Here you will learn:

- Features of parapet boilers

- Popular models

- Customer Reviews

Choosing a gas boiler for heating a household or apartment is a complex process that takes into account many factors. For example, this is the area of heated premises, the presence of a traditional chimney, the availability of free space and much more. In some situations, when there is not enough space in the home, a parapet gas boiler is purchased here. It is a compact heat source with an unusual design.

Features of the device

The body of such equipment has a rectangular shape, which adds convenience during installation, and the method of its mounting can be left, right or universal (double-sided).

The most popular are parapet boilers, whose power does not exceed 15 kW, although on the plumbing market there are more powerful samples designed for 35 kW or more.

Difference from analogues

At the time of development, boilers with convectors were conceived as a replacement for wall-mounted equipment for a similar purpose. After all, their predecessors require frequent maintenance, they are capricious and require high quality gas.

It is believed that the new type of heating equipment is less demanding to operate and does not require frequent maintenance. In addition, there is no connection to the chimney, which is a significant advantage and makes it possible to install it in any convenient room that has an external wall.

Installation location

In most cases, the parapet boiler is fixed in a niche under the window, where the radiator is usually placed. The main difference from wall-mounted and floor-mounted devices is the power range, installation method and output channel equipment. Currently, such a unit is a convector and a gas boiler at the same time, and can be installed not only in country houses, but also in apartment buildings.

Installation Requirements

If the basic installation requirements are not met, this may result in complaints from the neighbor. Combustion products have a special odor and are harmful to human health. Also, violation of the requirements may affect the stability of the equipment - the unit may regularly go out, not light up, or smoke. These shortcomings are corrected by re-installation with the involvement of professionals.

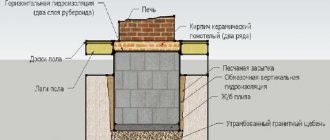

Boilers should be placed on the external walls of the house. The distance from the facade is from 0.3 to 3.0 meters (the indicator depends on the power of the boiler). The chimney is installed only in open rooms. The wall intended for installation should be treated with non-flammable and fire-resistant materials.

Boilers should never be installed dangerously close to upholstered furniture, curtains or other flammable materials. The room where the equipment will be installed must be equipped with a high-quality ventilation system. The power of the unit is selected according to the size of the house that needs to be heated.

Rating of TOP 5 parapet gas boilers

Parapet boilers do not have many of the disadvantages of wall-mounted models, so their range is constantly increasing.

Let's look at the most popular models:

Lemax Patriot-20

Floor-mounted parapet boiler produced by the Taganrog plant. The power of the unit is 20 kW, so the size of the room should not exceed 200 sq. m.

Only the basic task is performed - heating the coolant. If you need to expand the functionality, you should purchase and connect an external storage boiler.

Boiler parameters:

- Efficiency - 87%;

- coolant temperature - 80°;

- system pressure - up to 2 bar;

- gas consumption - 1.2 m3/hour;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

Users and experts note low fuel consumption, which increases the efficiency of the unit and allows for significant savings.

Lemax Patriot-12.5

This unit can be briefly described in two words – simplicity and efficiency. Despite the fact that the heat exchanger is made of ordinary steel, thanks to its coating with anti-corrosion enamel and an inhibitory composition, it is less susceptible to aggressive substances: acids, salts and mineral oils and can last 12-15 years.

With a power of 12.5 kW, its fuel consumption will be no more than 0.75 m3, which is one of the best indicators. But the “picture” is spoiled by a rather clumsy rectangular-shaped case and an uninformative control system: of the devices for monitoring current parameters, only a thermometer is included “by default.”

Cost: 16,130 – 21,580 rubles.

Manufacturer: LEMAX (LEMAX), Russia.

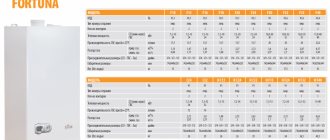

ATON Compact-12.5EB

A relatively multifunctional boiler with a power of 12.5 kW is distinguished by its modest dimensions, which is not inherent in every double-circuit analogue: for flow-through heating it uses an S-shaped coil made of copper - a metal more resistant to corrosion and with increased thermal conductivity, serving up to 17 years .

