Among the variety of modern solid fuel boilers, pellet burners occupy a special place. Their main advantage is the ability to work in completely autonomous mode for a long time. Unlike wood and coal units, fuel is supplied to the combustion chamber automatically, and the set temperature is maintained using an electronic control unit.

DIY pellet burner

The performance and efficiency of a pellet boiler depends, first of all, on the efficiency of the burner device; it is this module that ensures uniform combustion of fuel and heating of the coolant to a given temperature. The article will analyze the design and operating principle of pellet modules and provide recommendations for the independent production of this unit.

Why do you need a burner?

Pellets are just beginning to conquer the domestic market, but those who have already managed to use this type of good quality fuel choose it. But the question arises: if this is, by and large, ordinary firewood that can be loaded into the firebox, then is it necessary to bother with additional mechanisms. The opinion has a right to exist, but if you do just that, then the combustion of the material will be 80, or even 40%. Everything else will be recycled. In this case, the efficiency is minimal. The burner allows you to increase the combustion of material up to 98%. It is not recommended to use pellets in pyrolysis boilers, as pellets can cause damage that will require boiler maintenance.

The temperature in the burner when burning pellets can reach thousands of degrees Celsius. That is why the question arises about whether it is possible to install a pellet burner in your solid fuel boiler. If you understand well the principle of operation of a pellet burner during assembly and follow clear instructions, then it can be a good addition to the main type of fuel.

Preparatory stage

Most often, the part is used as the main element of a screw conveyor. In addition, it is possible to use the part for drilling wells. The manufacture of screws should begin from the preparatory stage. Its features are as follows:

- On the Internet you can find drawings based on which the device is created.

- If necessary, you can calculate the main parameters using special formulas.

- First, a suitable material for making the screw is selected. In most cases, steel with increased strength that undergoes heat treatment is suitable for this.

- To work, you will need a welding machine and some tools. Metal is considered a difficult material to machine and requires special tools.

- You can significantly simplify the task by making a template using cardboard. In this way, you can eliminate the possibility of making a serious mistake.

The correct shape of the finished product depends on the correctness of the preparatory stage. That is why it is necessary to create a blank from cardboard, after which it is applied to the main part and the main parameters are checked. The screw can be made from a variety of materials; if you choose durable steel, you can count on a long service life.

Using pellets

In areas where there is no centralized gas supply, pellets are the most effective and relatively inexpensive fuel. When 1 kg of pellets is burned, thermal energy is released, which is equal to what will be produced after burning half a liter of diesel fuel. The total output power is 5 kW/h. To heat a one-story house in an area where winters are not too severe, it will take approximately 50 kg of pellets per day. The advantage is that they can be filled once every few days, depending on the boiler model. Pellets are placed in a special hopper, from which they are automatically fed into the burner. You will have to service your homemade pellet burner twice a week.

One of the disadvantages of using pellets and pellet burners is the possibility of backdraft. In this case, fire may break out into the bunker. The consequences of such a process will not be the most pleasant, because it will be a good fire. The second nuance that requires special attention in relation to a pellet burner is the amount and intensity of air supply. Pellets are quite light, so an excessive flow can simply blow them off the device, and they will remain unburnt. With less air supply, the pellets also do not burn completely, which leads to the need to clean the burner. For the entire pellet combustion process to be correct, it must have a certain sequence.

To ignite, you must use a special lighter, which is a ceramic rod. It does not affect the pellets with direct fire, but heats up to a temperature of over a thousand degrees. This approach is necessary so that when igniting pellets, the flame does not go into the fuel bunker. The next step is to supply the required amount of air, which is necessary to ensure that the combustion flame is even and stable. Next comes the exit to operating mode. This occurs due to the larger amount of air supplied to the pellet burner. The important factor here is fire without smoke. The stop occurs due to the complete cessation of air supply to the pellet burner.

Pellets: what is it? Detailed fuel characteristics

This raw material is characterized by high energy intensity. It is thanks to this that it has become widespread. When processed, one kilogram of granulated pellets releases approximately 5 kW/h of heat. It follows from this that to organize the heating of a standard private house with average dimensions, you will need about 2 kg of material per hour.

Pellets for the burner are loaded into the device approximately 1-2 times a day. When loading a new portion of raw materials, it is recommended to clean the ash pan from combustion products. Store-bought burners require weekly cleaning, and homemade devices get dirty even faster. It is recommended to clean a home-made device approximately once every 3 days. Otherwise, it will fail quite quickly.

Some burner models do not require loading for 5 days. An example is the APG-42 pellet burner. This model is compatible with Teplodar-Cooper boilers.

