To regulate the flow of working media in pipelines, a variety of fittings are used. One of the representatives of locking and regulating mechanisms is a gate valve. A striking and oldest example of using a damper is a valve in a stove chimney. The principle of its operation is so simple and reliable that gate valves gradually began to be used to regulate working environments in many areas of everyday life and industry - from wastewater discharge to oil refining.

Why are gate valves needed?

The word “slide” has a German “pedigree”, it comes from the verb schieben ─ to push, move, thrust. Gates are metal plates (or wedges) that can block the flow and separate mechanical particles that pass through the barrier. For this reason, gate valves are used in pipes through which dry, bulk substances, heavy oil products, various types of gases, etc. move.

Like other locking products, gate valves can be operated by manual systems, or by electric or hydraulic motors. Similar types of dampers are now used in chimneys and ventilation.

A significant property of valves is the complete removal of the blocking object from the pipeline in open mode, due to which there is no resistance to the movement of exhaust gases. This property is used in cases where it is necessary to obtain a high vacuum.

Seals

Gate valves can be made with a metal-to-metal seal (metal/metal) or with the use of more airtight soft seals made of synthetic materials.

Nitrile rubber resists the effects of petrochemical products well.

The seal based on ethylene propylene diene rubber has proven itself to be extremely reliable. Russian abbreviation SKEPT; international designation EPDM.

Rubber compounds based on SKN are distinguished by their performance in contact with oils and fuel, including in areas with cold climates.

Types of gate valves

There are two main types of covering structures:

Rotary.

They are otherwise called throttle valves. A classic-looking damper is a plate that is attached to a rotating axis located in the smoke pipeline. Such dampers are not so reliable; for this reason, they are used only in cases where, for structural reasons, horizontal analogues cannot be used. Horizontal. Such retractable dampers control the flow movement in the chimney channel due to horizontally retractable plates, which allows you to change the cross-sectional area of the opening. Chimneys made of steel and brick are often equipped with similar valves. They are famous for their reliability, so if you are installing a product in a pipeline, then it is better to choose exactly this model of gate valves. It is also worth noting that the plates for such dampers are perforated or sawn through during manufacturing. The need for such actions is explained by the fact that fire safety requires that the gate valve not completely obscure the chimney opening.

What are they made of?

Knife or wedge gate valves are made of durable material. Steel is most often used, although cast iron is also sometimes found. When choosing, you should weigh the operating principle of the device, since the second option is less reliable. If the work will take place at sub-zero temperatures, then a steel gate valve will be the best choice. Impulse movements lead to a violation of the integrity of the cast iron structure. How the device can be closed:

- Manual gate valves.

- Pneumatics.

- There is also a gate valve with an electric drive.

Today, such devices are fixed to pipelines using several techniques. If wastewater, oil and sludge pass through such a design, then a flanged valve would be a suitable option. Since the fastening is carried out using bolts, it is easy to assemble or disassemble such an installation. Before installation, you should understand which design will be optimal and suitable for your installation.

A little about the functions of gate valves

The functional features of gate valves depend on the scope of their application:

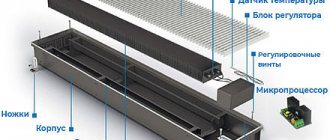

- They can be used in pipeline systems as shut-off valves, then they will act as limiters for the movement of liquids or bulk objects. These valves are called changeover valves.

- In ventilation systems, dampers perform the function of regulating air flow. By moving the valve back and forth, you can change the volume of air flow passing through the pipe, by partially or completely blocking it. Such valves are called control valves.

- In chimneys, as mentioned earlier, dampers are used as regulator valves, allowing the smoke channel to be fully or partially closed, which helps to avoid heat loss in the room.

- Chimney dampers perform another role - draft control, in other words, they act as dampers that regulate the flow of smoke. The system works according to the following principle: a large overlap of the chimney pipe cross-section leads to less air flow, which reduces draft. And vice versa: by opening the valve wide, you can provide greater air flow and increase draft, and then combustion in the furnace will be more intense and faster.

Classification by connection method

In order to ensure high reliability of operation of the system, it is necessary to consider the features of connecting shut-off valves. It can be carried out as follows:

- By welding. The valve can be connected using welding technology. It provides the required degree of sealing. Among the features of this connection method, we note that it can be used in a wide variety of cases, most often at the time of an accident. However, in such a case, quick dismantling is practically impossible.

- The flange and wafer methods are widely used today. This is due to the fact that after installation the valve can also be dismantled. If the technology is followed, the connection provides the required degree of tightness.

Today, the welding method is used less and less. This is due to the fact that the weld is characterized by relatively low strength and reliability; under variable loads and other impacts, a crack or defect may appear.

Design features of gate valves

The design of gates depends on numerous factors:

- temperature indicators of transported streams;

- type of pipeline section;

- passing conditions and so on.

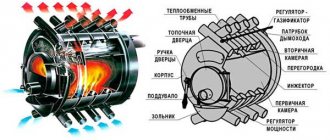

The gate valve is based on a sheet of metal of various parameters, which moves inside the chimney.

Gate valves differ according to different criteria. The valve that limits the movement of flows can be a shut-off valve or a reversible valve. The gates can be manual,

pneumatic, hydraulic, electric, etc.

