Having decided to create a heated floor system in an apartment or house, owners are faced with another choice problem - which heating technology for the lower part of the premises to choose. There are different types of systems on the market today (some run on water, others run on electricity). However, not everyone knows that there is also an electric-water heated floor - one of the newest technologies, which has already gained good authority among many craftsmen and those who have tried this floor heating system. What are the features of this system? This article will help you understand this issue.

Electric water heated floor

Why is it profitable to make heated floors?

The main advantage of heated floors over all other types of heating is that they are hidden from view and are ideal for families with small children. In addition to the fact that babies can crawl safely, they will not get burned on heat sources that are securely hidden under the finishing coating. There are no drafts in the room where heated floors are installed.

Warm floors reduce heating costs in houses with very high ceilings, where it is difficult to rationally organize heating of the entire volume of the room. In apartments located on the ground floor, above damp, cold basements, heated floors will provide a comfortable microclimate.

In addition, they do not dry out the air, which is especially appreciated by sensitive people prone to allergies. When heated floors are an autonomous type of heating, they will help out on cold days in the off-season. Ceramic tiles, even with the best heating system, remain cold, and here the use of warm floors will help out.

Thus, the decision to install heated floors is for the benefit of the health of family members. It is important to choose which system is best to use.

When it comes to which type of heating is better, the debate continues: using liquid coolant or electric heating elements? These methods differ in cost and complexity of work during their installation and connection, and have their own installation and operational characteristics.

How to assemble a collector with your own hands

It is impossible to directly connect a heated floor to the boiler with your own hands. For this you need a manifold with valves. It is installed in a cabinet, and the piping begins from there. The collector is provided with access to only one person who will service the system.

The range of collectors in stores is quite large, but it is often difficult to choose the right one for your heating system. In addition, a switchgear is needed on each floor of a private house, which leads to a significant increase in costs. A homemade manifold for heated floors is the right solution, allowing you to save a significant amount of money.

Connection

Since the heating system has a supply and return branch, the collector must consist of two combs connected to them. At the joints, branches are installed to drain water and remove air from the pipes.

The collector is assembled according to the number of connected loops. At each outlet, located at the top or bottom of the comb, taps are installed to ensure that individual circuits are turned off while the rest of the heating is running. It is recommended to make the distance between them 10-20 cm.

Manifold manufacturing

Before assembling a manifold for a heated floor, you need to understand the purpose of each element. It is recommended to make combs with your own hands from a square pipe. Round threaded pipes are welded to them for connection to the boiler and to the circuits. To do this, markings are first made, then holes are drilled, and then the pipes are attached. All joints are thoroughly scalded. A plug is made at one of the ends.

The scale is knocked off, the collector is cleaned and painted with oil compounds. In Fig. Below is a simple 3 loop manifold. The comb and coolant supply pipes from the boiler are painted red, and the return pipes, through which cooled water is supplied to heating, are blue.

DIY distribution manifold

Air vents are connected to the top of the combs, and plugs are installed at the bottom to discharge sludge. Each circuit can be closed with valves, which also serve to regulate temperature and pressure.

The distribution manifold is designed to control a small system that serves as additional heating. It will be much more complex if used for the main heating system in a large house. Assembling a manifold from polypropylene pipes is much simpler, but the simplest models are made this way.

DIY collector made of polypropylene pipes

Assembly of the collector unit

The underfloor heating manifold contains devices that ensure efficient operation of the system. Each circuit must have control valves. For a complex system, it is advisable to install automatic control valves.

Usually they operate in constant mode, the coolant flow changes only at the main supply inlet. For house areas up to 200 m², two-way valves are used. Their advantage is smooth adjustment. Valves often become clogged. Therefore, they are installed on detachable couplings (“American”) so that they can be removed for cleaning.

A more complex device is the three-way valve. It ensures mixing of forward and reverse water flows, maintaining the specified temperature at the outlet. Inside it there is a movable partition that regulates the flow of water from two inlet pipes. The device is used in all complex systems with automatic control of a large number of circuits. Its advantage is its significant throughput.

