How to select parameters

The hydraulic separator is selected taking into account the maximum possible coolant flow rate. The fact is that at high speeds of liquid movement through the pipes, it begins to make noise. To avoid this effect, the maximum speed is assumed to be 0.2 m/s.

Parameters required for the hydraulic separator

By maximum coolant flow

To calculate the diameter of the hydraulic arrow using this method, the only thing you need to know is the maximum coolant flow that is possible in the system and the diameter of the pipes. With pipes everything is simple - you know which pipe you will use for wiring. We know the maximum flow that the boiler can provide (it is in the technical specifications), and the flow rate through the circuits depends on their size/volume and is determined when selecting circuit pumps. The flow rate for all circuits is added up and compared with the power of the boiler pump. A large value is substituted into the formula to calculate the volume of the hydraulic needle.

Formula for calculating the diameter of a hydraulic separator for a heating system depending on the maximum coolant flow

Let's give an example. Let the maximum flow rate in the system be 7.6 cubic meters/hour. The permissible maximum speed is taken as standard - 0.2 m/s, the diameter of the pipes is 6.3 cm (2.5 inch pipes). In this case we get: 18.9 * √ 7.6/0.2 = 18.9 * √38 = 18.9 * 6.16 = 116.424 mm. If we round, we find that the diameter of the hydraulic needle should be 116 mm.

According to the maximum boiler power

The second method is to select a hydraulic needle according to the boiler power. The estimate will be approximate, but it can be trusted. The boiler power and the difference in coolant temperatures in the supply and return pipelines will be needed.

Calculation of hydraulic arrow according to boiler power

The calculation is also simple. Let the maximum boiler power be 50 kW, the temperature delta be 10°C, the diameters of the pipes be the same - 6.3 cm. Substituting the numbers, we get - 18.9 * √ 50 / 0.2 * 10 = 18.9 * √ 25 = 18.9*5 = 94.5 mm. Rounding, we get the diameter of the hydraulic needle 95 mm.

How to find the length of the hydraulic arrow

We have decided on the diameter of the hydraulic separator for heating, but we also need to know the length. It is selected depending on the diameter of the connected pipes. There are two types of hydraulic arrows for heating - with taps located one opposite the other and with alternating pipes (located offset from one another).

Determining the length of the hydraulic arrow from a round pipe

It is easy to calculate the length in this case - in the first case it is 12d, in the second - 13d. For medium-sized systems, you can select the diameter depending on the pipes - 3*d. As you can see, nothing complicated. You can calculate it yourself.

Types of hydraulic separators

The designs of hydraulic valves can be distinguished, depending on the number of pipes:

- The hydraulic arrow provides 2 circuits (has 4 pipes);

- The KV series hydraulic arrow has 2 pipes on one side, and 8 or 10 outlets on the opposite side;

- A collector water gun (has many pipes on both sides) makes it possible to create a separate heating branch from each pipe and connect its own circulation pump to each branch.

Stainless steel ring manifold with three circuits

Also, the location of the pipes relative to each other can be:

- On one axis.

- With a shift, when the outlet is lower than the inlet (type of alternating pipes).

In the second case, the coolant’s movement speed is slightly reduced, which provides better cleaning from impurities and air. In the first option, the flow accelerates more strongly, but particles can slip into the second circuit.

Devices are distinguished by power and volume. It won’t be difficult to choose the one you need if you have information about the characteristics of the boiler.

Most often, solid fuel boilers are installed forcedly if there is no gas. A solid fuel boiler with a water circuit is the best option for heating a room in the absence of centralized heating.

How a thermostat for a heating boiler works and how much such a device costs, read here.

If your house is heated with electrically dependent appliances, you need to consider the possibility of turning off the lights. In order not to lose heat overnight, it is advisable to purchase an uninterruptible power supply for the heating pump. Here https://microklimat.pro/otopitelnoe-oborudovanie/otopitelnye-pribory/besperebojnik-dlya-nasosa-otopleniya.html you will learn all about the features of choosing a device.