The hot water supply rate t 35±5 °C can reach 5–6 l/min, while fuel consumption will not exceed 1.53 m3/h. The convenience of installation work will allow you to appreciate the model even more - versatile outputs allow you to connect it on both the right and left sides.

Cost: 23,350 – 27,500 rubles.

Manufacturer: ATON (ATON), Ukraine.

TERMOMAX S-12E

Another unit, devoid of any hints of design. Despite this circumstance, you should not write it off, because the lack of external attractiveness is compensated by economy, efficiency and real comfort of operation: the main control elements are located directly on the front of the outer panel.

On request, the boiler can be supplemented with an expansion tank and a circular pump (not included in the basic package), which will make it suitable for connection to complex heating systems, including those with high hydraulic resistance. Maximum gas consumption at a power of 12.0 kW is 1.39 m3/h.

Cost: 15,860 – 20,340 rubles.

Manufacturer: TERMOMAX (TERMOMAX), Ukraine.

Hephaestus VPR KSG-10S

Perhaps this option is one of the best parapet gas boilers for heating a private home: it is clear, almost silent (distinctively quiet at start-up) and quite highly efficient, given the ability to operate in the “small flame” mode, which allows reducing the average gas consumption to 0.60 m3/h.

Despite the fact that the unit itself has a Russian-made assembly, it contains the well-known Italian automation of the “SIT” type, which, based on the current heat losses, maintains an optimal power level (within 10 kW), as well as a slot burner of the “BRAY” type , which does not require air flow adjustment.

Cost: 19,680 – 23,840 rubles.

Manufacturer: Gefest WPR (Hephaestus VPR), Russia.

Components

In fact, the design of standard and floor-mounted parapet boilers is quite simple. The difficulty in installation is that you need to ensure maximum tightness of the system to avoid gas leaks.

Components of a classic parapet boiler:

- Frame. It may have different dimensions, but almost always manufacturers strive to adjust the dimensions in order to save space.

- The combustion chamber. The system must have a closed combustion chamber, since there is no long chimney that creates powerful draft, and purchasing a sufficiently powerful compressor is impractical.

- Burner.

- Heat exchanger. Usually it consists of metal elements that combine the qualities of an emitter and convection components. When using dual-circuit systems, it is a tube with liquid flowing inside.

- Hood. It is more rational to use a coaxial pipe, since it requires less effort for installation and does not take up much space.

- Piece. A device that produces the spark needed to ignite fuel.

- Electronics. Most modern systems have many different sensors and relays. Thanks to them, the system recognizes the fading of the torch and stops the gas supply.

Installation of a parapet gas heating boiler

The internal structure of the parapet gas equipment was designed in such a way as to prevent the combustion of oxygen from the room in which the boiler is installed. For this purpose, several design changes were introduced. As a result of the modifications, a gas-fired boiler was obtained, characterized by the following characteristics:

- Energy independence - the boiler in its basic modification is capable of operating without electricity.

- The sealed combustion chamber is the primary and main gas burner, mounted in a closed combustion chamber. When burning, air is taken directly from the street.

- Vertical heat exchanger – built into the upper part of the firebox. Vertical hollow plates made of heat-resistant steel. Coolant circulates inside. Hot water supply is provided by a built-in copper coil.

The principle of operation depends on the time of year. A parapet double-circuit gas boiler has two operating modes, depending on the season. In the winter season, the coolant and hot water are heated. Heating occurs alternately. If the boiler starts to heat water for domestic hot water, the heat supply is turned off and vice versa. The principle of operation in the summer excludes the use of a heating heat exchanger. Hot water is exclusively heated using a copper coil. Gas consumption differs in different modes. When heating hot water in the summer, the costs are only 30% of the total energy costs during the heating season.

Automation - conventional boilers, equipped with a mechanical gas supply thermostat. The adjustment is carried out through a rotary mechanism connected to various sensors. Some modern models are equipped with a microprocessor controller that regulates the operation of the boiler automatically.

The internal structure and operation of a parapet boiler are in many ways similar to what is used in units of a classical design. But there are differences that make it possible to widely use the equipment.

How does a parapet boiler differ from a chimney boiler?

