil and the screed, to create a protective layer that prevents capillary moisture from penetrating upward.

The need for waterproofing

Everything is quite obvious here. Such a measure will direct heat upward, preventing it from passing through the ceilings. Quite often, many people forget about installing waterproofing under a warm water floor, but its necessity is explained by several reasons:

- It is imperative to install waterproofing under a warm water floor, since leaks in the pipes in which the coolant moves can cause damage to the base. And if the apartment is not located on the first floor, the neighbors living below you will suffer from the flood;

- Under water and electric floors, a waterproofing layer is necessary to separate the insulating material from the concrete floor. Changes in temperature and cold emanating from the base will cause condensation to appear, negatively affecting the layer of insulating material;

- in rooms on the first floor or located on the ground, it is recommended to lay waterproofing between the ground and the screed to create protection from capillary moisture. The second solution to the problem is to lay waterproofing between the insulation layer and the rough screed.

When using insulation material that is vulnerable to water from any side, experts advise laying it between two waterproofing layers in the following situations:

- The underfloor heating system is being installed, but there is a possibility of leaks;

- the installation of the floor is carried out using the wet method, and the insulation must be protected from the water that is in the solution;

- the floor is installed in a bathroom or other room with high humidity, and there is a possibility of water penetrating through the floor coverings.

As a rule, in underfloor heating systems, the underlay acts as a waterproofing layer for the insulation on top. For example, foamed polyethylene with a foil surface is responsible for reducing heat loss, uniformity of its distribution, and protects the insulating layer from moisture.

Many people are interested in whether waterproofing is necessary under a heated floor in principle, and whether in wet rooms there is a need to lay waterproofing on top of a heated floor - corrosion can begin from water leaks, and in the case of an electrical system there is a possibility of a short circuit.

Such worries are groundless, since heating elements and coolant pipes are created in such a way that they can be mounted under a screed, which creates an aggressive environment before final drying.

Cable and electrical underfloor heating systems, like water-based ones, have their own waterproofing, so the penetration of moisture from above does not pose a threat to them.

We do the design and calculations

Before purchasing materials and proceeding directly to installation, it is necessary to calculate the main parameters of the heating system, draw up an equipment layout diagram and determine the route for the heating circuits. This will help you purchase the necessary components in the required volume, facilitate installation and eliminate errors in operation.

It is better to entrust the calculation of power, number of pipes and drawing up a plan to specialists who will not only take into account all the features of the room and the heating system being developed, but will also select equipment that is optimal in price and quality.

You can also use special programs that perform all the necessary calculations based on the entered data.

Or manually draw a heated floor layout for each room. When drawing up a plan, it is worth considering the following nuances:

- The heating circuit is made only from solid pipe sections; it is unacceptable to use various connecting elements. At the same time, they try not to lay the pipeline in places where furniture or household appliances will be installed.

- The manifold cabinet, in which the distribution unit will be located, is placed in such a way that the pipes of the circuits are approximately the same length (let's take a run up to 15 meters). When installing under the box, be sure to leave free space sufficient for the supply of all pipelines.

- The length of one circuit should not exceed 100 meters so that hydraulic resistance does not increase in the pipeline, which negatively affects the efficiency of the system.

- The distance between laid pipes varies between 10-25 cm. You cannot lay the pipeline directly next to the wall; you need to move 20-30 cm away from it.

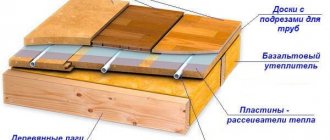

Laying the water heated floor circuit is carried out according to the following schemes.

In enclosed spaces - bathrooms, restrooms and corridors - a “snail” is usually installed, ensuring uniform heating of the entire floor surface. In kitchens and rooms where heat loss is higher due to the presence of windows and balconies, it is preferable to use a “snake” pattern for laying water-heated floors under the tiles.

Important!

Pipes through which the hottest coolant passes must be laid in the coldest areas.

After all the calculations, equipment is selected for the heated floor - a collector group, thermal insulation material, heating circuit pipes, etc. You should also entrust these works to professionals or seek help from the specialists of the store where you purchase everything you need.

Criteria for selecting waterproofing materials

According to the specific application, such materials are divided into different types, but their selection is subject to the same requirements:

- atomosphere resistance - protection from moisture must be distinguished by the ability to retain its original properties and quality characteristics for the longest possible period;

- moisture resistance and resistance to water is a very important criterion that determines the ability not to let or absorb water;

- chemical resistance - this parameter is important in order to avoid damage from exposure to chemical elements during operation;

- resistance to temperature changes - this property helps to maintain original performance at certain temperatures;

- biological stability - this characteristic allows you to prevent the penetration and impact of bacteria and microorganisms on the structure of the waterproofing material.