How is it arranged?

Although the hydraulic arrow is very important in the heating system, its structure and design are quite simple. This is a fragment of a round or square pipe in which there are two holes on the boiler side and the same number of holes on the heating system side. To prevent the hydraulic separator from becoming clogged, it can be equipped with mesh filters that trap debris formed in the coolant. After a certain period of time, the screens may become clogged and will need to be cleaned.

Using this device, it is possible to separate the hydraulic systems of the heating unit and the heating system itself. Moreover, the hydraulic separator can be used with a manifold for four, three, two circuits and with one branch boiler. The heating system and boiler circuits receive their own hydraulic mode.

When choosing a hydraulic gun, you need to understand its operating principle and the advantages it has:

- provides good performance, minimal pressure loss and productivity;

- creates hydraulic balance and the necessary temperature conditions;

- serves as protection against heat stroke;

- saves energy;

- reduces hydraulic resistance.

The air vent valve removes oxygen bubbles from the device, thereby protecting the rest of the equipment from corrosion, extending its service life and ensuring stable operation. The same applies to filters that trap debris.

A device with perforated partitions is provided inside the hydraulic separator. They are necessary to divide the internal space in half so that unnecessary resistance is not created.

Conclusions and useful video on the topic

Video about practical application: when there is a need to install a hydraulic arrow, and when it is not needed.

The importance of the hydraulic arrow in the distribution of heat flows is difficult to overestimate. This is truly necessary equipment that should be installed on every individual heating and hot water system.

The main thing is to correctly calculate, design, and manufacture the device - a hydraulic separator. It is accurate calculation that allows you to achieve maximum efficiency from the device.

Please write comments in the block below, post photos related to the topic of the article, and ask questions. Tell us about how you equipped the heating system with a hydraulic arrow. Describe how the operation of the network changed after its installation, what advantages the system acquired after including this device in the circuit.

Why do you need a hydraulic arrow in a heating system?

A hydraulic arrow is a part from the boiler piping, with the help of which the characteristics of the coolant circulation process are stabilized and thermal fluctuations in the heat-generating unit are leveled out. In addition, the hydraulic arrow can also work as a compensator, ensuring independence of the heating circuits.

As a result, the efficiency of the heating system increases, fuel consumption decreases, the operation of the heat-generating unit is facilitated and the trouble-free operation of all equipment is extended.

How does a hydraulic gun work?

A typical hydraulic arrow is a vertically oriented cylinder or rectangular parallelepiped with four working outlets - two at the top and two at the bottom.

Moreover, the central axis of the upper outlets is located along one line or with one fitting shifted upward. In turn, a pair of lower outlets are arranged either along one axis, or with one of the fittings shifted downward. The pressure branch of the system is connected to the upper branches, and the return branch, respectively, to the lower branches.

The principle of operation of the hydraulic arrow

In addition, a fitting with a valve is cut into the bottom of the housing “arrows” to drain the coolant from the system, and into the lid there is a fitting with a valve to remove air, which accumulates above the water (coolant) and is released due to the pressure in the system.

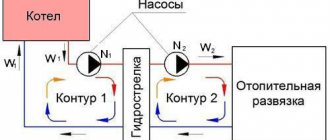

A hydraulic arrow arranged in this way divides the heating system into two circuits:

- A small branch, which includes the “arrow” and the boiler. Circulation diagram: horizontally from the boiler - vertically along the arrow - horizontally into the boiler.

- A large branch, which includes the boiler, pipes, radiators and arrow. Circulation diagram: horizontally from the boiler, through the arrow, to the battery - vertically along the battery - horizontally from the battery, through the arrow, to the boiler.

Circulation through the small circuit occurs only in the event of excess heat in the system. In this case, the overheated coolant is discharged through the arrow into the return line, after which the boiler temperature controller “extinguishes” the firebox.

In this case, the heat generating unit will be able to start operating the system only after the coolant temperature has dropped to an acceptable level, opening a large circulation branch.

