Generation of new heating systems

Modern models of gas boilers are more advanced in comparison with traditional analogues.

Both single-circuit and double-circuit devices are available on sale. The first ones are intended only for heating. The latter are capable of simultaneously performing two functions: heating the premises of the house and providing its owners with hot water supply.

Scheme: arrangement of single-circuit and double-circuit boilers

Innovations concern not only the design of the device itself, but the use of higher quality devices:

- The design now includes control and regulating devices that allow you to set different modes.

- In the ignition system, traditional handles have been replaced by piezoelectric elements.

- The casing coating is characterized by increased resistance to damage and durability.

They are convenient because they are able to operate smoothly and efficiently, without requiring constant human supervision. Sensors located on the body will indicate malfunctions, while at the same time identifying the system that has failed.

Thanks to the automatic AGV, in the event of a drop in gas pressure, unexpected extinguishing of the pilot flame or a decrease in draft, the system is instantly switched off, which is important for the safety of residents

- The main elements of the automation unit are:

- Electromagnet – controls the gas supply valve;

- Thermal sensor – controls water heating;

- Draft sensor – monitors the draft level in the pipe;

- Thermocouple – creates an electric current in a circuit.

Modern boilers are as compact and automated as possible

The gas supply to the burner is controlled by a thermal sensor. To ensure uninterrupted operation of the unit, you just need to set the desired parameters. When the shutter is automatically activated, the gas supply to the burner is reduced to a minimum, and the operation of the system is maintained only by a weakly burning wick.

As soon as the temperature sensor triggers to lower the temperature of the coolant, the automation starts and the wick ignites.

Let's consider the method for finding the above fault.

When repairing a gas boiler, testing begins with the “weakest link” of the automation device - the draft sensor. The sensor is not protected by a casing, so after 6...12 months of operation it becomes “overgrown” with a thick layer of dust. The bimetallic plate (see Fig. 6) quickly oxidizes, which leads to deterioration of contact.

The dust coat is removed with a soft brush. Then the plate is pulled away from the contact and cleaned with fine sandpaper. We should not forget that it is necessary to clean the contact itself. Good results are obtained by cleaning these elements with a special “Contact” spray. It contains substances that actively destroy the oxide film. After cleaning, apply a thin layer of liquid lubricant to the plate and contact.

The next step is to check the serviceability of the thermocouple. It operates in severe thermal conditions, since it is constantly in the flame of the igniter; naturally, its service life is significantly shorter than other elements of the boiler.

The main defect of a thermocouple is burnout (destruction) of its body. In this case, the transition resistance at the welding site (junction) increases sharply. As a result, the current in the Thermocouple - Electromagnet circuit.

The bimetallic plate will be below the nominal value, which leads to the fact that the electromagnet will no longer be able to fix the rod (Fig. 5).

Installation of a wall-mounted gas boiler

Diagram of a gas floor boiler.

Tools and materials:

- welding equipment;

- level;

- pencil;

- container for mixing the mixture for concrete screed;

- drill with a set of drills;

- metal scissors;

- screwdrivers;

- a set of keys.

- The height of the suspension of gas equipment along the edge of the lowest pipe must be no lower than the top of the sink spout and no less than 80 cm from the floor.

- The space under the boiler must remain free.

- There should be no cavities in the installation room that could become a place for the accumulation of combustion products or an explosive gas mixture.

- A strong fireproof metal sheet measuring 1x1 m should be laid on the floor.

- An expansion tank and an air valve are installed at the highest point of the system.

Installation diagram of a wall-mounted gas boiler.

When purchasing a boiler yourself, check the contents and availability of fasteners; if not, they should be purchased separately

Pay special attention to the availability of equipment certification, otherwise, after installing it yourself, you will not be able to register it; also check that the serial number in the accompanying documents of the boiler matches the number printed on the inner surface of the boiler

If the wall that will become the basis of a wall-mounted boiler is made or finished with highly flammable material (paper wallpaper, wood), a heat-resistant coating with a layer of at least 2 mm is laid on the surface. The boiler is installed at a distance of 4-5 cm from the wall level. Before installation, rinse the internal tubes by running water under low pressure. Thanks to this washing, it is possible to remove from the tubes all kinds of debris and dust that could have entered during assembly.

When starting installation yourself, attach the mounting strips at a height of 1-1.6 m from the floor. Check the position of the slats with a level and only then hang the boiler itself. Install a hard filter on the water supply pipe to prevent possible clogging of the heat exchanger. Thanks to the installation of shut-off elements on both sides, the filter can be periodically replaced without draining water from the system or cleaned.

Install the chimney and check the draft. Despite the fact that most modern wall-mounted boilers do not require strong draft, since combustion products are removed using a special fan, it is necessary to make sure that the draft is not reverse.

Connect the boiler to the pipeline using a threaded coupling from the side end. The water supply pipeline is connected from above, the water return - from below. The most convenient connection method is gas welding. Do-it-yourself installation rules allow for a slope of heating pipes within 5 mm per 100 cm of pipe.

To connect to the gas pipeline, the participation of a gas specialist will be required. A gas supply valve must be installed on the gas supply pipelines; to connect the boiler to the pipeline, the gas supply through the air line must be shut off. The gas supply is carried out using a metal pipe through an element such as an American pipe or a special squeegee, so this work can only be carried out by specialists.

If the boiler is volatile, it is equipped with automatic equipment that protects against short circuits and overheating, and requires connection to the electrical network.

At the final stage of connection, the boiler is put into operation with your own hands, which can only be carried out by a gas industry worker after checking compliance with the rules and safety requirements.

