To avoid problems with freezing of the well, it should be properly insulated.

In winter, frost and ice form on the outside of the shaft neck. This occurs due to the temperature difference between inside and outside. Icing of the chamber walls creates additional difficulties in the operation of the water supply and sewerage system, and also impedes repair work.

The best thermal insulators and insulation options

| Types of materials | Characteristics | Advantages | Flaws |

| Styrofoam | Foamed plastic boards measuring 90 x 100 cm, 100 x 200 cm. Thickness 5-15 cm. Density 5-10 | Does not break down when exposed to water. Does not absorb moisture. Lightweight and durable. Easy to install. Durable to use. Not afraid of aggressive environments, dirt, clay, groundwater and wastewater | He practically doesn't breathe. After installation, it is necessary to form ventilation holes between the shaft body and the insulation |

| Expanded polystyrene | Slabs ranging in size from 90 x 100 to 100 x 110 centimeters. Rectangular. Along the edges there is a ridged edging | Dense material. Suitable for insulation in places with very low negative temperatures. Not afraid of moisture and dense soil deposits. Has grooves for more reliable fastening together | Square slabs of polystyrene foam are difficult to fasten to a round reinforced concrete ring. There will be gaps between the joints. High product price |

| Polyurethane foam | A liquid chemical mixture containing polymer substances, polyurea and other elements. Apply with high pressure machine | After hardening, it gains strength within 24 hours and does not change for the next 50 years. Sprayed using a special gun onto any surface. Material harmless to humans and animals. Requires virtually no preparation | Hardware application. You cannot use such polyurethane foam on your own. |

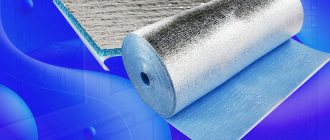

| Penofol | Soft material. On the inside, the polystyrene foam component ensures a tight fit of the insulation to the walls of the shaft. On the outside, the foil base prevents heat from escaping. Available in a roll of 100 cm. Length up to 20 m. Carpet thickness 12–20 mm | Ease of installation and durability of the insulation are achieved through polymer technologies. Fits tightly to walls, providing constant protection of the source from freezing | Unresistant to mechanical stress |

| PPU shell | Foam cylinder of different diameters. From 100 cm to 200 cm. Divided into two halves. There is a groove and a ridge along the entire length of the longitudinal section. Thickness 5–15 cm | Ease and simplicity of installation. No gluing or formation of a protective layer on the outside is required. No additional preparation of the base is required | High price of the product |

How to prevent well rings from moving in the future

You will have to come to terms with the displacement of the lower rings - digging out a trunk to such a depth is an extremely time-consuming and expensive task. Since most often the shift occurs due to weak soil or quicksand, there is no guarantee that after repair the problem will not recur. As for the upper 2-3 rings, they should be returned to their place without fail - this will allow for high-quality waterproofing and thereby avoid flooding of the mine with perched water.

The use of well rings with rebated locks prevents their horizontal displacement

The simplest thing that can be done to prevent horizontal movement of well rings is to replace them with hollow reinforced concrete modules with interlocking connections. For those who are embarrassed by the additional costs, we can recommend connecting adjacent rings using durable metal brackets or thick steel plates. To do this, holes are drilled at a distance of at least 25 cm from the joint, into which the bracket is driven from the outside. The edges sticking out inside are folded and carefully sealed. If plates are used, they are installed on both sides and secured with bolts with a diameter of at least 12-14 mm.

Concrete rings can be connected together with metal clamps and straight or curved plates made of thick steel strip

On heaving soils, cracks in the joints appear due to the fact that the soil tries to push the upper rings upward, lifting them above other parts of the well shaft. In this case, the trunk is dismantled to a depth below the calculated freezing point and the cylindrical modules are replaced with conical ones.

Factory or hand-cast cone rings will remain in place even on the most heaving soil

Prefabricated cone rings are almost impossible to find, so you will have to cast them yourself. The slope of the latter should be directed inside the structure and range from 10 to 15 degrees. Due to this, the buoyant forces reverse their direction, pressing the upper concrete module against the well shaft.

