What is polyurethane foam

Polyurethane foam refers to a type of plastic that is a product of the oil refining industry. The raw materials for production can also be oils of vegetable origin (soybean, rapeseed, sunflower). But due to their high cost, they are rarely used.

The porous material is 85-90% filled with inert gas. Depending on the cell fraction and wall thickness, several subtypes of polyurethane foam are distinguished regarding strength indicators:

- solid;

- hard;

- soft and very soft;

- viscous;

- elastic.

Important! In construction, energy-saving and sound-absorbing material with a density of 30-86 kg/cubic meter is more often used. m.

Hard PUF

If the indicator is close to 70 or more units, then such PUF products are distinguished by their ability to retain moisture without absorption, which is important for waterproofing work (but constant contact with water is excluded, since the development of a hydration reaction is possible). The thermal conductivity of polyurethane foam ranges from 0.019-0.035 W/m, so the scope of application includes protecting various structures from cooling.

Can you list all the names of polyurethane foam so that I can no longer be deceived?

Certainly! Get it!

- Foam rubber

- Foam

- PPU

- Latex foam

- Foam

- Highly elastic foam

- Vegetable foam

- Foamed corn oil

- Artificial latex

- Waterlatex

- Tiger touch

- Wisco shawm

- Sloth

- Memory

- Memorylatex

- Smart foam

What is foam rubber

*

Foam rubber is a modification of polyurethane foam. The name of this flexible polyurethane foam comes from the brand of the same name from a Scandinavian material manufacturer. Applications include the production of furniture and sports equipment (filler), construction (insulation against cold and sound). To a lesser extent, the material is used in the automotive, textile, shoe industries, manufacturing of household and medical orthopedic equipment, and soft toys.

If we consider the density of the elastic polymer, it ranges from 5 to 40 kg/cubic meter. m. The air content in the porous modification of polyurethane foam is 90%.

Soft PPU

Regarding rigidity, the material classification is as follows:

- ST - standard polyol foam;

- HL - hard;

- EL - increased rigidity;

- HS - soft;

- HR - elastic;

- LR - viscous;

- RTC is a highly porous reticulated polyurethane foam.

Important! Secondary foam rubber is considered separately, that is, recycled waste is used for production. As a result, the material almost completely absorbs sound and has a high density.

Table

| Polyurethane foam | Foam rubber |

| What do they have in common? | |

| Foam rubber is a soft type of polyurethane foam | |

| What is the difference between them? | |

| Hard, inelastic, has a lower percentage of air cavities in the structure | Soft, elastic, 90% air |

| Used as a building material, insulation | It is used as a material for hygiene items, furniture filler, and sometimes as insulation. |

How do the characteristics of foam rubber differ from polyurethane?

The slight difference between foam rubber and polyurethane foam is the chemical composition, but it is considered safe for humans, despite the release of toxic substances during production. An analogy can also be seen in the inertness of materials to biological damage, but poor resistance to UV radiation. The classification is based on density indicators.

Appearance of polyurethane foam when exposed to UV radiation

*

The structure in both cases is porous, which to one degree or another has a positive effect on the acoustic properties. The main differences in the characteristics of polyurethane foam and foam rubber are the air content, density and rigidity of the materials. According to these indicators, the scope of application also differs.

Okay, there are a lot of numbers, but I don't understand anything about it? Is it possible somehow easier?

Before purchasing a mattress, ALWAYS find out the density of the foam used by the manufacturer. This is a guarantee of durability.

Conventionally, in the context of the mattress topic, all foams can be divided into 3 groups:

- low-density 16-25 kg/m3 (not durable in mattresses, but cheap for a one-time purchase!). Buying a mattress with such a density means that it will collapse in the coming year. As a rule, such densities do not normally last longer than 2-3 years.

- medium dense 28-35 kg/m3 (in mattresses they serve well for medium-sized sleepers). Such densities are used by self-respecting, but not the best, manufacturers. Forecast of good service - 4-7 years.

- heavy quality foams 40-60 kg/m3 (very durable comfortable foams). These are cool mattresses with a service forecast of 10+. It is with these densities that GASH primarily works.

