The central element of a gas boiler should be considered the burner. All other components are built around it.

A lot depends on how this unit is designed, and first of all, the efficiency of the boiler, so the owner of an autonomous heating system should have a good understanding of this issue.

Our material will serve as a good assistant in this important matter. At the same time, let's see how to make a gas burner for a boiler with your own hands.

Working principle and requirements

In the burner, the burned gas is combined with air. At high temperatures, chemical reactions occur. reaction producing carbon dioxide and water.

The process occurs with the release of heat energy. The energy heats up the coolant in the next working unit – the heat exchanger. Gaseous, liquid and solid substances are discharged into the street in one way or another.

What requirements must the burner meet:

- conventional design, reliability;

- long service life;

- low noise level;

- ease of switching from one fuel to another (if it is provided for in the boiler design);

- The low emission of nitrogen oxides and carbon monoxide during fire makes the boiler practically environmentally friendly. Of course, the chimney and exhaust pipe must be arranged correctly.

What you need to know about gas cylinders?

The use of gas cylinders in homes and cottages where there is no centralized gas supply is a common practice. In this case, propane (or rather, a propane-butane mixture) more often becomes a fuel for gas stoves, less often for water heating systems. In order to protect yourself and your loved ones from unpleasant, often extremely dangerous consequences, before work you need to find out what rules for installing a gas cylinder in a private home must be followed.

But before moving on to them, you need to dwell on the mini-storages of this fuel themselves. First you need to provide information about the volume and weight of the tanks. It is better to list household containers immediately with their approximate weight:

- 5 l - 6 kg;

- 12 l - 11 kg;

- 27 l - 26 kg;

- 50 l - about 43 kg.

There are also the smallest cylinders - 220 and 400 ml, but their use is limited to blowtorches and portable hotplates. The elements are connected with thin hoses or directly.

Soviet style cylinders

Until now, some thrifty owners use old metal tanks, which belong in the trash heap. It is not recommended to keep such products in the house, and not only because of their unattractive appearance. The metal is susceptible to corrosion, so no one can vouch for the reliability of the old cylinder: in the house it becomes almost a real powder keg.

In some CIS countries, the use of such “rarities” is either completely prohibited or permitted, but only after inspection and issuance of a certificate confirming the satisfactory condition of the products. However, it is better to discard these vessels in time, replacing them with safer, modern analogues.

Steel modern containers

This option is a little better due to its not so “venerable” age, however, new tanks are not without the same disadvantages as old vessels. Welded steel cylinders are similarly susceptible to corrosion. They are sensitive to temperature changes and are explosive. Large containers (50 l) are strictly prohibited from being installed in the house.

They are stored outside, in special cabinets near the walls of the building in a place protected from sunlight. Installation of small tanks in housing is allowed, but in this case the rule must be followed: the minimum distance from the stove to the cylinder should be 1.5 m, but further is better. Other recommendations:

- containers should be stored in a room with a stable temperature, ventilation, away from heating devices and sunlight;

- Regular checking of the cylinder and gas pipeline for leaks is mandatory.

To ensure safety, it is recommended to periodically change the gasket on the neck of the container. A gas leak due to a malfunction of this element already poses a great danger, especially indoors. In addition, gas consumption increases.

Composite gas tanks

These are the latest models that can be placed in residential premises: both a private home and a summer house. Their main advantage is absolute safety. Composite tanks are made from epoxy resin and fiberglass. First, threads of material are tightly wound onto the mold, then they are impregnated with resin and treated with a hardener. A plastic casing with handles is placed on top of the container. This element is removable, so after accidental damage it is easy to replace.

Composite or Euro cylinders have quite a lot of advantages when compared with metal products. The list includes:

- a wide range of;

- maximum strength;

- possibility of storage in stacks;

- maximum safety: the container will protect the gas even at a temperature of 100°;

- light weight of the tanks: it is almost half the weight (including the casing) than that of metal tanks;

- convenience: it is guaranteed by transparent walls, allowing owners to monitor the level of liquid in the cylinder;

- the presence of a bypass valve, which gives a chance to relieve excess gas when the pressure suddenly increases.

These are the reasons why Eurocylinders can be considered optimal containers for everyday use: they are convenient, practical, lightweight and safe. If you look for shortcomings, then they include the high price of the products. But it is explained by the fact that composite tanks are currently produced only in European countries.

Classification by air supply method

This option depends on the design of the combustion chamber.

The combustion chamber can be open or closed.

In the first option, the air intake is performed directly from the room, and combustion gases exit through an ordinary chimney.

Another option implies that both air intake and smoke exhaust are carried out using coaxial tubes passing through through holes in the wall.

Low temperature burner

In open fireboxes, gas burners are used for heating boilers.

The working principle is simple: gas enters the wick through an ejector, air is drawn from the room by the heat generating unit.

Ignition is performed by small low-temperature flames. This type can be used in a wide variety of boilers, from conventional units of an old design to modern advanced models.

In addition to simplicity, low cost and versatility, gas burners have another advantage: low noise level.

Possibility of using ejector burners

If you have enough cash to purchase a multi-fuel boiler, you are lucky: two independent combustion chambers, you can switch from wood-fired heating to gas and vice versa without much effort (review of types of gas heating boilers for a private home). But multifunctional/universal boilers are not an economical option.

For example, you already have a wood chip boiler, and you want to convert it into a gas boiler - there are many options for automation, and there are fewer difficulties with the supply of fuel. Atmospheric burners for solid fuel heating boilers are in most cases atmospheric: the device is ordinary, there is virtually nothing to break.

Do-it-yourself atmospheric burners for heating boilers work on a similar principle. To use this device, you do not need to radically reconstruct the entire heating unit.

