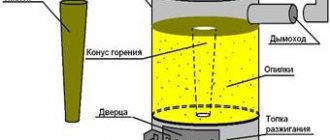

A stove, a fireplace, and a stove are structures familiar to Russian people that allow them to heat a house, even during severe frosts. Currently, they continue to serve as an excellent means of heating in villages and dachas.

Gradually, cracks may appear in the brickwork of the stove for various reasons. The following article will talk about how to coat the stove so that it continues to fulfill its useful role and at the same time be safe for others.

Brick oven

The brick kiln is still in demand by people. Some populated areas are not gasified and a stove in a residential building is necessary. Sometimes it is an additional source of heat in order to save gas or electric heating.

In a country house you can not only spend the summer, but also celebrate New Year, Christmas and other holidays - romantic, unusual and healthy. A simple stove or fireplace will create comfort in the house; you will want to be at the dacha on weekends, sitting comfortably in the warmth.

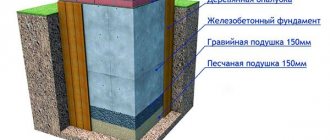

When installing the stove, a number of conditions must be observed. In addition to choosing the correct design, installation location, components and materials, you need to understand what stoves are coated with so that they do not crack or crumble. A responsible attitude to the work at the construction stage of the building itself and the use of appropriate quality materials does not lead to cracks in bricks and finishing materials.

How can you coat cracks and crevices on the stove - possible methods

Those who use stoves know firsthand that cracking of walls is a completely natural process that causes a lot of trouble. This can crack both the plaster and the masonry itself. Sometimes it happens that in brick and tile stoves through defects form (in the latter this occurs at the joints of the tiles) - through the entire thickness of the wall. Iron stoves are no exception - they also crack, but due to the properties of the material this does not immediately become obvious. These problems can only be caused by smoke inside the room where the unit is located. To avoid this, it is important to know how to cover cracks in the stove.

Exterior finishing of stoves

You can increase heat transfer, hide minor deformations and give the stove a more aesthetic appearance by plastering or tiling.

Plastering is the most common; it is possible after settling and complete drying of the masonry.

Important! The walls of the oven intended for plastering should not be dirty and smooth; the solution will not have the necessary adhesion to them. The plastered surface will have defects after drying.

Tiling gives an elegant look and protects the room from the penetration of flue gases when small cracks appear in the masonry.

You need to know this

Before you start sealing the seams, you need to prepare them: remove residual clay, rinse thoroughly with water using a brush, then prime with heat-resistant glue (50% solution is suitable). When grouting joints, you need to ensure that the repair mixture fills the joints completely, leaving no voids. If a gap is too large in the masonry, in addition to the mixture, you also need to place a ceramic cord into it. Due to its physical properties, it not only withstands open fire, but also very high temperatures - over 1000 degrees.

Ceramic cord is often counterfeited, so before purchasing it, you need to hold a lit match or lighter to it to evaluate the heat resistance of the product. The cord is placed in the masonry seams around the perimeter of the cast iron slab, using heat-resistant glue for fixation.

To protect stove parts that do not need repair, they must be covered with masking tape.

What causes cracks

When malfunctions of the furnace equipment are discovered during use, the first thought that arises is: the furnace is cracking, what should I do? To begin with, it doesn’t hurt to figure out what led to this.

The following factors may be the reasons:

- donkey foundation or structure itself;

- unscrupulous craftsmen and unprofessional work;

- low quality material or unsuitable mortar for masonry or plastering was used;

- the drying process of the masonry is disrupted;

- long heating breaks, sudden temperature changes;

- the technology was not followed when applying each layer during plastering;

- The ventilation system is faulty, condensation.

Note!

Chipboard: what is it? Types, application features, photos, sizes, thickness, explanation, manufacturers

DIY houses made from shipping containers step by step: instructions, diagrams, pros and cons, photos, design

- Working pressure in the heating system in a private house: what it should be, how to create it, instructions for adjusting it yourself

Reasons for appearance

Before properly and reliably caulking the stove, in order to prevent repeated malfunctions, you need to know what can affect the integrity of the stove coating:

- during a long break in heating the house and sudden temperature changes;

- the furnace was laid using low-quality mortar;

- Perhaps the reason is the settlement of the building or foundation. In this case, it will be necessary to carry out major repairs to the foundation, increasing its size and strength;

- after laying the stove, the process of normal drying of surfaces was disrupted;

- when plastering the stove, a low-quality solution was used or a thick or very thin layer was applied;

- Perhaps the reason is faulty ventilation and condensation deposited on the walls of the furnace.