The disadvantage of pellet burners is reverse combustion, which is accompanied by the penetration of the pyrolysis zone into the bunker intended for storing and supplying fuel. This entails smoke in the room in which the heating equipment is located, and there is also the possibility of a fire.

Pellets are small granules that are made from wood and used as fuel.

Pellets made from sawdust or any other processed waste can be blown away if there is excess air in the structure, which will lead to the generation of a large amount of waste (ash). The air supply must be clearly regulated, otherwise not only its excess, but also its deficiency can lead to ineffective operation and rapid clogging of the device.

The need for granular fuel in air is determined primarily by the combustion mode

Selecting the right regimen is a primary and very important task. The burner enters the operating mode in 5 stages

Before starting to operate the device, you must become familiar with each phase in more detail.

The first step is to ignite. The burner for a pellet boiler is ignited using a special ceramic lighter rod, which, when turned on, heats up to a very high temperature (900-1100 °C). Devices made by yourself can be ignited with an ordinary torch.

When burning, 1 kg of pellets releases approximately 5 kW/h of heat

The second stage of preparing equipment for operation is launching

It is very important to adjust the correct air supply to adjust the burner flame. Next, the device is overclocked

At this stage the burner enters normal operating mode.

After acceleration, it is necessary to adjust the air so that the correct temperature of the coolant in the return is set inside the device. Then you need to stop the supply of granular fuel and set the required air intensity.

Types of burners

Pellet burners have several types. Reviewing them will allow you to decide which one is best suited for certain conditions. In most cases, a pellet burner requires electricity to operate, which powers the pellet feed mechanisms. Is there anything that can be done if it often disappears?

With forced fence

Such pellet burners are considered one of the best in terms of fire safety; they are used, for example, in Teplodar boilers. But for a burner with such a mechanism you will have to pay a considerable amount, which easily reaches 3 thousand US dollars. Burners with forced intake have several mechanisms through which pellets are supplied. One of them involves the use of a pneumatic system, and the second - an auger. Safety is ensured due to the fact that the channel through which the pellets move goes from bottom to top. Fire is known to move in the opposite direction, so it is unlikely that it will enter the bunker. The pneumatic system for the pellet burner has maximum safety. This is true, because the pellets are supplied in portions and do not remain in the pipe through which they move. For burners with a pneumatic feed system, large hoppers can be installed, which are loaded no more than once a month.

Screw feed mechanisms for pellet burners, for example, Teplodar, consist of two main units. One of them is an auger, which takes pellets from the bunker. He pours the material into another receiver, from which another auger lifts the pellets directly into the burner. In this case, the fire from the burner still reaches the mass. This is due to the fact that the pellets are located along the entire length of the auger. To further secure the mechanism, engineers make a unit that fits the burner from a material that melts and self-extinguishes. It acts as a fuse to cut off the path of fire.

One of the disadvantages of forced-feed pellet mechanisms, such as Telpodar, is their dependence on the availability of electrical energy. If it disappears, the supply of pellets will stop and the heating system may fail. Two electric motors have to be powered. If there are no problems with power fluctuations in your area, then you can purchase additional air boost. It allows you to increase the efficiency of pellet combustion, and accordingly increase the efficiency of the entire system. Mechanisms with a retort are becoming more common. The Fire Chalice has shown to be problematic when it crashes. In this case, the bowl itself became clogged and frequent cleaning was required. In retort burners, the combustion of pellets and pyrolysis gas occurs in the burner itself.

Gravitational

The gravity feeding device of the pellet mechanism is much easier to use. Also, such a device can function without electricity. The bottom line is that the pellets fall under their own weight. Domestic manufacturers of such burners are Pelletron and Begemot. You can start the product from Pelletron and Behemoth by simply adjusting the supply damper and the draft regulator on the chimney. But the disadvantages of the burners from Behemoth and Pelletron are the high probability of ignition of the pellets that are in the bunker. This is due to the fact that the hopper itself is fixed to the hole through which pellets are supplied to the burner. The efficiency of such pellet products is less than that of those with forced feeding.

To solve the fire hazard issue, manufacturers try to install special thermal dampers on such pellet appliances. If a flame escapes from the hearth and moves towards the bunker with pellets, then the heating triggers a special gateway, which simply blocks the movement corridor. Another interesting method of protection is the double grate. It is a simple mechanism. Its upper part approaches the hopper and takes the required number of pellets. After this, it moves to the combustion zone with pellets. The second part at this moment dumps the ash into the receiver, from where it can be cleaned.

