The mid-90s of the last century was a turning point for the building materials market. Practical and inexpensive types of thermal insulation began to appear, for example, mineral wool, glass wool, and cellulose-based insulation. These materials attract the attention of buyers with their affordable price and relatively good characteristics.

However, there are also significant drawbacks. In particular, these are quite large materials, and the thickness of the insulation board “conceals” the interior space of the premises. In addition, such thermal insulation can dry out and become painted, which invariably leads to heat loss. Of course, mineral wool is still considered one of the popular thermal insulation materials today.

However, this is not due to high efficiency, but to an affordable price. If there is a need for really high-quality thermal insulation of premises, penoizol is used during construction. This is a liquid insulation material that is rapidly gaining popularity in our country.

What kind of thermal insulation material is this?

Let's start with definitions. The name "Penoizol" is a trademark of insulation created on the basis of urea resins. The material is in high demand, so it has become a household name, combining the following names:

- "Teploizol"

- "Mipora"

- "Unipor"

- "Mettemplast"

However, among professional builders, insulation is better known as liquid or poured foam.

In appearance, thermal insulation resembles marshmallows, which, after hardening, turns into an elastic mass that is guaranteed to fill all voids.

The composition of the insulation includes the following components:

- Urea resin

- Orthophosphoric acid

- Foaming additives

The ingredients are mixed in certain proportions and pumped into special cylinders where the mixture is under pressure.

How to make penoizol yourself

Ready-made liquid foam is very expensive, but if you make it yourself, it will cost you much less.

But even if you prefer finished products, ask the seller about the availability of quality certificates and information about the composition of the product. If you follow all the stages of creating penoizol yourself, the insulation process with its help will be high-quality and effective.

In order to make penoizol with your own hands, you need to mix water foam with a hardener and urea resin. Then you need to let the finished substance harden.

After hardening, the material takes the form of foam. It should be applied to the surface in the form of a thick mixture. Thanks to this consistency, you can insulate even the most inaccessible places; take care of the method of applying pressure so that the foam can completely cover the surfaces.

After hardening, the material serves as insulation. Insulated in this way, the house does not need excessive heating, therefore, you can save on this.

First you should pour the material onto the insulated surface , adhering to all recommendations regarding the installation of the gap.

As a rule, to insulate a house with an area of about 70 square meters, you need to allocate about 6 hours for repair work. If you invite a team of specialists to do this, they will probably do it better and faster, but you will significantly reduce costs on your own.

To insulate the surface with liquid foam, you need to fill all empty areas of the walls with foam. To do this, you first need to drill holes and insert a hose into them. And the pressure will ensure the tightest possible fit of the foam to the wall and will ensure that all penoizol and cavities are closed.

Technical characteristics of urea-formaldehyde foam (UFP)

It is believed that, in terms of its stated performance properties, penoizol is superior to any insulation available on the domestic market. The main characteristics of thermal insulation look like this:

- Thermal efficiency . The thermal conductivity of insulation varies between 0.031-0.041 W/m on the Kelvin scale. 10 cm layer of liquid foam to provide reliable insulation to the interior.

- Soundproofing . Penoizol absorbs up to 65% of street noise, which is considered a very good indicator.

- Fire safety . The material is not flammable and does not support combustion. However, when exposed to high temperatures, the insulation will simply evaporate without releasing toxic substances into the air.

- Dependence on chemical and biological factors . The insulation is neutral to any aggressive environment. In addition, the insulation is of no interest to rodents and is resistant to pathogenic microflora: fungus, mold.

- Moisture resistance . The material absorbs moisture well, but subsequently evaporates it without losing its original properties. Given this feature, it is recommended to install ventilation gaps to prevent the appearance of mold on the walls.

- Durability . Indicators of linear compression of insulation are 0.07-0.5 kg/cm2 . Accordingly, the material holds its shape well and quickly restores its structure.

Manufacturers claim that thermal insulation can last 30-50 years without loss of quality. However, insulation appeared on the market relatively recently, so there is no evidence of such an impressive service life yet.

Insulation with polyurethane foam - step-by-step diagram

Step 1: Preparing for work

If you are filling a cavity between walls where there will be nothing but foam, then no special preparation is required.

Also, you don’t need to worry too much if you spray foam; you will then lay all communications directly in it. The only thing is that to spray the foam you need a frame that will divide your wall into sections, which you will fill in turn. Usually this role is performed by the sheathing. The rest of the preparation will consist of following safety precautions, get a respirator, goggles, preferably a mask to cover your face, a thick work suit and gloves. Foam is difficult to remove not only with solvents, but also with acids, so you risk wearing the “gift” on your skin for a very long time. If you are pouring polyurethane foam into a wall with finishing, but you need to drill technological holes in it according to the size of the hose, the first one is at the level of the middle of the wall, the second one is at the top. Seal all holes and cracks with masking tape so that, as the material expands, it does not leak out and pollute your wall; damage in the form of several holes will be enough. These gaps include sockets for sockets, window and door openings, etc. If there are any niches, then they should not only be glued, but also the fabric should be stuffed there in a dense layer.

