What is the best way to insulate a floor under a screed? We understand the choice of optimal material

Since about 30% of all heat loss occurs through the floor, it needs insulation in the same way as other structural elements of the room - walls and ceiling.

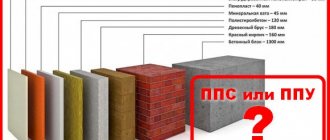

The main method of thermal insulation is insulating the floor under the screed. When insulating under a screed, it is very important to choose the right thermal insulator. Insulation materials such as expanded clay, polystyrene foam, mineral wool, penoplex and polyurethane foam are most often used as insulation for installing a heat-insulating layer under screed. You can also install a floor heating system, which can be infrared, electric or water.

Options for thermal insulation materials

The result of the work depends, first of all, on the quality of the materials. When assessing the positive qualities of thermal insulation and the thermal conductivity coefficient of different materials, one should not forget that natural and synthetic materials have different technical characteristics, on which the quality of work and the quality of the thermal insulation itself depend. Among the most popular materials today, it is worth highlighting insulation made from natural materials - mineral wool, expanded clay, glass wool. And artificial materials - polystyrene foam, extruded polystyrene foam, polyurethane foam. These insulation materials are quite widely represented on the market, however, in order to select the right material you need to know the basic characteristics of the material.

Expanded polystyrene

Expanded polystyrene or polystyrene foam consists of granules bonded together during the manufacturing process. Density is a qualitative indicator of a material. The higher the density of expanded polystyrene, the higher its thermal insulation qualities. Expanded polystyrene is produced in slabs with a thickness of 20 to 50 mm. The main application is thermal insulation of buildings and communications. The material is lightweight and does not absorb water. However, among the disadvantages it is worth noting that mice often settle in the thickness of the foam. It is flammable, so you need to be careful when installing. To insulate the floor on the ground, material with a high density is used, low density is used for installation on walls and ceilings. For the floor, slabs with locking joints at the ends are used.

How to choose floor insulation: a comparative review of 10 different options

The question “Which insulation is better for the floor?” are asked by everyone who loves comfort. It's always nice to walk barefoot without fear that your limbs will freeze. And this is especially true in the off-season, when central heating (if any) is not yet turned on, and in winter, when the temperature outside is sub-zero. It is then that people often turn their attention to floor insulation. We will tell you how to choose the material and how to lay it correctly. After all, a well-insulated floor is one of the components of heat preservation in a living space. When choosing insulation materials, it is important to take into account the climate zone (how cold it can be in winter), the characteristics of the room and its purpose, the type of existing or planned floor covering. For example, floor insulation in an apartment and in a wooden house will differ significantly.

Forced insulation of a finished wooden floor

A cold floor in a room does not leave a pleasant impression and sometimes you have to insulate it.

To do this you need:

- Remove the baseboards around the perimeter of the room.

- Carefully, without damaging, remove the finishing boards. Number them in order of location, remove the nails.

- Remove the subfloor.

- If necessary, add expanded clay just above the bottom level of the joists, carefully level it and tamp it down.

- Cut penoplex plates according to the distance between the joists and along the length of the room.

- Lay the first layer, seal the joints with tape.

- Lay the second layer in the same way, ensuring that the joints overlap. Tape the joints.

- Restore the subfloor.

- Lay the finishing coating, installing the boards according to the numbering in reverse order.

- Nail the baseboards.

In this case, we recommend using plates with a minimum thickness of 20 mm in two layers. This is enough to successfully resolve the issue.

Useful article? Add to your bookmarks!

How to choose the optimal insulation?

There is a wide variety of materials on the heat insulator market. The most popular are:

When asking the question which insulation is better for a floor screed, you need to consider:

High physical and technical characteristics lead to a higher cost, but saving on thermal insulation of floors is not advisable. Modern insulating materials are produced on high-quality equipment using the latest scientific achievements and are distinguished by truly unique properties.

Foam insulation

Insulation with foam plastic sheets is carried out by analogy with floor insulation with penoplex.

You can insulate the floor either with foam plastic slabs or apply a screed with the addition of insulation granules.

When insulating with polystyrene foam granules, they are mixed in a 1:1 ratio with cement and the resulting mixture is poured onto the floor. It should be taken into account that the thermal insulation properties of such a coating leave much to be desired, and the strength characteristics of the floor also decrease.

Insulation with foam plastic sheets is carried out by analogy with floor insulation with penoplex. Sheets of material can be fastened either with adhesives or with dowels.