DIY assembly

When making a pellet burner with your own hands, it is important to pay special attention to the basket. Often, due to improper implementation, pellets can get stuck. In this case, the combustion process does not follow the required algorithm and the fire returns to the bunker. To eliminate this drawback, you need to look at the upper right part of the figure below. The slot through which the pellets will be supplied does not need to be made solid. It should have holes that are 2 mm smaller than the pellets themselves. It is also worth paying attention to the gap between the bottom of the basket and the back wall. It should be at least 6 mm, but 2 mm smaller than the size of the pellets. The unit where the pellet combustion chamber is separated from the pyrolysis gas combustion chamber must be made with continuous slits. If the burner is designed for a boiler with an area of 150 m2, then the height of the secondary air channels that pass under the bottom of the basket should be 30 mm.

In addition to the basket, a scrupulous approach also requires a bunker in which the pellets will be stored. The problems begin with those pellet bins that are made by eye and according to a loose drawing. On the left in the diagram above are the dimensions and drawings of the hoppers that are used in Pelletrons. With a home area of 150 m2, one such bunker is enough for a day. At the bottom right in the same figure is a drawing and dimensions of the combustion chamber. The basis for them was the Pelletron 15 pellet burner. The corridor through which the secondary air will move is best done in the shape of the letter “L”. This is necessary for better mixing of secondary air with pyrolysis gases. This will increase the efficiency of the installation. The combustion chamber will require a special type of steel that can withstand high temperatures. At the same time, welding it at home can only be done with spot welding, since a conventional welding machine will have difficulty warming it up. You will need sheets with a minimum thickness of 2 mm. An interesting design of a pellet burner is shown in the video below.

Design and principle of operation of a pellet burner

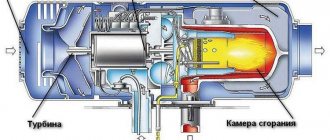

Most pellet burners include the following modules:

- Screw conveyor, through which granular fuel is supplied to the combustion chamber;

- Drive motor;

- An electronic controller that monitors fuel combustion parameters and ensures timely adjustments to the operation of the device;

- A special sensor that controls the amount of oxygen in the exhaust gases;

- Corrugated hose to prevent pellets from burning in the hopper when backdraft occurs;

- Combustion chambers with built-in grate;

- A blower fan that supplies the air necessary for efficient combustion of pellets. The amount of air supplied to the combustion chamber depends on the fan rotation speed and is regulated automatically depending on the selected temperature mode;

- An electric heating element that provides automatic ignition of pellets in the combustion chamber.

Operating principle of a pellet burner

From the external hopper, the pellets fall into the loading window of the screw conveyor, which delivers the pellets to the combustion chamber of the burner. The intensity of combustion depends on the amount of fuel entering the combustion chamber, which is directly related to the rotational speed of the drive motor shaft. The engine speed required to ensure the specified temperature regime is regulated by an electronic controller.

An equally important factor for ensuring the stability of the combustion process and complete combustion of fuel is the presence of a sufficient amount of oxygen in the combustion chamber. In pellet modules, air is supplied to the combustion chamber using a special fan, also controlled by an electronic controller.

The coolant temperature adjustment scheme looks like this:

- From the bunker, using a screw conveyor, pellets enter the combustion chamber. At the same time, the fan turns on to provide air supply.

- Based on a signal from the controller, the granules are ignited using an electric heating element;

- As soon as the coolant temperature reaches the set value, the temperature sensor transmits a corresponding signal to the electronic control unit, which switches the device to standby mode;

- If the coolant temperature drops below the programmed value, the temperature sensor again sends a signal to the electronic controller. The automatic control unit turns on the fan, thereby providing additional oxygen flow into the combustion chamber. Excess oxygen leads to an increase in the intensity of the combustion process and the coolant is again heated to the set temperature.

- If the pellets fade in standby mode, the automatic control system sends a corresponding signal to the electric heating element, which ensures automatic ignition.

Despite the fact that the operating principle of a pellet burner is not particularly complicated, the cost of this unit is quite high. To reduce material costs associated with converting a boiler to pellet fuel, some owners of solid fuel heating units make a pellet burner with their own hands. Like any other production, the manufacture of this device begins with the creation of a set of technical documentation, in other words, drawings.

Automation tools

Automation requires a special control unit - the automation of a solid fuel boiler does not have the appropriate capabilities. The auger and blower motors, as well as temperature sensors, are connected to the controller. Receiving a signal from the sensors, the controller will control the operation of the engines, regulating the fuel supply and traction.

The homemade product can also be equipped with a device for automatic ignition and flame control with a photosensor, which are also controlled by the controller. The filling sensor in the fuel pipe will allow you to control the supply of bulk energy.