Storage and care

During operation, to maintain the functionality of the AGV-80, it requires systematic care: keep the water heater and heating system clean and in good condition, protect it from impacts, and make sure that no moisture gets on the magnetic valve.

In the summer, the heating system is filled with water, and before the start of the heating season, it is thoroughly washed by filling and draining water two or three times.

Check the filling of the heating system with water once a week. Uninstalled AGV-80 should be stored packaged in closed, dry warehouses.

How it all began

At one time, gas boilers of the AGV-80 or AGV-120 brand were used to heat a private house. This equipment had low productivity, but given the low cost of gas, this fact did not bother anyone.

AGV gas boilers for private homes were equipped with primitive automation, which failed in the first year of operation. However, the equipment functioned normally without it.

Installation of pipes for distribution is carried out outside around the perimeter of the house. However, this issue was not relevant at that time, and heat was supplied to the house in full. Pipes were used with a diameter of 2 inches, since a smaller diameter could cause the formation of air pockets that impede the natural circulation of the coolant.

After a slight modernization, gas boilers for heating AOGV and AOKGV appeared on the market, but this equipment was characterized by the same shortcomings (low performance and unreliable automation).

Despite this, boilers of this type have held up quite confidently on the market due to a serious advantage: the AGV heating stove operates without being connected to a power supply.

Other advantages of a heating system using AGV include the following:

- If we compare imported equipment and AGV, we note the affordable cost of the latter option.

- In contrast to the AOGV and the gas boiler produced by domestic manufacturers, the efficiency of the AGV can be noted.

The listed characteristics help in deciding what is better: an AOGV or a boiler.

This is interesting: A stove with a fireplace designed for long-term heating - how to choose for a summer house. Types, models, burning duration and other characteristics

general description

AGV gas boilers have always been characterized by rather low efficiency, but this is not so important if gas is the cheapest fuel. Old models of autonomous water heaters were equipped with very unreliable automation, which could completely fail within a few years.

Of course, it could always be turned off, and this did not affect the performance of the boiler in any way - but positive emotions could not arise because of this.

When choosing an AGV for a private home, it is necessary to correctly select the number and sizes of main pipes. Their minimum diameter is two inches. If the diameter of the pipes is smaller, then, firstly, their throughput will not be enough, and secondly, air pockets and water turbulence will form in the line, interfering with the normal circulation of the liquid.

The use of wide pipes, in turn, leads to a significant increase in the amount of coolant in the circuit. A large volume of liquid means more energy spent on heating. This feature must be taken into account when designing a heating system powered by AGW.

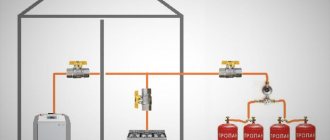

Composition of the AGV system

The AGV system for heating devices consists of the following main elements:

- AGV boiler;

- pipelines;

- heating elements (radiators, registers);

- expansion tank, which is mounted above all other elements (necessary when starting the AGV heating system).

The basis of the AGV is the AGV boiler. It is a tank mounted in an iron casing, inside of which a pipe for burning gas is mounted. It looks like a samovar. The combusted gas heats the water flowing inside the tank. Gas combustion products are released into the atmosphere through the chimney.

The heated water enters the heating system, where, in accordance with the known laws of physics—hot water is lighter than cold—it flows through pipelines into heating radiators. There, having given up thermal energy, it cools and again enters the AGV for heating. This creates a closed circuit through which the coolant flows by gravity. Its driving force is the difference in height between the heating (AGV) and cooling devices (radiators). The greater this difference, the more intense the water circulation. Such a heating system is called a thermosiphon or a system with natural circulation of coolant. However, recently heating systems with forced water circulation have become increasingly used. In this case, a circulation pump is installed at the outlet of the AGW into the pipeline, which significantly increases the rate of water circulation and, as a result, reduces the time for heating the premises at a given temperature and the consumption of gas consumed. In this case, automation is used that maintains the specified parameters and monitors the fulfillment of basic safety requirements (switching off the gas supply when the water pressure in the line decreases or the burners go out).

AGV heating of a private house is convenient, warm, inexpensive

Today, gas heating remains the most economical way to heat a house and provide hot water for household needs.

And although modern gas boilers are more economical and easier to use, many homeowners continue to use traditional AGVs or install their newer modifications. An automatic gas water heater is used in central water heating systems in single-story and low-rise buildings. AGV boiler

It can be single-circuit - only for heating, or double-circuit - for heating and water heating. Its modern modifications (AOGV and AKGV) are structurally different from the old model. Therefore, when replacing an old unit with a new one, as a rule, it is necessary to modernize the home heating system (for example, change pipes and / or radiators, etc.). A compromise could be the AOGV of the Italian company Beretta, which is manufactured specifically for the CIS countries according to “Soviet” GOSTs.

Operating principles of AGV

So, AGV heating - what is it and how does the boiler itself work? In its design, the simplest gas hot water boiler resembles an ordinary samovar. Its main part is a tank made of three-millimeter galvanized sheet steel, placed in a casing. A fire tube (heat exchanger) is mounted inside the tank, which is heated by natural gas burning in the combustion chamber. The water heated by the heat exchanger goes into the heating system, and combustion products are discharged through the chimney.

The boiler is equipped with a thermostat - it automatically turns on and off the gas supply magnetic valve, maintaining the desired water temperature. Warm water is lighter than cold water, so it rises through the pipes to the radiators, and when it cools in them, it returns to the tank for heating. This is how a heating system with natural (thermosyphon) water circulation works. With forced circulation, the circulation of water in the pipes is accelerated by the electric circulation pump that forces it.

The safety of the gas boiler is controlled by simple but effective automation. If the burner flame goes out or the pressure in the water line drops, the gas supply stops. It turns off if the draft in the chimney is disrupted (for example, if it is clogged).