If, for example, you are converting a wood chip boiler into a gas boiler, you can use an ash pan to install the burner, and connect an automatic device from the outside for control and adjustment.

Atmospheric burners for outdated heating boilers of domestic production are also recommended to be purchased of the atmospheric type: the design features of such units do not make it possible to make the fuel chambers completely sealed, and therefore quite effective.

Some solid fuel boilers (for example, gas generator models) are already equipped with atmospheric burners for ignition.

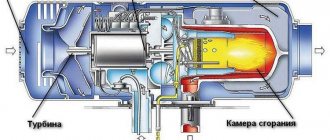

Pressurized burner (pressurized)

In closed fireboxes, free flow of air to the wick is impossible, so they resort to artificial injection. The combustion chamber includes a built-in fan that forces air into the chamber forcibly.

This burner is not as versatile as the previous one, but it has another advantage: it is easier to integrate into a fully automatic boiler control system (about heat supply schemes for a private house with a gas hot water heater).

The fan burner multiblock includes the following parts:

- gas filter;

- pressure regulator;

- flow regulator;

- gearbox;

- relay for turning off and forcibly turning on the burner when pressure drops/increases;

- fan relay (turns off the burner when the fan motor stops).

It is best to have an uninterruptible power supply in the system in case of a sudden power outage.

The disadvantages of this type of burner are high price and complexity. Boilers for them need to be completely reconstructed; they are not suitable for all units.

Zota Topol VK

Solid fuel boiler ZOTA Topol VK 16 Passport and instructions for the boiler ZOTA Topol - VK 16: &nbs..

Solid fuel boiler ZOTA Topol VK 22 Certificate and instructions for the boiler ZOTA Topol - VK 22: &nbs..

Solid fuel boiler ZOTA Topol VK 32 Passport and instructions for the boiler ZOTA Topol - VK 32: &nbs..

Showing 1 to 3 of 3 (total 1 pages)

Boiler Zota Topol VK - high quality solid fuel model

The Zota Topol boiler is an excellent alternative to gas and electric heating, which today is only becoming more expensive every day. Solid fuel boilers are characterized by maximum ease of operation and low cost of fuel, which is especially important for using equipment in villages.

Solid fuel boiler Zota Topol BK: features and benefits

- High efficiency. The boilers are suitable for both home and industrial use.

- Possibility to heat rooms with an area of 140-230 square meters. To do this, just choose a model that suits your power.

- Convenient loading of solid fuel. A person of any build, age and physical strength can easily handle operating the boiler.

- Maximum environmental friendliness – safety for the environment and your health.

- Both coal and firewood can be used as fuel. The Zota Topol boiler is a high-quality solid fuel model

Advantages of solid fuel boilers of the ZOTA “Topol-VK” series

Functionality and design features:

- power range of the three-product line from 16 to 32 kW;

- fuel: coal, firewood, fuel briquettes;

- work in systems with pressure up to 3 atmospheres;

- the main difference from the Topol M series is water-filled grates and a modified heat exchanger configuration;

- The boiler body is thermally insulated and gas-tight; the water jacket is covered with basalt cardboard, which reduces heat loss;

- loading fuel in vertical and horizontal planes (provided by lockable combustion doors);

- adjustable ash pan door ash flap (adjustment is carried out using a screw in manual mode or controlled by a mechanical draft regulator - optional);

- the highest efficiency among budget models of solid fuel and combined boilers;

- increased heat exchange area increases heat transfer efficiency;

- removable damper for easy cleaning of the heat exchanger;

- cleaning hatch on the flue for easy removal of soot;

- thermometer on the top panel of the boiler (to measure the water supply temperature);

- firebox depth ranges from 38 to 64 cm;

- a separate ash door allows you to remove ash at any time while the boiler is firing;

Burning duration

- combustion cycle on one load up to 10-12 hours;

Additional devices

- it is possible to install a heating element unit with an external control panel (optional);

- To increase combustion duration, it is recommended to use the TurboSet kit. In this case, the combustion process is controlled automatically;

- if you install a Fox 5-25 pellet burner, the manual boiler will become automatic;

- It is possible to install a gas burner (in place of the screw door).

The Zota Topol boiler is an excellent alternative to gas and electric heating, which today is only becoming more expensive every day. Solid fuel boilers are characterized by maximum ease of operation and low cost of fuel, which is especially important for using equipment in villages.

Solid fuel boiler Zota Poplar: features and advantages

- High efficiency. The boilers are suitable for both home and industrial use.

- Possibility to heat rooms with an area of 140-230 square meters. To do this, just choose a model that suits your power.

- Convenient loading of solid fuel. A person of any build, age and physical strength can easily handle operating the boiler.

- Maximum environmental friendliness – safety for the environment and your health.

- Both coal and wood can be used as fuel.

Boiler Zota Topol VK - high quality solid fuel model

The Zota Topol boiler is an excellent alternative to gas and electric heating, which today is only becoming more expensive every day. Solid fuel boilers are characterized by maximum ease of operation and low cost of fuel, which is especially important for using equipment in villages.

Solid fuel boiler Zota Topol BK: features and benefits

- High efficiency. The boilers are suitable for both home and industrial use.

- Possibility to heat rooms with an area of 140-230 square meters. To do this, just choose a model that suits your power.

- Convenient loading of solid fuel. A person of any build, age and physical strength can easily handle operating the boiler.

- Maximum environmental friendliness – safety for the environment and your health.