Organization of floor heating by installing a “warm floor” system

When installing a heated floor system, it is necessary to install a waterproofing layer, then lay insulation (penoplex, polyurethane foam, polystyrene foam, mineral wool mats), cover the structure with aluminum foil, which will act as a heat shield that reflects thermal energy, install the “warm floor” system (lay pipes or electric mats), complete the finishing fill and lay the selected floor covering.

We recommend that you first watch the video below to clearly understand how this happens:

Insulation with mineral wool

Mineral wool has high sound insulation properties. Due to the high hygroscopicity of the insulation, the mineral wool thermal insulation layer must be completely isolated from contact with moisture.

Technology of floor insulation with mineral wool mats

Before installing mineral wool mats, it is necessary to remove the old floor covering

Before installing mineral wool mats, it is necessary to remove the old floor covering, clean the floor from existing contaminants, cover cracks and crevices, then lay a waterproofing film, mineral wool mats and a vapor barrier membrane. Clamps are installed on top of the structure in order to provide the necessary ventilation gap, and a reinforcing mesh of 3 mm wire is mounted on top of the clamps.

A leveling concrete screed is applied on top of the reinforcing mesh. If significant static and dynamic loads will not act on the floor, then the concrete screed can be lightened by adding expanded clay to it.

Thermal insulation technology

Let's look at two main methods of how to insulate floors in a private house under a screed.

Insulation on the ground

This method is used at the construction stage of a house if a basement is not provided. The order of work should be as follows:

Advice! The horizontal plane and uniformity of the layers of the insulation cake should be controlled from the very first stage - backfilling the base. This will avoid uneven heating of the floors in the future.

Insulation on a concrete base

This method is used in already built private houses and in city apartments. This method is less labor intensive and faster, but still requires a carefully thought out approach. Let's figure out the sequence in which floor insulation is carried out using this method:

Advice! There is a small nuance here: if the concrete base is uneven, then in order to save materials and time on leveling, it is better to use expanded clay while simultaneously leveling the floor. Expanded polystyrene boards are best used for insulating pre-leveled floors.

After the screed has completely dried (usually this takes from two weeks to one month), you can begin installing the finished floor covering. Any material is suitable for this: laminate, linoleum or ceramic tile.

If you have some skill and follow the given technology, it will not be difficult to insulate floors in a private house or city apartment. When doing such work with your own hands, you need to follow the sequence and technology of the installation process, and then the result will not disappoint you.

Expanded clay as floor insulation or mineral wool - the choice of specialists

Nowadays, the cost of heating housing and premises in general is constantly increasing.

At the same time, for some reason, salaries remain almost the same - not a good trend, but it has to be taken into account. In such conditions, almost every owner of a house or apartment begins to worry about the issue of saving energy. Today, walls, floors, ceilings, and slopes are being insulated en masse - such measures make it possible to distribute heat throughout the room as efficiently as possible due to the fact that the level of heat transfer of the building is reduced. This article will touch upon such a difficult issue as floor insulation - we will figure out what is better suited for this: mineral wool or expanded clay. In principle, foam plastic is also often used, but this is not the best option, because the possibility of ventilation and ventilation of the ceiling practically disappears. Although, undoubtedly, the thermal insulation characteristics of polystyrene foam are excellent.

So, mineral wool and expanded clay, which is better - you can start with a review of the first material and compare everything based on specific properties.

Expanded clay

Expanded clay is best suited as insulation for concrete floors. Porous granules of baked clay have the same thermal insulation properties as polystyrene foam and polystyrene foam. However, unlike them, expanded clay is an environmentally friendly material that has the following characteristics.

In addition, if you are planning to install a screed for a country house, then it is recommended to lay expanded clay on the ground as insulation.

This material can be laid as an “independent” heat-insulating layer or expanded clay concrete can be made from it. In the second case, insulation granules are added to the cement-sand mortar, so you get a light but durable screed composition. If you use dry expanded clay, then chipboard sheets are usually laid on top of it, rather than concrete flooring.

When choosing and laying expanded clay, pay attention to the following recommendations:

Dry screed with expanded clay

- If the subfloor is made of concrete, it must be insulated from moisture. To do this, lay a thick plastic film, preferably in one piece; but if its width is not enough, overlap the strips by 20 cm and glue the joints with tape. The film sides should rise along the perimeter of the walls. Their height should exceed the total thickness of the screed and floor covering.

- A damper tape is laid along the perimeter of the walls. It is used to compensate for the expansion of materials, preventing arbitrary opening of the floor and their deformation due to increased air temperature.