The non-volatile parapet gas boiler is a closed type unit. Gas combustion and all other processes occur in a completely sealed closed combustion chamber. The main difference from classic units is several characteristics:

- Lack of a classic chimney pipe. In classic boilers, air is taken directly from the room. After burning the gas, the combustion products go into the vertical chimney under the influence of natural draft. In parapet equipment, air intake and combustion products removal occur using a coaxial chimney pipe.

- The special design of the combustion chamber - a steel heat exchanger, two burners, a DHW coil, are enclosed in a sealed chamber connected to a coaxial chimney. Air is taken in along the outer contour of the chimney pipe, after which it enters the burner from below. The heated air passes through a vertical heat exchanger and is discharged from the boiler body through the core of the coaxial pipe.

The normal volume of gas consumption for a 10 kW parapet boiler will be about 1 m³/hour. A double-circuit unit will consume approximately 15-20% more fuel required to heat the hot water supply.

Strapping scheme

What the harness should provide:

- Coolant pressure stability.

- Removing air from the coolant. If an air lock forms, liquid will not pass through it. You need to know how to tie the system correctly. Air vents must be installed.

- Cleaning the coolant from contaminants that impair functioning. The solution is to install filters.

- To compensate for expansion of the coolant due to heating, you need to install an expansion tank.

In the simplest piping scheme - with one circuit - a check valve with a ball valve is installed on the supply side. The pump is installed on return or discharge pipes, since it is necessary to force the liquid to circulate through the system. A strainer is connected in front of the pump. A filter is also needed at the coolant inlet to the boiler. An expansion tank with a membrane is placed nearby to relieve excess pressure resulting from expansion of the coolant.

The latter, circulating, enters the radiators. There is a second piping option, more relevant, when the coolant passes through a manifold that distributes liquid along the circuits. The presence of a safety valve is mandatory: if the coolant boils, the expansion tank may not withstand high pressure. The valve protects against possible risks:

- pipe ruptures and leaks;

- rupture of fittings;

- apparatus explosion.

The best foreign floor-standing single-circuit boilers

Let's look at the most popular models from Western manufacturers:

Protherm Wolf 16 KSO

The brainchild of Slovak engineers, the Volk 16 KSO floor-standing boiler is designed for heating medium-sized private houses. With a power of 16 kW it can heat 160 sq. m.

Main characteristics:

- Efficiency - 92.5%;

- coolant temperature - 80°;

- heating system pressure (max) - 1 Bar;

- fuel consumption - 2.4 m3/hour;

- dimensions - 390x745x460 mm;

- weight - 46.5 kg.

The unit is non-volatile, which is not typical for European models - they prefer fully functional designs. In addition, it is equipped with a two-pass heat exchanger, which increases the performance of the unit.

BAXI SLIM 1.230 iN

Italian boiler from a famous European manufacturer. Its power is 22.1 kW, designed to operate in a room of 220 sq.m.

Boiler characteristics:

- Efficiency - 90.2%;

- coolant temperature - 85°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 2.59 m3/hour;

- dimensions - 350x850x600 mm;

- weight - 103 kg.

The heat exchanger of this boiler is made of ductile cast iron, the warranty period is 2 years.

MORA-TOP SA 20 G

Czech engineers offer users a 15 kW boiler capable of heating 150 square meters. m. area. A cast iron heat exchanger stabilizes the operation of the system and equalizes the temperature, eliminating sudden jumps.

Boiler parameters:

- Efficiency - 92%;

- coolant temperature - 85°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 1.6 m3/hour;

- dimensions - 365x845x525 mm;

- weight - 99 kg.

An additional advantage is the non-volatile design, which expands the capabilities of the unit in difficult conditions.

MORA-TOP SA 60

Another Czech boiler with a capacity of 49.9 kW. Suitable for heating a house of 500 square meters. m., as well as for public or commercial premises.

Unit characteristics:

- Efficiency - 92%;

- coolant temperature - 85°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 5.8 m3/hour;

- dimensions - 700x845x525 mm;

- weight - 208 kg.

The boiler is equipped with a cast iron heat exchanger consisting of 7 sections. Electronic controls provide constant control over the operating mode of the system.

Protherm Bear 40 KLOM

Slovak floor-standing unit with a power of 35 kW. Heating area - 350 sq. m.