The use of automation equipment significantly increases the cost of the unit, but makes it as convenient to use as possible.

Automation of boiler operation using a pellet burner

How to draw a drawing of a pellet burner

Before starting to develop drawings, it is necessary to carefully study existing designs. This will allow you to choose the right material and avoid design errors.

The presence of drawings greatly simplifies the manufacturing process of the unit. A set of drawings for a pellet burner must include details of the main components and an assembly drawing of the unit, which must indicate:

- The combustion chamber;

- Container for loading pellets;

- Screw conveyor;

- Blower fan.

When used individually, structural elements can be displayed schematically, without elaboration of specific details, however, overall and connecting dimensions must be indicated with maximum accuracy. Drawings of individual parts must contain comprehensive information about the configuration and material used.

Depending on the type chosen, the unit drawings may have a number of significant differences.

Calculation of the feather of a screw conveyor or auger

The most important parameter is the size and geometric parameters of the auger feather. Special programs are used to determine properties. An example is KOMPAS-3D. This program also includes a package that allows you to automatically perform calculations when you enter the following information:

- Product diameter.

- The diameter of the shaft acting as the base.

- The pitch of the turns.

- Thickness of the material used.

- The angle of the feather in relation to the base.

As a result of automatic calculations, you can obtain a detailed drawing on which the main parameters are indicated. In addition, the usual formulas can be used to determine the main parameters.

Gravity pellet burner: manufacturing

Making this module yourself will save you from $300 to $2500. In addition, the use of a gravity pellet burner allows you to completely avoid connecting the boiler to the electrical network. In this case, granular fuel enters the combustion chamber directly from the bunker, and the air supply is ensured by natural draft. The intensity of fuel combustion is adjusted by changing the position of the chimney damper.

The disadvantages of such systems include:

- Possibility of ignition of pellets in the bunker when reverse draft occurs;

- Reduced installation efficiency to 85-90%;

- The need to manually adjust the supply of granules and the position of the gate valve.

Materials for making a gravity burner yourself can include:

- A heat-resistant steel pipe with a wall thickness of at least 4 mm is used to make the combustion chamber;

- Sheet structural steel with a thickness of 3 - 4 mm is used to manufacture the mounting flange;

- The main bunker can be welded from sheet steel with a thickness of 2-3 mm.

Torch pellet burner: manufacturing

Unlike a gravity burner, a flare burner is equipped with a screw conveyor, a fan and an electronic controller, which significantly increases the material costs of manufacturing the unit. Despite this, this design has become widespread due to the following advantages:

- High performance;

- Unpretentiousness to the quality of the granules used;

- Possibility of working in autonomous mode, while the duration of operation is determined solely by the capacity of the fuel bunker;

- High degree of fire safety.

To make a fecal pellet burner with your own hands, you will need to purchase:

- Low-speed electric motor (or two, depending on the design of the feed mechanism);

- A fan that will provide forced air supply to the combustion chamber;

- An electronic controller that monitors changes in coolant temperature and sends corresponding signals to the actuators of the device.

As for the manufacturing process itself, it is much more complicated than the manufacturing process of a gravity burner, since it becomes necessary to install temperature sensors and connect an electronic control system. The materials for manufacturing the unit do not differ from the previous version.

Brief overview of imported products

A foreign alternative to domestic products is the Kiturami pellet burner, the list of its characteristics is as follows:

- power range – from 8 to 33 kW;

- Product efficiency is up to 95%, the overall efficiency value depends on the design of the boiler;

- remote controller;

- sensors for temperature, water level, overheating, overflow of auger with granules;

- self-cleaning grate.

The disadvantages of this device are its high cost and dependence on the reliability of the power supply. Otherwise, the product is quite reliable and does not cause any complaints; it is equipped with DRAGON KRP solid fuel installations.

Ferroli pellet burner

The Ferroli Sun P7 and Sun P12 pellet burner, which is installed on solid fuel units BUDERUS and SFL, is no less highly reliable. Maximum power is 34 and 55 kW, respectively, the set of options is the same as that of the previous manufacturer. The fan is a centrifugal type that provides a sufficient amount of air.

The imported Pelltech pellet burner has a wide range of available capacities, from 20 kW (Pelltech PV-20) to 1 MW (Pelltech PV-1000). It works well in conjunction with VIESSMANN boilers; the latter’s delivery package includes, as an option, a gas cleaning unit with a smoke exhauster; it is needed for installations with a power of over 200 kW.

