began the history of Russian extruded polystyrene foam by launching in 1998 a production line for PENOPLEX boards at a plant in Kirishi, Leningrad Region.

Penoplex production method: Polystyrene granules enter an extruder, where they are heated and mixed under high pressure. At the same time, a gaseous blowing agent is supplied to the extruder. Thanks to high pressure and heat, the blowing agent enters the granules and increases their volume. The resulting mass is pressed through a die, the material is cooled and cut into slabs. As a result, small closed cells are formed in XPS, which give penoplex excellent thermal insulation properties and negligible water absorption.

Penoplex brands

- Penoplex COMFORT

- Penoplex BASE

- Penoplex FOUNDATION

- Penoplex GEO

- Penoplex ROOFING

- Penoplex FACADE

- Penoplex 45

Penoplex COMFORT

Overall dimensions: Length-1185 mm, width-585 mm, thickness 20; thirty; 40; 50; 100 mm.

TU 5767-006-54349294-2014

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex COMFORT

It is used for thermal insulation of canopies, plinths, and pitched roofs. Strictly not applicable:

- in loaded structures.

Areas of application of Penoplex COMFORT:

- Roofs, walls, balconies, loggias.

- Thermal insulation of utilities.

- Insulation of livestock farms, cowsheds.

- For insulation of greenhouses.

Advantages of Penoplex COMFORT:

- Thermal conductivity coefficient is 0.032, hence high thermal insulation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

- Resistant to temperature changes.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Easy installation, convenient dimensions.

- Poor steam conductivity.

- Selected quarter (L-shaped edge). Allows you to join slabs like a construction set.

Penoplex COMFORT technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.15 (1.5; 15) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | from 20 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.25 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 100 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Features of using insulation

A material based on polyethylene foam with a reflective layer can become independent thermal insulation for a balcony or loggia, as well as an attic intended for living in the summer and off-season.

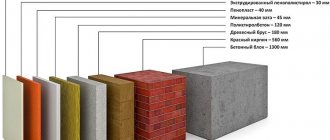

It must be remembered that foamed polyethylene alone is not enough to ensure complete insulation, so it is often combined with mineral wool as a vapor barrier and protection from external moisture and weathering. When used in combination with extruded polystyrene foam, such materials make it possible to reduce the layer of basic insulation by approximately 1.2 - 1.5 times, which significantly reduces the cost of protecting the structure from heat loss.

Penoplex BASE

Overall dimensions: Length-1185 mm, width-585 mm, thickness 20; thirty; 40; 50; 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex BASIS

This brand of penoplex is intended for insulation in civil and industrial construction, in walls, roofs, anywhere where there are no special loads on the structure being insulated.

Advantages of Penoplex BASIS:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex OSNOVA technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.17 (1.7; 17) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | from 20 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.20 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20; 30, 40, 50, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Price

In construction stores, this insulation product is sold in packages. How many pieces does the package contain? Each individual package contains 4-20 pieces. The number of pieces in one package depends on the thickness of the heat insulator. The weight of one package is usually 15 kilograms.

According to information provided by online stores, the wholesale price per cubic meter (10 m3) is:

- Comfort – about 4000 rubles;

- roofing – 4300-4400 rubles;

- base of the building (foundation) – 4200-4300 rubles;

- penoplex - 5500 rubles.

So, we can assume that Penoplex is one of the materials that is used for insulation. The service life is almost 50 years. The structure obtained as a result of manufacturing helped to make a product with low mass and low thermal conductivity. You can carry out insulation using thin layers of the product. But be aware of the risk of fire and solve this problem in advance.

Penoplex FOUNDATION

Overall dimensions: Length-1185 mm, width-585 mm, thickness 50; 100 mm.

TU 5767-006-54349294-2014

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex FOUNDATION

Thermal insulation of deeply low (buried) places. Namely deep and shallow foundations, garden paths, septic tanks.

Swedish stove technology.

Engineering Communication.