- Both coal and firewood can be used as fuel. The Zota Topol boiler is a high-quality solid fuel model

Advantages of solid fuel boilers of the ZOTA “Topol-VK” series

Functionality and design features:

- power range of the three-product line from 16 to 32 kW;

- fuel: coal, firewood, fuel briquettes;

- work in systems with pressure up to 3 atmospheres;

- the main difference from the Topol M series is water-filled grates and a modified heat exchanger configuration;

- The boiler body is thermally insulated and gas-tight; the water jacket is covered with basalt cardboard, which reduces heat loss;

- loading fuel in vertical and horizontal planes (provided by lockable combustion doors);

- adjustable ash pan door ash flap (adjustment is carried out using a screw in manual mode or controlled by a mechanical draft regulator - optional);

- the highest efficiency among budget models of solid fuel and combined boilers;

- increased heat exchange area increases heat transfer efficiency;

- removable damper for easy cleaning of the heat exchanger;

- cleaning hatch on the flue for easy removal of soot;

- thermometer on the top panel of the boiler (to measure the water supply temperature);

- firebox depth ranges from 38 to 64 cm;

- a separate ash door allows you to remove ash at any time while the boiler is firing;

Burning duration

- combustion cycle on one load up to 10-12 hours;

Additional devices

- it is possible to install a heating element unit with an external control panel (optional);

- To increase combustion duration, it is recommended to use the TurboSet kit. In this case, the combustion process is controlled automatically;

- if you install a Fox 5-25 pellet burner, the manual boiler will become automatic;

- It is possible to install a gas burner (in place of the screw door).

The Zota Topol boiler is an excellent alternative to gas and electric heating, which today is only becoming more expensive every day. Solid fuel boilers are characterized by maximum ease of operation and low cost of fuel, which is especially important for using equipment in villages.

Classification by type of fuel

The gas boiler will operate on natural (main) methane gas or liquefied gas from cylinders (propane-butane). At this time the difference in price is insignificant.

Since in conditions outside the city it is not always possible to connect to the main line, you will most likely need a propane or butane atmospheric burner for your heating boiler.

Structurally, these boilers are the same; the burners have their own small parts. Burners for real and liquid gas are distinguished by the design of their spray devices. Many units are equipped with spray devices for two types of fuel.

As a result, atmospheric burners for propane heating boilers can be easily reconfigured to work with main gas and vice versa.

Recommendations for storage and disassembly

All gas appliances require careful handling and compliance with safe operation rules. Therefore, it is not recommended to repair malfunctions without permission or disassemble the burner and the gas boiler itself.

In order to avoid emergency situations, as well as to ensure the correct and efficient operation of the device, it is best to contact the gas company with which you have a maintenance agreement. Calling a specialist will be the most reasonable decision, because the price of your life and the lives of the people around you is much higher than calling a specialist.

As for storing household gas burners, everything is simple. They must be stored in a dry and ventilated area to avoid corrosion of metal parts.

Make sure that there is no moisture inside your boiler's heating system; if the outlets are rusty, then most likely there is moisture present. If you plan to leave the gas boiler in a garage or other unheated room for the winter, then make sure that these entrances are not closed. What is needed for the natural evaporation of water

To store the boiler itself, you need to make sure that there are no plugs at the outlets for connecting the heating pipes.

You also need to make sure that there is no water inside. If you do not drain the water, the tank will rust and the boiler will be unusable.

How to choose a burner

When choosing, the following characteristics are important: range, power and adjustment method. The power should be more than that of the firebox: this will make it possible to subsequently adjust the operation of the boiler over a huge range.

The adjustment differs in the number of power steps. There may be one or two steps, as well as modulated adjustment (smooth over the entire range).

Among the brands, German (Buderus, Vaillant), Italian (Lamborghini), and Slovak (Protherm) are especially popular. Atmospheric burners for heating boilers of domestic production were demonstrated by products of the companies Zhukovsky Machine-Building Plant, Lemarx, Conord.

It is also necessary to note atmospheric burners for heating boilers Vakula. The company specializes in the manufacture of automatic equipment for burners.

Specifics of atmospheric burners with automation for heating boilers produced by Vakula:

- piezoelectric ignition;

- temperature adjustment of the coolant – from 40 to 90?;

- adjusting the gas supply to the fuse;

- gas flow adjustment;

- ability to work at reduced gas pressure;

- automatic shutdown in the event of reverse draft or sudden cessation of gas supply.

Atmospheric burners for floor heating boilers come in various types: atmospheric and forced, electronic and with piezoelectric ignition.

Which type of ignition is better depends on whether you want the system to be fully automated or whether you like manual control and non-volatile equipment.

The choice between an atmospheric and forced-air burner is in most cases determined by power. A floor-standing boiler with a gas burner produces from 10 to 80 kW or more.

Boiler power with a turbo burner can reach several thousand kW. Whether it is necessary to pay good money for a boiler with similar characteristics is up to you to decide.

If you are preparing to add underfloor heating to your heating system, then see this section.

Video of atmospheric burners for heating boilers. Perestroika.

Gas burner “Garant-M” UG-24 for the boiler “Zota mix 20″, “Master 20″, “Topol M 20”

Gas burner UG-24 with a power of 24 kW with volatile automatic control SIT 630, designed to convert the solid fuel boiler “ZOTA Mix 20”, “Master20”, “Topol M 20” into a gas atmospheric boiler.

This burner uses SIT 630 automation - this is its main feature. It consists of a safety valve and a modulating valve of different series. When you press the ignition button, the main valve blocks the gas flow, and the magnetic valve opens gas access to the burner.

This generates an electric current to maintain power to the solenoid valve. The temperature here is regulated using a special selection knob, and the thermostat sensor regulates the gas flow. The inlet and outlet pressure can be adjusted in the same way.