The movement of coolant along a large branch - in fact, the entire wiring of the system - occurs only in the case of normal operation of the boiler, which generates the portion of thermal energy “necessary” for the batteries.

Simply put: a heating system with a hydraulic arrow spends a minimum of fuel and produces a maximum of thermal energy.

How does a hybrid of a hydraulic gun and a manifold work?

Such a hydrodynamic thermostat can be made from any standard arrow by replacing the “right” taps with collectors. That is, opposite each “left” fitting connected to the boiler, it is not the “right” fitting that is welded to the body, but a long pipe with many vertical bends - the heating system manifold.

Hydraulic boom

The coolant flows from the boiler into the “arrow”, moves along it in a horizontal direction and passes into the radiant distribution manifold, distributed over multiple circuits of the heating system. Moreover, each pressure pipe at the “outlet” of the manifold arrow is equipped with its own pump, which ensures the circulation of the coolant in a specific wiring circuit.

As a result, the heating manifold with a hydraulic arrow regulates not only the temperature of the coolant, but also the direction of circulation, equalizing the pressure between the branches of the system. Moreover, the construction of such a hybrid is justified only if it saves space in the boiler room. Since a trivial connection of a pair of manifolds to a standard arrow with four pipes will give the same effect.

How to choose a hydrodynamic thermal separator?

The relatively low price of a hydraulic arrow for heating eliminates the very idea of building this unit with your own hands.

Therefore, most homeowners prefer “factory” switches to homemade ones, choosing a hydrodynamic thermostat according to the following parameters:

- Thermal power of the boiler.

- The volume of coolant in the system.

These parameters must correspond to the “passport” data of the hydraulic arrow, that is, the selection procedure itself is as follows:

- We find out the thermal power of the boiler (from the unit’s passport) and the volume of water in the system (from the length of the pipes and the dimensions of the boiler and batteries).

- We go to the store and buy an arrow that matches the volume and power.

https://youtube.com/watch?v=sLsOysrbhb8

We also recommend watching:

- Film heated floor with infrared radiation

- Alternative heating sources for a private home - what to choose?

- Why is a bypass needed in a heating system?

- Corrugated stainless steel pipes for heating

Advantages

If we briefly summarize all the advantages that the installation of a simple dismountable device provides, we get:

- pressure balance in the system;

- temperature distribution in different circuits;

- protection against water hammer;

- the ability to disable a separate system without losing the functionality of the others;

- increasing boiler efficiency, saving resources and energy;

- air vent;

- protection of pipes, fittings and boiler from damage by impurities in the coolant.

Operation of the hydraulic gun in different modes.

There are three main modes in which the hydraulic separator

.

Depending on the switching on and off of heating system consumers, the operating mode of the hydraulic switch

or

modular type hydraulic switch

(hydraulic switch + manifold) also changes.

So what happens after launch? After starting the heating system, until the coolant has reached the required temperature, the liquid circulates in a small circle and the entire flow moves down the hydraulic arrow

.

After the temperature of the coolant reaches the required operating mode of the hydraulic separator, into the secondary heating circuit, with uniform analysis, with equalization of incoming and outgoing flows, hydraulic arrow

works as

an air vent

and cleans the coolant from dirt.

Note that it is practically impossible to achieve complete equality between the two flows, hence the 100 percent feasibility of installing a hydraulic arrow.

When heating the room, the automation regulates the coolant flow in the secondary circuit, for example, if a certain DHW temperature is reached, the pump in this circuit is turned off, or if the radiator thermal heads reduce the coolant flow, which in turn increases the hydraulic resistance in the heating circuit, which is monitored by an adaptive pump - thus, adapting to this and reducing its productivity, as a result the total flow of Q2 decreases. As a result, the difference between the two flows (primary and secondary) goes up the hydraulic needle. If the hydraulic valve had not been installed, significant hydraulic imbalances would have occurred in the heating system, and as a result, failure of the heating equipment (pump, heat exchanger). What happens if the consumer circulation pumps stop, then the primary circuit of the heating system goes into mode 3.