- In order to spread expanded clay in an even layer, beacons are used. It should be noted that beacons that are used under concrete mixture are not suitable, since they are not high enough. Usually take guides at least 3 cm high and attach them to the floor with mortar. Expanded clay is poured between the guides and the surface is leveled with a wooden rule. As a standard installation of a new expanded clay floor, the floor rises by 6-8 cm. This value includes the height of all materials, including the top slabs.

How to cover expanded clay?

The bulk material is covered with slabs of plywood, chipboard, OSB, gypsum fiber board. Of these, the most popular are gypsum fiber sheets (GVL). They are laid in 2 layers. The reverse side is first coated with special glue for gypsum plasterboard. A good option if the sheets have folds along the edge of the perimeter. They allow you to join them tightly, without gaps. The folds are also coated with glue.

Laying the slabs begins from the corner near the window and moves towards the door. At the same time, make sure that the seams of each next row are spaced apart from the adjacent ones. It resembles brickwork. Upon completion of work, any finishing coating is laid.

Installation features

Before you start insulating the floor with foam plastic under a screed with your own hands, you should familiarize yourself with some useful information that will help you do everything correctly (more details: “Insulating a floor with foam plastic under a screed - installation instructions”).

If you plan to make a screed from cement-sand mortar, then a waterproofing material must be laid on top of the insulation. This is done to protect the material from exposure to moisture from the solution. The waterproofing must be laid overlapping, the joints must be secured with tape.

If a “floating floor” is being made, then even before screeding, it is recommended to lay strips of wooden slabs, which should be equal in height to the thickness of the future screed.

A small gap of approximately 1-3 mm should be left between the screed and the wall. This will help avoid the formation of “sound bridges”.

Conclusion

After studying all the information about thermal insulation materials for screed, you can choose the most suitable one for yourself. You should also remember about consistency and compliance with the rules when performing floor insulation, otherwise you may get a completely different result than you would like.

The use of expanded clay for floor screed

In terms of thermal insulation qualities, the material is inferior to a number of modern insulation materials: expanded polystyrene, mineral wool and other foamed, porous and fibrous synthetic insulation materials. This becomes especially critical in rooms with low ceilings. For reliable thermal insulation, the expanded clay layer should be 10 cm or higher, while using polystyrene foam, 5 cm is sufficient (in specific situations it may be less).

In what cases is it advisable to use expanded clay:

For screeds with expanded clay, three methods and their combinations are used:

- Expanded clay concrete. When mixing concrete mortar, expanded clay is introduced in different proportions and different fractions depending on the purpose;

- Backfill. Expanded clay is not mixed with concrete, but simply piled on (a thermal insulation layer, leveling, like a filler). This layer can subsequently be either isolated from liquid concrete or concrete poured directly onto it;

- "Dry" screed. In fact, this is a layer of expanded clay covered with sheet flooring material (gypsum fiber, plywood, chipboard, fiberboard).

Expanded clay concrete

To obtain an insulating layer, a thickness of expanded clay concrete of at least 10–15 cm is required. No preliminary preparation of the base is required before pouring. The exception is large uneven ground (holes, dips), which are recommended to be filled and compacted first. Waterproofing is also done on the basis of general construction indications. Those. if there is a need to hydroprotect the structure from groundwater or high humidity.

The process of laying expanded clay concrete screed is identical to the process of laying conventional screed. The only differences are in the preparation of the mixture.

Advice! If the thickness of the screed is more than 6 cm, then for simplification it is poured in two layers. The first layer does not reach 4 - 5 cm to the floor level. The second layer is leveling.

Stages of expanded clay concrete screed:

- Floor level markings. Marking can be done using a building level or a water level (preferred).

Marking using a water level. First, a level is marked at any convenient height along the entire perimeter of the room. Then the required distance is measured from these marks.

Waterproofing with polyethylene film.

Installation of reinforcing mesh.

Installation of beacons on the solution.

Fixation of the damper tape is only necessary at the time of pouring; durability of the fastening is not required.

The method is used both as an independent screed and as one of the layers in multi-layer pouring. Under tiles, self-leveling floors on this screed are quite sufficient.

Backfill

Something between dry screed and expanded clay concrete. Also, depending on the purposes, different fractions and types are used. For thermal insulation, the expanded clay layer must be at least 10 cm, and the gravel fraction must be at least 20 mm. For leveling, smaller fractions, crushed stone and sand are preferable. It is not advisable to use the backfill method if there is a high risk of direct water ingress. Moisture insulation, if necessary, on the first and semi-basement floors is required.