VALVE DESCRIPTION Automatic SIT is a multifunctional gas supply regulator consisting of a thermoelectric flame control device with re-ignition lock, a pressure regulator or maximum flow adjustment screw, a modeling thermostat with an active instant on/off function. Automation device 630 EUROSIT 1 - temperature-sensitive thermostat cylinder 2 - gas pressure regulator 3 - minimum gas flow screw 4 - control handle 5 - screw for regulating gas flow to the pilot (ignition) burner 6 - point for checking the gas inlet pressure 7 - point for checking the outlet gas pressure 8 — main gas inlet 9 — main gas outlet 10 — magnetic block 11 — pilot burner connection outlet 12 — SIT thermocouple connection hole 13 — maximum gas flow screw

Thermal power - 24 kW Gas consumption - 2.5 m³/h Length - 341 mm Height - 147 mm Width - 275 mm

Making an atmospheric burner for a boiler with your own hands

The main element of a gas boiler is the burner. Actually, all the other details are placed around it. Many aspects of the use of the equipment depend on the design of the unit. First of all, it is safety and economy. Thanks to this, many people strive to make with their own hands an atmospheric burner for a boiler that will suit all the necessary needs of the owners. As it may seem at first glance, this may seem like a time-consuming process, but in reality it is not.

Equipment setup

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional configuration.

Scheme of actions for setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a pressure gauge, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers and phases are connected correctly.

- Place a gas analyzer in the chimney pipe.

- Start the device.

- Using a pressure gauge, take pressure readings at the outlet of the burner block. Pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow using the air damper.

- The gas analyzer readings must also comply with all gas equipment installation standards.

Setting up gas equipment should be carried out by specialists. The simplest open-type boilers can be configured independently if you have certain skills and knowledge of the design of the burner unit. The efficiency of the boiler, its level of efficiency, and fuel consumption depend on the quality of the burner. It is possible to superficially determine that the equipment is malfunctioning by the changed burner flame.

A heating system where the main element is a gas stove is a common type of heating for private households and cottages. There are many things in favor of natural gas as a heat source: high efficiency, environmental friendliness, and the ability to make the heating process fully automated. The fuel itself is also the most inexpensive at present, unless, of course, you take into account wind energy and solar radiation. But these methods have not yet found wide demand due to the unaffordable price of the equipment.

The quality of gas heating depends on how efficiently the gas burner for the stove works.

Types of burners

Most people think that a burner is simply a nozzle through which gas is supplied. But it's not right. It also mixes air into the fuel. At the same time, the main thing is not to forget to take into account that the product must have a specialized design that makes it possible to make the mixture stable.

The device can be of different types, depending on the method of adding oxygen to the gas:

- gas-burner;

- ventilator;

- diffusion-kinetic.

Atmospheric

The working principle of this component is simple: gas flows through an ejector, where its pressure is reduced. In this case, air penetrates into the middle due to different atmospheric parameters.

These devices have many positive characteristics:

- conventional design;

- compactness;

- silent operation;

- good price;

- the possibility of converting the boiler heating system for this equipment - the burner is simply mounted in the ash pan chamber.

Fan

In this type of device, air is supplied in the required quantity using a fan. Due to this oxygen supply, they have a lot of positive qualities:

- There are no restrictions on power - any amount of gas is provided with the proper amount of air, which is necessary for complete combustion without residues.

- The chamber in which the reaction takes place may be closed. Oxygen is supplied to the middle using a specialized air channel. This makes it possible to absolutely prevent combustion products from entering the middle of the house due to reverse draft. In this case, there is no need to install a separate air duct. To do this, specialized coaxial-type chimneys are used, which in fact are a pipe located in the middle of another. The smoke is discharged through the internal element, and oxygen enters the boiler, passing between the internal and external walls.

- Human participation during use is reduced to zero, since the equipment has a “smart” configuration function.

This type of burner also has a number of disadvantages:

- Compared to atmospheric ones, they are noticeably louder.

- Highly Appreciated.

- They only work in conjunction with electric current - they must contain their own uninterruptible power supply. Otherwise, they may break due to a voltage drop.

Diffusion-kinetic

For the most part, similar equipment is found in large industrial heaters. The working principle is based on both atmospheric and fan heating.

DIY atmospheric burner

Since the design of a fan type requires the presence of special equipment, let’s consider creating an atmospheric burner in a high-pressure boiler with our own hands. It is most optimal for this to select a valve from an oxygen cylinder, standard VK-74. To do this you need:

- The outlet section of the pipe is additionally equipped with a threaded connecting element, which can be connected to the reactor using a hose.

- A cap with a smaller hole for connections to the nozzle is placed on the inlet side of the pipe section connected to the cylinder. The final one can be taken from a blowtorch or stove.

- A profile pipe 100 mm long is welded to the cap and the wall has a thickness of 2 mm.

- First of all, you need to make sure that there is a gap of 15 mm between the cap and the nozzle, through which oxygen will flow. This is why, first of all, you need to attach three small pieces of wire to the first one (they can then be bent for the required placement), and only then the pipe.

- The burner itself is ready. After this, it is necessary to make a base on which it will be placed for installation in the combustion chamber.

In addition to creating the burner itself, it is also important to carry out the process of igniting it:

- The gas supply valve on the cylinder or line opens.

- A match is brought to the nozzle.

- The key valve opens.

Important! The power of the device can be adjusted using a valve. The hottest flame is green-blue.

The entire setting is in the location of the torch in the very center. To do this, the wire brackets are slightly bent.

Installation of a gas burner in a heating furnace

We remind you that it is prohibited to install gas equipment yourself. However, it won’t hurt to familiarize yourself with the nuances of installing a gas burner in a stove.