When deciding which waterproofing material to use for underfloor heating, it is recommended to pay attention to the following important aspects:

- price. As a rule, rolled materials are cheaper. Mastic materials and primers are more expensive, but provide better protection from moisture;

- features of the premises - for rooms with a small area it is better to use mastic, but large rooms are easier to cover with roll materials;

- the possibility of installing waterproofing on your own - it is easiest to work with impregnating compounds, but difficulties may arise with the deposited layer.

In most cases, manufacturers of underfloor heating systems recommend types of waterproofing materials as recommendations. These include:

- polyethylene and polyvinyl chloride film materials. They are equipped with thermo-reflective layers. For ease of installation, the edges are heated and joined, insulation is performed with adhesive flax;

- cement-polymer - a freshly prepared elastic composition is applied to the surface using a roller or spatula, and a special tape is laid at the joints. The result is a durable and waterproof coating that is excellent for concrete surfaces. Many note its elasticity, which is very important during changes in temperature conditions and shrinkage of buildings recently put into operation;

- cast - the most reliable option. Today, liquid silicone membranes are used for this purpose, creating good adhesion and being elastic.

Liquid silicone membranes - a type of waterproofing for underfloor heating

Content

- Which waterproofing to choose, roll or coating

- How to choose the right waterproofing

- After which layer of floor pie should waterproofing be applied?

- Is it possible to save on tape?

- Do I need to use two-component formulations?

- Is waterproofing necessary in the bathroom of a private house?

5nizza Member FORUMHOUSE

Explain to the dark one: why is it necessary to waterproof a bathroom in a house made of gas silicate blocks and bricks, if the bathroom is on the first floor of the house with a ground floor?

Bathrooms are traditionally considered the most “complex” rooms in a country house, and not only in a wooden one. Many homeowners waterproof them simply by default - there is still always a risk of leaks. Another category of homeowners is inclined to believe that in a one-story house without a basement, “you don’t have to do any waterproofing - there’s nothing to flood,” and you can get by with epoxy grouting of the joints - it doesn’t allow water to pass through. But it's not right. In a house with a floor on the ground, GI still needs to be done to prevent gradual wetting of the structures from the side of the room.

Mastergidro FORUMHOUSE Member

Waterproofing of the bathroom is done in accordance with all SNIPs. It’s better to do it right away than to dismantle the floor later if there are leaks.

SanSanych-Moscow Member of FORUMHOUSE

Let's assume there is no basement. There will be a leak. The water will sit for a day, some will go into the stove and will come out of it for a long time. Dampness, mold... Do you need it? Take the coating waterproofing and cover everything with it.

Wind4625FORUMHOUSE Member

In the bathroom and in the bathhouse, waterproofing is always necessary. There are a million risks in these premises: spilled water, cracks, damaged washing machines... Waterproofing is a minuscule part of the overall construction costs. Stick a roll of waterproofing on top of the screed, some with a self-adhesive layer.

Types of waterproofing under a water floor

Several types of waterproofing materials are known, differing in composition, principle of operation, and efficiency.

Roll

Inexpensive and most common option for insulation. For this type of protection, roofing felt, a thick polyethylene film, is used. Fused waterproofing materials are applied using the gluing method with pre-heating with a gas burner or a hair dryer.

Water based mastic

Creates maximum surface protection from moisture penetration. Recommended for use in multi-storey buildings for maximum protection against water leakage if the water circuit has lost its integrity. In order to prevent leaks, the water circuits of heating systems are placed in special corrugations as an additional measure. This measure ensures that if the integrity of the pipes is compromised, water will not flood the lower floor.

Water-based mastic is one of the options for waterproofing under heated floors

Seam processing

After the glue has dried, it should be carefully removed from the seams with a spatula, and the separators should also be removed. Now you can start cleaning the seams.

Using a rubber spatula, apply a little mixture to the seams using cross-shaped movements. Excess is immediately removed from the tiles with a rag.

The mixture should be allowed to harden slightly and the quality of filling the joints should be checked. In places where there is not enough grout material, you should add a solution. Photo - Grouting joints

For your information! The grout mixture protects the seams from mold and dirt accumulation.

Turning on a water heated floor laid under the tiles is allowed only 20 - 25 days after the installation of the tiles. This time is necessary for the screed to completely harden and the tile adhesive to dry.

A warm water floor plus tiles is an ideal option that allows you to justify your financial investment in a short period of time. In addition, this design will provide comfort in your home for many years.

Laying principle

The laying technique and preliminary preparation of surfaces will be determined by the selected material. There are simple application options that can be done independently; in other cases, special skills and appropriate tools are required.