Advantages and disadvantages of AGV heating

Among the main advantages of traditional AGW heating is the low price of the boiler itself, especially in comparison with imported water heating units, and its efficiency. The energy consumption of the circulation pump is low (with a power of 48 kW per month - approximately 34-35 kW). You can reduce energy consumption by installing an automatic system on the boiler to turn off the pump at a time when water is not heated. Thanks to its simple technical design, AGV is inexpensive to repair and maintain.

However, the AGV water heater is inferior to modern boilers in terms of efficiency and ease of use. In addition, it is massive, and since it exists only in a floor-standing version, it takes up quite a lot of space. The AGV heating system uses large diameter pipes, so the house takes a long time to warm up and takes a long time to cool down. This is not very convenient in the off-season - spring and autumn.

AGV in city apartments

Boiler room

Today, many people would like to refuse the services of a centralized heating network and equip their apartment with AGV heating. However, the transition to autonomous boilers is not possible in all buildings. It is easier to obtain permission to install an autonomous boiler in low-rise old houses, where chimneys of the required diameter have been preserved from the time of stove heating, and where the diameter of the underwater water pipe allows this.

In some cases, in houses where there are no chimneys, it is allowed to install so-called “attached chimneys” (they are brought out through the wall). If central heating pipes are abandoned, they are thermally insulated with special casings. However, with rare exceptions, Russian legislative standards do not allow the transition to autonomous heating and hot water supply in multi-storey buildings.

Operating principle of AGV

The main structural element of the AGV is the container in which the coolant is heated. When gas burns, a heat exchanger, made in the form of a pipe and installed inside the AGV housing, heats up. The heat from the heated pipe is transferred to the coolant, which is subsequently sent to the heating circuit.

Gas combustion products are discharged through a chimney built into the boiler design. All automation is a valve that opens the gas burner. Thanks to the operation of the valve, the required temperature is constantly maintained in the tank.

AOGV boilers also have an automation unit that turns off the device in case of a number of problems:

- Traction disorder;

- Significant reduction in gas supply pressure;

- The igniter stops burning.

- Expansion tank;

- Heating devices located in each room requiring heating;

- Main pipeline providing distribution of heated coolant;

- Upper pipe distribution;

- Return pipe.

To know how an AOGV gas boiler works, you need to imagine the physical laws that arise in the heating system during its operation. The heated coolant has a lower density, which allows it to independently rise above the cold liquid. The coolant enters the main pipeline, is carried through the heating devices, gives off heat to them, and returns to repeat the heating cycle.

In AOGV boilers, the liquid moves by gravity, without any additional effort. If during the heating process the coolant expands too much, then its excess is drained into the expansion tank. This element is installed on the uppermost section of the heating circuit. When the temperature in the circuit decreases, the coolant returns to the OGV gas boiler.

To increase the efficiency of the system and make it more stable, you can supplement the AGV with a circulation pump, which forces the coolant to move forcibly and ensures more uniform heating of all sections of the circuit. It must be remembered that the pump requires electricity to operate - and the main advantage of the AGV is its independence from electricity.

Nuances of choice

The main criterion when choosing a boiler is its power. And the differences in the level of technical equipment are secondary and insignificant. If the model index contains numbers indicating the volume of the water tank, as is the case with the AGV-80 and 120 boilers, then divide them by two and get the optimal value for the area of the heated room. Power values expressed in kilowatts must be multiplied by five. A double reserve guarantees that the premises will be comfortable even at extremely low temperatures “outside”, and will also allow you to compensate for heat loss if the house is dilapidated or has design flaws.

AGV heating scheme

AGV heating based on boilers from the Zhukovsky Mechanical Plant can be installed in any locality if it has a reliable supply of mains or liquefied gas. The simplicity of the design and independence from the quality of the power supply make their operation completely safe and relatively inexpensive.

What is the peculiarity of AGV gas boilers in the heating system, see in the video:

Turning on the gas boiler

A prerequisite for warranty service of a gas boiler is that the first switch-on must be carried out exclusively by a specialist from the gas service. If the user follows all instructions and safety precautions when starting up independently, then you can also count on the reliability and durability of the heating system.

The initial start-up of a wall-mounted boiler is carried out strictly after checking the following points.

The first thing you need to do is make sure that the gas pipes are tight when the gas valve is closed and open. If gas flow is not recorded within 10 minutes after connecting all pipes, then it can be stated that the system is sealed.

The gas supplied from the main pipeline must meet the requirements specified in the instructions for the boiler. When transferring the unit to process a liquefied mixture, you need to change the nozzles in advance.

You also need to check the pressure level in the system. It should be as recommended. The air intake and carbon dioxide exhaust pipes should be checked for blockages.

Sometimes users encounter the problem of poor circulation of the pump. Often the cause is low mains voltage. This problem is solved by installing a stabilizer

It is necessary to make sure that the room with the boiler has a working ventilation system. Additionally, the smoke pressure safety switch is checked.

After carrying out the preliminary work, the procedure for starting the boiler follows:

- The gas boiler is connected to the network, the gas supply to the device is opened;

- Check that all valves at the inlet and outlet of the coolant into the unit are open;

- Press the button or turn the switch on the boiler dashboard depending on the switching method specified in the instructions.

You can adjust the temperature using the corresponding buttons. Working in automatic mode, the boiler independently turns on the burner if it is necessary to heat the water in the system. If the boiler is double-circuit, then when hot water is turned on, the burner automatically turns on for heating.

On the boiler display, after the initial start-up, it is recommended to configure all boiler parameters. The instructions usually indicate the sequence of necessary actions.