Retort pellet burner: manufacturing

The supply of granular fuel in such devices, as well as in flare devices, is carried out using a screw conveyor. The difference is that the granules are fed from below. The air required for combustion is forced through special holes in the walls of the retort. For the effective operation of such a device, a controller is required that promptly responds to changes in coolant temperature and makes the necessary adjustments to the operation of the auger and fan.

Unlike flare devices, the flame in a retort pellet burner is directed upward, so the design of the heat exchanger for these units is very different. The disadvantages of retort systems include:

- Possibility of frequent clogging of the air duct openings, leading to attenuation of the device;

- The need to manually clean the retort from combustion products and granulated fuel residues;

- No gaps in the supply of granules. If reverse draft occurs, the possibility of ignition of the pellets in the bunker remains.

Heat-resistant steel and cast iron can be used as the material for the bowl. In some models, the retort can be made of ceramic concrete or fireclay.

The complexity of manufacturing such a device at home is quite high, since in addition to plumbing and welding work, skills in connecting electronic control systems will be required.

Automation methods

The ratio of fuel and air supply to the combustion chamber must be adjusted, otherwise the operation of the heating equipment will be unstable or constantly occur at high power.

The easiest way to change the speed of the fan and screw motor is to install a simple regulator. But in this case, there will be an added need for regular supervision and adjustment of the equipment, taking into account the ambient temperature and coolant. Setting up a heating system with your own hands consists of selecting, in different operating modes, such a ratio of air and fuel supply, during which the flame will be stable and even. This can only be achieved by automating the operation of the boiler.

First you need to purchase an electronic control unit. If the boiler is already equipped with this device, then you need to carefully study the possibilities of its use. Typically, controllers from leading manufacturers have free control contacts where electric auger and fan motors can be connected. In this case, taking into account the sensor readings, the controller will begin to increase or decrease the fuel supply and regulate the fan speed.

In terms of ignition and flame control, the burner can also be automated. It is necessary to purchase a photosensor, as well as an electronic filament element. The latter turns on at the very beginning, igniting the pellets, and the photosensor, when a persistent flame appears, will notify the controller, which will turn off the incandescent element.

A filling sensor is installed on the pipe; its main task is to send a signal to the electronic control panel if the auger is filled with pellets in order to complete the fuel supply. All these automation methods make it possible to burn fuel efficiently and create comfort during heating boiler maintenance. But there are also certain disadvantages:

- The cost of manufacturing the burner increases significantly.

- The electronic unit of the heating boiler included in the kit is usually not suitable for simultaneous operation with devices for controlling and igniting the burner; in this case, it is necessary to purchase a new one.

- The burner cannot be connected to any controller.

Do-it-yourself automation for a pellet burner

The most difficult stage in the manufacture of a pellet burner is the manufacture and installation of electronic control modules. If we consider this issue from a theoretical point of view, if you have special knowledge, you can make a controller yourself, but in practice this is almost impossible. In addition, the cost of components will reduce cost savings to a minimum, and the result may be very questionable. Therefore, even if you make your own burners, controller, sensors and other automation, it is better to purchase them in a specialized store.

For efficient operation of the burner, the automation must provide:

- Dosage of pellet supply and control of the screw conveyor;

- Automatic ignition and extinguishing;

- Adjusting the air supply by changing the fan speed;

- Estimation of the amount of coolant in the heating circuit;

- Control of coolant temperature in the boiler water jacket;

- Assessment of draft parameters in the chimney.

Failure to comply with even one of these conditions can lead to failure of not only the heating boiler, but also the entire heating system.

Making a pellet burner is a labor-intensive and responsible process, however, if you have the necessary knowledge and equipment, it is quite possible to make such a device yourself. Particular attention should be paid to the selection of parameters and installation of electronic control systems; the efficiency of the boiler will depend on the correctness of their operation.

The unique smell of natural wood, a clean and decorated room in a modern style - this is exactly what a boiler room in a house can look like if you choose the right equipment. Innovative heat-generating equipment that will create the described conditions indoors is a pellet boiler or an automatic pellet burner, running on special fuel pellets, which are created from waste from agro-industrial or woodworking production.

If just a few years ago pellet installations were used in only 20% of homes in Europe, now the figure has increased to 70%. The use of pellet boilers and burners is the most beneficial option for heating a living space from an environmental and economic point of view. Today we will talk about the operating principles of the equipment, its advantages and disadvantages, and also consider a diagram for making a pellet burner with your own hands.

Positive Features

The described equipment has an automatic ignition system and is also fireproof. The consumer will have the opportunity to reduce costs due to the insignificant cost of pellets. Among other things, you will not need to spend additional money on maintenance. You can count on a high efficiency, and the service life of such equipment is 20 years, which will depend on the correct manufacturing and operational features. The device does not depend on central heating sources and tariffs for such services.