Is it possible to use a stove with cracks?

There is only one answer to this question: it is prohibited. Do not use a stove with cracks and endanger people’s lives. If there are no structural defects, it is necessary to begin troubleshooting as soon as possible.

Important! Fires in most cases result in death due to carbon monoxide released, not fire.

How long does it take to dry?

It is not recommended to use the oven until the solution is completely dry. When using different materials, this period may vary. Using heat-resistant glue as a putty, the layer of solution will dry within a few hours.

It will take more time for the solution of clay and sand to dry and form. In this case, you will be able to use the stove only after a day. Then the brick oven, protected from cracks with mortar, will remain crack-free for a long time.

Therefore, we do not advise you to rush, immediately flooding your Russian stove with a stove bench. Repairing cracks in a furnace is a simple but important job. The choice of material for the solution is a purely individual matter. The main thing is to do the work carefully and responsibly. Then your house will always be light and clean, without the smell of burning and smoke penetrating through the cracks in the walls of the stove.

Diagnosis of problems

The diagnostics of all surfaces will answer the question why a brick stove is cracking. The worst option would be widening through brick cracks. You can’t do this without the help of a specialist; you may need to re-lay the furnace.

Small cracks in bricks caused by high heat allow you to carry out the work yourself. The cracks need to be filled and the surface re-plastered.

Plastering process

Large and small cracks increase in size. To do this, use a spatula, chisel, or hammer. Jointing will allow the grout to fill the gap as much as possible and adhere to the surface of the masonry.

Sequence of work:

- prime the surface of the crack from the inside with a special impregnation or plain water;

- heat the fireplace with a small amount of firewood;

- apply a thin layer with a brush to a warm surface to create a basis for future coating;

- on large chips, use a reinforcing mesh, thin fabric or burlap.

The main mass is applied in 2 layers, wait for it to dry and prime before applying the next one.

Oven adhesive

In building materials retail outlets there is a dry adhesive special mixture, as well as a ready-made solution of fireclay clay and cement. This glue is durable and fire-resistant. It is convenient to fill the voids of bricks with ready-made plastic material.

The dry composition is not difficult to dilute in accordance with the instructions. It is recommended to work with a small amount of material, as it dries quite quickly. Along with the advantages, ready-made glue has the disadvantage of being quite expensive.

How to determine

The only outward sign of a cracked stove is the characteristic openings that can be found in both the bricks and the mortar.

- More can not be determined visually. A specialist, having carried out diagnostics with the necessary equipment, will be able to determine these causes in a non-visual way.

- If there are any, as a rule, even invisible cracks are already present.

- It is better to eliminate them in time so as not to shift the oven again.

- And this is no longer such a cheap pleasure, because there are very few stove makers left and they rarely learn this craft.

If you are absolutely sure that there are cracks in the stove, then they can be eliminated with plaster. But first the cracks need to be filled. There are many solutions for this, which will be discussed below.

Clay-sand mixture

Affordable economy class material. To prepare the proper quality solution, only high-quality clay and river sand are used. The clay is poured with water in a convenient container and diluted to the state of milk, then rubbed through a fine sieve.

When the clay and water settle, the liquid top layer is drained. Sand, sifted twice, is added to the clay mixture, ratio 1:2. The liquid composition is diluted from the clay mixture to a creamy consistency and mixed thoroughly.

Note!

- Three-way valve in a heating system: instructions on how to choose and install correctly in a private home

Why the bottom of the battery is cold and the top is hot - let's look at the reasons. Review of recommendations on what to do and how to fix it

How to insulate a dog house for the winter with your own hands and inexpensively - step-by-step instructions with photos and descriptions of all stages

It’s easy to check whether the solution is ready. If small pieces of the mixture remain stuck to the stirrer, then the solution is ready, and if large enough pieces remain, then by diluting with water the mixture is brought to the required condition.

A solution containing clay is more likely to lead to defects. There are no exact instructions for preparing the solution; it is prepared based on the experience of the master. There are not many professional craftsmen, so such a solution is not often in demand.

Fireclay clay

One of the best materials to cover the stove so it doesn’t fall off. Affordable, sold in stores, packaged in 20 kilograms. Resistant to moisture and temperature. Also intended for plastering surfaces.

The finished solution is obtained as follows: fireclay clay is mixed with cement and sand, the ratio of the components is 2: 1: 7, respectively, water is added. For better pliability of the material, you can initially fill the clay with water, then wipe out the lumps, add cement and sand. The thickness of the mixture depends on what type of work is being carried out, and skill experience also plays a role.