The interlock system cuts off the gas supply if the burner does not ignite within approximately ten seconds. When starting for the first time, it may be necessary to remove the ignition lock due to the presence of air in the gas line. You need to wait until the air is replaced by gas. The lock is removed when the device is restarted.

To start a floor-standing gas boiler, you need to carry out the same preparatory procedures as for a wall-mounted one. Before starting up, you need to ventilate the boiler room, make sure that all heating pipe taps are open and that there is draft in the chimney. You can check the traction using a piece of paper.

There are two options for turning off a floor-standing gas boiler. You can turn off only the main burner or the main burner together with the pilot

Switching on the floor-standing boiler:

- The door of the device is opened, the position of the boiler control knob is checked in the off position.

- The gas supply valve opens.

- The control knob is set to the piezo ignition position.

- Next, press the handle for 5 - 10 seconds so that the gas passes through the pipes and displaces the air. The piezo ignition button is pressed.

- Then the presence of a flame in the burner is checked. If the burner does not light, the procedure is repeated.

After igniting the main burner, you can use the control knob to adjust the heating temperature.

First launch and adjustment

At the preparatory stage, you should ensure the tightness of the threaded connections of the gas pipeline, the tightness of the shut-off devices, and the proper operation of the automatic systems. It should be borne in mind that it is not recommended to carry out most of the listed work yourself. Therefore, to receive qualified assistance, it is recommended to contact a specialized company providing these services.

Before starting the AGV-80 water heater for the first time, you must make sure that the heating system connected to it is filled with water. The storage tank of the tank must also be filled with liquid. This can be easily done by looking at the signal tube. The appearance of water in it indicates a sufficient level. After this, turn off the water supply and carry out the first start.

Preliminary work before the first launchSource 1-teplodom.ru

The next steps are to ensure that there is adequate draft in the chimney. This can be done in any convenient way. The simplest one involves manipulations like this:

- Light a match and bring it to the cap located on the traction breaker.

- With a well-functioning draft, the flame will tend (to be drawn) into the hood.

Gas burner AGV-80Source chipmaker.ru

It should also be taken into account that other reasons may also be the cause of poor traction. Often, disruption of the home drainage channels occurs for the following reasons:

- Strong squally or gusty wind.

- Heavy precipitation (rain, snowfall).

- Low atmospheric pressure.

When igniting the AGV-80 for the first time, the following actions must be performed:

- Open the gas supply valve on the pipeline.

- Open the firebox door slightly.

- With your left hand, bring a lit lighter or match to the top holes on the igniter.

- Press the magnetic gas valve button until you hear a characteristic click. By doing so, you open the gas supply, causing it to ignite.

- Do not release or release pressure on the valve key for 1 minute.

- After the specified period of time has passed, smoothly release the key.

- Slowly turn the tap on the gas burner clockwise.

After the water temperature in the heater tank warms up to the required temperature, the AGV-80 automatic system automatically stops the gas supply to the burner. The fire on the burner goes out. If the set water heating value decreases (when taken through a tap and then refilled with “fresh” cold water or as a result of heat loss from the heating system), the gas supply is resumed. The aforementioned thermostat is responsible for this. Self-ignition occurs from the igniter flame.

User manual

Activating the system is a rather complex procedure, so we will provide step-by-step instructions for using it.

- First you need to pour water into the device and check whether there is traction in it. You should also make sure that the temperature control lever is closed.

- Next, open the tap to supply gas to the boiler.

- We open the viewing window - to do this you need to move a special flap.

- We tighten the air regulators.

- We light the piece of paper, press the activation button and, holding it in this way, bring the burning piece of paper to the igniter through the window.

- After thirty to sixty seconds, the button should be released, and the fire on the igniter should remain. If this does not happen, the operation is repeated.

But the main burner is ignited as follows:

- Turn the temperature dial until the main burner lights up.

- Adjust the air supply until the fire turns bluish.

- We set the temperature mode we need.

Important! To avoid “popping” noises when a fire occurs, make sure each time that the temperature and air regulators are in the full position

Features and differences of AOGV from other gas heaters

Versatility and autonomy are the main advantages of a boiler in a private home. The versatility lies in the fact that the equipment can operate not only from a centralized gas pipeline, but also from bottled gas - just change the type of burner. In addition, in the absence of electricity, the electronic control system is successfully replaced by mechanical automation - this is complete energy independence and autonomy.

For housing of different sizes, you can select boilers of the appropriate power, and this parameter is reflected in the marking of the unit: thus, the brand of boiler AOGV 17 stands for gas-fired water heating unit with a maximum power of 17 kW.

Schematic diagram of the AOGV boiler

Heat-generating elements of the unit: automation devices and sensors, combustion chamber, jacket (heat exchanger), air duct (chimney duct). In the Russian Federation, the main suppliers of this autonomous heating equipment are the Borinsky and Zhukovsky plants - all Zhukovsky and Borinsky aogv are produced in a floor-standing version. The Borinsky plant produces floor-standing heaters in a rectangular casing, with automation located in the same casing at the back. All automation is installed in different versions and configurations - this can be domestic mechanical and/or electronic equipment, as well as automation made in Europe or America.

The Borinsky plant produces boilers with a rated power of 7, 11, 17, 23 and 29 kW in two modifications - a single-circuit boiler and a combined unit with two circuits, and this allows you to heat even small houses with a total area of up to 70 m2 in an economical mode. This feature demonstrates the advantage of Borin units over Zhukov units, which are designed for large areas.