Wooden house

A common option for the cold season, if the site is located in a place where the average depth of soil freezing is no more than 1.5 meters.

The wooden house is installed at the very top of the well or sewer. An integral element of the structure is the installation of a door or window that opens as needed. It must be correctly positioned in the front part of the roof or in the slope itself. It all depends on technical capabilities.

Important: during construction, all wooden parts should be treated with a protective compound against the formation of mold in a humid environment.

Before starting construction of the hut, the source will still have to be insulated (foam plastic, expanded polystyrene, covering material, old sweatshirts).

Protective waterproofing is laid along the entire perimeter of the shaft walls.

When insulation is advisable: how to do it yourself

If the well was built from wood and according to old traditions, like centuries ago on the same land, then it does not need any protection at all, or it is enough to protect only the neck.

You can add a small plug to it inside the structure. It can reliably protect from:

- snowfall;

- leaves, garbage and other household items;

- temperature changes.

There are three technologies that are successfully used by well owners. Let's take a closer look at them.

How to insulate and cover the cover (hatch) of a well at the dacha for the winter

This system is simple and is used if people use water lifting only in a modern way - through an electric pump. The protection consists of creating an additional plug at ground level.

You will need:

- plywood - you will need to cut two even circles that match the diameter of the structure, in each there are 2 holes for ventilation and for a hose, and on the other side 4 for fastenings;

- wire - a ring is made from it for fastening to the surface;

- glue – for assembling a “sandwich”;

- polyurethane foam;

- insulation more than 5 cm thick, usually polystyrene foam - the third circle is made from it for insulation.

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

SF-mix manual up to 0.8 m3/h

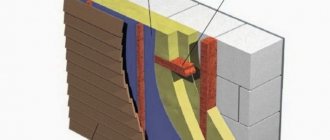

Insulating the outer part of the ring

Any master will tell you that it is important to minimize the thermal conductivity of the upper part above the soil. This can be done in any convenient way:

- polystyrene foam;

- polyurethane foam.

We build a log house from wooden strips and insulation

If your area doesn't get too cold in the winter, you can build a small building over the neck that is just the right size for a small dog.

Required:

- wire;

- waterproof film;

- nails;

- boards;

- plywood;

- insulation materials.

You can do it yourself or buy a ready-made one.

First, the top ring is covered with a special film. Then rectangles of polystyrene foam are cut out so that after gluing you get an even hexagon. Their use in this format increases the density of the material. With a tight fit, there will be no temperature changes inside.

The insulation is attached with glue and covered with aluminum wire for better effect. A small frame of minimal dimensions is assembled on top. Then the cover is installed. You can build everything so that it looks useful and aesthetically attractive.

A caveat is that it is not placed directly on the ground. It will require a modest foundation. To do this, the area is leveled, a blind area is made, which is filled with fine gravel or covered with tiles. From such a pillow to the house, the entire space is filled with foam plastic.

Water can be of very different quality. To find out whether it can be eaten without purification, you need to get it analyzed. Specialists from ovteh.ru will help with this. We cooperate with the laboratory at Moscow State University at the Department of Soil Science. We will collect it and submit it for inspection. If filtration is required, our employees will help you choose equipment that will reliably perform its functions and for which you will not have to overpay.

Do-it-yourself insulation of sewer well rings from the inside for the winter with photo

The inside of any well can be covered with heat-insulating materials only if it is a technological reservoir with technical moisture. In other cases, it is advisable to get by only by installing a high-quality hatch, possibly with an additional warm layer.

Attaching film, polyurethane foam, or other similar substances from the inside is harmful and hazardous to health. How they will behave in conditions of constant humidity is unknown. In addition, they will not perform their main functions, so you should not attach them contrary to the general rules.

Thermal insulation of the cover

This happens in several stages.

First stage . To make a pie, you will need two panels of plywood or moisture-resistant chipboard and a piece of polystyrene foam or polystyrene foam. A round washer is cut out of plywood to match the internal diameter of the well ring. If the chamber is square, then cut out a square according to the internal markings of the caisson. A piece equal to the rest is also formed from the foam.