- Efficiency - 90%;

- coolant temperature - 85°;

- heating system pressure (max) - 4 Bar;

- fuel consumption - 4.1 m3/hour;

- dimensions - 505x880x600 mm;

- weight - 130 kg.

The features of the boiler include the design of the heat exchanger - it is a cast iron two-pass unit of 5 sections.

How to choose the right parapet boiler

In addition to technical characteristics and power, all parapet-type gas boilers are divided according to the degree of reliability and fuel economy.

First of all, when choosing, you need to pay attention to what material the device was made from. Usually they look at the thickness of the steel sheet. Unfortunately, not all manufacturers indicate this indicator in the accompanying documents

But the service life of the unit depends on it. Therefore, choose a heating boiler that uses steel sheets with a thickness of at least 3 mm. The ideal option is 4 mm. But keep in mind that the thicker the metal, the more expensive the device itself. But the high cost is compensated by the long-term operation of the boiler. The quality of steel also plays an important role. The better quality it is, the more pressure it can withstand. By the way, the pressure level must be indicated in the product passport. The economic performance of a parapet boiler depends on the operation of the heat exchanger. Pay attention to the efficiency factor. The higher it is, the less you will have to pay for used natural gas. The efficiency of parapet boilers varies in the range of 90-92%. Please note that even one percent affects the savings. Since different rooms in the house have different degrees of thermal insulation, consumer reviews cannot be objective. But the efficiency established by the manufacturer is an objective and accurate indicator of the effective operation of the device. A very important selection criterion will be the location of the connectors. In the room, the water supply and gas pipe can approach the boiler from different sides or from one of the sides. This must be taken into account. Manufacturers have taken care of consumers here too; today on the market there are parapet boilers with one-sided connection and with multi-sided connection. There are universal designs for which it makes no difference which side the connections are made from. Dimensions. In this case, the dimensional parameters depend on the power of the device. The more powerful, the larger the dimensions of the main parts (heat exchanger, burner, furnace and others), and, accordingly, the larger the dimensions themselves.

Therefore, each consumer himself chooses in accordance with this dependence. The power of the unit is an important component of the choice at the level of efficiency. Here it is necessary to approach the issue of choice very seriously. Everything will depend on where the parapet boiler is installed

If this is a city apartment, then the ratio of 1 kW of thermal energy per 10 m² of heated area is a normal condition. If this is a house, then this ratio may not be suitable, because in private housing construction there is a fairly wide range of indicators on which heat loss depends. This is the number of windows, the thickness of the walls, the quality of the insulation, etc. Taking all this into account, we can determine another dependence. For example, 1.5-2.0 kW per 10 m². But here everything needs to be calculated accurately.

Everything will depend on where the parapet boiler is installed. If this is a city apartment, then the ratio of 1 kW of thermal energy per 10 m² of heated area is a normal condition. If this is a house, then this ratio may not be suitable, because in private housing construction there is a fairly wide range of indicators on which heat loss depends. This is the number of windows, the thickness of the walls, the quality of the insulation, etc. Taking all this into account, we can determine another dependence. For example, 1.5-2.0 kW per 10 m². But here everything needs to be calculated accurately.

Presentable appearance

Automation and appearance of the boiler

Modern parapet gas boilers are equipped with the latest automatic process control and regulation systems, which ensures quality and safety of operation. Each manufacturer in this case has its own approach and its own automation. But most often, control panels are mounted into the design of parapet boilers, which are displayed on the external panel of the unit.

- Firstly, it is convenient in terms of maintenance.

- Secondly, it has a modern appearance, very presentable. So this type of heating equipment can fit into any interior.

- Thirdly, a modern approach to the design of the device makes it possible to use it as an element of the design of the room itself.

The most popular manufacturers

One of the most popular devices is the Aton parapet boiler. This manufacturer has been on the heating equipment market for a long time. It produces various boilers, which, according to consumer reviews, are characterized by high efficiency and performance, long service life, small size and the presence of additional functions.

Units such as Atem are also in demand. This manufacturer has also been on the market for a long time. An important characteristic of the device is its fairly high efficiency - 92% or more. Buyers say that the device is very easy to use with a user-friendly interface. The boiler also pleases its owners with its beautiful design.

