For autonomous heating systems, gas boilers are considered the most efficient.

They are economical, operate automatically and do not require increased user attention.

Among manufacturers of such equipment, European companies are confidently leading, including the world-famous Bosch.

Its products are known in many countries; they have their own production in Germany, Slovakia, Turkey and, more recently, in Russia.

Let's consider one of the most popular groups - double-circuit boilers from Bosch.

Double-circuit gas boilers from Bosch

Double-circuit boilers are capable of simultaneously heating the coolant for the heating system and preparing hot water for domestic needs. At the same time, both functions are provided by one gas burner .

The transfer of thermal energy occurs either from a coolant heated to the maximum (if separate heat exchangers are installed), or in one bithermal heat exchanger, where the coolant and hot water move through their channels without mixing.

Double-circuit boilers are much more profitable for use in private homes or other types of housing, as they allow you to obtain full functionality with the same dimensions of single- and double-circuit models.

The ability to provide a home with all types of thermal energy is highly valued by users, which is why double-circuit boilers are always in demand and in demand.

Condensation heating

The most important feature of condensation heating is maximum efficiency, which is achieved due to minimal heat loss during gas combustion. In terms of energy efficiency, devices with condensation heating can compete with heating equipment from other manufacturers. Peculiarities:

- Almost silent operation.

- Use of circulation pumps for maximum energy savings.

- Affordable price, unlike other European analogues.

Advantages and disadvantages

The advantages of Bosch double-circuit boilers include:

- High quality, reliability and stability.

- The ability to ensure the operation of the heating circuit simultaneously with the preparation of hot water.

- Full automation of the workflow, minimal user participation.

- Multi-stage protection of the structure from any emergency situations.

- Possibility of separately adjusting the temperature of the coolant and hot water.

- Gas consumption does not increase compared to single-circuit models.

Disadvantages of double-circuit boilers:

- Phase dependence (incorrect connection will not allow the boiler to start).

- High sensitivity of electronics, the need for high-quality grounding and voltage stabilization.

- High cost of spare parts.

- The performance of the DHW circuit may not be sufficient for a family with high hot water needs.

IMPORTANT!

All disadvantages are characteristic of most double-circuit boilers from any manufacturer, so they can be considered a design feature.

Owner reviews of Bosch gas boilers: advantages and disadvantages

Let's look at the reviews. Since my opinion is subjective, I want to highlight the pros and cons that owners of Bosch wall-mounted gas boilers talk about.

| Advantages | Flaws |

| Many users note that the boilers have worked for more than 5-8 years without any problems | Afraid of power surges |

| Compared to other boilers it works very quietly, almost at the Viessmann level | Not every region has service centers |

| Stylish design allows it to fit into any interior, dimensions and adequate space requirements for maintenance allow the boiler to be placed in a kitchen cabinet | Some owners have difficulties with the first start-up (but here it is worth recalling that the initial commissioning must be carried out by a specialist, who will then put the appropriate mark in the boiler passport; without it, the warranty may be denied) |

| A varied pricing policy will help you choose a boiler for almost any budget |

As you can see, the shortcomings are not that significant. All mounted boilers are afraid of voltage surges, and the first start-up should generally be carried out by a specialist. As for the lack of service centers, this is indeed a problem, but often caused by the desire to save money when a person goes to buy a better offer in another region. However, there may not be specialized service centers in the region where you live, and others do not want to service the boiler. Otherwise, most reviews about Bosch boilers are still positive.

Current requirements for installing a gas boiler in a private home

Kinds

All Bosch double-circuit boilers are wall-mounted. They differ in other design features.

By burner type:

- Atmospheric . They have an open combustion chamber, smoke and other combustion products are removed using natural draft.

- Turbocharged . The combustion chamber is closed; a turbocharger fan is used for smoke removal.

By type of heat transfer:

- Convection . Heating of the coolant and hot water is carried out in the traditional way using a heat exchanger of one design or another.

- Condensation. A recently introduced technique in which the coolant is first preheated from the heat obtained in the condensation chamber. Condensation of water vapor from the exhaust smoke occurs. The heated coolant requires less energy for final heating, which saves fuel and uses all the resources of the unit more efficiently.

Condensing boilers physically cannot work if the difference in temperature outside and indoors is more than 20°. This makes them unsuitable for use in Russian conditions.