So, installation of a gas burner is permissible in furnaces in which the length, shape, nature and temperature of the flame can be adapted to the nature of the material of the combustion chamber. The flame should not touch the walls, but should be freely located in the combustion space. If it is a brick wall, then the firebox should be made of refractory bricks.

Before installation, check the walls of the stove for cracks, voids, and unsealed seams through which combustion products can enter the room. The room into which the firebox door opens must have an opening window, a ventilation duct and a gap in the door for air to enter from below.

Gas burners of any type are characterized by the creation of high temperatures - more than 1000 °C in the combustion chamber. When installing a gas burner in the oven, you must ensure that the flame does not touch the walls.

The installation process itself is not complicated and is carried out in the following sequence:

- Remove the firebox door.

- A burner is placed in the combustion chamber.

- The shield is secured in the door frame.

- Connect the automation according to the manufacturer's instructions.

At the end of installation, connect the burner to a hose, the other end of which is connected to a gas source.

Installing a burner using the example of an AGG gas burner device: the stage of installing a gas burner block in a furnace with dismantling the ash pan

The system is launched by a master from the gas service, he checks the operation of the nozzles, the automatic control and safety systems, configures and tests the response of the sensors.

Installation of a gas burner in an industrial furnace using the example of an AGG gas burner device. Connecting automation, placing the remote control and thermal cylinder

Another step is to check the tightness of all connections and the presence of traction. After successful startup of the system, the gas installer must issue a completed control certificate for the installation of the burner.

When starting the heating, you should first select the minimum thermal power, heating the stove continuously and little by little or, if there is no power adjustment, cyclically, turning the burner on and off

This is especially important for a brick kiln - strong continuous heating of a cooled brick can lead to cracking.

Application Specifics

Atmospheric burners are easy to maintain. The main feature is annual cleaning. In this case, the procedure should be carried out exclusively by experts in their field, since this requires dismantling the boiler. Very often, the warranty center is responsible for cleaning the burners.

Dirt can be easily removed using compressed air. It is important to set the appropriate pressure. But the thing is that some modern parts most likely will not withstand a flow of 10 atm.

To make the cleaning process quick and less frequent, a specialized filter is installed on the gas supply. This is performed by a specialist after submitting an application to the required structure.

Well, despite the fact that an atmospheric burner in a heating boiler, although it seems like a very complex engineering unit, is no less easy to create with your own hands. To do this, you need to prepare all the accompanying materials and have experience working with metal. Moreover, you need to have several units of special tools.

Practical recommendations

Gas heating installation schemes must be thought out to the smallest detail, so projects must be carried out by professionals.

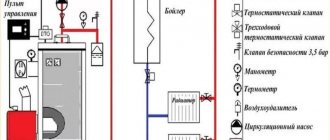

One example of drawing up a professional heating system plan

When choosing equipment for gas heating, remember that the main indicator is the area of the heated room. The volume of equipment, the number of radiators, the footage of pipes, fittings, valves and valves, and plugs depend on it.

Experts recommend installing taps on each battery. Thanks to this, it will be possible to control the supply of hot water to a separate room of a private house. If you are using an expansion tank of 20 to 30 liters, then it should be installed at a height of 3 meters above the heating boiler.

Types of atmospheric burners for heating boilers

Here you will know:

The heart of any gas boiler is a burner with a heat exchanger installed above it. The burner burns gas fuel, creating heat. For its part, the heat is absorbed by the heat exchanger and sent to the heating system. The current review will be devoted to the burners themselves.

We will tell you what an atmospheric burner is for a high-pressure boiler, and we will also give information about the types of burners for gas-fired boilers.

Pellet burners ZOTA Fox

Zota Fox pellet burners are designed for installation on solid fuel boilers of the Master series (without stove, models 14 and 20 kW), Master X, Topol-M, Topol VK, Zota Bulat, Mix, and Zota Magna (from 15 to 60 kW).

The package includes the Zota Fox pellet burner itself, a hopper with a capacity of 200 liters and an auger that supplies fuel. The hopper can be installed on any side of the boiler; there is a sufficient supply of fuel lines for free maneuvering of the hopper.

Additional equipment purchased to install the burner and increase efficiency:

- Additionally, you need to purchase a burner adapter that matches the boiler model. No adapter is required for BULAT boilers.

- For Zota boilers of the Master and Topol-M series, it is advisable to buy (depending on the situation, not everyone needs it, after checking the operation of the boiler using a gas analyzer) and install a set of turbulators to increase the resistance of the firebox. For other models we suggest doing the same.

The burner is installed instead of the ash drawer using an adapter. When setting the grate mode, you can heat the boiler with wood or coal without dismantling the Zota Fox pellet burner. Standard pellets with a diameter of 6-8 mm are acceptable as fuel.

Burner with automatic power control (5-25 kW) and (7-43 kW), ignition and cleaning.

What is an atmospheric burner?

The atmospheric burner is one of the very important components of any boiler. She is responsible for creating a stable flame. This is where the supplied fuel is burned. The resulting heat rises upward to the heat exchanger, where it is virtually completely converted into a heat carrier. Gaseous, liquid and solid substances, along with the remains of heat, are removed into the atmosphere in one way or another.

The design of an atmospheric burner for a boiler is extremely simple - it includes several main components:

The low emission of nitrogen oxides and carbon monoxide during fire makes the boiler practically environmentally friendly.

- Spray device - gas is released from here;

- Ignition system – provides gas ignition;

- Automation system – controls the temperature;

- Flame presence meter – monitors the presence of fire.

To put it simply, everything looks like this. You will know a little later how these or other types of atmospheric burners differ from each other in different boiler models.