With the slightest turn of the tap, the temperature regime of the system changes. The adjustment can be manual or automatic. A three-way valve is often combined with a servo drive operating from an outdoor air temperature sensor. When the weather changes, the temperature in the rooms is maintained constant. As soon as cooling occurs, a signal from the weather sensor enters the control unit and the coolant temperature rises.

Water floors: installation and operation features

Water floors are an economical type of heating due to the use of water as a coolant. After installing them, you don’t need to think about where to put the furniture. There will be no radiators on the walls, floors with a water circuit are not afraid of heavy interior items.

The main distinguishing feature of water floors is the difficulty in connecting them. For example, to install water heated floors in an apartment, you need a document confirming the consent of the management company to connect to central heating.

When the heating is individual, it is necessary to install a unit for heating the coolant. This means that all the difficulties associated with installing and servicing a boiler are added: gas, electric, solid or liquid fuel. You need to allocate a specific place for its installation, and at the same time comply with all the rules and regulations.

Installing a water circuit for a heated floor requires a lot of preparatory work. This is a rather labor-intensive process that requires attentiveness and professionalism, because in the event of a leak, you will have to open the entire finishing coating of the room.

Experts do not recommend leaving warm water floors as the main source of heat in houses where there is no good insulation of walls and windows. In addition, wall-mounted radiators would be more appropriate on landings or in small corridors.

Using a convector

A simpler and more affordable alternative to an electric boiler is a convector. Its installation does not require laying highways or purchasing numerous equipment. Due to the heating elements, the surrounding air is heated. Thanks to this, the convector is able to quickly warm up a small room.

The convector heats up to +70…+110°С. The heating equipment system is also equipped with thermostats that help set comfortable heating parameters for the house. It is recommended to install convectors on both walls and floors. Thus, when the cooled air falls, it will fall into the field of action of the heater and begin to rise again. This results in a vicious circle in which the air is constantly heated. You can speed up air movement using additional fans.

This explains why the convector does not provide uniform heating of a wooden house with electricity. So, warm air will collect closer to the ceiling, but the floor will remain cool. Because of this, it is worth making additional insulation of the floor.

You may be interested in 220V household voltage stabilizers for the home

To provide economical heating with electricity using a convector, you need to first calculate the number of appliances needed to warm up the house. The greatest effect from the use of a convector is achieved when using electric heating for a summer house, small apartments or wooden houses.

The use of such devices in large stone buildings would be too costly and ineffective. This is explained by the fact that large volumes of cold air require a lot of time to heat, and consequently, energy consumption increases.

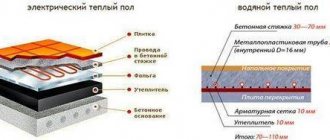

Electric floors: pros and cons

Rooms with electric cables or heating mats installed in the floors are always warm and cozy. To obtain heat energy in this case, only electricity is needed. Electric floors are demanding for premises: they must comply with the standards for the installation of electrical appliances, that is, dry.

If with the water heating method the surfaces are heated unevenly, since they have time to cool down while running through the pipes, then electric ones are stable in this regard and provide heat evenly over the entire area.

But there are also disadvantages of heated floors. Electric floors are not always convenient to use. Many factors need to be taken into account: what kind of finishing coating will be in the room, how to arrange the furniture. Before installation of electric heated floors begins, a floor plan is drawn, which is then adhered to.

Electric floors come in film and cable types. The film is laid on a flat, clean subfloor under the finishing coating. Cable lines, by analogy with a water circuit, are filled with a concrete screed. By choosing any heating option, you can build warm floors in any house or apartment. There is a third method that combines the advantages of water and electric floors: liquid electric heated floors.

Scope of application

When such heating systems appeared on the market, the scope of application of heated floors expanded greatly. This is due to the fact that if previously they acted exclusively as a source of additional heating, today they are increasingly used as the main method of heating homes, replacing typical radiators.