About the pellet burner

A pellet burner is a special heating device that produces heat by burning pellets or fuel granules in a boiler. In some cases, these burners use unnecessary dry grain.

There are manual and automatic burners; in automatic burners, fuel is supplied to the combustion hopper using a special auger, and the entire process is controlled by sensors, due to which the device requires minimal control from the user. Pellet burners have found their use not only in everyday life, but also in industry. They are used for space heating, water heating and to meet a number of other needs.

Pellets, or fuel granules, are a special solid fuel that is obtained from wood or agricultural waste by pressing and granulating under high temperatures.

Pellets are an environmentally friendly type of fuel, since when they are burned, the same amount of carbon dioxide is released into the atmosphere as is formed during the natural decomposition of wood

In countries where agriculture and the woodworking industry occupy leading positions, the cost of pellet fuel is much lower than that of coal. The only exceptions are those regions in close proximity to which coal mining enterprises are located.

When burning pellets, hazardous fumes are not released, as happens when burning liquid fuel.

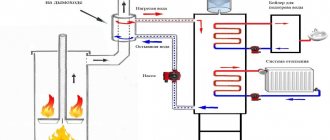

Installation

Pellet boilers must be installed in compliance with certain requirements for the installation site.

Choosing a place

It is better to install the unit in a separate room due to its impressive dimensions. The best option is a room with a temperature of at least +10 °C.

Installation outside the building is not recommended. However, when placing equipment outdoors or in a garage, pipes should be located underground below the freezing level to reduce heat loss.

Preparing the floor and walls

It is necessary to level the floor in the place where the equipment will be installed. The platform must be strong enough to support the weight of the device itself and the pellet hopper. Non-flammable plates should be fixed to the walls and floor. There must be a place for pellets near the device.

Ventilation and chimney

We install ventilation and a chimney made of non-combustible material. The latter, as a rule, is displayed on the roof, protruding above its surface by at least half a meter. It should be protected from precipitation and insulated.

The cross-section of the chimney pipes must be larger than the diameter of the hole intended for removing exhaust gases from the equipment.

Installing equipment

Having prepared the site, we install the device itself. We install and connect the burner, hopper, auger and automatic control panel. Communications are connected to the equipment through ball valves.

This will make the system easier to maintain. It is advisable to install filters. After connecting all the elements, a test run of the heating system is performed.

Principle of operation

All pellet installations that can be purchased in the store are equipped with additional components:

- Auger – supplies fuel from the bunker to the combustion chamber;

- Controllers for automating the work process;

- Bunker – the place where the fuel is located before being supplied to the combustion chamber;

- A lambda probe is a special sensor that monitors the oxygen content in smoke chambers and independently controls the fuel combustion process depending on conditions.

The pellet burner must be protected with a plastic corrugated pipe. It acts as a fuse when reverse draft occurs. If the fire begins to move towards the bunker, the pipe burns out, preventing the flame from spreading.

Additionally, a fan is used, which enhances the combustion of pellets by pumping air, as well as a thermoelectric heater, which allows the fuel to be ignited without human intervention.

In automated devices, pellets are fed into the combustion chamber automatically; a person is only required to monitor the amount of fuel in the bunker. The need to supply fuel to the combustion chamber is determined using temperature sensors (they can monitor the air temperature in the room, the water temperature, or any other environmental indicators depending on the operating mode of the equipment).

The required temperature of the coolant is set by the user, all further increases and decreases are controlled using automated equipment. As soon as the temperature reaches the set level, the burner begins to operate in standby mode (the pellets do not go out, they begin to smolder). If the temperature, on the contrary, drops, the controller activates the built-in fan. Under the influence of air, the pellets flare up and the burner goes into operating mode. If during downtime the pellets go out for any reason, the heating element is activated, which re-ignites.