Figures 3-5 show these modes:

Figure 3:

The total flow rate of the boiler pumps is equal to the total flow rate of the heating system pumps. This mode is rarely achieved. In this case, all the coolant heated by the boiler enters the heating system to consumers.

Figure 4:

The total flow rate of the boiler pump is less than the total flow rate of the heating circuit pumps. This mode is possible when the boiler cannot cope with the load. In this case, the boiler operates in maximum mode and constantly heats the coolant.

If there are several boilers, the total flow rate of the boiler pumps is less than the total flow rate of the heating circuit pumps. In this mode, one of several boilers and its pump is turned off, since the operation of one boiler is enough, while the heating circuit pumps take the necessary coolant from the heating return pipe through a hydraulic valve. Thus, the flow rate in the boiler circuit remains constant, corresponding to the required value for the operation of the boiler.

Figure 5:

The total flow rate of the heating circuits is less than the flow rate provided by the boiler pumps. The most common mode in which boiler pumps are selected correctly and have a slightly higher flow rate than required by the heating system. This mode provides all the necessary conditions for the heating system to operate in the boiler’s economical mode.

. In this embodiment, the hydraulic arrow plays a protective role for boilers, since the addition of hot coolant in the hydraulic arrow creates a minimum temperature difference in the boiler return line, and the required amount of coolant enters the heating circuit. This mode is the most optimal, so it is adopted when designing the system.

The power of the hydraulic switch must be higher than the total power of the boiler used.

Device Description

The device itself resembles an elongated parallelepiped, with six different outputs located opposite each other. Each of these outputs is responsible for a separate function. For example, the highest of the 5 valves allows air to flow out of the system without problems, so as not to increase all the pressure. This happens automatically, the owner does not have to control anything.

Photo 1. Hydraulic arrow installed in the heating system. Red indicates hot coolant, blue indicates cold fluid.

The lower pipe helps destroy and remove “garbage” that remains in the hydraulic separator device. Dirty air from the pipes (its particles) and sediment from the onset of corrosion or another process falls down, where, like a blade, the lowest, sixth pipe is located. Water pipes are connected to the remaining valves. Inside, the entire hydraulic arrow is hollow; there is nothing in it except water and decay products.

Schemes for self-manufacturing hydraulic arrows

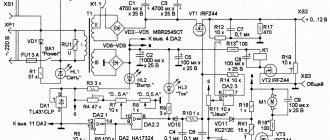

When assembling a hydraulic arrow with your own hands, the main thing is to make the calculations correctly and have the skills to work with a welding machine.

First of all, it is necessary to find the optimal dimensions of the hydraulic separator:

- internal diameter: divide the sum of all heating boiler capacities in kW by the temperature difference between the supply and return, take the square root of the resulting parameter, and then multiply the last value by 49;

- height: multiply the inner diameter by six.

- spacing between pipes: multiply the internal diameter by two.

Based on the obtained parameters, you need to draw up a drawing or use one of the diagrams of the future hydraulic distributor presented by the Plumber Portal resource. After this, you need to prepare a steel tube of round or square cross-section, which corresponds to the calculated indicators, and weld the required number of pipes with threaded connections into it.

Despite the simplicity of the device, the characteristics of the hydraulic gun must still correspond to specific conditions. Also, when assembling it yourself, you need to understand what to start from.

The classic assembly of a typical hydraulic boom is based on the “three diameter rule”. That is, the diameter of the pipes is three times smaller than the diameter of the main cylinder of the separator. The pipes are diametrically opposite, and their height arrangement is also tied to the main diameter.

Classic hydraulic separator diagram:

Some change in the position of the pipes is also used - a kind of “ladder”. This modification is aimed mainly at more efficient removal of gas and insoluble suspended matter. When circulating through the supply pipe, a slight change in the direction of the liquid flow in a zigzag downward manner contributes to the best elimination of gas bubbles.