You can often find a Danko parapet boiler in stores. According to buyers, its main advantage is energy independence. Thanks to the new heat exchanger design, it is possible to save useful space.

Devices of the “Senior Duval” brand demonstrate high efficiency and manufacturability. This is a relatively new manufacturer, but its products have already proven their quality, as evidenced by the satisfied owners of such devices.

Advantages and disadvantages

The positive features of gas appliances from Conord can be determined according to the reviews of those owners who actively use them:

- large model range;

- models have 3 types of automation;

- efficiency;

- high efficiency;

- in the event of a boiler breakdown, you can find spare parts quite quickly;

- good thermal insulation;

- guarantee of flawless operation for 3 years;

- uninterrupted operation for almost 15 years;

- steel heat exchangers help withstand thermal deformations;

- the use of water from the water supply system as a coolant;

- the ability to connect to a system with various types of circulation of the working environment;

- almost complete absence of wall-mounted appliances;

- energy independence of devices;

- use in certain series of automation parts made in Italy and Poland;

- simplified process of using the device.

Boilers from this manufacturer are created in accordance with the characteristics of the domestic climate and are designed to generate the required amount of heat to warm the home even in the most severe frosts.

The reliability of these popular devices is guaranteed by the increased level of durability of heating devices, and their independence from electricity will allow them to function without any failures or delays, especially in conditions where there is no electricity.

The low level of noise impact during operation, compact size and stylish design will allow you to place the device in the kitchen or any other room without harming the design of this room.

A gas unit with 2 circuits from Conord can heat the room as quickly as possible, and also provide home owners with heated water for personal needs.

The safe operation of the products is guaranteed by the arrangement of various protection components of the automation box, which will help turn off the product when the traction is lost. In addition, the boiler will be turned off in the event of any breakdown or any other type of failure. You will be able to automatically adjust the heating temperature of the device, and if the fuel pressure level is too low, the device will provide rapid forced air injection to maintain the functionality of the device.

Disadvantages of Conord products:

- not the highest build quality of some models;

- the steel thickness will be no more than 3 mm;

- ban on the use of antifreeze.

What are parapet gas boilers and their structure

The main difference between a parapet gas boiler and devices of a similar type is energy independence. The incoming fuel burns by igniting the burner in a closed chamber, smoke and combustion products are discharged through a coaxial chimney.

The structural diagram consists of a set of basic and additional elements:

- igniter;

- closed gas combustion compartment (chamber);

- burners;

- steel heat exchanger in a single-circuit device;

- heat exchanger and secondary type copper coil in a dual-circuit model;

- coaxial chimney.

The unit is enclosed in a durable steel case and equipped with a security system, which includes draft sensors, a thermocouple, and a thermometer.

Features of parapet boilers:

The coaxial chimney pipe is a double system. The chimney works to intake air to create a gas-air mixture, which burns in a closed chamber, and to remove combustion products. The special burner design ensures increased efficiency of parapet models. The absence of forced air supply is a property that allows you to create a non-volatile autonomous network in the house

This is especially important for buildings located outside the city. The convection principle of operation of the device ensures rapid heating of the premises. Efficiency of heating by perforating the steel casing is achieved; thermal energy is transferred directly to air flows, thereby increasing the efficiency of the equipment. The sealed combustion chamber minimizes the risk of release of combustion products, so people in the house are protected from gas poisoning.

Advantages and disadvantages of parapet boilers

In addition to the fact that a double-circuit parapet gas boiler will provide heat and hot water in the house, the devices have a number of additional advantages.

Experts highlight the following advantages of purchasing single- and double-circuit models:

- No restrictions on the location of the device. You will only need the proximity of an external wall, through which you will have to bring out a coaxial type chimney; a regular chimney will not be useful.

- Small dimensions of the device. The parapet model can be installed in the kitchen or bathroom of a private house, if one of the walls is external. The boiler body is equipped with perforations, so there is no need for an additional heat source in the installation area (room). The device serves as a kind of stove, warming both the room in which it is installed and other rooms of the house.

- Versatility. There are no restrictions on the installation of units; if installation conditions exist, the devices are installed in private houses, apartments of multi-storey residential buildings.