In fact, this is a screed device for expanded clay:

- Floor level markings.

- Preparing the base (if necessary).

- Installation of beacons based on fill level.

- Backfilling and leveling the expanded clay layer. Sometimes, to improve the insulation properties, you can additionally lay a layer of waterproofing from the liquid solution - a regular polyethylene film. It is advisable to spill the top layer of expanded clay with a liquid solution so that it does not float up when pouring the screed and it is convenient to install beacons. The only plus is that expanded clay will not float when pouring a sand-cement screed if the solution is too liquid. The polyethylene film also prevents the granules from floating.

- Installation of fittings (if necessary).

- Pouring sand-cement screed along the top. It is recommended to dilute the solution thicker, possibly in smaller batches, or to prevent the granules from floating using the above methods.

The method is also used as an independent screed, and as part of multi-layer “pies”.

Do-it-yourself floor insulation on a balcony: what materials to choose?

If you decide to start arranging a balcony, and decide to do it yourself, you will certainly encounter such a problem as insulating the floor on the balcony. Like all repair and construction processes, insulation has several solutions:

How to insulate a balcony floor with expanded clay

Remember! Any balcony slab has a slope towards the street so that rain and melt water flows away from the slab by gravity. Therefore, before insulating the floor on the balcony in any way, the slab must be leveled with a concrete screed.

When to choose expanded clay

The range of heat-insulating materials on the modern market is so large that it can be difficult to settle on just one. However, it is worth learning the full range of properties of this unique material in order to understand that there is no better option than to insulate the floor with expanded clay.

A list of properties that make this simple material a leader among its competitors:

- Low thermal conductivity - the porous material contains air bubbles, which provide high-quality thermal insulation. A 10 cm layer of expanded clay exceeds the thermal conductivity parameters of a similar wooden surface by 3 times, and brickwork by 10 times.

- Sound insulation is a property that is in demand in apartments of multi-storey buildings; the expanded clay floor will serve as a reliable barrier to the penetration of noise from neighbors below, while simultaneously preventing the spread of sounds in the opposite direction.

- The strength of the material allows it to be used in the bottom layer of the floor pie without additional supporting structures (expanded clay is available in different grades of strength from 250 to 600).

- Resistance to rot and fungi, mold (unlike wood-based materials) increases the service life of the floor and its durability.

- Chemical inertness - expanded clay is a natural material, does not release any substances into the environment, and is also resistant to chemicals.

- Heat resistance - quality is important in terms of fire safety.

- Frost resistance - expanded clay does not lose its properties at extremely low temperatures.

- Light weight - allows you to insulate the floor with expanded clay under a screed in houses where a large load on the floors is undesirable (read: “Insulating the floor under a screed - practical tips”).

- The granular fraction of the material makes it easy to work with - one person who does not have construction skills can handle the backfill.

- Low cost is an additional bonus for a material that has a range of excellent qualities.

The only disadvantage of expanded clay is its ability to retain moisture for a long time. This drawback can be easily mitigated by following the technology of installing a floor with expanded clay and carefully gluing the waterproofing layer.

Insulation with polyurethane foam

Liquid thermal insulator polyurethane foam is an ideal insulation material for floor insulation

Liquid heat insulator polyurethane foam is an ideal insulation material for floor thermal insulation, since it is sprayed directly onto the surface to be insulated and does not require the creation of additional vapor and waterproofing layers.

Among all thermal insulation materials, polyurethane foam has the lowest thermal conductivity coefficient, which allows the insulation to be sprayed in a thin layer, significantly saving the usable area of the room.

Polyurethane foam has all the properties necessary to ensure high-quality thermal insulation of the floor. It is fireproof, environmentally friendly, chemically and biologically inert, and has high sound and moisture repellent properties. The high strength of the polyurethane foam layer allows you to apply a leveling screed on it without laying a reinforcing mesh.

The technology of spraying insulation makes it possible to easily and quickly insulate surfaces of even very complex configurations. The polyurethane foam thermal insulation layer hardens within 3-4 hours. Immediately after the thermal insulator has hardened, you can begin applying the leveling screed.

Penoplex

Penoplex, which is often called extruded polystyrene foam, has high strength, resistance to deformation and rotting, water resistance, environmentally friendly composition and the absence of toxic substances. Using penoplex as insulation can significantly reduce energy costs and save on the purchase of additional heating devices.

With high-quality installation, penoplex can provide ideal thermal insulation properties.