Step 2: Pouring and Spraying Foam

To spray, you just need to spray starting from the bottom. Apply a small layer and work your way up evenly. Having sprayed 30 centimeters high, stop, watch how the foam expands, how thick it is, and how far up it will creep. If necessary, spray a little more foam on top of the finished layer, achieving the desired thickness. This way you will develop the desired pace of work and spraying strategy.

Advantages and disadvantages of hardened thermofoam

The popularity of penoizol did not arise out of nowhere. Among the undeniable advantages of insulation are the following features:

- High technical properties - even a 45 mm can prevent heat loss.

- Resistance to dynamic loads - the elastic structure allows it to be restored to its original state even after prolonged compression.

- Neutrality to any external influences - sudden temperature changes do not affect the quality of the insulation.

- Excellent adhesion - thanks to its liquid structure, thermal insulation adheres well to any surface and fills all voids.

- Multifunctionality - insulation is suitable for any structure, regardless of geometric shape.

- Vapor permeability - when using penoizol, condensation does not form on the walls, which is very useful for wooden structures.

In addition, liquid foam does not form cold bridges.

Of course, it wasn't without its drawbacks. The weak points of insulation are:

- Shrinkage - after pouring, the volume of material can be reduced by 0.1-5%.

- Moisture absorption - when it comes to insulating the foundation, this parameter can be regarded as a disadvantage.

- Dependence on temperature conditions - you can work with penoizol only at air temperatures above +5 degrees .

- Low tensile strength - despite the elastic structure, the insulation is easily torn and pierced, which violates the thermal insulation performance.

The disadvantages include high cost. It is curious, but the price of insulation does not exceed the cost of mineral wool and other thermal insulation materials. However, pouring liquid foam requires special equipment, which private developers do not have.

Therefore, you have to rent equipment or hire a team of construction workers, which adds to the overall cost of the work.

Technology of home insulation using penoizol

The surface should be filled with liquid foam directly at the construction site, so everything happens easily and quickly. Penoizol does not expand, but may experience slight shrinkage. In order to prevent cracks from appearing during the shrinkage process, you must strictly follow all the rules for insulating houses using this material.

As we said earlier, carefully choose purchased penoizol or material for its own preparation. Read the instructions carefully .

When dry, polystyrene foam is suitable for insulating any surface. After pouring it, a seamless layer appears, which has excellent characteristics in terms of sound and heat insulation. Despite minor cracks, this protective layer practically does not allow moisture to enter the house.

Independent reviews from construction forums

To understand the real effectiveness of insulation, you should not unconditionally trust the words of sellers and manufacturers. It will be much more effective to turn to the reviews of real people who have already used the subject of our conversation for insulation. Let us immediately note that opinions on the properties of liquid thermal insulation are divided.

Not bad, but there was a small nuance. Alexander (www.forumhouse.ru)

Penoizol is an excellent alternative to any type of modern insulation. The price is quite reasonable, the mice will not be stolen, the declared characteristics are at a high level. However, during practical use, a small drawback emerged: when insulating wooden walls, unfilled areas remained.

Recommended by friends. The house has a comfortable microclimate. Ildar (mastergrad.com)

We decided to insulate the walls with foam insulation about 5 years ago: the outer wall is made of block and brick. 6-7 centimeters left between the masonry . Glass wool and mineral wool did not give the expected result: the wall began to mold, the rooms were quite cool.

Friends recommended penoizol. As the crew worked, one could hear and see the insulation filling the space between the walls, emerging from the cracks. Now the house maintains a comfortable microclimate at any time of the year.

No complaints, but problems arose during the filling process. Mikhail (forumnov.com)

It is clear that seamless insulation has undeniable advantages. There are no complaints about the quality of insulation, however, for the operation of the equipment, a connection to a 380 V . I did not have such an opportunity, which caused some difficulties during the pouring process.

I really don't like the toxic smell. Konstantin (forum.vashdom.ru)

After pouring, penoizol noticeably decreased in volume, which already reduces the quality of thermal insulation. In addition, the material has an unpleasant and clearly toxic odor. They said that the composition includes formaldehyde, the use of which has long been abandoned in European countries. I recently insulated the house, so I can’t say anything about the properties of the material, however, doubts about the correctness of the choice are already tormenting me.

The price of the work is steep. Eduard (www.forumhouse.ru)

Personally, I am satisfied that penoizol will not be chewed by mice, the insulation accurately fills any gaps, and provides reliable heat and sound insulation. I didn't like the fragility of the material and its susceptibility to deformation. And the overall price of the work is a bit steep.

Where to start finishing

If during the work the foam composition is poured into the layer between the elements of a well or three-layer masonry, prepare holes in the material of the outer layer to supply insulation through them. This applies to already completed buildings. When insulating structures during their construction, drilling is not required.