- Having a choice. Single- and double-circuit models with power ranging from 15-40 kW are available for sale. The most productive units are designed for heating houses with a living area of up to 200 m2.

Affordable cost is one of the main advantages of the models. Compared to standard type equipment, parapet boilers are 30-45% cheaper. There is one minus - the devices are not designed for heating large rooms. When choosing boilers with a power of 20 kW, suitable for heating more than 100-150 m2, care must be taken to thoroughly insulate the building. Otherwise, an additional heating source will be needed.

What is the difference from the usual?

The main difference between parapet models and conventional boilers is the ability to obtain increased safety from a non-volatile design and no impact on the internal atmosphere of residential premises.

If a conventional atmospheric boiler consumes ambient air, actively burning oxygen and requiring constant ventilation, then parapet models are completely separate and do not disturb the air exchange regime.

Another difference is the ability to independently heat air, making a parapet boiler similar to a stove.

Advantages

Positive aspects are guaranteed in each case if you manage to choose a suitable model taking into account its characteristics.

- It is assumed that parapet gas boilers can be used indoors, regardless of their purpose. Moreover, the creation of additional structures is not necessary.

- The price is expected to be affordable compared to other gas boilers.

- Compact dimensions make it easier to find a place for installation.

- Installation activities are extremely easy.

- Design features allow the use of a parapet boiler without additional heating radiators. The boiler is capable of being a functional heater, and this requires convection holes.

- High level of functionality.

- Various power options.

Kinds

There are different design options for parapet boilers, which can be divided according to specific characteristics.

By installation method:

- wall-mounted Installed in a hinged manner on an external (load-bearing) wall. According to installation conditions, weight and power are limited;

- floor Installed on the floor. If it is wooden, a non-flammable stand is required. There are no restrictions on weight, dimensions and power.

By power supply method:

- volatile. The design contains components that require the use of electricity - a circulation pump. electronic control board, etc.;

- non-volatile. They work only with mechanical control. A good choice for remote villages and areas with intermittent power supplies.

By feature set:

- single-circuit. Capable only of providing heating of the coolant;

- double-circuit. In parallel with heating, the heating agents are capable of preparing hot water for domestic needs.

NOTE! Most users prefer single-circuit floor-standing models, which demonstrate the greatest efficiency.

Zoning

Designers do not advise giving in to fashion trends and copying design ideas without taking into account dimensions, location and other nuances. Before planning and arranging furniture, every detail is thought through.

There are several simple rules that experts advise you to follow:

- Let the room have natural light. To do this, remove excess walls (except for load-bearing ones).

- If the rooms in the apartment are small (12 sq. m or 16 sq. m), the layout of the kitchen combined with the dining room will be the right solution.

- If the ventilation system is not designed correctly, the smell of food will spread throughout the apartment.

TOP 5 single-circuit gas boilers

Single-circuit models are used either only for heating, or in conjunction with an external indirect heating boiler. This option allows you to obtain hot water without restrictions on water volumes and without temperature fluctuations. Let's consider several popular models:

Lemax Premium-10 10 kW

Single-circuit gas boiler of domestic production. Designed to heat 100 sq.m. The non-volatile design allows the unit to be operated without being connected to power supplies.

Main parameters of the boiler:

- installation type - floor;

- energy consumption - independent;

- Efficiency - 90%;

- gas consumption - 1.2 m3/hour;

- dimensions - 330x748x499 mm;

- weight - 41 kg.

Advantages:

- energy independence;

- well-organized service and spare parts supply;

- The design was created taking into account Russian climatic conditions.

Disadvantages:

- when heated to 50°, condensation appears in small quantities;

- there is no display, there is no way to obtain information about the state of the boiler components.

Non-volatile models are reliable and simple. They are quite safe, but require a high-quality chimney.

Lemax Premium-20 20 kW

Russian-made gas boiler. The power of the unit is 20 kW, which is suitable for rooms up to 200 sq.m. Equipped with fully mechanical control.

Boiler parameters:

- installation type - floor;

- energy consumption - non-volatile;

- Efficiency - 90%;

- gas consumption - 2.4 m3/hour;

- dimensions - 556x961x470 mm;

- weight - 78 kg.

Advantages:

- reliability, stability;

- Ease of Management;

- low cost.

