Ecology of consumption. Estate: Household heating boilers have been replenished with new models - Galan electrode boilers, which have an obvious advantage. Unlike other heating devices, an electrode boiler does not require approval for installation in accordance with the current “Rules”.

Domestic heating boilers have been replenished with new models - Galan electrode boilers, which have an obvious advantage. Unlike other heating devices, an electrode boiler does not require approval for installation in accordance with the current “Rules”. What are the models of the new boiler, and what conditions exist for connecting it yourself?

Galan boilers, operating principle, technical characteristics and design

The electrode heating boiler is a heating element design equipped with materials from a European manufacturer. Let us remind you that this is AISI 316L stainless steel and nichrome with increased load capacity that can withstand a long operating cycle.

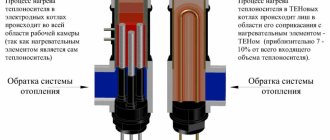

The operating principle of the galan electrode boiler is to pass electric current (electrolysis) through a special non-freezing coolant.

Electrolysis and heat transfer of the heated state of the electrodes is carried out at constant current. The compact design of the heating blocks is distinguished by the small overall dimensions and weight of the boiler assembly. The coolant of the heating electrode system is antifreeze.

technical characteristics of electrode boilers

The main technical characteristic of an electrode boiler is power.

The line of electrode boilers is represented by the models Hearth, Geyser and Vulcan.

The smallest heating boiler is the OCHAG , which has a low power consumption (from 2 to 6 kW), designed to heat an area of 120, 230 and 280 cubic meters.

For example, the electrode boiler galan hearth 3 has the following characteristics:

- overall dimensions: length 275 mm, 35 mm, device weight less than 1 kg.

- a power of 3 kW allows you to heat a room with an area of 120 m3.

GEYSER models of medium productivity have increased power - 9 and 15 kW with the ability to heat a room with an area of 340 and 550 m3. Overall dimensions are 360 and 410 mm, 130 mm, weight 5 kg.

The most powerful models are VULCAN , with a power of 25, 36 and 50 kW and are designed for heating rooms from 830 to 1650 m3.

The linear efficiency of an electrode boiler can reach 96-98%. Compared to a traditional heating element, the efficiency of an electrode boiler is up to 50% due to the method of direct heating of the coolant.

The first thing that catches your eye when you see electrode boilers is their unusual design. Instead of a pot-bellied and voluminous boiler, there are long cylindrical structures with two threaded flanges, indicated by arrows of different colors (incoming blue and outgoing red). The metal body of the boiler can have a diameter from 40 to 100 mm and a length of 310 - 350 mm. design of electrode boilers

During the process of electrolysis and when heating the coolant in the boiler, the internal pressure increases to 2 atm. The heated water is pushed upward, providing the functions of a circulation pump. In addition, galan electrode boilers are distinguished by the presence of heating automation with a simple device control system.

Multifunctional control units designed to implement a specific algorithm for the operation of electric heaters deserve special attention. It will be difficult to install and assemble an electrode boiler without certain knowledge.

The installation process boils down to installing the Galan boiler itself, attachments, piping, connecting electronics and pumping coolant into the heating system.

DIY installation

Preparation

Algorithm of actions:

- Ground.

- Protect terminals and live parts from moisture and contact with the surfaces of the unit.

- Install a circuit breaker - a switch to cut off the current. A 25 A automatic machine, for example.

- Follow the connection diagram recommended in the data sheet.

- Observe the connection rule: phase - zero - ground.

- Check the tightness of threaded and welded connections.

- Minimize, it is better to prevent the possibility of water getting on the body of the ion boiler.

- Buy an expansion tank.

- Turn off the boiler if ice forms in the heating system and defrost.

- Ensure the cleanliness of the pipeline and prevent the penetration of metal shavings and foreign substances into the device and system.

Installation

Sequence of work:

- Connect the coarse filter.

- After installation, rinse the system thoroughly with Galan inhibitor.

- Install the equipment in a vertical position, with the protective cap at the bottom.

- Secure the equipment to one of the walls of the room. The connection to the heating system is not decisive.

- The unit must be connected to the electrical network by an electrician who has permission to work with electrical equipment up to 1 kW.

- Thoroughly strip the ends of the wire of insulation.

Setting the temperature value

Procedure:

- Set the coolant outlet temperature within 70-75 ºC.

- The input temperature is calculated based on numerous factors: the volume of the heating system, the temperature of the surrounding atmospheric or air space inside the room, the condition and indicator of the thermal insulation protection of the room, the volume of space. On average, this temperature ranges from 40 to 45 ºC.

If the unit is connected correctly, the current parameter reading will be within 23 A. The equipment operates in “automatic” mode during operation. Read sewn in our article.