Gas boiler produced by Borinsky plant

The copper thermocouple is the next main element of the circuit, which activates the solenoid valve, which shuts off the gas into the combustion chamber when the wick is extinguished. The combustion chamber, which is equipped with gas boilers for private houses of the AOGV brand, is open, which means that air to support combustion enters the chamber from the surrounding atmosphere. Such an installation scheme must provide for the presence of both natural and forced ventilation in a private house. But if there is good natural draft, an electric fan can be used only in extreme cases.

Ventilation diagram for gas heating

The coolant jacket is located in the upper part of the combustion chamber, above the burner. Both circuits (if the AOGV boiler is double-circuit) have their own separate heat exchanger with separated flows of water and/or coolant.

Zhukovsky Machine-Building Plant produces AOGV boiler with rated power of 11, 17, 23 and 29 kW in three versions: economical heater (economy class), universal boiler (universal class), and comfort class.

The automation in these units differs depending on the configuration and country of origin. All boilers have piezoelectric burner ignition, which corresponds to the definition of heater autonomy. Depending on the power of the device, you can find out from the markings in the passport how much area a particular unit can heat.

New generation of AGV devices

The main model produced at Russian factories is AOGV-23.2-1 (domestic gas heating apparatus). It is designed to heat houses with an area of 140-200 square meters. There is a device with less power, designed to heat areas of 100-140 m2. In appearance, these two brands are practically no different from each other.

Not so long ago, manufacturers began to offer a new combined model AKGV-23.2-1 with a water circuit. This unit can be used both for heating the house and for organizing the supply of hot water. Its filling has also changed. Instead of a pipe running inside the boiler, manufacturers began to install three steel sections. They are made by stamping and are hollow inside. The sections are mounted vertically, connecting into one chimney, through which gas combustion products enter a separate chimney pipe.

The most amazing thing is that water for domestic needs is heated using a coil that encircles the entire circuit inside the boiler. Water flows through it, which is used for everyday life. And in the boiler itself the water for heating is heated. An excellent device, so to speak, two in one. By the way, the coil is made of copper pipe.

An injection burner has been added to the kit of the new model, ensuring efficient combustion of gas without residue. This type of burner works great even if the gas pressure in the pipeline drops.

AKGV-23.2-1 with water circuit

Special conversation about the automation of the new AGV. This is a unique system that completely controls the entire water heating process. The automation unit consists of:

- Thermal sensor that controls the water temperature;

- An electromagnet responsible for controlling the main gas supply valve;

- Thermocouple, which is installed near the igniter. It is heated by a constantly burning torch, thereby creating an electric current in the circuit. And the current guarantees that the gas supply valve will always be open;

- A draft sensor, which is mounted in the chimney and monitors the effective draft of the pipe.

In general, the automation unit will never give you the opportunity to play a cruel joke on you if one of the indicators of the boiler’s efficient operation suddenly goes wrong. There will be no fire or gas leak. The most important thing is that the automation is correctly adjusted.

History No. 943054

AGV-3u or auto-degassing station is designed for degassing uniforms, felted shoes, equipment and personal protective equipment contaminated with droplet-liquid toxic substances and their vapors with a steam-air-ammonia mixture.

The station can also be used for disinfection and disinsection of uniforms, shoes, equipment and personal protective equipment. The station consists of a power, two degassing and auxiliary machines, the equipment of which is located on ZIL-131 vehicles. Now about the main thing. For degassing and disinfection of personnel arriving from the affected area, wearing protective equipment, the kit includes a special folding tent. The tent is connected by a special hose to a power plant from which steam is released at 110 degrees Celsius and hot water heated by the same power plant can be supplied separately.

The width of the tent is less than a meter, the length is 3-4 meters, I don’t remember exactly. In general, the personnel there seem to be standing in line for heaven.

In peacetime, chemists, that is, the RCBZ, use the tent as a bathhouse. 110 degrees after all. At the training camp after the fourth year, our entire battalion was struck down by dysentery; the city bathhouse refused to wash students who were not systematically pooping. They were also not allowed into the division room for the sake of protection from bacteriological damage to privates and officers. A washing station was set up in the field. About two hundred meters from the village with weavers (Ivanovo region). Three hundred naked men. In field. They wash themselves in the shower using improvised means. And one by one they go into these steaming tents.

Out of pure curiosity, the division commander arrived to watch this action. And he was extremely annoyed by the obscenities that were being heard around the area.

“You’re crazy,” he said, “to the head of the department.” My officers don’t swear like your crap intelligentsia. Stop immediately. And let them set up a separate, newer tent for us, let’s go take a steam bath.

And they got a new one. And instead of the old proven hose for supplying steam, they also took a new one. Oiled. And they gave steam. Those same 110 degrees.

From the tent. But I must say that it’s dark, steamy and you’ll just get out of there. Pushing each other. On all fours. Two undressed colonels got out. Brown in color with iridescent oil stains. Everything was silent except for the engine of the power plant. Two cuckoos in the forest shut up, missing one of them by ten years. And over the field hung such a military mat, which a thousand experienced shoemakers are not capable of.

“You see,” half an hour later one washed-up colonel said to another, pouring cognac into an aluminum mug, “and you, you say, are the intelligentsia.” Still, the right officer is capable of cursing anyone.

Speaker repair

AGV – 80 gas heating boiler. Technical characteristics of agv-80:

- Heat load 6000kcal/h

- Water temperature setting 40 - 90gr/C

- Heated room area up to 60m2

Main components of the AGV-80 heating boiler.

- Galvanized tank (80 liters), thermal insulation, min. cotton wool. In the center of the tank is a flame tube with a heat flow extender.

- The main burner, in front of it, the tap regulates the gas supply.

- Automatic security.

- For flame, solenoid valve, thermocouple, igniter.

- For draft, tee, connected pipe, draft sensor.