Advantages of Penoplex FOUNDATION:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex FOUNDATION technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.3 (3.0; 30) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 27-35 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 50, 80 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Advantages and disadvantages

Penoplex

*

Thanks to the production technology described above, the insulation acquires a high level of density and a low water absorption rate. This is possible due to the porous structure. These parameters make it possible to carry out thermal insulation indoors and outdoors on any surface.

Let's look at the advantages of this thermal insulation material:

- There is no hygroscopicity. A synthetic product simply cannot absorb moisture. This allows penoplex to be stored in open warehouses. You can even insulate damp and damp surfaces that are regularly subject to waterlogging.

- The product has a high level of resistance to temperature changes and other climate factors.

- The insulation is not afraid of any microorganisms, mold, or mildew.

- As noted above, the material is completely environmentally friendly. Does not have any toxicity.

There are also some disadvantages:

- Although penoplex has a high level of resistance to chemical influences and can withstand bitumen mixtures, lime, and so on, exposure to acetone and other organic substances can make polystyrene foam an unusable material.

- The surface requires additional vapor barrier before using penoflex. It has vapor permeability.

The thermal conductivity of penoplex is 0.028 W/m×K.

Penoplex GEO

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 40, 50, 60, 80, 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex GEO

This brand of penoplex is used for thermal insulation of loaded floors, foundations, roofs, stylobates, as well as in places where high fire resistance is not required. All these are areas of civil and industrial construction.

Advantages of Penoplex GEO:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex GEO technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.3 (3.0; 30) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 28-36 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4-0.7 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Penoflex

This material is a derivative of polyethylene foam; its production method allows us to obtain the most reliable basis for thermal insulation . It belongs to a new generation of thermal insulators; it is considered a universal means for insulating various types of buildings.

The insulation has high strength due to sealed cells with air; some types have a reflective film, which provides penoflex with high thermal insulation properties.

Penoflex is a lightweight and durable material with high strength. It is very easy to install, convenient to use; in order to cut penoflex, you do not need to have special tools, this can be done with an ordinary knife. Today, among a variety of insulation materials, it has become the most popular in Russia. In finished form, penoflex can be in the form of foil products, perforated film and orange plates, standard sizes 2400x600mm and thickness 30 and 50mm .

Penoplex ROOFING

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 30, 40, 50, 60, 80, 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex ROOFING

Penoplex ROOF is used for insulation of load-bearing roof structures of any type. Including for thermal insulation of stylobates and parking lots.

Advantages of Penoplex ROOFING:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex ROOF technical specifications

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.25 (2.5; 25) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.4% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 26-34 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Types of thermal insulation

The basic characteristics of polyethylene foam-based materials may vary depending on their purpose. So, for additional thermal insulation, it is best to choose a material with a thickness of 10 mm. A larger layer of porous polyethylene becomes unstable due to the low strength in the polymer body due to the developed pore structure.

As a vapor barrier, protection from wind and external moisture, an option with a thickness of 2–4 mm is more suitable. To effectively dampen sounds, the polyethylene layer must be at least 6 - 8 mm.

Foil products

Applying a layer of foil on both sides allows you to improve the insulation characteristics and use Penoflex for external insulation of building walls. Reflection of external heat protects the structure in summer, preventing it from overheating. And in winter, the internal reflective surface becomes an effective barrier, helping to retain heat in the room.

Perforated film

To protect communications and create ventilation ducts, special perforated types of reflective insulation are used. Such materials have greater permeability and therefore effectively regulate air flow.

It must be remembered that when installing complete thermal insulation, such material may not be enough. Therefore, it is often combined with more traditional insulation, using it as waterproofing, as well as an additional barrier to heat, wind and sound.

Penoplex FACADE

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 20, 30, 40, 50, 60, 80, 100, 120, 150 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex FACADE

It is used as thermal insulation for insulation of internal and external surfaces, that is, facade systems, walls, wall partitions). Penoplex FACADE is designed with a milled surface, which facilitates the adhesion of plaster and glue to the surface and reduces the time required for plastering the building facade.