Background

I live in an urban-type settlement, we are relatively recently settling into a new place of residence. And now, as it were, winter begins, and we heat the house with wood in the old fashioned way. It was not my desire that prompted me to make a homemade product, since I was already doing well, but my father. He decided to make a pellet torch burner. Everything would be fine, but when the body has already been welded, the pellets have been purchased, the question remains of how to start it all. A radical decision was made: the feed auger moves thanks to a wiper motor from a VAZ, of which we have a lot, because we are engaged in car repair/disassembly, in which case it can be replaced with the same one without losing performance. But the inflation was carried out by a centrifugal fan of the stove from some Nissan, the breakdown of which is definitely not worth worrying about. We assembled it, launched it, but how to manage it?

basic diagram for boiler combustion control

Here I have already joined, who seems to have a diploma as a “programmer”, but unfortunately, I gave up on studying, and naturally, I am an ordinary lover of all kinds of electronics and nothing more. I immediately and indiscriminately ordered a time relay for the auger and a PWM controller for the fan. I connected it, selected the work timings, but because of such a simple “automation”, sleepless nights began. What if it boils and the pipe bursts, what to do next? But the scheme was really dangerous, because... The efficiency of the boiler turned out to be very high for our burner, so the water temperature is either 60+, or the boiler goes out. Therefore, my father fixed the air supply system by welding, thereby lowering the minimum temperature threshold. But now, who knows, is there enough power for the required temperature, or vice versa, will it boil?

The temperature that this product produces

And then I remembered that I once played with the Arduino. Exactly from that moment I thought, why not build automation on its basis? Yes, I know that trusting such a dangerous gadget to the Arduino is a bad idea. But I have no choice, because the budget is a little tight in winter, and the factory automatics are not so wonderful (my father’s friend has exactly this, he played with it for a long time). As soon as I told my father about this idea, an ultimatum was immediately given: you programmer, let’s do it, otherwise you’ll sit by the boiler at night and tweak the boiler settings so as not to burn everything to hell.

Device

Any burner has one goal - creating a powerful flame to heat the air or water jacket of the boiler. At the same time, the combustion power itself can be adjusted independently.

A pellet burner has similar goals. The device is a wind tunnel into which solid fuel is supplied and air is pumped for combustion. Fuel is supplied to the pipe using a special screw-type conveyor. The fuel itself is located in the loading hopper before combustion. The bunker can have a different volume, and it depends on the volume how long the burner can burn on its own without human intervention (adding fuel).

Pellet burner structure: 1 - The pellet enters the burner under the influence of gravity; 2 - Air enters the burner due to the vacuum created by the draft of the chimney; 3 - Pellet combustion occurs in the combustion chamber, which is called the “basket”; 4 - Due to the high temperature, thermal decomposition of wood occurs in the basket, which forms a flow of flammable gases; 5 - A secondary air flow passes under the basket; 6 - In the burner nozzle, the flow of combustible gases and secondary air mixes, forming a torch; 7 - Solid combustion products are ejected from the burner into the ash pan of the boiler or furnace by a stream of secondary air; 8 - Ventilation of the supply channel does not allow hot gases to diffuse up the channel and destroy the pellets, ensuring a stable supply of pellets.

Air is forced into the combustion zone by means of a fan.

The combustion chamber in the burner can be round or rectangular. Round burners are the most common due to their ease of manufacture. A pipe connection is attached to the outside of the combustion chamber, through which fuel is supplied from the conveyor.

The design also includes an ash pit in which combustion waste accumulates. During the combustion of pellets, a little ash is formed, so you need to clean the ash pan no more than once a week when the burner is actively used.

There are several types of pellet burners, each of which has its own advantages and disadvantages.

Flare type

Initially, the device was used to generate heat by burning grain, but later it was converted to burn solid compressed fuel.

Side view of a flare type burner

- Small overall dimensions;

- Can be used in conjunction with boilers with a small combustion chamber;

- Simplified operation;

- Increased reliability;

- You can burn low quality pellets.

- Low power compared to other burners;

- The flame is directed horizontally, which is why it heats the boiler locally.

Volumetric type

Unlike the previous model, they have increased power and high efficiency. The disadvantages of the device include a complicated design, large overall dimensions, and dependence on the quality of the pellets used.

General view of the volumetric combustion burner

Fireplace

Burning pellets in a fireplace burner

Such designs are mainly used in domestic conditions, installed in fireplaces and boilers. The operating principle of the device is as follows: pellets fall into a special bowl, where they are burned under the influence of air supplied from below.

The disadvantages of the model include the size of the device and the need for precise adjustments for proper combustion.

Product structure

Let's look at what main parts a homemade pellet burner consists of. Its task is to ensure uniform combustion of fuel and stability of the flame, due to which the water jacket of the boiler unit is heated

Particular attention is paid to the possibility of adjusting the combustion intensity

The pellet burner consists of the following elements

:

- combustion chamber (in the form of a round or rectangular pipe);

- loading hopper for fuel;

- screw conveyor for supplying bulk fuel;

- fan for forcing air into the combustion chamber.

The volume of the loading hopper determines how often the boiler operating in automatic mode will have to be serviced. The operation of the blower fan is regulated by an electronic control unit - the intensity of the air supply affects the rate of fuel combustion.