It is necessary to clean the base from dust, prepare a frame or sheathing, between the elements of which liquid material will foam.

At the preparatory stage, it is important to choose high-quality working material. When purchasing the composition, a demonstration sample of the prepared penoizol should be dazzling white, not literally settle before our eyes after leaving the supply hose, after 12-15 minutes. must withstand pressure by hand and quickly restore its shape; large or heterogeneous pores should not form in the volume of high-quality insulation.

Rules for pouring liquid foam

In order for penoizol to fully live up to the hopes placed on it, it is necessary to strictly adhere to the pouring technology. If this is your first time dealing with liquid thermal insulation, it is better to immediately contact specialists who can do the job efficiently.

Wall insulation is carried out according to the following scheme:

- Holes are drilled in the wall structures, into which penoizol is pumped through filling hoses.

- Install a protective facade made of metal profiles, leaving a gap of 5-10 cm between the wall and the metal.

- Fill the free space with insulation.

- Wait 4 hours for the material to set, cut off excess insulation, and begin finishing.

Roof insulation:

- The surface intended for insulation is covered with a film, which should extend 10-15 cm .

- Fix the membrane with staples.

- The slats are stuffed on top of the film.

- The space between the slats is filled with insulation.

- Wait 15-20 minutes for the insulation to become viscous and level the surface.

- After 4 hours, you can begin further work.

Floor insulation:

- Wooden sheathing is being installed.

- All sections are filled with insulation.

- When the material hardens, a plastic film is placed on top.

- Finishing is carried out: boards are laid or concrete is poured.

In principle, working with penoizol is practically no different from installing other types of insulation.

Tools

When filling internal gaps and cavities, you will need a hammer drill (to form foam filling points) and a knife to remove dried excess insulation.

When insulating surfaces, a frame can be constructed; usually, subsequent protection of the insulation with vapor barrier films and a layer of facing material is required. In these cases, the list of tools is supplemented by a drill, screwdriver, hammer, level, and stapler. Due to the specifics of the work and differences in objects, the list may be adjusted upward and vice versa.

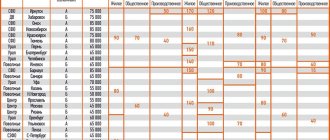

Consumption rates for insulating material per 1m2

When planning a construction budget, you need to accurately determine the amount of material. To determine the amount of liquid insulation that will be required to insulate the entire building, you need to know the consumption rates of penoizol per square meter.

According to manufacturers, the consumption of liquid foam per 1 m2 varies between 1-1.3 liters.

To calculate the required amount of material, you need to multiply the length and width of the wall by the consumption rates stated by the manufacturer. For example: 7*3.2*1.3=29.12 l. In this case, the final amount of thermal insulation must be taken with a small margin, taking into account unforeseen situations.

Myths about the dangers of foamed plastics

Conspiracy theorists and unscrupulous advertisers of competing classes of insulation products often spread rumors about the terrible health risks caused by foamed plastics.

If you look at it without hysterics and exaggeration, polyurethane foam actually has one property that carries a potential threat.

When burned, it can form toxic volatile substances based on formaldehyde resins. During a fire, this may be an additional risk factor for those who did not have time to leave the burning premises.

During application of the foaming composition, some inert gas and other chemical compounds are also released.

However, after the foam coating has completely hardened for the entire period of its operation, no harmful emissions occur. The complete film surrounding each microcell is chemically inert and impermeable.

To summarize, we can say that the foam coating is completely safe during operation.

During application, all precautions specified in the user manual should be observed:

- use only serviceable equipment;

- exclude the use of open fire and high-temperature heating devices during application;

- use personal protective equipment: respirator, gloves, protective overalls with a hood and thick shoes;

- When working indoors, ensure ventilation

- do not use the premises for people to stay in them until the composition has completely hardened (usually 24 hours.)

Of course, during the operation of foam coatings in the house, it is necessary to establish and strictly observe fire safety rules.

Manufacturers of urea foam plastic in the Russian Federation

Many companies in Russia and Europe are engaged in the production of penoizol. However, to purchase quality material, you need to take a responsible approach to choosing a manufacturer. Therefore, we advise you to pay attention to the products of such companies:

- "New construction technologies" . The company was founded in 1990 and specializes in the production of thermal and waterproofing, fiberglass, fiber-reinforced concrete. Today, this is one of the main suppliers of penoizol on the Russian market. By the way, the rights to use this trademark belong to this company.

- "Varmal LTD". This is a British company engaged in the production of liquid insulation flotofaum - the name of penoizol.

- LLC "Uveis" Russian company located in the city of Orenburg. The manufacturer has been working on the market for a long time, so it carefully monitors the quality of its products.

In addition, buyers speak positively about the products of ProTeplo LLC, Penoizol-Omsk LLC, and Murmansk Universal Plant CJSC .