Considering the fact that such systems are laid in a screed, you can choose almost any materials used for flooring as their location: tiles, laminate, natural stone. The exceptions are: parquet, carpet, cork panel. Their unsuitability is due to the fact that they do not allow maximum transfer of thermal energy into the room. In addition, wooden parquet can dry out when heated for a long time, and synthetic carpet fibers can poison the air with harmful substances.

You can learn more about the types of heated floors and how to install them here

What are liquid electric floors?

Consumers have already appreciated the advantages of the new generation of heated floors, which autonomously provide electric floor heating with a liquid coolant. It is not correct to call these floors electric-water, since the coolant is not water, but antifreeze. Therefore, it is correct to say “liquid floors”.

Liquid underfloor heating includes a set of polyethylene tubes filled with coolant. An electrical cable is inserted along the entire length of the tubes. When the electric heating is turned on, the coolant is heated by the cable and begins to release heat to the environment.

In various models of liquid heated floors, the coolant is antifreeze or distilled water.

Types of electric heating

Heating your home with electricity can be a technically challenging process. Therefore, attention should be paid to the selection of specific electric heating, which is divided into two types: with an intermediate coolant; with direct heat transfer.

The group of intermediate coolants includes boilers that heat a special substance that is distributed throughout the entire pipeline system.

Devices with direct heat transfer operate from the electrical network. These include convectors, heat fans, as well as infrared heaters, which have simpler technical characteristics. However, devices with direct heat transfer require high energy costs.

Separately, it is worth mentioning the floor heating system, which provides a comfortable temperature with low electricity consumption.

Advantages of liquid electric floors

The new form of heating compares favorably with its analogues in many respects.

The advantages of electro-fluid systems compared to conventional water systems are as follows:

- no need to connect to a heating boiler or central heating system;

- to perform its function, the coolant does not need the help of a circulation pump;

- installation is extremely simple: there is no need to build a collector and distribution board;

- the operation of the system is ensured by a very small amount of coolant, therefore, even if there is a leak, the apartment is not in danger of flooding;

- warm floors are heated as evenly as possible over the entire surface;

- much less labor is required when installing them, in contrast to water heated floors.

If we talk about the advantages over electric heated floors, then the following qualities should be noted:

- overheating of the cable, which is located inside the liquid, is excluded;

- Repairing liquid floors does not cause problems.

Add antifreeze or change electrical components through a convenient installation box. Damaged areas are identified instantly by wet circles on the screed. The heating effect ensures maximum floor heating due to the fact that the heat energy is stored not only under the screed, but also in the pipe.

There are certain advantages to liquid floors compared to infrared film floors:

- can be installed in rooms with any humidity, which is very important in many cases;

- Liquid floors can be installed under any floor covering.

There are currently two model ranges of electric water floors: XL Pipe and Unimat Aqua. The former are produced in Korea, the latter - in Korea and Russia. These models work on the same principle, but have their own design features.

Requirements for laying capillary electric flooring

Unlike other systems, there are specific requirements for the installation of a capillary electric heating system. The arrangement of the screed is carried out according to standard requirements. The base to be poured is leveled, a waterproofing material and foil heat insulator are laid, then a metal mesh or substrate for the route is placed and a circuit of pipes and couplings is mounted. Pouring the screed includes preliminary work:

- The heating system is undergoing a filling process. To do this, water is poured into a special tank, after which the heating control unit is turned on;

- after the volume of the route is filled and stable circulation begins, the heating is turned off;

- the filled system must cool down.

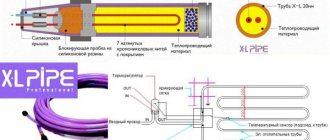

XL Pipe: design and principle of operation

The xl pipe warm floor is arranged as follows. The coolant container is a system of thick-walled polyethylene tubes with a diameter of 20 mm. The coolant in this case is antifreeze (of a certain brand). The tubes contain a seven-core electrical cable made of chromium-nickel alloy, covered with a Teflon insulator.

The pipe is hermetically sealed at both ends. That is, there is no need for circulation of the coolant. The entire system warms up very quickly and as evenly as possible.