- Temperature-thermostat.

Boiler solenoid valve. The boiler solenoid valve consists of two parts: gas and electromagnetic. There is a membrane between them. The thermocouple consists of two metals, chromel and copel, welded together. The flame heats the boiler thermostat, generating an electric current that magnetizes the core. By pressing the start button, the armature is pressed against the core by a pusher, while the paired valves move inside the gas part, opening the gas to the boiler igniter and compressing the return spring. At the end of the thermocouple warming up for 60 seconds, you must smoothly release the boiler button; under the action of the return spring, the paired valves are shifted back - 2.3 mm. Gas opens to both the igniter and the main burner of the boiler. The valve cannot return completely to its original position. They are held by an anchor magnetized to the core. If the igniter goes out, then the thermocouple of the heating boiler cools down and the magnet releases the armature; the return spring pushes the valve to its original position, no gas flows to the burner.

Malfunctions of the gas heating boiler AGV-80

- Contamination of the surface of the core and armature (clean, degrease)

- Thermocouple burnt out (Replace)

- No electrical contact.

Automatic traction (with gas removal from the igniter)

Gas from the electromagnetic valve of the heating boiler flows through the tee to the igniter, as well as through the connecting tube to the draft sensor installed under the hood of the device. The draft sensor is a bimetallic plate with a plug, which, during normal draft, closes the gas from the connecting tube. When the draft is covered, combustion products come out from under the hood and heat the bimetallic plate. It unbends, the plug opens the gas from the connecting tube, and gas is supplied to the igniter. Response time from 10 to 60 seconds.

Gas boiler thermostat. Operation accuracy 5gC, thermostat parts.

- Frame.

- Toggle lever system.

- Valve with spring.

- A brass tube with an invectar rod is screwed into it.

- Lever for thermostat.

When the water in the tank is heated, the brass tube lengthens, but the intar rod does not. The rod moves behind the tube and stops pressing on the system of closed levers, which, under the action of a spring, closes the valve with a click, blocks the passage of gas to the burner; when the water cools, the brass tube shortens; the rod presses on the levers, they close and turn off the valve. When the setting lever is rotated counterclockwise, the response temperature increases.

Malfunction of the boiler thermostat.

- The thermostat does not work and cannot be adjusted: The lever system has stretched or burst.

- The large or small levers are deformed.

- The supporting edges of the levers are worn

The thermostat operates but does not stop the gas supply: The valve stem sets the guide bushing.

AGV, or automatic gas water heater, is an element of the heating system, thanks to which it becomes easy to operate along with a fairly long service life. However, the presence of these characteristics is possible only if the gas boiler is properly installed and properly maintained.

Epilogue

In conclusion, it is worth recalling that the repair of AGV, along with the maintenance of gas boilers, are quite difficult operations that must be carried out by specialists. Only by observing this condition can the risk of damage to housing and injury to its inhabitants be eliminated.

Repair of AGV, OAGV, gas heating boilers 8-903605-49-99

Features of operation of AGV 80

The manufacturer stipulates that certain phenomena may occur during operation of an automatic gas water heater. Below is a list of them and recommended actions to eliminate them (according to the operating instructions for this unit):

- Starting the device after a long break may be accompanied by a concentration of moisture droplets at the bottom of the container. This occurs as a result of the accumulation of condensate particles formed as a result of temperature differences on different sides of the walls. After the water temperature reaches 25-30°, the accumulation of condensate stops.

- Periodic gurgling sounds heard from the insides of the working volume are explained by the movement of heated water particles up and cold particles down.

- As a result of long service, foreign bodies may accumulate inside the working volume. They are often presented in the form of tow, clay or limestone deposits, rust or other particles of third-party origin. To reduce their concentration on the key elements of the water heater, it is necessary to periodically carry out high-quality cleaning of the internal system. This is done by flushing the heating system and tank two or three times with a strong stream of water, connecting through the inlet fitting.

AGV 80 with a modern heating systemSource eco-kotly.ru

Generation of new AGV systems

Some units are produced at Russian factories. One of them is AOGV-23.2-1, which structurally looks like a household heating cylinder. It is used in houses with an area of 140-200 square meters. There is a unit with a lower heating power - approximately 100-140 square meters. Apart from power, these two devices are no different from each other.

Recently, a new system was released called AKGV (Combined Gas Water Heating Apparatus). According to the method of use, it is no different from AGV; it is used both for heating the house and for supplying hot water. But the design of the AKGV unit is different - instead of a pipe that goes inside the boiler, three steel sections are installed, which are stamped in a special way, they are mounted in a vertical position and connected into one chimney.

This device is rightly called “two in one”, because it initially heats the water using a coil, which is encircled along the entire contour of the boiler. The water flowing through the coil is used for domestic purposes, and in the boiler the water is heated for heating.

The newest models have an injection burner. It ensures gas combustion without residue and works even when the gas pressure drops.

Automation of the new AGV

This irreplaceable item fully controls water heating and consists of:

- Thermal sensor, which gives the system an idea of the current temperature;

- Electromagnet - valve control device;

- Thermocouples, which are installed next to the igniter and are responsible for generating electric current when heated from the torch;

- Traction sensor. It is installed in the chimney to control draft.

With proper adjustment, the automation unit will prevent sudden shutdown of the AOGV in the event of a breakdown or failure in the boiler settings, and most importantly, will extend its service life.