On the reverse flow, on the contrary, the step is upward, and this simplifies the removal of solid sediment. In addition, this placement promotes optimal mixing of flows. The proportions are chosen to create vertical flow conditions in the range of 0.1 to 0.2 meters per second.

Exceeding this limit is prohibited. The lower the speed of the vertical flow, the more effective the separation of air and sludge will be. The slower the movement, the better the mixing of flows with different temperatures. As a result, a temperature gradient is formed along the height of the device.

Diagram of a hydraulic arrow with a stepped arrangement of pipes:

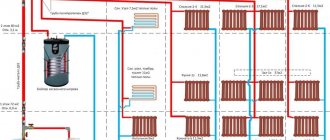

If the heating system contains circuits with different temperature conditions, then it is worth using a hydraulic distributor that acts as a collector, and different pairs of pipes will have their own temperature pressure. This will significantly reduce the load on thermostatic devices, making the entire system more manageable, efficient and economical.

The closer the pair of pipes is to the middle, the lower the temperature pressure in the supply tube, and the smaller the temperature difference in the supply and return. For example, for batteries the best mode is 75 degrees in supply with a difference Δt = 20 ºС, and for a heated floor system 40÷45 with Δt = 5 ºС is enough.

Diagram of a hydraulic separator with three outputs to the heating circuits:

Horizontal placement. In such variations, of course, there is no question of removing sediment and air. The placement of fittings varies significantly - to effectively move liquid, circuits are often used even in the opposite direction of the flow of the “small” and heating circuits.

Such a hydraulic arrow is made in order, for example, to place equipment more compactly in a boiler room, since the counter direction of flows makes it possible to slightly reduce the diameter of the tubes. However, the design must meet certain requirements:

- between the pipes of one circuit a gap of at least 4d must be maintained;

- if the inlet pipes have a diameter of less than 50 mm, then the distance between them should not be less than 200 mm.

Options for horizontal hydraulic separator circuits:

There are also completely “outlandish” designs. For example, one craftsman was able to build a hydraulic arrow from two sections of an ordinary cast-iron radiator. This device copes with hydraulic separation without problems. However, this method requires very reliable thermal insulation of the device, otherwise it will result in absolutely unproductive heat losses.

Calculation of parameters of a “classical” hydraulic arrow

The schemes proposed above are wonderful. But how can you accurately determine the specific values of these same D and d?

We offer two calculation options. The first is based on the power of the heating system. The second is on the performance of circulation pumps installed in the boiler circuit and in all heat exchange circuits.

We will not bore the interested reader with a series of formulas. It is better to invite him to use the capabilities of the online calculators located below, which will make the necessary calculations quickly and accurately. The result will be shown in millimeters - the recommended minimum internal diameters of pipes for the manufacture of the hydraulic arrow itself and the pipes for connecting the circuits. Next, in accordance with the diagrams proposed above in the publication, it remains to determine the remaining dimensions.

Calculator for calculating hydraulic separator parameters based on boiler power

In the data entry fields you must indicate:

- Speed of vertical flow movement.

- Maximum design power of the heating system.

- Temperature operating conditions of the “small” circuit, that is, the temperature level in the supply and “return” directly near the heating boiler.

Go to calculations

Calculator for calculating the parameters of a hydraulic separator based on the performance of circulation pumps

The initial data are:

- Desirable speed of vertical movement of flow in a hydraulic arrow.

- The performance of all pumps that ensure the operation of “large” hot water heating circuits connected to the hydraulic separator.

- circuit, that is, ensuring the operation of the boiler. If two boilers are installed in the system, and it is assumed that they can be connected simultaneously, then the capacity of both pumps must be indicated. If paired operation is not planned, then the most productive pump is indicated.

Please note: circulation pump models of different brands may have performance parameters expressed either in cubic meters per hour or in liters per minute. For user convenience, it is possible to select the desired units of measurement. But at the same time, naturally, they must be the same for all pumps participating in the calculation.