The energy consumption of the xl pipe underfloor heating system is 14.5 watt/m2.

One of the advantages of XL Pipe is that you can place furniture on top of the covering where they are mounted. Heavy objects will not cause harm, since installation is carried out under a five-centimeter cement screed.

The pipes are laid according to a special pattern. To regulate the temperature, install a thermostat and a temperature sensor. They are connected here in the same way as for other heated floors. However, you need a special thermostat, which is suitable specifically for liquid heated floors.

The manufacturer provides a 10-year warranty on the operation of its product. However, if the installation is done correctly, then such a system will last up to half a century.

Table 3.4 - Fans

| Designation | Designation code |

| 3.4.01 | |

| 3.4.02 | |

| 3.4.03 | |

Radial with V-belt drive | 3.4.04 |

Radial with coupling connection | 3.4.05 |

Radial without casing, general designation | 3.4.06 |

Radial without casing, first version | 3.4.07 |

Radial without casing with V-belt drive | 3.4.08 |

| 3.4.09 | |

| 3.4.10 | |

| 3.4.11 | |

| 3.4.12 | |

| 3.4.13 | |

| 3.4.14 | |

| 3.4.15 | |

| 3.4.16 | |

| 3.4.17 | |

Roof axial with side discharge | 3.4.18 |

| 3.4.19 | |

| 3.4.20 | |

Roof radial with upward discharge | 3.4.21 |

| 3.4.22 | |

| 3.4.23 |

XL Pipe performance characteristics

In terms of its operational capabilities, the xl pipe electric water heated floor has several undeniable advantages:

- does not create an electromagnetic field;

- no need to install additional expensive equipment;

- there is no risk of system overheating;

- no negative impact on the finished floor covering;

- You can install furniture and heavy household appliances on top;

- it is possible to repair the system without the need to dismantle the finishing coating;

- savings in energy costs (20-30 percent less electricity required than with conventional electric floor heating);

- It’s not a complicated installation that you can do yourself.

How to install an XL Pipe liquid floor

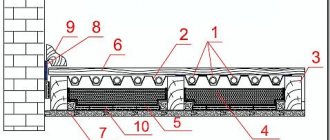

Installation stages of electric water heating xl pipe:

- Prepare the rough base. They clear away debris, smooth out uneven areas, and seal cracks. Extruded polystyrene foam slabs are laid on the base. It plays the role of a heat insulator.

- The heat insulator is fixed using “umbrellas”. To do this, holes are made in the slab for fastening, and umbrella dowels are inserted there.

- A reinforcing mesh is laid on top of the heat-insulating slabs. Cell sizes from 100 to 200 mm.

- The mesh sections are tied together using metal tying wire.

- The heating cable from the heated floor kit is checked for resistance compliance.

- Then the pipes are laid out according to the diagram specified in the instructions. The tubes are fixed with plastic clamps to the reinforcing mesh.

- Connect the power cable from the thermostat to the junction box.

- The wires from the pipe are connected to the power cable. Terminals are usually used for this.

- Grounding cables are connected to the reinforcing mesh.

- Fix the temperature sensor at approximately a distance of 50 mm from the tube.

- Close the installation box. Seal the cracks with sealant.

- Then they make a concrete screed and wait for it to dry. Then a finishing coat is applied on top.

When installing XL Pipe electric water floors, the tubes must not be twisted or pinched. The work is carried out taking into account all the manufacturer’s recommendations. In winter, it is allowed to start the system at an average temperature to ensure the fastest drying of the concrete screed.

This system is expensive and must be handled with care during installation, avoiding tube fractures. The XL Pipe heating method is suitable for premises of any purpose: residential, office and industrial.

Preventative work on XL Pipe is carried out by specialists. As a rule, it is necessary to replace the coolant. This is done approximately once every 10-15 years. The final floor covering is not touched. This is a big advantage of XL Pipe over other systems.

The main disadvantage of this heating method is the rather high price of the system itself. However, the reliability, durability and heating efficiency of such heated floors justify these costs.