Roll materials

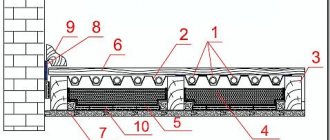

This type of waterproofing under a heated floor is laid over a rough screed. The materials are spread over the surface so that the joining areas form an overlap of several centimeters.

If bitumen covering materials are used, then waterproofing is arranged as follows. The base must first be leveled and treated with a primer. The roll of waterproofing material is gradually rolled out, while its lower surface warms up. The seams are processed especially carefully. Bituminous materials are glued to the base, creating high-quality protection against water penetration and condensation.

Rolled materials for waterproofing under heated floors

Liquid mastic

Working with such material on your own is quite simple. The mastic is applied with a brush or spray gun in several layers. Impregnations penetrate deeply into the surface, creating a moisture-proof layer. Ultimately, reliable protection against leaks is provided if the water circuit breaks. It is worth noting that this option of waterproofing under heated floors is recommended for installation in the bathroom.

The technological process of working with mastic involves careful surface treatment, applying the next layer perpendicular to the previous one.

Waterproofing helps prevent the formation of condensation and provides high-quality protection against leaks if damage occurs in the water circuit. If such a layer is missing, it means that the installation work was carried out with a gross violation of technology.

Marking the room

To facilitate the process of laying tiles, you need to mark the room. The easiest way to do this is with a laser level. Although it is possible to use the old, proven method - a lace with dye powder.

The process looks like this:

- A line is drawn in the center of the room parallel to the longest wall:

- the second line is located perpendicular to the first, also in the center;

- A block of wood is installed in the doorway; it will serve as a limiter.

Backfill insulators

Bulk materials are usually represented by a mixture of bentonite and water-repellent granules. In fact, it is an alternative to insulating wool. This coating has a minimal level of moisture absorption and excellent thermal insulation characteristics. Sometimes loose insulation is used not only for protection against moisture, but also as insulation.

You should be aware of the following nuances before starting work on backfilling the insulator:

- Preliminary finishing of the subfloor is carried out only with bentonites filled with water. Such a connection will lead to the formation of a kind of liquid, water-resistant gel-like layer.

- The resulting moisture-repellent material is poured over the rough base.

- Hardening occurs within a few days.

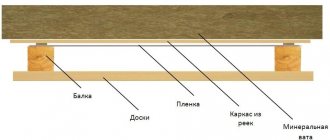

The advantage of this technology is that the material can also be poured into wooden houses between the joists at the base. The thickness of the layer can correspond to the level of the log.

Insulation for heated floors description and cost on the market

This article examines the types of heat-insulating underfloor heating coatings, their features, properties and purpose. We will also present several companies offering insulating materials at reasonable prices and contact information (addresses, telephone numbers, etc.) for direct communication with specialists.

Types of insulation

Insulation for underfloor heating comes in various types: cork, polystyrene foam, metal-coated Mylar film and reflective.

Cork insulation (backing) is a natural material, supplied in a roll. Its use is not appropriate in all cases, since the use of cork raises the floor by 4 cm, which is not acceptable for rooms with low ceilings.

Expanded polystyrene 100 mm

polystyrene with metallized coating

note

, the fact that reflective insulation for underfloor heating is the same metallized thermal insulation, but its service life is 1000 times longer, since it can withstand the action of an alkaline environment. Metal-coated Mylar film can last approximately three weeks in a screed; reflective insulation will last fifteen years. Suitable for any heated floor: water, electric, infrared, etc.

Price issue - where and how much to buy insulation

For insulation for underfloor heating, the price varies from 300 to 1100 rubles per square meter. Below in the table we provide information on the prices of several companies, including the cost of insulation for a warm water floor.

Source

Roll insulators

The most durable and hard materials with a low degree of moisture absorption are usually sold in roll form. The basis of such material is: bitumen, glass fiber or fabric, polyethylene. Modern manufacturers replace bitumen with synthetic materials to eliminate the unpleasant odor of the coating.

The installation method determined the formation of the following types of rolled waterproofing materials:

- Self-adhesive. They are pre-equipped with an adhesive layer, so they are simply laid on a prepared rough base.

- Requiring warming up. Heating such a material makes it more plastic and increases its adhesion to the base, i.e. it can be glued without the use of auxiliary means.

- Used in combination with an adhesive mixture.

Do-it-yourself infrared film heated floor

Floor power and coverage area

As in the case of an electric heated floor (which we wrote about earlier), before laying an infrared floor, you need to decide on the area on which it will be laid. That is, this is free space on which light interior items can stand. The floor is not laid under heavy furniture and appliances, as this is unjustified. The power of the mats depends on the area covered by the infrared floor. For an area of 20 m2, a more powerful film floor (220 W/m2) is suitable; for an area of more than 20 m2, you need to choose a lower power. In any case, the consultant will calculate the required power of the floor and thermostat depending on your area.