Flaws:

- complex ignition;

- you have to adjust the gas pressure so that there is no popping noise when igniting.

Domestic non-volatile boilers are much simpler and cheaper than their European counterparts. This is both a plus and a minus of the units.

Protherm Wolf 16 KSO 16 kW

Slovak gas boiler with a capacity of 16 kW. Optimally suitable for heating a house with an area of 160 sq.m.

Main technical characteristics:

- installation type - floor;

- energy consumption - independent;

- Efficiency - 92.5%;

- gas consumption - 1.9 m3/hour;

- dimensions - 390x745x460 mm;

- weight - 46.5 kg.

Advantages:

- simplicity and reliability;

- no need to connect power supply;

- economical fuel consumption;

- stable operation in automatic mode.

Flaws:

- there is no indication of the state of the main components of the boiler;

- ignition using a piezoelectric element is somewhat difficult.

Gas boilers made by Slovak engineers are highly rated by users, which confirms the high demand.

BAXI ECO-4s 1.24F 24 kW

Gas boiler from a famous Italian manufacturer. The power of the unit is 24 kW, which corresponds to a service area of 240 sq.m.

Options:

- installation type: wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 92.9%;

- gas consumption - 2.73 m3/hour;

- dimensions - 400x730x299 mm;

- weight - 29 kg.

Advantages:

- compactness, light weight;

- reliability, stability;

- full control over all systems and components using self-diagnosis;

- There is a display showing all the parameters of the unit, both current and permanent.

Flaws:

- when the power supply is turned off, the boiler operation stops;

- high price for the boiler itself and for spare parts.

Italian heating technology is considered elite. It successfully competes with German models in all respects, enjoys well-deserved recognition and high demand among buyers.

Lemax Leader-16 16 kW

Russian single-circuit non-volatile boiler. Its power is 16 kW, which allows you to heat rooms up to 160 sq.m.

Main characteristics:

- installation type - floor;

- energy consumption - independent;

- Efficiency - 90%;

- gas consumption - 1.9 m3/hour;

- dimensions - 431x856x515 mm;

- weight - 95 kg.

Advantages:

- stable, sustainable work;

- low cost of the boiler and repair work;

- independence from power supply.

Flaws:

- minor flaws made during assembly;

- heavy weight.

Floor-standing gas boilers are not limited in the weight and size of units, which allows you to create more powerful and durable units.

Reviews

Zh7-KS-GS-7.0 S: Roman G., Shakhunya

The main advantages are low cost and compactness. The disadvantage is that it sometimes goes out and does not flare up the first time. After listening to the advice, we bought a Taiga and described the boiler as reliable. In fact, it turned out that there were a lot of problems. The most unpleasant thing is to light it. It happens that you light the wick several times until the burner lights up. The wick goes out on its own. Dissatisfied with the choice.

KS-G-12.5 DS: Victoria E., Bryansk

We have long wanted to replace the old-style boiler with a more manageable and economical one. We chose the floor option. We have a boiler, so we installed a single-circuit boiler. I was attracted by the cost and simplicity of the design. It does not have super functions, like its European counterparts, but it works properly. There were no problems during the season. A powerful device capable of heating our large house in the most severe frosts.

Gas heaters "Taiga" are an advantageous offer in the segment of parapet-type devices. They combine an affordable price with high performance characteristics. This inexpensive and unpretentious device operates smoothly in the harshest climatic conditions. All lines of equipment from Termotechnik are reliable, energy efficient and are in deserved demand among domestic consumers.

Strengths of parapet heating boilers

Parapet gas boilers have the following advantages:

- Compact sizes. This allows you to easily solve the problem of how to install a parapet gas boiler inside a small apartment, the owners of which have decided to acquire an individual heating system. Equipment of this type can even be installed under the kitchen table or in a niche near the window. The main thing is that the gas pipes reach there.

- High-quality smoke removal. This is ensured by the use of coaxial pipes, which can be laid at any convenient angle.