Advantages and disadvantages

The advantages of polyurethane foam materials include resistance to deformation, that is, after compression, the material quickly restores its original shape. Regarding products for washing and cleaning, painting and priming the surface, the ability of foam rubber to absorb liquid, which can occupy up to 40% of the volume of contained air, is relevant. Application is possible in a wide temperature range: from -40 to +100 degrees Celsius.

The service life of elastic polyurethane foam declared by manufacturers is in the range of 5-15 years, and rigid polymer materials can maintain quality indicators for 30-80 years.

Among the disadvantages, there is flammability with the release of toxic substances and toxic smoke harmful to humans.

Behavior of polyurethane foam in open flame

Modern additives allow manufacturers to produce polymer products that do not support open fire. And under the influence of direct ultraviolet radiation, materials begin to deteriorate.

Important! If foam rubber is characterized by a relatively low price, then polyurethane foam as insulation is more expensive compared to other analogues.

Polyurethane-based polymer materials have a porous structure, due to which they have noise-absorbing properties. Depending on its density, polypropylene either absorbs moisture or acts as a water barrier. Hard types are actively used for insulating structures, and soft types are used for filling furniture, toys and sports equipment.

Varieties

In the production of sofas, different types of polyurethane foam can be used as filler.

There are the following varieties, as well as types of polyurethane foam:

- Standard

. It is marked ST. Suitable for sofas with a load of up to 80 kilograms. Mainly used for office chairs, backrests, and armchairs; - Increased rigidity

. Or increased density. There are EL and HL markings here. They can withstand loads of up to 100 and more than 100 kg. Recommended for installation in orthopedic mattresses, sofas, as well as folding chairs and children's furniture. They perform well during active use; - Soft

. Withstands a load of no more than 60 kg. Mainly used in additional elements of sofas. These are pillows, headboards, and armrests; - Highly elastic

. It is marked HR. Used in expensive furniture.

Read what the density of foam rubber says in this article

PU foam differs in class and physical and chemical properties.

Also in furniture production, block and cast polyurethane foam can be used in the manufacture of sofas.

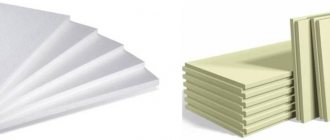

Block material is supplied in large blocks. At a furniture factory, polyurethane foam is cut into the required sizes and thickness, and then the sofa padding is formed.

Molded PU foam sheets are solid products that are made in special molds for a specific furniture configuration. The advantage of this method is that there is no waste. Not suitable for non-standard shaped sofas.

Cooperation

The main activity is the B2B market. We are always open to new cooperation and are ready to offer even the most non-standard solutions.

We guarantee our partners an integrated approach to solving problems.

The key advantages of working with us are:

- Innovative approach to production. The FomLine team of technologists is continuously working to improve polyurethane foam formulations, study the best practices of foreign manufacturers, and develop new brands of polyurethane foam.

- The widest range of elastic foams in Russia. The FomLine line includes its own collection of mattress blocks and blanks for pillows, as well as ready-made solutions for furniture and sleep products. In the company's research centers it is possible to develop unique foam rubber according to special customer requirements.

- European product quality. Process automation, proven raw materials, and strict quality control at all stages of production ensure that our customers receive foam rubber of the European level. The quality of FomLine products is confirmed by the most stringent certificates (ISO 3386-1-86, CertiPUR).

- Efficiency in production and delivery. The convenient location of our foam rubber production factories in every region of Russia allows our customers to quickly receive products and not incur additional costs for its transportation.

- Import substitution. Our customers can significantly reduce their import costs. The production capabilities of the plants make it possible to produce foams for technical purposes, which were traditionally supplied from abroad. the only one in Russia that produces high-quality foams based on polyesters.

We are focused on long-term cooperation and will do our best to give our clients competitive market advantages and maximum profits.

Once you become our partner, you will remain one for many years.

Scope of application

You need to choose a material based on the required properties . Polyurethane foams have been used in various fields of activity for a long time. Specialists know in which case the material is needed.