Putty materials

Inventive people are ready to give advice on any matter, including the choice of materials for repairing stoves. Recommendations must be taken carefully, separating the wheat from the chaff.

A mixture of clay and sand

There are well-known putty compositions that have been tested many times over. You can use them without any doubt.

Oven grout

To eliminate defects that occur in the oven, ready-made heat-resistant grout is sold. Because of its high cost, home craftsmen prefer to make such a solution themselves.

The clay is prepared as for a clay-sand mixture. The soaked clay slurry is combined with sifted sand and while mixing, chopped straw is added, the component ratio is 1:4:5. 1 kg of coarse salt is added to the finished solution, which makes the composition more plastic and resistant to cracking.

Grout perfectly fills voids. You can also use it to plaster the stove surface with the first rough layer.

Fire-resistant silicates

The group of silicate sealants can withstand significantly greater heat.

Temperatures equal to 1200-1500 °C and the action of open fire are not scary for them. Silicate sealants are used to seal cracks directly in the fireboxes, through gaps, and places where cast iron elements meet the furnace masonry. The fire-resistant composite will withstand the effects of heating parts of sandwich chimneys and heating boilers.

The silicates that form the basis of heat-resistant sealants often have grayish or black tints, which determines the color of the paste. The heat-resistant composite adheres well to the surface of the oven.

If necessary, smooth fragments can be lightly treated with abrasives before processing to increase the area of contact with the sealant. The heat-resistant sealant composition completely loses its elasticity after curing.

Seams made from silicate agents should not be subject to vibration or mechanical stress. Silicates are used to seal problem areas in ovens that have already undergone shrinkage. The advantage of non-flexible seams is that they can be safely painted. No cracks or defects will appear on the paint layer.

Before using any heat-resistant sealants for primary finishing or repair of furnaces, you should carefully study the accompanying information.

The compositions can only be used in the temperature ranges indicated on the packages. Some products consist of two components. They must be mixed in a strictly defined proportion. You need to apply the paste quickly. It must not be stored open.

Covering stove cracks

The material for the upcoming work has been selected, and another question arises: how to properly seal the stove?

You can start working only after cleaning the brick from decorative finishing and plaster. Using a suitable tool, the gaps between the masonry with cracks are widened to fill an area of about 10 mm with adhesive.

When using ready-made adhesive solutions, it is advisable to adhere to some rules:

- prepare the working solution in a limited volume due to the drying speed;

- Wet all cracks with water;

- tightly fill the gaps with adhesive;

- Lubricate the top of the oven with the prepared solid mixture;

- wait for it to dry completely and start plastering.

An unheated stove is a bad option for carrying out repair work with materials containing clay. It is recommended to heat it slightly; this will help you see imperfections and eliminate defects before the putty dries.

The sequence of work will be slightly different:

- Before sealing the cracks, stir the mixture again until smooth (the contents have different densities);

- make sure the material is of high quality. To do this, you can manually make a spherical object, and if cracks appear on it, add a little water;

- wet all the cracks with water and fill tightly with glue (it’s safer to use your hands);

- Plaster also after final drying. Next you can use whitewash.

Briefly about the main thing

If cracks appear on the stove, it is important to find out how critical they are and what to do about them. Inspection of the masonry allows you to determine the cause. We can easily eliminate the defect if the cause of the cracks is infrequent or improper use, finishing errors or design flaws. Restoration will not help if a problem with the foundation or an error in the calculations is revealed.

Ready-made and home-made compounds are used for smearing. All of them, from sand-clay mixtures to ready-made adhesive compositions, are capable of qualitatively eliminating defects. To prevent cracks from appearing again, a technique has been developed for applying a plaster layer to the stove; special sealant pastes are used to restore metal surfaces.

Oven overheating

Having installed a new stove, or repaired damage to the old one, you should not test its strength by heating it to its fullest.

The first fire must be carried out with a small amount of firewood, increasing the amount each time. And then there will be no need to get rid of the next problems again.

Replacing the grate

Repairing a grate that has lost its performance is simple. To do this, remove it, clean the grooves from ash and put in a new grate. If the old grille was installed with a certain slope, then the new one is mounted in the same way. At the same time, along the entire perimeter between adjacent masonry bricks and the grate, a gap of 5 mm or more in width is left in order to fill in sand, ash, or lay a ceramic insulating cord.

This cord can withstand heating up to temperatures exceeding 1000 °C. It is placed in the groove between the grating and the masonry and fixed with heat-resistant glue.