To lay penoplex, the soil is leveled with gravel, thoroughly compacted and covered with a layer of compacted sand. Then a rough base is created from reinforced concrete, which is left to dry for a week, after which a waterproofing layer is laid on it, and penoplex is placed on it. Penoplex is covered with another layer of waterproofing and filled with concrete screed.

Types of thermal insulation for floors

The modern market of finishing and building materials provides a wide selection of insulation for floor screed. Each variety has its own characteristics, which are expressed in a combination of quality characteristics and installation technology.

Expanded clay

This material is quite popular for screeding in private homes on a pre-prepared soil base.

This option has a number of advantages:

Expanded clay is clay that has boiled at a high temperature; therefore, the material is absolutely harmless. The material is laid according to the following scheme:

Thus, the screed is created quite quickly, and the result is of high quality.

Bulk insulation materials are more suitable for arranging a dry screed; in the wet version, expanded clay is better used as a mortar filler (expanded clay concrete)

Styrofoam

Foam plastic under floor screed is used for installing flooring in apartment buildings or private cottages, on the second or first floor if there is a basement.

Semi-dry and dry screed

Dry screed gets its name due to the fact that liquid cement-sand mixtures are not used at all in its construction.

In essence, the creation of such a screed is the filling of expanded clay as insulation and filler between the joists of the subfloor.

The technology for laying dry screed consists of laying waterproofing, damper tape and backfilling the expanded clay itself. The base of the subfloor is laid on top of the dry screed. GVL sheets are most often used as such.

Dry expanded clay screed can be covered only with materials that can withstand moisture, withstand severe mechanical loads and not crumble. Therefore, the use of chipboard, plywood, etc. is strongly not recommended.

A semi-dry screed is a cross between a regular cement-sand screed and a dry expanded clay screed. The meaning of this option is to pour expanded clay onto a rough base (as in the case of a dry screed), followed by pouring concrete.

This solution is convenient due to the absence of the need for thorough preparation of the subfloor and lower consumption of central fiber. However, it is worth considering that in terms of its ability to withstand loads, a semi-dry expanded clay screed is much inferior to the “wet” version.

Styrofoam

Very often polystyrene foam is used for insulation. Its main advantages are:

Among the disadvantages of foam plastic under floor screed is its toxicity. However, it all depends on the type of foam. Suitable for residential premises:

In order for a floor screed with foam to have all the necessary parameters, it is necessary to select a material of a certain density. Therefore, when buying polystyrene foam, look at its markings - after the letters PPT there should be a number no lower than 25; such sheets are best suited for the heat-insulating layer of the screed. It is also worth paying attention to the PSB marking.

Another disadvantage that this material has is the complexity of its installation. In order for the foam floor screed to be durable, it is necessary to create the most even surface possible. To do this, quartz sand is first poured onto the rough screed, and only after that the insulation sheets are laid.

Healthy! For even cutting of insulation sheets, it is best to use a special construction cutter with a hot wire.

Foam sheets must be laid very carefully. If cracks or gaps have formed between the plates, they must be eliminated using polyurethane foam. Otherwise, the thermal insulation properties of the material will noticeably decrease.

If the foam screed will be located close to the foundation (first floor), then you should choose a material with a thickness of at least 10 cm, and for the upper floors slabs 5 cm thick will be sufficient.

Penoplex screed - what kind of technology is it?

Penoplex boards have good density and strength; they are not afraid of high loads. Both sand and cement screed and self-leveling mixtures fit well on their flat surface.

Its homogeneous structure is similar to a whole arsenal of small cells measuring 0.2 mm in size. Unlike other insulation materials, it has virtually no vapor permeability and does not absorb moisture. Penoplex is produced by industry mainly in the form of rectangular slabs of different lengths, widths, and thicknesses.

For insulation, you can use not only slabs, but also polystyrene granules, which are sold in bags. Granules are added to the concrete solution to produce polystyrene concrete. But it is more convenient to use penoplex in slabs under floor screed for insulation.

An uninsulated floor leads to increased humidity in the house, which results in the appearance of fungal mold. The room loses up to 20% of heat through cold floors. People suffer from colds and leg joints suffer.

Before insulating floors with foam boards, you need to prepare the base. The concrete base is freed from dirt, potholes and irregularities are repaired. The earthen base is first covered with a sand cushion, and before screeding it is compacted and leveled.

Pros and cons of floor insulation under screed

Compared to other insulation materials, the manufacturing technology of tile penoplex is aimed at protecting the material from moisture absorption. Its closed cell structure gives the material frost resistance and compressive strength.