If we talk about the origins, this type of heating equipment was developed back in the 50s, due to the lack of central heating in villages, villages and small towns. Since then, AGVs began to systematically gain popularity, and soon most houses in the USSR began to be heated with them. Thus, this system, of course, after modernization and modifications, fits well into modern realities

It is only important to know how to choose AGV heating, remember the rules for handling this system and follow them, then the boiler will serve you much longer than its declared service life. After all, the system in which hot water circulates does not tolerate jokes and amateur activities. In general, this system is quite economical both in terms of funds and in terms of space occupied

And with the introduction of ACS (Automated Control Systems), its operation and maintenance does not cause any trouble at all. After proper setup, according to instructions or with the help of a specialist, the coefficient of intervention on your part becomes minimal, and guarantees warmth to your home

In general, this system is quite economical both in terms of funds and in terms of space occupied. And with the introduction of ACS (Automated Control Systems), its operation and maintenance does not cause any trouble at all. After proper setup, according to the instructions or with the help of a specialist, the coefficient of intervention on your part becomes minimal and guarantees warmth to your home.

Thermocouple check

In order to check the AGV-120 thermocouple, you should unscrew the union nut, which is located to the left of the solenoid valve. Then you need to turn on the igniter and use a multimeter to measure the value of the constant voltage at its contacts.

Removing thermocouple AGV-120Source tskl.ru

In a heated state, 25-30 mV should form. If the measuring device shows a lower value, the thermocouple has become unusable.

The final check is carried out as follows:

- The tube is disconnected from the magnetic tip.

- A multimeter measures the resistance of a heated thermocouple.

- It should be less than 1 ohm.

- If the multimeter screen displays 100 Ohms or more, a new one is installed.

The discrepancy between the values produced by a thermocouple and the real ones can occur for a number of reasons. The most popular are:

- The igniter nozzles are clogged, which affects the thermocouple heating temperature below the nominal value. It is easy to solve the problem; to do this, just use a soft copper wire to clean the igniter channel.

- Displacement of the thermocouple position relative to the flame. This affects the insufficient heating of its tip. To eliminate the defect, it is necessary to loosen the screw that secures the wiring next to the igniter and adjust the location of the tip.

How to repair an AGV-120 with your own handsSource images.ru

If the voltage of the thermocouple tips is normal, you should check the following nuances:

- Traces of oxidation and integrity of contacts at the junction of the draft sensor and thermocouple. If a malfunction is detected, fix it: create a new contact or clean the old (oxidized) one. When performing these manipulations, you should be careful, since the union nut is tightened by hand, since a strong clamp can damage the soft wiring.

- There is no break in the contacts of the electromagnetic winding. If a malfunction is detected, they are soldered. To check the functionality of the electromagnetic coil itself, you will need to disconnect it from the thermocouple wiring, press and hold the start button, and light the igniter. A voltage of 1-2 V is supplied to the electromagnetic contact (from a AA battery). If, after releasing the button, the igniter continues to burn, then no malfunctions were detected in the operation of the electromagnet and the draft sensor.

- Traction sensor performance. First of all, you should make sure the quality of the contact clamp and the bimetallic plate (in most cases, malfunctions in its operation occur precisely for this reason). To do this, you need to break the contact, clean the above-mentioned washer and wiring and reconnect. There is no need to make additional adjustments; if there is good contact, this will not affect the sensor response temperature in any way.

Modernization of AGV boilers by the manufacturer

The boiler manufacturer AGV was in no hurry to discontinue them due to obvious advantages.

However, taking into account that this equipment needed a thorough modernization, the following design changes were made:

- Fragile glass thermometers have been replaced with more reliable instruments made in Italy;

- The new systems were equipped with automation from the American company Honeywell;

- To turn on the device with a handle, a piezo ignition system was used;

- New coating technology has made the appearance of the unit more aesthetically pleasing.

Boiler diagram AOGV - 23

Rules for handling the heating system

The unit is installed in a separate room. It is advisable that this room be soundproofed, since when the boiler burner is turned on, a rather loud bang occurs.

In some new modifications (AOGV-23.2-1-U), this drawback has been largely eliminated, since when the water overheats, the automation does not turn off the burner completely, but switches it to a mode in which the flame is minimal.

A chimney (with a diameter of 140 mm) for combustion products is installed outside residential premises. Below the junction of the pipe from the heating tank with the chimney, there is a garbage container - a “pocket” for foreign objects and waste that accidentally fell into the channel.

Option for a chimney for AGV in a private house

For the unit, a room should be allocated in the lower part of the building. The ascending pipeline needs insulation. The return line should not be insulated.

The installation instructions for heat transfer devices (radiators, convectors and heating panels) provide for their installation at the highest possible height from the unit itself. To circulate layers of air, such devices should be installed under windows. The return pipeline is laid under the floor of the room.

If the return line is laid above the door jambs, airing of the system may occur.

General view of a fragment of the pipe layout of a heating system with AGV

Two-inch network pipes do not look very aesthetically pleasing, however, when replacing them with pipes of smaller diameter, it is necessary to take into account that as the diameter of the pipe decreases, hydrodynamic resistance increases, which weakens the water pressure in the system. This, of course, can seriously impair the performance of such a unit.

AOGV connection: rear view

During installation, pipelines are installed with a slope of 1 cm for each meter of pipe length. This avoids the appearance of air locks in the system, facilitates water circulation and allows water to be drained from the system.

This video examines some practical issues of installing AGV in a private home:

Some Caveats

- When the water temperature in the system drops below 55-50°C, condensate begins to release abundantly. If it accumulates, it can extinguish burners;

- Combustion products, when mixed with condensate, form nitric and sulfuric acids, which cause corrosion of equipment;

- If the water temperature in the system drops below 50°, then its circulation in the system almost completely stops;

- If the room is not heated in winter, the water from the system must be drained, but in this case corrosion increases significantly;

- To get hot water without heating the entire system, you can use a tap that shuts off the circulation in the heating system. And if you connect the forward and return lines, you can maintain turnover.