A modern atmospheric burner for a heating boiler is a device that has certain requirements. Quiet operation is of primary importance. I immediately recall many models of Soviet instantaneous boilers, where the flame roared with the force of a hurricane. Modern samples burn relatively quietly (they also pay attention to quiet ignition, without pops or explosions). The design of the furnaces has an additional effect on the noise parameter.

Long service life - if you remember the old gas-powered units, they served for a very long time (at that time everything was done for centuries). Today, these technologies no longer exist, so burners in boilers can often break down. There is one way out - to purchase units from trusted brands that use components of normal quality. As for any Chinese junk from unknown manufacturers, then everything is clear - there is no need to take it.

Absolute combustion of gas is another main condition. A burner for a gas boiler must burn fuel completely, with very little release of carbon monoxide and other related elements. However, everything here will depend not only on it - other components also affect the quality of combustion. You must always remember about proper gas removal, which is why it is necessary to have a clean chimney with good draft at your disposal. As for the working principle of the atmospheric burner, it is simple:

In the burner, the burned gas is combined with air. At high temperatures, chemical reactions occur. reaction producing carbon dioxide and water.

- The boiler detects a discrepancy between the temperature in the heating circuit and the parameters specified by the clients;

- The gas valve opens and gas begins to flow into the burner;

- At the same time, the ignition system is activated;

- The gas is ignited and a flame is formed.

At the same wonderful time, the control of the presence of flame begins and does not stop working - if the fire goes out for no reason, the automation will shut off the supply of blue fuel. As soon as the temperature in the heating system reaches the set limit, the gas supply will be closed.

Selection of gas equipment - main criteria

You need to decide on the settings of a gas boiler before purchasing it. We recommend starting with the power of the equipment. The features of your home matter a lot. The main condition for the normal and uninterrupted operation of such a unit is the presence of a centralized gas supply. Naturally, you can try to use imported gas cylinders, but this will significantly increase costs. In some cases, it is even cheaper to purchase electrical equipment for heating a building than to purchase gas cylinders.

For rooms larger than 300 m2, it is better to choose a floor-standing boiler

Heating boilers are single-circuit and double-circuit. In the first case, we recommend purchasing an additional indirect heating boiler. Only then can the unit be used to heat sanitary water. The best option is to purchase a double-circuit boiler, which has all the necessary functions for heating the building and water. Its key feature is the transfer of priority control over the operating mode to the hot water supply. In other words, after opening the hot water supply system, the heat supply to the main circuit, which also includes the heating system, stops.

There are some features of choosing a floor-standing and wall-mounted boiler. Wall-mounted equipment has less power, so it is not enough to heat rooms with a total area of over 300 square meters. In this case, you will need to either purchase another boiler or install a floor-standing gas boiler. In stores you can purchase floor-standing units of any power.

Classification of atmospheric burners

For a long time, very simple boilers, devoid of complex electronics and advanced automation, reigned on the market. They needed full-fledged chimneys and had to be installed in rooms with excellent ventilation. There are now units on sale that can be used in virtually a variety of conditions. Classical models are implemented in the same way. They all differ in the design of atmospheric burners.

Atmospheric atmospheric burners

The use of atmospheric burners greatly simplifies the design of heating equipment. They work due to the natural flow of oxygen, and full-fledged chimneys are used to remove combustion products. Since oxygen is taken from the room, it must have a good ventilation system. It is necessary to consider the main positive qualities of chimney boilers:

- Structural simplicity - has a direct impact on the price of equipment;

- Low noise level - there are no additional fans, only the flame hums;

- Greater reliability - there is a very clear pattern at work here: equipment with a minimum of parts breaks down much less and less often;

- Energy independence - as a result, the equipment will work in buildings that do not have electrification.

There are also certain disadvantages:

- Not the greatest efficiency factor - such a drawback must be reconciled. Much improved gas water heaters with closed burners are more economical and productive;

- The need for a real chimney that goes out onto the roof - in houses under construction this is an extra expense;

- Installation of a boiler with an atmospheric burner must be carried out in a specially designated room, which has a ventilation system and a window - sometimes it is problematic to comply with these requirements.

It is also worth highlighting the possibility of incomplete combustion of gas fuel.

Flueless burners

We are close to the most modern heat exchange equipment, equipped with closed-type atmospheric burners. Such boilers are often called “flueless”. They are equipped with miniature chimneys, often extending directly beyond the opposite wall. This is very convenient, especially when the building is located at the construction stage - there is no need to worry about arranging a chimney and ventilation channels.

A heating boiler with a closed firebox is a heating unit in which the atmospheric burner is enclosed in a specialized chamber. Oxygen comes here from the outside, through a specialized coaxial chimney. Through it, gaseous, liquid and solid substances are removed. All flows are controlled by a powerful fan with automatically controlled speed. If desired, a “flueless” boiler can be installed in a completely sealed room, devoid of ventilation and windows.

Positive qualities of gas-fired boilers with closed burners:

- Possibility of installation in a variety of rooms - in kitchens, basements, in the bathroom (even in the bedroom);

- Very high safety - the gas burns in an isolated chamber. Even if it goes out, and the automation does not react to this, the gas-air mixture will be removed outside the house or apartment;

- Very high efficiency - gas water heaters with closed burners are actually very productive, but this does not apply to all models;

- Much more effective temperature control - for this, a fan shaft speed control system is used;

- High environmental purity - the fuel burns virtually completely.

Unfortunately, there are also disadvantages:

For very high safety and increased efficiency, you will have to pay for a higher noise level and increased maintenance bills.