Selection of heating system components

The main element of a heated floor is the cable, the choice of which determines the route of installation and the power of the system.

Resistive cable

Outwardly, it is indistinguishable from the usual one, but has completely different characteristics. If for the core of a conventional electrical cable, manufacturers choose a material with the lowest resistance in order to reduce energy losses to overcome it, then when manufacturing a heating cable, they do just the opposite. Most often, the cable core is made of nichrome, which has a very high resistance.

Heating resistance cable

The decisive factor in choosing a cable is the value of its linear power (specific heat release). For domestic use, this figure ranges from 15 to 21 W/m. When choosing a cable, remember that the distance between turns when laying should not be less than 5-6 cm - this is fraught with overheating, and more than 10-12 cm - otherwise temperature changes will be felt on the floor. Based on these values, the linear power of the cable should be selected. That is, with a distance between turns of 10 cm, per 1 m2 you will need 9 meters of cable. With a required system power density of 140 W/m2, the calculation will look like this:

140:9=15.6 W/m.

At the same time, when laying cable sections at a distance of 5 cm from each other, the calculation will look like this:

100 cm (1 m): 5 (distance between wire sections) = 20 m – required wire length.

140 W/m2: 20 = 7 W/m – required linear power of the cable.

Self-regulating cable

This is a two-core cable, both cores of which are made of low resistance material. The role of the heating element here is performed by a semiconductor polymer matrix. It is the properties of the semiconductor that allow such a matrix to perform the function of self-regulation.

Self-regulating cable for heated floors

The use of this cable eliminates the possibility of local overheating and allows its installation under coverings such as laminate and parquet boards. There is also no need to take into account the location of the furniture. So this cable is ideal for those who like to change their interior frequently. The only drawback of the self-regulating system is the rather high price.

Heating mats

Heating mats are essentially the same resistive cable, only laid out like a snake and attached to a polymer mesh.

Heating mats can greatly speed up the installation process

Thus, the installation of electric heated floors is greatly simplified, but its price increases. The cost of mats is on average 20-50% higher than the price of a cable of comparable quality.

Thermostat selection

The thermostat is no less important part of the underfloor heating system than the heating cable. Non-programmable thermostats must be turned on manually. The adjustment of such a device can be either stepwise or resistor (smooth).

Non-programmable and programmable thermostat

Programmable thermostats are much more complex devices that allow you to maintain a constant temperature in a room. Some are equipped with timers that turn the system on and off at specific times.

Choice of thermal insulation

To prevent heat from being wasted on heating the basement or ceilings, it is necessary to lay a layer of insulating material under the cable. There are two ways to do this, each of which has its opponents and supporters. The first method involves the use of extruded polystyrene foam with a thickness of about 30 mm. Opponents of this method argue that raising the floor so much does not make sense and advise using foil insulation. To which EPS supporters say that in the alkaline environment of the cement screed, the foil insulation will collapse in a few years, which will lead to additional heat loss.

For those who decide to install a heated floor themselves, but are afraid of mistakes in selecting the parts that match each other, there are ready-made kits that include a cable, a thermostat, a tube for installing a sensor under the floor surface and detailed installation instructions.

Date: September 25, 2022

Features of the capillary heated floor Unimat Aqua

Liquid underfloor heating Unimat Aqua differs from XL Pipe in that the system does not consist of one thick pipe, but is equipped with many small diameter pipes. Hence the name of the system - capillary. It is connected to a device that has a power of 2.4 kW. In this way, the coolant is heated and heat is released. The whole system is closed. Installation of an additional heating unit is not required.

The coolant in the Unimat Aqua system is distilled water. It will require no more than 6 liters. The size of the heated area that one set can heat is approximately 20 square meters. How warm the room will be depends on the thermal insulation properties of the walls and ceilings. Warm floors very quickly create a comfortable indoor microclimate.

If necessary, several Unimat Aqua systems can be installed in one room. However, most often it is used to heat a small room. The service life of capillary heated floors is approximately 5 years.