Float-type objects, mechanical supports, and heat-insulating elements with a wide temperature range are made from elastic polyurethane foam. Foam rubber does not change its properties upon contact with liquid nitrogen and heated elements at temperatures up to 120 ° C. Thanks to the open pores, various household items are made from the material (sponges, pillows, seats, soundproofing systems, etc.).

Rigid polyurethane foam in aircraft, automobile and ship construction. Poor water absorption is used to produce unsinkable boats, pontoons and other elements. The material produces heat- and vibration-resistant systems with permeability to electromagnetic waves.

Repair and constructionComment

How to do it yourself?

Everyone needs a new mattress from time to time. And many people can do it themselves. This could be an option for the dacha. And it happens that the fabric on the mattress is still good, but the foam has already sagged.

You will need:

- Foam rubber.

- Mattress cover material.

- Felt.

- Glue for foam rubber.

If the spring blocks are in good condition, then it is enough to replace only the pieces of foam rubber with new parts.

Work algorithm:

- Lay foam rubber on the floor and cover it with felt.

- Glue pieces of foam rubber to the sides to hide the springs.

- On top, when the glue dries, put felt, and then foam rubber.

- The final step is to insert the foam into the case.

If you need a new mattress without springs, you first need to decide on its size. Purchase foam rubber with the required parameters. Then sew a mattress cover. When cutting, take seam allowances into account. All that remains is to place the polyurethane foam in the case.

Video of a DIY foam mattress:

Cutting polyurethane foam

A soft, elastic material with small cells, foam rubber causes certain difficulties when it is necessary to give it a given shape. In industry, until recently, cutting presses were used. The creation of a shaped matrix, necessary for this type of processing, influenced the increase in the cost of the final product.

Currently, CNC laser machines are widely used. New devices significantly expand the use of polyurethane foam due to the ability to cut products of complex configurations without a significant increase in labor intensity. Laser cutting is performed silently, quickly, and no solid waste is generated during the cutting process.

Main types of rooms for sound insulation

Let's consider the main rooms, the sound insulation of which is of practical use.

Such premises include:

- Office

- Residential house/apartment

- Sound recording studio

An office is a place of high concentration of a large number of people who perform certain duties and create serious noise pollution. For example, telephone calls, knocks and creaks of office furniture, the noise of footsteps, the operation of various office equipment (computers, printers, etc.). All this creates an atmosphere in which employee productivity decreases, absent-mindedness and fatigue increase. A significant reduction in noise level (almost twice) can be achieved by placing several foam panels on the shelf of a cabinet or cabinet.

A residential building or apartment is a place to relax and recuperate after a hard and difficult day at work. However, if the house is located on a busy street, and the owner has begun renovations in the apartment next door (or an ardent fan of loud music lives in the apartment on the next floor), relaxation becomes an unattainable dream, because it is impossible to fully relax in such conditions.

Sound-absorbing boards can help solve this problem - they do an excellent job of preventing the penetration of extraneous sounds into the room not only from the outside, but from the inside. Acoustic insulation is especially useful for those who have small children - it will help maintain an atmosphere of calm and comfort.

Recording studios are almost unimaginable without sufficient noise insulation. Any extraneous noise and sounds negatively affect the quality of the recorded sound. For this reason, acoustic panels are installed not only on the walls - the ceiling is also treated.

Etymology in the service of spelling

Most etiquette formulas in the Russian language originate from verb phrases that have lost their basic lexical meaning. These are “hello” - a wish to be healthy, “thank you”, which comes from the expression “God bless”, or “thank you” - from the phrase “to give good”. This is the etiquette formula of the request. This word comes from the imperative mood of the verb pozhalovat, meaning to give as a gift, to present. To it was added the particle hundred, which was, according to one version, an abbreviation for sir, according to another - the past tense form of the verb to become. Thus, the spelling can be explained by knowing the origin of please from welcome:

- Pozhat is formed from complain by adding the prefix po-. This prefix is always written the same way: with the letter o.

- The imperative form is formed by adding the suffix -й- to the present tense stem. For example: give-give-give. The welcome form is formed in the same way.

- Whatever the origin of the particle -sta, its spelling is the same: with an “a” at the end.