Contents of delivery

The delivery set of the electrode boiler from the manufacturer includes:

- electrode block with power from 3-50 kW

- power unit including circuit breaker, modular contactor and digital water thermostat

- digital thermostat for air climate control unit.

Attachments (expansion tank and pump) are not included in the delivery package, so their parameters are pre-calculated and the equipment is purchased separately.

Heating system requirements

To ensure the normal functioning of the heating system, a number of requirements must be met:

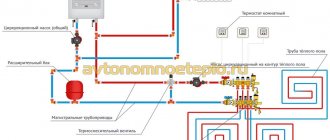

- the proposed heating system should be a closed two-pipe type with a membrane expansion tank (volume characteristics 1/10L)

- the boiler is mounted vertically, not exceeding the level of the radiators

- When piping the boiler, it is recommended to observe the ratios of the diameters of the boiler block (Ø 32), riser Ø32 (1″/1/4), main line (Ø 25), radiator outlets (Ø 20).

For connection to the heating system, cast iron, aluminum and bimetallic types of radiators are recommended, as well as a register system in compliance with the standard configuration and coolant displacement.

Electrode boiler wiring

The following components of the heating system are subject to piping of the electrode boiler:

- expansion tank

- circulation pump

- security group

- return taps and coarse filter

- coolant fill valve

- coolant drain valve from the system

- supply tap.

Before mounting and installing the galan electrode boiler, it is necessary to calculate the components of the heating system. The boiler power is calculated according to the area of the room and the height of the ceilings, as well as the material of the walls of the house or apartment. Then they determine the location of the future installation of the boiler and develop a diagram and junction of the mains, and the type of radiators.

If you plan to install the boiler into an existing heating system (in most cases), then the calculation may be limited to the correct piping and connection of the power unit and thermostat.

Very important point

Despite the fact that the boiler itself is relatively small in size, it must be installed correctly. Prepare a niche in advance and provide free access to the network. Do not forget that the equipment is powered from a three-phase network. As noted above, antifreeze or drinking water can be used as a coolant. The specific resistance of the liquid should not be less than three and more than thirty-two thousand Ohm/cm at a maximum temperature of 150 degrees. By the way, the quality of the media can be improved. This way you will extend the life of the boiler. This is quite easy to do. You can install a filter to remove mechanical impurities, which it is advisable to install on the pipeline. A significant amount of insoluble compounds will be retained, which will have a beneficial effect on the longevity of the equipment.

Galan boilers were discussed in detail above. Equipment specifications vary by model. But speaking in general, such devices can heat a room ranging in size from 75 to 550 cubic meters. In this case, the power varies from 3 to 25 kW. But how much you save depends only on the insulation of the room. Some users report savings of 45% compared to gas equipment. This is an impressive figure, but not everyone can achieve this. But everyone can reduce costs by 5-20%; the main thing is to correctly install and calibrate electronic equipment.

We install the Galan boiler

To install the Galan boiler, plastic pipes are used. In horizontal wiring it is necessary to create a slope of 3 degrees. The height of the vertical riser must be at least 2 m above the boiler. The electrode boiler requires grounding with a grounding resistance of 4 ohms.

After installing the boiler, the expansion tank and circulation pump are installed. Shut-off valves on the pipeline are installed after the return and expansion tank. Valves are installed before and after the radiator group.

How to install the boiler and standard attachments is shown here.

Boiler connection diagrams

There are several boiler connection schemes: basic standard, parallel connection and connection to a heated floor system for a rated voltage of 220 and 380 V, and many other equally interesting schemes.

The simplest are considered to be connection diagrams for a single-phase electrode boiler or a three-phase electrode boiler with control electronics, a circulation pump and a filter. But no matter what scheme you prefer to implement, grounding the installation is a prerequisite.

For example, for an electrode boiler galan hearth 3 with a power consumption rating of 3 kW, according to the basic connection diagram, a voltage with a frequency of 50 Hz and a maximum boiler phase current of 13.7 A and a starting current of 5 A are required.

In this case, the connection is made using a conductive copper wire with a cross-section of 4 mm2 and to the heating system using a DN 32 mm coupling.

But the electrode boiler remained an ordinary boiler if the heating system did not contain control elements with a unit for measuring and adjusting the operating parameters of KROS.

Full glazing of the veranda

If you don’t have the necessary tools at your dacha or in a private house, and you simply don’t have the funds to buy expensive wooden blocks, then there is only one way out - solid window frames.

In order to create such a masterpiece, you need to prepare:

- Planks of wood from which the structure will have to be made. Small blocks of 50/50 mm are best suited. They must be cut in the required quantity, after which they are fastened to the frame, which is also made independently.

- It is recommended to fasten the glass to the frame using silicone sealant, but if this is not available, then you can do it the old fashioned way with glazing beads.

- The final stage is processing the joints with platbands.