Go to calculations

What is a hydraulic arrow in a heating system

Hydroarrow

(hydraulic separator, hydraulic arrow) - part of the heating system, with the help of which the heating circuits are connected. It provides the smallest pressure difference between them, which makes it possible to turn off one without losing pressure in the others. In other words, the hydraulic arrow for the heating system removes the influence of the heat consumer pumps on the circulation pumps of the heat source and in the reverse order.

In addition, the hydraulic arrow is used for hydrodynamic balancing of heat supply. This simple device plays an important role in the entire heating system of a home. The hydraulic separator prevents the formation of thermal shock in cast iron heat exchangers and boilers.

Some boiler manufacturers include in the maintenance document a clause on the installation of a hydraulic arrow for heating. Without its use, the buyer loses the warranty on the device (for example, on a floor-standing gas boiler).

The hydraulic arrow for heating systems is balanced by the hydrodynamic parameters of the system. Thus, the mutual influence of various thermal circuits on each other is completely eliminated, which leads them to operate without failures and maintain the specified parameters and modes.

In addition to the above-described capabilities, a hydraulic gun for heating systems can also clean the coolant from impurities, for example, sand or rust (for this it is necessary to correctly calculate the parameters). In addition, the hydraulic separator also removes air from it, and this, in turn, extends the service life of metal parts, since their oxidation slows down. Increasing the service life of shut-off valves, pumps, sensors, radiators and heat exchangers directly affects the reliability and durability of the entire heating system.

The hydraulic boom performs the following functions:

- Function for maintaining hydrobalance in the heating system. Elimination of the influence of one circuit on the hydraulic characteristics of the others when turned on and off.

- Preservation function for cast iron boiler heat exchangers. The use of a hydraulic arrow for heating systems protects heat exchangers from sudden temperature changes that can occur when the boiler is first started or during repair work when the circulation pump is turned off. It is well known that such differences have a negative impact on cast iron devices.

- Air vent function. The hydraulic arrow is also needed to remove air from the heating system. For these purposes, a pipe is mounted on it in its upper part, intended for mounting an automatic air vent.

- Coolant filling and draining function. The vast majority of hydraulic arrows, both industrial and self-made, are equipped with drain valves, with the help of which the coolant is filled or drained from the heating system.

- Heating system cleaning function. In the hydraulic arrow, the coolant moves at a reduced speed. Thus, this installation collects various types of dirt: scale, rust, sand, scale, and so on. These solid fractions accumulate in the lower part, which allows their removal through the drain valve. There are models of hydraulic arrows that are equipped with magnetic catchers for collecting metal debris.

Read the material on the topic: Pipe winding: rules for selection and use

Purchased models

A typical example is the Sever-M5 collector. It works in heating systems with a power of up to 70 kW. The cost of the unit is about 9.5 thousand rubles.

A hydraulic arrow in a heating system is a hydraulic distribution device designed to distribute coolant over several circuits. Its installation is recommended in cases where the power of the boiler used is over 50 kW. The arrow is also used in complex branched systems with many secondary circuits - it is needed for balancing. You can buy it or assemble it yourself.

The easiest way is to buy a hydraulic gun in a ready-made factory version. The simplest model, for example, SINTEK ST-35, will cost 2,700 rubles if you buy it directly from the manufacturer. It can withstand pressure up to 6 bar and can be installed in heating systems with a heating power of up to 35 kW.

A heating manifold with a hydraulic arrow for 5 circuits is designed for the branched systems mentioned above. You can connect an indirect heating boiler to it, heated floors in the bathroom, kitchen and hallway, as well as three main circuits - on the ground floor, in the basement, and in the attic.

Other store equipment:

- Hydraulic arrow WOODSTOKE 331 – for heating with a power of up to 70 kW for 7 circuits. The cost of the device is 11 thousand rubles.