In addition, condensing models are extremely expensive, their cost is 2-3 times higher than that of convection boilers and reaches 240 thousand rubles.

Installation Features

According to the installation method, the equipment is divided into floor and wall mounted. The power of floor-standing boilers is greater than that of wall-mounted ones, so this type of equipment is suitable for heating large apartments and houses.

The power of wall-mounted analogues is inferior to floor-standing devices. The technology compensates for its shortcomings with wide functionality and simple installation. Among models of this type, Bosch 4000 ZWA 24 2a and Bosch 4000 W are popular, which are most often installed in small houses and apartments.

What series and models are dual-circuit

Dual-circuit models are available in all GAZ series lines:

- Bosch GAZ 3000 W. Models with a power of 24 and 28 kW.

- Bosch GAZ 4000 W. Power 24 kW.

- Bosch GAZ 5000 W. Boilers with a capacity of 24 and 28 kW.

- Bosch GAZ 6000 W. 18 and 24 kW.

- Bosch GAZ 7000 W. Boiler power is 28 and 35 kW.

In addition, dual-circuit models are available in the Bosch ZWC series (with a power of 22 and 24 kW). They have an innovative Heatronic control system, which is also installed in the older lines of the GAZ series.

The Heatronic module allows you to implement many useful functions and capabilities, in particular - saving and viewing the last error issued by the control board.

About the manufacturer

Back in 1886, Robert Bosch opened a mechanics and electronics workshop. But after 15 years it turned into a full-fledged plant, which became an international supplier of various equipment. A representative office appeared in Russia in 1904. When you see Bosch equipment today, associations with quality and reliability immediately arise in your head. In 2004, Bosch bought shares of the famous companies Buderus, Junkers and others, merging them into the Bosch Thermotechnology company. It is she who deals with equipment for heating and hot water supply. The main office is located in Moscow, and official dealers are present in many cities of Russia.

The company is known for its latest generation technologies; they file applications for several patents almost every day. Let's add here German production and quality control standards, stylish design and a variety of models. By the way, all gas models are marked GAZ with a letter designation.

Mounted boilers are equipped with a copper heat exchanger with an oxide film. This makes it possible to achieve high efficiency and durability of spare parts; copper is much more thermally conductive and more resistant to corrosion than steel. Other advantages include high safety, automatic control of operation and compact dimensions of the equipment. Even condensing models do not take up much space.

The device is based on the example of Bosch Gaz 6000 W WBN 6000-24 C. Typical layout, everything is standard, but the connections are metal, threaded, the pipes are copper, everything is insulated. There are rubber anti-vibration elements in critical areas.

The only disadvantage I can highlight is the price, which is often higher than similar boilers from other manufacturers. But they did not reduce the cost of production by replacing hydraulic group units with composite materials. Here they are made of brass.

I would also like to tell you about the assembly. Yes, now the boilers are assembled in Russia, but all spare parts are German and equipment from the manufacturer is installed at the plant in Engels. In addition, if you bring boilers from Germany, they will be much more expensive. But always check the serial number against the Bosch database when purchasing. The fact is that the manufacturer began to be counterfeited in the CIS and illegally supplied to Russia. Such equipment is much cheaper, but the quality leaves much to be desired.

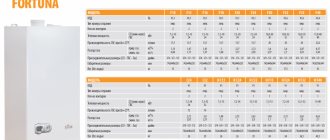

Specifications

Let's look at the technical parameters of Bosch double-circuit boilers:

| Options | Values |

| Boiler type | Gas heating |

| Purpose | Heating and hot water heating |

| Installation type | Wall |

| Fuel type | Mainline or liquefied gas (optional) |

| Heat transfer method | Convection or condensation |

| Efficiency | 93% (convection) 107% (condensation) |

| Power | 18-35 kW |

| Heating circuit temperature | 40-82° |

| DHW circuit temperature | 30-65° |

| Heat exchanger type | Separate or bithermic |

| Power supply | 220 V 50 Hz |

Device

The design of a Bosch double-circuit boiler depends on the type of heat exchanger. For models with a separate heat exchanger, the device is no different from all modern types of gas boilers.

Under the action of the circulation pump, the coolant enters the primary heat exchanger, combined with a gas burner, where it is heated to the highest possible temperature.

At the exit, it immediately enters the secondary heat exchanger, where it transfers some of the thermal energy to prepare hot water.