Unimat Aqua comes in two types. Basic, which includes a control unit, an installation kit, and two pieces of pipe for connections. All this will be needed to form a small pipeline. The additional kit consists of a coil of small diameter tubes, which is enough to heat an area of 10 to 20 square meters. meters.

For installation, you need damper tape, tube fasteners and heat-reflecting material. After installation, the floors are filled with cement screed.

Boiler installation

An electric boiler will be a profitable purchase both in price and quality. When choosing, you must carefully study the characteristics of all presented models. An important parameter is the volume of the heating system. So, if you need to heat 100 square meters of living space, you will need at least 100 kW per day. Boilers with smaller parameters simply cannot withstand such a load.

The new equipment is connected to a standard heating system , heating the coolant instead of water. All modern boilers are manufactured with a control unit, thanks to which you can independently adjust the desired temperature in the house. According to the entered values, the program automatically adjusts the power of the device, thereby reducing energy consumption. The coolant is supplied by a built-in pump, which provides the required pressure inside the system.

You might be interested in: Protective properties and types of electrical outlets

You should also not forget about possible heat losses in the room. The indicator may differ depending on the density of the walls, the number of doors and windows, and the presence of insulation. Most of the heat escapes through windows and doors, so it is worth replacing them with energy-saving models.

Heating efficiency also depends on the type of boiler. You can purchase simple boilers with a tubular electric heater or give preference to modern induction and electrode models. Despite the fact that all boiler options have approximately the same efficiency, they differ in their efficiency.

The main advantage of using a boiler is the ability to regulate the temperature of the coolant . This is especially useful when there is heavy load on the electrical network. In this way, energy consumption can be reduced and significant savings can be achieved. For example, with continuous operation of a boiler with a power of 3 kW to heat a house with an area of 50 square meters, the monthly electricity consumption will be slightly more than 2 thousand kWh.

You should not take into account readings for only one month, since the real amount of electricity consumption can only be determined over time. Based on the calculations obtained, it will be possible to change the power of heating devices and determine the feasibility of operating other equipment.

Pros and cons of the Unimat system

The Unimat system is very smart. It is equipped with a multifunctional control unit that can adjust the room temperature or heating of the coolant to the desired level. You can also set the period and operating time of the system.

Unimat heated floors are highly safe. They are installed in rooms with any humidity (for example, in bath complexes).

The disadvantage of Unimat underfloor heating is that the heating of the floor is not uniform. This is due to the fact that the coolant comes from the heating block hot, then gradually cools down. That is, the disadvantage is similar to conventional heated floors with a water circuit.

How to install Unimat Aqua Caleo underfloor heating

Installation of Unimat Aqua electric water floor heating is carried out as follows:

- Preparing the rough base is the same as for XL Pipe: cleaning, removing uneven surfaces.

- Prepare a place on the wall for the thermostat.

- A groove for the temperature sensor is made on the rough base.

- Heat-reflecting plates are laid out. They are fastened together with staplers.

- From the side where the thermostat is located, they begin to lay out the Unimat Aqua.

- When laying out the system, in the places where the mat is rotated, one of the connecting wires is cut, and the mat is turned 180 degrees. The tubes should not touch or intersect. The power wire is cut strictly in the middle. The maximum permissible strip length is 25 meters.

- The entire system is carefully glued with tape to the heat reflector.

- Mounting wires connect the mats. This is done as follows: the ends are stripped and sleeves are installed, which are clamped with pliers.

- Heat-shrinkable tubes are placed on the wires. The power cable is spliced with the connecting cable.

- The system is connected to the thermostat according to the diagram that is attached to this device.

- To connect the concrete screed to the subfloor, small through holes are cut into the heat reflector.

- A temperature sensor is installed along the rods, previously laid inside the corrugated pipe.

- Checking how the Unimat Aqua works.

- If the tubes have warmed up within 15 minutes and no failures have been identified, the heated floors are filled with concrete screed.

Liquid electric floors are an excellent source of comfortable heat. They can become either a primary or an additional heating device and will perfectly cope with their function in any room.