Have a warm winter!

Advantages and disadvantages of AGV

Like any device, AGV also has its advantages and disadvantages. Its main advantages are:

- reliability and safety during operation;

- independence from power supply;

- possibility of heating automation;

- the use of various installation methods (wall or floor);

- simplicity of design, which allows for high-quality and reliable maintenance of the equipment;

- low cost and economical operation.

There are two main disadvantages:

- some massive equipment, which occupies about 1 m3. Therefore, AGVs are often installed in a separate room.

- deterioration of the design of heated rooms (pipes, radiators or registers), which forces the use of additional elements when arranging the interior.

The best condensing gas boilers

These boilers are considered the most economical because they can use the energy of not only gas combustion, but also condensing steam. As a result, their efficiency is almost close to the coveted 100%.

Vaillant ecoTEC plus VUW

89%

buyers recommend this product

Stuffed with intelligent electronics and eBus switching, the unit works not only for efficient heating, but also for preparing hot water, that is, it also belongs to double-circuit units. The capacitor system is more environmentally friendly compared to the traditional one, and also provides a very high efficiency of 98%.

The combustion chamber is equipped with a modulating burner with wide power adjustment capabilities (from 28 to 100 percent). With such efficiency and equipment, the dimensions of the boiler are quite acceptable: 720x440x372 mm. The ecoTEC line itself consists of three models with a maximum power of 24, 30 and 34 kW.

Advantages:

- Digital control and diagnostic system;

- The most informative panel;

- Possibility of control from a mobile phone and connection to a “smart home”;

- The burner can receive air both from the room and from the street;

- Short-term increase in power for quick water heating;

- Removal of condensate outside.

Flaws:

- Difficult to repair;

- High price.

ecoTEC Plus boilers still scare off many due to their high cost. But there is minimal hassle with them, and the fuel savings will pay off the investment over time.

Viessmann Vitodens 100-W

88%

buyers recommend this product

An expensive boiler, capable of operating at a power of 4.7-35 kW, saves not only blue fuel, but also electricity - due to the adjustable operation of the fan. This model also has other highlights. We are talking about a cylindrical MatriX burner, consisting of many micro-nozzles, which practically does not allow heat loss. A ring heat exchanger made of stainless steel works no less efficiently.

Advantages:

- Compact housing 400x400x350 mm;

- Two ways to prepare hot water;

- Maximum efficiency and energy efficiency;

- High efficiency (98%);

- Intelligent automation;

- Remote control – from a touch panel or smartphone;

- Possibility of working on LNG and biogas;

- Easy access for repairs and maintenance.

Flaws:

Price.

If your home is equipped with a smart home system, the equally smart Viessmann Vitodens will be the best solution for creating a heating and hot water system.

Viessmann Vitopend 100-W A1HB003

Baxi Eco Four 1.24 F

Vaillant AtmoTEC Plus VU 240/5-5

Heating power 34 kW 24 kW 24 kW Type single-circuit single-circuit single-circuit Efficiency 90% 92.9% 91% Combustion chamber closed closed open

About the types of gas equipment

Installation of gas boilers

Installing gas equipment in any case will require going through the authorities, obtaining the necessary permits and a whole heap of various documents. Both the devices and the room itself must meet the requirements and standards laid down in the regulatory documentation. Installation of units must be carried out according to the rules. However, before you start visiting regulatory organizations, it is worth understanding the types of gas equipment used for heating and hot water supply.

To create a complete heating and hot water supply system, you will need to install a double-circuit boiler. The unit must have all the necessary automation. Such devices are expensive, and their installation should only be carried out by specialists.

The budget option is to use gas equipment only to produce hot water. That is, we are talking about a gas water heater. Compared to electric heaters, it is more efficient and cheaper to operate. Even an expensive device will pay for itself in about a year and a half. Here you need to take into account that its installation is not permissible in all apartments. The advantage of water heaters is that you can easily install them yourself. You need to decide which option to choose based on specific conditions.

What is the difference between non-volatile and conventional boilers?

Conventional (volatile) boilers require an electrical supply, without which they cannot operate. The turbofan, circulation pump, and electronic control board require high-quality and stable power supply.

Particularly capricious are control boards, which immediately fail when the current parameters change. Manufacturers claim the ability to withstand large voltage fluctuations, but in practice this is not observed.

At the same time, volatile units have a set of additional capabilities - they can be controlled remotely, integrated into a smart home system, and programmed for some time in advance.

Non-volatile boilers do not have all these additions. They work exclusively with the help of mechanical components and parts, like a regular gas stove.

The design of such units is devoid of all unnecessary components, it is functional and therefore very reliable. In addition, owners of non-volatile boilers do not face the risk of being left without heating in the event of a sudden power outage.

Dilapidated and overloaded networks are a typical phenomenon for remote villages, so the use of independent heating systems is very valuable for many users.

Types by type of smoke removal and which one is better?

There are two types of smoke removal systems:

- Open (atmospheric). It works on the principle of stove draft; smoke is removed through a common house or its own vertical chimney.

- Closed (turbocharged). The smoke is forced out by the turbocharger fan.

Natural cravings are unstable and depend on many external factors. Sometimes a reverse draft occurs, which, instead of removing the smoke, begins to draw it indoors.

Turbocharged boilers are completely free of such problems and demonstrate a stable smoke removal regime in any conditions. This makes the choice of atmospheric installations less attractive, however, all non-volatile boilers operate on this principle.

In order to get rid of possible problems, external additional devices are used - turbo nozzles.

They help stabilize and equalize the smoke removal regime, although they can only work if there is a power supply.