- Warme WGR 80 is a simple hydraulic valve with two pipes and two outlets for connecting an air vent and a tap. Cost – 4000 rubles. The model can operate in heating systems with a power of up to 80 kW.

- Proxotherm GS 32-1 - hydraulic needle is made in a shiny case, as it is made of stainless steel. It is designed to work in heating systems with a power of up to 85 kW. Cost - about 7-8 thousand rubles.

- Gidruss BM is a whole series of hydraulic arrows for heating systems with a power from 60 to 150 kW. They are made of high-quality structural steel and can withstand pressures of up to 6 bar at temperatures up to +110 degrees. The cost varies from 9 to 30 thousand rubles.

There are thousands of ready-made hydraulic guns, there is plenty to choose from.

The advantages of magazine-operated hydraulic shooters are quite obvious. First of all, they are characterized by impeccable build quality. The equipment must withstand significant pressure - up to 3-4 atmospheres for autonomous heating and up to 20-25 atmospheres for general heating. It is made from proven grades of steel created for the construction of heating equipment and other systems.

Secondly, the factory water guns are already designed for use in heating systems with one or another power. They have been verified many times, so their use will not cause any accidents. The stores will also offer auxiliary equipment for the installation of heating systems. And then there will be no problems with the warranty on boilers and radiators.

Where can I buy?

Hydraulic distributors are produced here from high-carbon steel with a thickness of 3 mm.

Simple devices with 4 pipes cost from 3.1 thousand rubles. (up to 50 kW). A similar device up to 100 kW will cost almost 4 thousand rubles.

There are models combined with a collector. Such a kit for three circuits will cost 6.8 thousand rubles. Five-circuit – 9.3 thousand rubles. Among the products there is also powerful boiler equipment. For example, a DN100 switch, designed to operate up to 500 kW, will cost 25 thousand rubles.

You can contact the organization by phone +7 913-953-16-80.

Many other manufacturers also produce hydraulic distribution equipment (only the prices are much higher):

- Italian company Immergas;

- Ariston;

- Meibes and others.

Hydraulic gun device

Now let's look at the hydraulic arrow device. The device has a simple design. There are units of different sizes and configurations, but they all meet certain rules. On sale you can find models that combine a separator and a collector.

A hydraulic arrow is a device in the form of a cylindrical body with pipes extending from it. It's easy to make yourself. The classic location of the hydraulic separator is vertical, but it is not mandatory. It’s just that with a vertical arrangement it is more convenient to remove air and collect solid suspensions. The hydraulic separator is not necessarily a welded structure. The device can be made of polypropylene or copper pipes.

Combining the heating manifold with a hydraulic arrow

Small houses are heated by a boiler with a built-in pump. Secondary circuits are connected to the boiler through a hydraulic valve. Independent circuits of residential buildings with a large area (from 150 m2) are connected through a comb; the hydraulic separator will be bulky.

Which pipes for heated floors are better and more convenient to use. Technical characteristics of each type of pipe products used for heated floors.

The distribution manifold is mounted after the hydraulic switch. The device consists of two independent parts that are connected by jumpers. According to the number of secondary circuits, pipes arranged in pairs are cut in.

The distribution comb facilitates the operation and repair of equipment. The shut-off and control valves of the heating system of the house are located in one place. The increased diameter of the collector ensures uniform flow between the individual circuits.

The use of a hydraulic arrow will protect the boiler from thermal shock

The separator and coplanar distribution comb form the hydraulic module. The compact unit is convenient for cramped conditions in small boiler rooms.

Mounting outlets are provided for star tying:

- the low-pressure underfloor heating circuit is connected from below;

- high-pressure radiator circuit - on top;

- heat exchanger - on the side, on the opposite side from the hydraulic arrow.

The figure shows a hydraulic arrow with a manifold. The manufacturing scheme provides for the installation of balancing valves between the supply/return manifolds:

Diagram of a hydraulic arrow with a manifold

The control valves ensure maximum flow and pressure on the circuits farthest from the hydraulic valve. Balancing reduces the processes of improper flow throttling and allows you to achieve the calculated coolant supply.