- Very high complexity - atmospheric burners for heating boilers have a more complex design, which complicates repair work;

- Slightly reduced reliability - the more parts, the lower the reliability of the system (quite often very affordable samples and models made in China fail);

- High cost - in order to purchase a “flueless” boiler, you will need to pay a large amount (they cost 10-15% more than their own atmospheric substitutes);

- High noise level - the fan installed in the system makes a hum (the noise parameter depends on the specific model);

- Lack of energy independence - when the lights are turned off, the equipment will stop working. The problem is solved by installing an uninterruptible power supply.

Despite this, the use of these boilers for heating apartments and houses becomes a specific focus.

flame Setting the gas burner

In order to properly set up the burner of a gas boiler, you must first of all follow the operating instructions for the gas appliance. Let's talk further about how to properly start and set up a gas burner, and in what cases flame adjustment is necessary. But first things first.

Features of the boiler settings burner

It is recommended to adjust the flame using a burner gas analyzer. It shows information about the amount of air mixed with gas, namely the level of oxygen involved in the process, and the amount of CO.

As a rule, CO should be no more than 50 ppm, oxygen concentration should be approximately 3 to 5%. If it is less, then most likely the gas will not have time to burn, as a result of which a lot of soot will accumulate, the CO2 level will be higher than the efficiency, and equipment standards will decrease.

If there is more air than normal, then the temperature of the household gas burner of the boiler will be too high, and this can lead to tragic consequences, including an explosion.

To ensure maximum equipment performance, ensure that the gas burner flame is blue. If it is yellow, blue or orange, it means that it is necessary to do the opposite; in this case, the gas will burn without leaving a lot of soot. This in turn will lead to damage to the device.

The flame in the gas burner should be blue. If you find that the color has an orange tint, try it, which means reducing the amount of gas. Reduce until the color becomes blue (color). This color is a sign of optimal gas operation of the device. The main thing is not to reduce the fuel supply until the moment when the flame becomes almost colorless. In this case, it will go out very quickly.

Setting the starting gas supply is only necessary during ignition and does not affect the performance of the device. But depending on the need, it is possible to adjust For. its beginning, the starting fuel supply should be reduced. Reduce until the burner stops turning on. After this, you can turn the regulator until the ignition is no more. will resume in detail about setting the flame of a household gas burner, you can watch in the video at the end of this article.

We also recommend that you familiarize yourself with the intricacies of gas boiler adjustment.

When adjustment is necessary Gas

flame? An atmospheric burner, which does not have a built-in fan, very often fails; a turbocharged burner breaks down much less often. During long-term operation of the device, its components may break or stop working at full capacity.

A floor-standing gas boiler takes up useful space in your room, so such heating systems are suitable for private homes more often. In all houses, a special room is allocated for such devices - a boiler room, in which wall-mounted units are installed. boiler boilers save space, so they are installed preferably in apartments or houses with small For example

area, the efficiency indicators of a gas boiler may decrease or a decrease may be observed.

And the flame may occur for the following reasons:

- power Large burner installed for equipment intended for less powerful burners. In this case, there is not enough space for proper combustion of fuel, the fuel burns unevenly, which leads to soot quickly accumulating on equipment parts.

- A lot of soot in the chimney can have a bad effect on the draft of a gas boiler. Because of this, the output of subsequent combustion products is very weak, little air enters, and the flame becomes yellow.

- The color of the burner defects is one of the reasons for the efficiency of the boiler, but in this case, the adjustment will help the flame not to correct the problem.

- Gas supply pressure differences can also contribute to the formation of soot and deposits, and this will significantly reduce equipment productivity.

All these reasons can affect the temperature of the flame in the gas burner, in which case repairs will be required.

Wall-mounted heating boilers and gas water heaters are installed, most often, in apartment buildings. But at home they may need to adjust the flame. Recommendations

Other differences

Let's consider the division of atmospheric burners according to the type of ignition. A simplified version is with a burning pilot wick (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to warm the coolant. There are two disadvantages here - very high gas consumption and low safety (the ignition wick may go out). Primary ignition is performed with matches or using a piezoelectric element that produces a spark.

Mains gas from the mains provides even combustion without creating excess soot on the walls of the chimney pipe.

Electronic ignition of the burner takes into account the presence of a high-voltage converter in the gas boiler. Energy is taken from batteries or an electrically powered network. The first option is used in non-volatile boilers that do not have electronic automation. Another option is important for complex units with electronics on board. Simultaneously with such ignition, modules for ionization control of the presence of flame are often installed.

There is also a division according to the type of fuel used. The network gas supplied from the mains is cleaner, it is supplied at good pressure (we do not consider situations of pressure drops back and forth). The flame in the boiler comes out clean, without soot. The equipment is connected to the network without modifications. There are burners that can operate on propane - this requires setting up the system and installing a jet. The flame from propane combustion gives off a yellow color, and there is a very high soot deposit on the chimney.

Oven nozzle

Gas stove burner is used to burn gaseous fuels such as gas. They are available as atmospheric or pulse burners. When comparing the two systems, especially the blower burners provide very clean and efficient combustion of gas products in all power ranges by precisely controlling the supply of fuel and combustion air.

Modern and compact heaters currently use mainly flat burners, in which the flame is distributed over several nozzles over a larger area. The operator's hand makes the combustion particularly efficient and also cleaner due to the lower temperature. Particularly favorable and clean is the so-called catalytic combustion, in which the gas enters into a chemical oxidation reaction on the surface of the catalyst with oxygen from the air. This process does not require conventional ignition and is characterized by a very low flame temperature.