Advantages of Penoplex FACADE:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex FACADE technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.2 (2.0; 20) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G3 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 25-33 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.25 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Mounting technology

Insulation installation diagram

Installation of this thermal insulation product includes fastening using construction adhesive to a surface that must be flat and dry. Therefore, before starting the procedure, it is necessary to prepare the surface, that is, level it. After securing the installation of insulating boards, protection must be carried out. Decorative cladding products are used as a protective layer. To strengthen the adhesive fastening, you need to use umbrella dowel nails. Typically, this technology for installing insulation boards is used for walls or ceiling surfaces.

If you must insulate the floor, there are other recommendations. First you need to build up the subfloor. This can be done using DSP and GVL boards. A waterproofing layer is laid on the subfloor. Then the joints of the rolled insulation are overlapped using construction tape. This is done so that the concrete solution cannot seep into the wall product. There should be thermal insulation gaps between the walls and the subfloor; upon completion of installation, they are foamed with polyurethane foam.

Important! Winter grades of polyurethane foam contain substances that contain toluene. This substance is destructive to polystyrene foam.

During the procedure for thermal insulation of the wall surface, it is necessary to fill the gaps that are located between the penoflex and the walls of the structure using construction foam. The top is protected using a heat-reflecting foil film. It is the film that will be firmly held on the polyurethane glue. The joints of the film must be glued using metallized tape. Thanks to this, you will be able to achieve the performance of a thermos.

Penoplex 45

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 40, 50, 60, 80, 100 mm.

TU 5767-006-56925804-2007 amended. No. 1-6

Orange color.

Surface: smooth.

Plates 45 are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex 45

Wherever there are special requirements for the heaviest loads. This, for example, is the construction of airfield runways and roads.

Advantages of Penoplex 45:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex 45 technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.5 (5.0; 50) MPa |

| Compressive strength at 2% linear deformation, not less | GOST R EN 1606 | 0.19 (1.9; 19) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.2% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G3 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 38-47 kg/m3 | |

| Elastic modulus | 20 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.35-0.7 MPa | |

| Standard sizes | Width | 600 mm |

| Length | 1200/2400 mm | |

| Thickness | 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Why is it necessary to do a vapor barrier when insulating with polystyrene foam?

Since the air humidity inside the building is higher than outside, steam moves from an area where there is more of it (high pressure) to an area where there is less of it (low pressure). When it passes through a wall or insulation, along its path it can hit the dew point (the point at which the temperature of the wall corresponds to the value at which steam begins to condense, approximately 13-17 ° C).

When condensation occurs a short distance from the outer surface, this is normal. But when the dew point moves inside the structure, the wall freezes, and moisture gradually permeates the structure until it reaches the inner surface. This way the wall gets wet.

To avoid this, you must:

- move the dew point outward of the wall. This can be achieved by insulating the walls from the outside, in which case a vapor barrier will not be needed; to prevent moisture from penetrating inside the structure when the dew point is closer to the inner surface, a vapor barrier is installed.

The difference between foamed polystyrenes

As mentioned above, the use of liquid and powder gas-forming agents is better, so products obtained using this technology have stable thermal insulation characteristics. Although, this cannot be called the only reason why Technoplex and Penoplex do not contain freon. There are two more:

- Sealed cells of new material that have not yet been used have remnants of freon. Formally, it is called safe, but in reality it is better not to deal with it. It can cause lung problems in children.

- Over time, the gas will be forced out of the cells by air and humidity. And if dirty raw materials containing styrene were used in the manufacture of the material, then the contents will penetrate into the external environment.

And if technical grades of EPS, such as Penofol, are used to treat foundations, highways, and plinths, then the presence of freon in the composition does not affect the material in any way. But to insulate your home, it is better to use safe products. Therefore, the answer to the question: Penoplex or Penofol, which is better, can be answered - the first option.

How do you know which is better Penoplex or expanded polystyrene? After all, many recommend insulating with foam plastic, because it has a low price and excellent characteristics. To answer this question, you need to know how penoplex differs from expanded polystyrene. Let's start with production technology.

Technoplex, Penoplex and even Penofol are created during the extrusion process. This allows you to obtain a very dense linear structure, which affects the material’s resistance to water and humidity, as well as strength. Therefore, foam plastic is somewhat worse than materials created by extrusion methods.