Important! An autonomous heating system refers to systems that operate with a high-temperature environment under pressure (including the hydraulic heating system for a private house). A specialist with sufficient knowledge in heating engineering, experience and work skills (electric and gas welding, plumbing, working with hand-held power tools) can make a hydraulic heating switch with their own hands. Numerous Internet sites offer step-by-step instructions for making a hydraulic arrow for heating; video clips can also help in this process

Numerous Internet sites offer step-by-step instructions for making a hydraulic arrow for heating; video clips can also help in this process

A specialist with sufficient knowledge in heating engineering, experience and work skills (electric and gas welding, plumbing, working with hand-held power tools) can make a hydraulic heating switch with their own hands. Numerous Internet sites offer step-by-step instructions for making a hydraulic arrow for heating; video clips can also help in this process.

Dimensions of the heating manifold with hydraulic arrow

Theoretical knowledge will help you draw up diagrams and drawings of a hydraulic heating arrow, place an individual order for equipment in a specialized organization, and monitor the work of the contractor. Entrusting the manufacture of critical components of the heating system to non-professionals is dangerous to life and health. It should be remembered that equipment damaged due to the fault of the owner is not subject to warranty repair or return.

How does a hydraulic arrow work in home heating systems?

The coolant passes through the separator, its speed is no more than 0.2 m/s. Due to the pump located in the boiler, hot water accelerates to almost 1 m/s. From here you can see for what purpose a hydraulic arrow is needed in heating systems. The coolant changes its volume and direction of movement, and the speed of water flow is reduced. At the same time, energy loss in heating systems is minimal. There is no hydraulic resistance in the hydraulic needle body, since the flow moves laminarly. If you make a device with your own hands, then all these nuances need to be taken into account.

Due to this buffer zone, it is possible to separate the consumer circuits and the boiler. This is what a hydraulic arrow is needed for; you can do the calculations and manufacture it yourself, provided you have experience and tools. In each of the heating system circuits, the pumps operate autonomously, the balance is not disturbed. Operating modes of various schemes and design options for hydraulic arrows for heating a private house:

- The neutral operating mode of hydraulic separators is characterized by the fact that the flow rate, pressure, return and supply heat energy, and temperature fully correspond to the parameters for which the system is designed. Pumping equipment has very high power, and due to the laminar movement of flows, deaeration and sedimentation of solid particles from the collector, hydraulic valve, and pipes are ensured.

- If the boiler has low power, the operating principle of the hydraulic arrow will be slightly different. Since there is a lack of flow, cold water is added. Due to the fact that there is a very large temperature difference in the return and supply circuits, the sensors are triggered. With the help of automation, the boiler reaches the highest power, it burns in maximum mode, but despite this, the required amount of heat will not reach the consumer. Heat stroke may occur because the heating system is unbalanced.

- If the flow in the primary circuit is greater in volume than the total flow rate, the following occurs. The boiler operates in the most gentle mode. During ignition or when turning off the blowers in the secondary circuits, water circulates through the hydraulic arrow and the small circuit. In the return circuit, the temperature is equalized due to the addition of hot liquid. At the same time, a sufficient amount of coolant is supplied to the consumer.

The pump in the primary circuit must have a performance 10% higher than the total performance of devices in the secondary circuit. This is one thing, but a mandatory condition.

Schematic solution for shifting pipes

The classic version of a hydraulic separator involves the creation of pipes symmetrically located relative to one another. However, a circuit version of a slightly different configuration is also practiced, where the pipes are located asymmetrically. What does this give?

Manufacturing diagram of a hydraulic separator in which the secondary circuit pipes are slightly offset relative to the primary circuit pipes. According to the inventors (and proven by practice), this option seems to be more productive in filtering particles and separating air

As the practical application of asymmetrical circuits shows, in this case more efficient air separation occurs, and better filtration (sediment) of suspended particles present in the coolant is achieved.