Penoplex on the floor under the screed has the following advantages:

- Expanded polystyrene boards are not subject to combustion, do not emit toxic fumes, are not afraid of high humidity, and do not wear out or rot for a long time. Their service life is determined to be 50 years.

- The material is endowed with a high thermal conductivity coefficient. Its value is 0.030 W/(m*C), which indicates its good thermal insulation properties. The vapor permeability coefficient is 0.007-0.008 mg/(m*hour*Pa). Its low vapor permeability is comparable to roofing felt.

- The high strength of the material allows you to place heavy pieces of furniture on it without fear of squeezing.

- The slabs are well cut to the required dimensions and are easy to install.

- The porous structure of penoplex gives the slabs light weight.

- Weather conditions do not interfere with working with the material.

Important! Penoplex panels do not lose their thermal insulation and other qualities throughout their entire service life.

The disadvantages of penoplex products include their high price, strong smoke during smoldering, and the fact that they are destroyed under the influence of chemical solvents and high temperatures.

↑ Characteristics of thermal insulation materials

The thermal conductivity coefficient determines the ability of a material to transmit heat. It is equal to the amount of heat that passes through a material 1 m thick, with an area of 1 m 2 per hour, provided that the temperature difference on the two sides of the material is 10 ° C.

Porosity is a very important indicator; it is determined by the ratio of the number of pores to the total volume of the material. Affects all other characteristics of insulation.

The vapor permeability of a material determines its ability to “breathe”.

Water absorption affects the ability of the material to be used in conditions of high humidity. The lower this figure, the better.

The strength of the material is important for its use in structural elements where there are compressive loads.

Biostability means whether the material is able to withstand the action of pathogenic flora.

Fire resistance determines the ability of a material to withstand high temperatures for a certain period of time without breaking down.

Heat capacity is the ability of a material to retain heat under conditions of frequent temperature changes.

There are several other important characteristics:

We insulate the floor in our own home using polystyrene foam and expanded clay

Insulating the floor in a private house is an obvious need that owners are trying to solve with the help of various thermal insulation building materials. It is directly related to economic calculations and the desire of the owners to create a pleasant, warm home environment. Insulating the floor will significantly reduce heat loss, and this is the first way to eliminate hypothermia and all related diseases. In this case, many materials are used, both advanced and conservative. But more often than not, people don’t know what to give preference to: polystyrene foam (in all its forms) or expanded clay. Let's consider both options.

Extruded polystyrene foam

Expanded polystyrene foam is perfect for floor screeding, as this material meets all the requirements for high-quality insulation. Compared to polystyrene foam, it has better performance.

If we talk about choosing the right component composition of EPS, then you should be guided by the following indicators of various brands of expanded polystyrene.

| Name of insulation | Density, kg/m3 | Coefficient of thermal conductivity | Tensile strength, MPa | Hygroscopicity |

| Penoplex 35 | 28 – 38 | 0.030 W/m x 0С | 0,4 – 0,7 | 0,4% |

| Penoplex 45 | 40,1 — 47 | 0.030 W/m x 0С | 0,5 | 0,2% |

| Penoplex Foundation | 29 – 33 | 0.030 W/m x 0С | 0,27 | 0,4% |

| Penoplex Comfort | 25 – 35 | 0.030 W/m x 0С | 0,18 | 0,5% |

It is not recommended to choose polystyrene foam whose density is below 20 kg/m3, since such a base will not withstand the load from furniture. Based on this, the thickness of the sheets should be at least 30 mm for standard Penoplex boards and at least 7 mm for thin sheets (for example, Pufatherm).

There is also foil-coated polystyrene foam, which, thanks to the additional layer of foil, is the best option for insulating screeds for wooden floors and when installing heating systems. Foil can not only retain heat, but also reflect it. However, this material must be laid on the screed, and not under it.

Screed in the apartment.

Dear REPAIRERS, please tell me how best to make a screed in an apartment, beat off the horizontal with a water level without taking into account the tiles and glue, the result is 12 cm, you can simply fill it with sand concrete solution, hiding all the electrics, or you can put 5 cm of red penoplex, secure it with fungi, lay out the wiring, throw cellophane around the edges of the damper tape and fill in 7 cm of screed. And another question is penoplex for soundproofing the floor, is it normal?

Asks

Tusin Sergey Yurievich

Masters online: 312 Orders per week: 1,375 Offers per day: 701

I like the second option better