For models with a bithermic heat exchanger, the process proceeds somewhat differently - both the coolant and hot water are heated at the same time.

The pipeline has a complex cross-sectional shape - coolant flows through the external pipeline, and hot water flows through the internal pipeline.

This design makes it possible to reduce the number of components and increase heating efficiency, but complicates the repair and maintenance of the heat exchanger.

The final preparation of the coolant occurs in a three-way valve, where it is mixed in a certain proportion with the cooled “return”. The coolant is then discharged into the heating circuit.

Smoke removal and air supply to the combustion chamber are carried out using a turbocharging fan (for turbocharged models). The operation of all components is monitored by a control board and a system of sensors that monitor the condition of parts and signal the occurrence of problems.

Why choose Bosch

In addition to the world-famous name, the equipment has several advantages over models from other manufacturers. Among the features there are several main ones:

- Large selection of functions and additional options.

- Energy efficiency.

- Reliable design.

- Easy installation.

- Environmentally friendly.

The equipment is perfect for those who value simplicity and convenience. Most settings are fully automated - this allows you to use the device with minimal intervention. The screen displays all operating modes, and in the event of a breakdown, error codes. In addition to the listed advantages, all Bosch models are equipped with a protective system that shuts off the gas supply in the event of a malfunction.

Connection and setup instructions

Bosch boilers are connected according to the instructions for service workers.

After installing the boiler on the wall and connecting the chimney, communications are connected to the corresponding pipes:

- Direct and return heating lines.

- Water supply for hot water supply.

- Gas pipe.

- Power supply.

The power supply must be connected properly, with the phase connected to the appropriate electrode and grounding must be present. This will eliminate the constant appearance of the EA error (no flame).

After connecting the pipelines and checking the tightness, the system is filled with water, monitoring the pressure using a pressure gauge or display signal.

The working pressure is 1-2 Bar, however, it should be taken into account that cold water is poured in, which will expand when heated and increase the pressure, so it should be limited when the value reaches 0.8-1 Bar.

Some models come with a fan speed setting of zero. It is necessary to set a higher stage, otherwise the boiler will not start.

After this, the required temperature of the coolant and hot water is set . This will automatically trigger a request to start the burner and start the boiler.

Operating adjustments are made upon reaching a stable temperature in the room; when external conditions change, they are periodically adjusted according to the user’s own feelings.

The first start-up and adjustment of boilers should be carried out by employees of service organizations.

Download instructions

Download instructions for a Bosch double-circuit gas boiler.

The combustion chamber

Open

Stations with an open combustion chamber are a classic version of instantaneous water heaters and floor-standing boilers. The design provides for natural air flow during fuel combustion. After gas combustion, waste products are sent into the chimney, so the room must have good ventilation and a fire protection system. The advantage of a device with an open burner is the absence of unnecessary functions. The disadvantage is lower performance and incomplete combustion of fuel.

Closed

Equipment with a closed combustion chamber is often called turbocharged. With the help of a powerful fan, air enters from outside the room, after which it burns in a special burner. Waste after combustion is removed forcibly, so draft in the chimney is not required. For convenience, compact coaxial chimneys are installed together with turbocharged boilers. Devices of this type have several advantages, including high performance and the ability to be installed in any room. There is also a drawback - the noise that occurs due to the operation of powerful fans. Almost all models are equipped with burners with variable speed control. This feature helps reduce noise levels at low speeds.

Price range

Prices for Bosch double-circuit gas boilers are in a very wide range - from 30 to 240 thousand rubles. The difference is quite large; the reasons for this price range are structural differences.

Convection models are relatively inexpensive, while condensing units cost 2, 3 times more (or more) due to the presence of additional design elements.

When choosing a boiler, you should keep in mind the need for additional costs for related equipment (chimney, stabilizer, filters) and a warranty agreement.

IMPORTANT!

When concluding a warranty agreement, you should decide on the time of installation and adjustment of the boiler, which must be performed by technicians from the warranty workshop.

Official website: where to view all models and operating instructions

A snapshot of the official website of Bosch climate control equipment in Russia.

If you want to learn more about the models or download the operating instructions, you can do this on the official website: https://www.bosch-climate.ru/

If you go to the “Equipment” section, you can see all available models and their descriptions. In the “Information” section you can find official representatives for sales, installation and maintenance.