List of sources

- sovet-ingenera.com

- build-experts.ru

- www.steklogaz.ru

- udobnovdome.ru

- obrabotkametalla.info

- master-kleit.ru

- chebo.biz

- remoo.ru

Atmospheric burners for combi boilers

An atmospheric burner for a solid fuel heating boiler is a complex apparatus. It is made to convert heating equipment from one type of fuel to another. In other words, you can buy a solid fuel (multifunctional) device to work with wood, and when a gas line appears, switch it to work with network gas.

It is best to entrust the maintenance of even a very simple atmospheric burner to a specialist - the services of a professional will be more affordable than purchasing a new unit.

An automatic atmospheric burner for a solid fuel boiler is built according to a fan circuit. Gas is supplied here, mixed with air, after which the finished fuel-air mixture is sent to the atomizer. Here it is set on fire, creating a high-temperature flame. On board the burner there is a powerful fan, an automation system, a reducer and a gas filter. The unit requires electrical energy to operate. The product itself has a modular design (removable).

What to look for when choosing?

If the purchase of a device is due to the desire to convert a solid fuel boiler to gas fuel, its power should significantly exceed the power of the firebox.

It is also necessary to take into account the compatibility of the boiler and burner.

So, for example, not every “solid fuel” can be converted to install a fan burner, and in boilers such as, for example, “DON”, it is impractical to install them due to insufficient thermal insulation of the boiler tank.

The nature of the movement of the gas-air mixture has an important influence on the operation of the burner. Based on this feature, these devices are divided into straight-flow and twisted. The latter are characterized by a more powerful air flow.

Homemade units

Some craftsmen make atmospheric burners for boilers with their own hands (for boilers running on solid fuel). Please be warned that this is not safe. And no one will allow such a structure to be connected to the gas main. Very often, such “crafts” are made on the basis of some out-of-date gas-powered units. Do not forget that a homemade atmospheric burner for heating your own home is far from a very good option. It is more advisable to buy the most ascetic gas non-volatile boiler and convert it to bottled gas.

Safety regulations

Frequently encountered dangerous malfunctions and methods of elimination according to safety rules:

- flame failure is a moment during which the flame extinguished, but the gas supply did not stop. The solution is to turn off the gas supply and open the room in which the boiler is located for ventilation. During ventilation, it is strictly forbidden to use open fire, turn on and off electrical appliances, lighters, etc.;

- decrease in the filling of the circulation circuit with water - occurs when there is a water leak. If a leak is detected, turn off the boiler, but under no circumstances start filling the circulation circuit. Wait until it cools down completely, find the leak, and fix it. After which you will have to fill the circulation circuit again;

- the draft in the chimney has disappeared - stop the boiler, clean the chimney. Ventilate the room. When the draft resumes, return the boiler to operation;

- The pilot light goes out - turn off the boiler, carry out the switching procedure according to the passport and the attached instructions.

Ventilation, air conditioning and heating

Gas burners for heating boilers

Heating a house with gas is 2-3 times cheaper than any other method of heating a home. However, this gap can be increased by 4 times superiority. To do this, you just need to choose energy-efficient gas burners for heating boilers.

Since the efficiency (efficiency factor - the ratio of consumed and supplied energy) of the boiler, for the most part, depends on this unit. Types of gas burners

From a technical point of view, a burner is a regular mixer that ensures the formation of a gas-air mixture that is oxidized in the combustion chamber of the boiler. Moreover, the energy efficiency of the boiler depends on the degree of fuel combustion, which, in turn, is related to the percentage of gas and oxygen in the mixture supplied to the combustion chamber.

Gas burner for heating boiler

Therefore, the classification of burners is based on the method of supplying oxygen to the combustion chamber.

This sorting method allows us to distinguish the following types of gas burners:

- An atmospheric version of the “mixer” , which involves a natural flow of air.

- Inflatable option , which involves mechanical inflow, organized using pressure equipment (fan).

- A diffusion-kinetic design option that involves a dosed supply of air flow, mixed into the flow directly during combustion.

In addition, the energy efficiency of the boiler depends on the ability to regulate the intensity of fuel combustion in the working chamber of the heat-generating installation. And the wider the adjustment range, the higher the energy efficiency of the equipment . Moreover, this rule applies to both stationary boiler equipment and portable (cylinder) gas burners - KS 1005 and its analogues.

Therefore, the secondary classification of burners is based on the ability to control the flame in the combustion chamber of the boiler.

This sorting method distinguishes the following types of burners:

- Single-stage option , which eliminates the possibility of adjustment during the combustion process.

- Two-stage option, providing two modes of boiler operation.

- Modulating option , which provides the ability to adjust the combustion intensity in the range from 10 to 100 percent.

Of course, all the types of burners described above provide completely different energy efficiency. Therefore, each type of burner deserves a separate assessment.

Advantages and disadvantages of atmospheric burners

Such mixers are installed on floor-mounted household boilers designed to heat buildings with an area of up to 100-120 square meters. Externally, such a unit looks like a hollow tube with perforation. The gas-air mixture enters the firebox through these holes. In this case, typical atmospheric gas burners for heating boilers receive oxygen-containing air naturally, and a piezoelectric element is responsible for igniting the torch.

Prices: summary table

| Manufacturer and model | Heat exchanger material | Number of circuits | Efficiency, % | price, rub. |

| Teplodar Kupper OK 15 | steel | single-circuit | 78 | 26 900-36 200 |

| Viadrus Hercules U22 D-4 | cast iron | single-circuit | 80 | 83 000-90 500 |

| Roda Brenner Classic BCR-04 | cast iron | single-circuit | 80 | 53 000-55 000 |

| HEPHAESTUS VPR KSTGV-20 | steel | double-circuit | 80 | 23 500-26 400 |

| Karakan 20 TEGV | steel | double-circuit | 75 | 28 500-31 000 |