Stage two. Using wood glue, the pie is held together, leaving foam between the panels.

To further secure these layers, you can screw in screws. A handle is installed on the top of the washer, making it easier to remove and reinstall the lid. Third stage. Insulation of a well in a summer cottage is complicated by rare inspection of the inside of the collector. Not all owners audit the source. Therefore, the installation of the insulated cover must be securely fastened. To prevent the washer from falling into the water or onto pumping equipment, but to remain at ground level, it must be secured. Four holes are drilled crosswise in the shaft wall at a depth of 50–60 centimeters from the lid, and a small piece of reinforcement is driven into them. 2-3 centimeters should stick out inside the ring. The insulated pie will rest on these ledges.

Important: if the ground freezes below 2 meters, you should make two such washers and install them 15 centimeters apart. This will create an additional air curtain.

Why is freezing of wells dangerous?

It is a mistake to think that well insulation is only necessary when it is used year-round. Many summer residents and seasonal residents of country houses sincerely do not understand why insulate a well that no one uses in winter anyway. Meanwhile, such seasonal wells also need effective thermal insulation!

Otherwise, a variety of problems may arise that make the operation of the well difficult or completely impossible:

- the formation of an ice plug in the water supply system;

- displacement of the rings resulting from the expansion of frozen water in the surrounding soils;

- failure of the ice plug and damage to pumping equipment;

- divergence of the joints of reinforced concrete rings when water gets between the seams.

Wells that are not protected from low temperatures require repair work much more often. And in terms of financial costs, repair measures are often more significant than carrying out one-time insulation work.

Image gallery

Photo from

A good reason to insulate a well

Ice plug in an uninsulated well

Destruction of concrete well walls

Shift of concrete well rings

If a water supply system based on a well is installed in a suburban area, then in addition to the shaft itself, it is necessary to insulate the pipes to protect the supply line of the system from low temperatures.

What to do if you're already frozen

Having opened the well, it is clear that frost has covered the entire area of the walls of the ring and has tightened the pumping equipment. Perhaps the installation depth of the cover is incorrectly calculated, or the source is not insulated correctly.

If there are signs of freezing, but water is still flowing into the house, nothing needs to be done until the air temperature rises. Then it should be properly insulated.

Frozen equipment can be warmed up with a hair dryer right on the spot, or, after removing it, bring it into a warm place and let it stand for a day.

Preventing the well from freezing

To prevent the well structure from freezing with the onset of winter, thermal insulation should be taken care of during its construction. If the suburban area will be visited occasionally (for example, only on weekends), then, in principle, there is no need to insulate the well. In such cases, it is only necessary to clean it and treat it with some kind of disinfectant (such as chloramine) before leaving.

After this, pump out the water completely and close the structure with a lid. Lay a polyethylene film over the lid and cover it all with leaves. Now you can go to the city with a clear conscience, because with the onset of warmth, the well will again provide clean water.

But if the well is used regularly, then the measures should be more serious. For example, pipes to the house must be located below the soil freezing line, the structure itself must be protected by the house described above, or by other available means.

Sticking foam sheets onto concrete rings

What to do in a situation where you are insulating round concrete well rings with foam sheets? The easiest way is to cut the foam sheets into segments 100 millimeters wide and stick them one after another on the concrete.

After the first layer is completed, continue gluing the penoplex segments (layer 2) onto the penoplex of the 1st layer in the same way, making sure to overlap the seams.

Is it necessary to insulate a well in autumn and winter: which structures need it?

This process is recommended for almost any well, even in the southern regions. The fact is that modern mines are built from concrete, which is significantly different from wood and easily conducts cold. As a result, the water constantly freezes and becomes impossible to use.

Only structures built from wood in hot countries do not require additional protection. Where the air temperature does not drop too low and there is no snow, it is permissible not to perform this work.

In all other cases, we advise you to install at least an insulated cover, which will serve as a gasket between the source and the weather outside.

It is important to understand that this is a necessity, not a whim. Without this, it may not only be impossible to use the well. There is a risk of structural damage and damage to the pump.