The shape of the product can be straight or oblique:

- Straight gates have the usual appearance of a classic damper. They are used in supply and exhaust forced ventilation systems.

- Oblique gates are used in pneumatic transport (transportation of bulk cargo under the influence of compressed gas) and aspiration (production of powders and bulk materials) industrial systems. They were called “oblique” because of the installation method - the valves are installed at an acute angle with respect to the pipe, and not at an angle of ninety degrees, as is done with straight gates. Oblique dampers allow air flow to flow in the most precise and smooth way.

Materials for the manufacture of gates

Basically, valves for stove heating are made from steel . The advantages of this material include:

- Good thermal conductivity;

- Resistance to high temperatures;

- Sufficient strength characteristics;

- Resistance to corrosion;

- Low coefficient of thermal expansion.

Sometimes gate valves are made from other metals, but, more often than not, they are inferior in their performance characteristics.

For example, cast iron gates are very heavy. Hence the difficulty arises when installing them into ready-made structures. Their scope of application is limited to brick pipes.

Advantages of gate valves

The damper for chimneys and ventilation has a number of advantages:

- Most often, gate valves are made of steel. This material has such an irreplaceable quality as corrosion resistance. A millimeter thick plate can withstand considerable load.

- The gate valve is polished smoothly, so there are no defects on the surface. The ideal smoothness of the gate valve allows it to be easily and quickly cleaned of soot and other contaminants that gradually accumulate on it.

- Steel gates can withstand temperatures up to a thousand degrees.

- Thanks to the smooth surface of the damper, the pipeline draft does not encounter resistance, which allows gas particles to move freely in the chimney or ventilation system.

- Stainless steel material facilitates improved removal of carbon monoxide from the system, which reduces the risk of accidents, for example, people in a bathhouse with improper ventilation can be poisoned by it.

Application

From the above we can conclude that gate valves have a wide variety of models and application areas. Scope of use:

- Chemical industry.

- Oil and gas industry.

- Production of building materials.

- Utilities.

- Mining industry.

- Electricity and others.

In addition, large particles are crushed during the process, which allows a wide variety of working masses to be passed through such a wire. Often such closure structures are located in chemical production. When giving preference to this system, the user should know that it is better to order the installation from a trusted manufacturer. Otherwise, problems may arise during use. There are many types, so everyone, if necessary, can find their own installation and use it for its intended purpose.

Self-installation

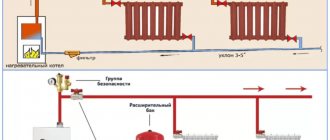

There are three main installation methods:

- A damper can be used to equip a fireplace insert. The distance between the heating device and the gate valve should be one meter; thanks to this installation, the gate valve can be pulled out easily and safely.

- With the second method of installing the damper, it is necessary to combine the damper with other elements of the heating system, without using additional fasteners. This process is also called “pipe to pipe”.

- The final method involves installing a gate structure in the ventilation pipe. The valve is used to protect the fan motor from overheating when it is turned on.

These methods of installing gate dampers are used in the construction of ventilation and smoke exhaust systems.

On the market you can find stoves and fireplaces of various designs. Each individual model requires the use of different types of dampers.

For example, a gas heating stove requires a classic throttle valve (rotary valve) or, better yet, an automatic rotary valve, which will independently shut off the pipeline, which will not allow the flame to escape outside.

If you want to build a sauna stove, then it is better not to buy rotary dampers, because they allow steam to pass through in closed mode, and in open mode the rotary dampers will be difficult to clean.

Slide dampers are often sold as a complete set with a chimney. But if the chimney is not equipped with this part, then you can purchase the valve yourself at a hardware store. The main thing you need to pay attention to when purchasing is the size and material from which the product is made.

Pneumatic drive

Cast iron, steel and other gate valves have different operating principles. But it is worth noting that there is also a system with a pneumatic drive. Sometimes an installation is required that completely eliminates contact between the working mass and the drive mechanism. If we consider the principle of operation, there is still a small distribution:

- Jet.

- Piston.

This part contains a jet turbine. In order for the valve to operate fully, the following conditions must be met:

- Irreversibility of movement.

- Easy movement regardless of the available pressure.

- Active drive shaft reverse.

- No additional seals are needed.

The biggest advantage is that the pneumatic drive has a remote control system. Without such installations today it is difficult to imagine the operation of any pipeline. Before making a choice, each person tries to understand the technical background of any installation. It is in this situation that there will be no problems with internal flows.

Features of gate valves

The body of the gate structure is usually made in a rectangular or cylindrical shape; it is made in one-piece monolithic or prefabricated form by welding metal parts.

Such valves have their own characteristics, which you should familiarize yourself with before going to the store and starting to use them. For example, damper bodies are made using only certain types of steel: CF8, CF8M, 904L, LC1 and WCB. Other types cannot be used regardless of the manufacturer. Occasionally you can find cases made of high-strength cast iron - GGG40. The gate itself is made of CF8, CF8M and 904L steel. These dampers come with a special coating designed to protect against wear and improve corrosion resistance.

If in a store you come across gate valves made from types of steel that are not on the above list, then you should avoid such models, because the reliability and safety of such a product leaves much to be desired. The biggest disadvantage of such valves is the lack of high-quality tightness.

It is best to purchase gate valves from official manufacturers, this way you can prevent the risk of purchasing a low-quality product.