Electricity is required to operate the electronic unit, fan and screw conveyor, so this burner device is energy dependent.

Principle of operation

The pellet stove is equipped with a burner that works according to the following principle

:

- The first portion of fuel entering the combustion chamber is ignited with minimal air supply.

- During the combustion of the first portion of fuel, the air supply increases, the flame intensifies and warms up the combustion chamber.

- The fuel supply begins in small portions, the air pressure stabilizes, and the flame becomes even.

- Operation of the burner in a stable mode allows for economical fuel consumption and efficient heating of the water jacket of the boiler unit.

Design Features

The combustion chamber, made of a round or square pipe, has a tray inside for burning fuel, and on top there is a pipe with a screw conveyor for dosed supply of sawdust, granules or other fine-grained energy carriers. The chamber is attached to a flange plate, which is adjacent from the outside to the front plane of the boiler unit.

The natural flow of air does not make it possible to burn fuel in a suitable mode, so a fan is installed, turning the combustion chamber into a wind tunnel.

Dry bulk fuel with optimal air supply burns with virtually no residue. The flow of forced air carries a small amount of ash into the ash pan - that is, the combustion chamber cleans itself during operation. It is necessary to remove ashes from the ash pit once every 7-10 days - the frequency depends on the intensity of the accumulation of unburned residues. If the fuel moisture content is high, the ash pan must be cleaned more often.

Organizing the supply of bulk fuel to a homemade pellet burner is carried out in two ways

:

- A large hopper is installed in the room, into which fuel is loaded for 7-10 days of continuous operation of the boiler (it is with this frequency that the burner ash pan needs to be cleaned). To supply fuel to the burner nozzle, it is necessary to install a screw conveyor, the length of which depends on the distance between the hopper and the boiler.

- The hopper is mounted directly on the pellet burner so that bulk fuel enters the burner auger under its own weight. A gravity pellet burner is simpler and cheaper to manufacture, but it will have to be serviced more often - usually a hopper is used, the volume of which is enough for 1-3 days of boiler operation.

Positive Features

A do-it-yourself sawdust burner is a device that helps expand the functionality of a conventional solid fuel boiler. Its installation allows you to save firewood and coal if inexpensive or free waste from wood processing or crop production is available. This approach will significantly reduce the overall heating costs of a private house, cottage or garage.

Pellet burners have a number of advantages, including

:

- economical fuel consumption;

- minimum amount of ash and harmful emissions into the atmosphere due to optimization of the combustion mode - fuel and combustible gases burn almost completely;

- little need for maintenance - fuel is added no more than once a day, the ash pan is cleaned no more than once a week, the operation of the unit is automated.

Pellet burner device

Advantages and disadvantages

The equipment has a number of advantages:

- Pellets are a safe fuel compared to gas and electricity;

- Allows you to significantly reduce space heating costs compared to using electric boilers. At the same time, pellet installations are more expensive than gas equipment, but do not forget that it is not always possible to supply gas and purchase gas cylinders;

- Homemade installations guarantee high efficiency - 95%. Some store installations are over 97%;

- They are used not only for heating the room, but also for producing hot water;

- There are no rules for transporting and storing fuel. When near a person, pellets do not cause allergic reactions, and there are no toxic fumes when burning;

- Fuel is available for purchase. Equipment owners complained about the lack of fuel and the need to prepare a supply of pellets from the winter when the devices appeared; now there is no need to store a large volume of pellets at home; if necessary, they can be bought everywhere;

- The price of pellets is on average at the same level, unlike gas and electricity, the tariffs for which periodically experience seasonal fluctuations;

- Installation of the device does not require special skills, and there is no need to coordinate the installation with authorized bodies;

- After combustion of pellets, natural mineral ash is formed, which does not require special rules for disposal.

Along with the advantages of such equipment, there are also a number of disadvantages:

- High cost of ready-made store equipment. Despite the popularization of devices in recent years and some reduction in prices, pellet boilers are still more expensive than gas or electric equipment of similar power;

- The equipment requires constant maintenance (especially outdated models). The user will have to clean the ash pan and heat exchanger from accumulated ash once a week. In modern models, cleaning is provided at an automatic level;

- In the absence of automatic fuel supply, the user has to load pellets into the bunker manually;

- It is necessary to ensure minimum humidity conditions in the rooms in which pellets will be stored awaiting use;

- Imported equipment is practically not designed for the conditions of the harsh domestic winter, as a result of which breakdowns and malfunctions often occur;

- In remote areas, fuel for the winter still has to be stored due to the instability of supplies.