- Easy to install. This is especially true for wall-mounted parapet boilers. Before installing a floor-standing parapet boiler, you will have to equip a separate room (boiler room) in accordance with the recommendations of the gas service. A prerequisite for using floor-standing gas boilers is a chimney pipe and a wide entrance door (from 80 cm). The boiler room must be equipped with a window for regular ventilation. The chimney must be equipped with a series of small ventilation holes. Parapet boilers do not have similar installation requirements

- Possibility of connection on any part of the heating circuit. Some boilers have only a right- or left-hand installation principle, but this restriction does not apply to parapet devices. Thanks to this, the installation of a parapet gas boiler can be carried out in a convenient place.

- Aesthetics. Parapet models are distinguished by their visual appeal. Most often they are tinted in a light color, which allows them to fit harmoniously into any modern design. Very high-quality material is used to paint the devices, which retains its original decorative qualities over a long period of use. Such a surface is not afraid of sunlight and frequent wet cleaning.

- Ease of management. Gas parapet boilers are equipped with a modern control unit. Thanks to the automatic control system, the condition of the coolant is constantly monitored. If its temperature goes beyond the preset parameters, the sensors immediately send a signal to the main control panel, which turns on the heating or cooling system. The pressure level inside the pipes is controlled in a similar way. Thanks to automation, it is possible to select the most optimal mode of operation of the device, which makes it possible to save energy resources.

- Presence of piezoelectric ignition. This allows a single- or double-circuit parapet gas boiler not to depend on the availability of electrical energy in the room. This is especially convenient outside the city, where power outages often occur.

- Full set. The device is already equipped with all the necessary elements, which are compactly located under a beautiful body. A parapet boiler hung on the wall will not be hung on the sides with additional equipment that spoils the overall interior.

- Possibility of conversion to another fuel. When switching to another type of fuel (electricity, liquefied gas), you do not need to buy new boilers: parapet models can be reconfigured and the nozzles in them can be changed.

In the room where a single-circuit gas parapet boiler is located, heating radiators do not need to be installed. The fact is that the body of the device is equipped with many convection holes through which heat enters the room.

Bottom line

A parapet boiler is an excellent opportunity to solve the issue of organizing heating in any home (private house or apartment). When researching the question of which parapet boiler is better, it is necessary to take into account a number of factors. For example, if in addition to heating it is also necessary to provide heating of water for domestic use, imported double-circuit parapet boilers are available for sale. Some of them do not require connecting a chimney pipe at all. In situations where the home already has a single-circuit heater of low power, the organization of a hot water system can be carried out using a boiler

Installation

The instructions describe the ignition process in detail. The launch is carried out after installation and strapping. The correct installation must be checked by the gas service. Before lighting the boiler, a number of preparatory and installation work should be performed:

- Avoid proximity to flammable materials.

- Connect cold water, remove the plugs from the pipes. Install a filter and ball valve at the inlet to protect the system from blockages that could cause malfunctions.

- Ball valves are mounted on all pipes involved in the piping.

- Gas pipes are installed by gas workers; they carry out the connection and installation of the meter.

- They lay a power line for volatile models. They make a separate outlet.

- Installation work related to the removal of combustion products is determined by the type of firebox. There are naturally aspirated or turbocharged models.

- After disconnecting the device from the power supply, fill the system with coolant. Check for leaks. Before the first ignition, all components of the system must be carefully checked.

Gas boilers from Ochag

, which is the owner of the Ochag brand, is located in Ulyanovsk. The beginning of its activities is considered to be 1993.

Today the company produces a wide range of heating equipment and individual components for it of its own design. There are many standard sizes and designs of gas boilers in production, capable of heating rooms from 70 to 1000 V. m.

The company carries out its activities based on the principles of simplicity, reliability, and stability of its equipment. The main advantage of Ochag boilers is their low cost, which makes them preferable and accessible to the mass buyer.

At the same time, the functionality and quality of the boilers are at a high level, which confirms the high demand and positive user ratings.

The boilers are non-volatile, which for the Russian user is a guarantee of reliability and continuous operation of the heating system.

Project

When there are technical conditions, you should start developing an installation plan.

The project represents an installation diagram, as well as laying a gas main from the point of connection to the city gas communication network. For the private sector, a drawing of the passage of gas communications throughout the entire site is additionally required. The entry point to the house must be marked. The project will be developed by engineers. In this case, all provisions of the GOS are taken into account. The design company must have a license for this type of service.