When building a house, one of the priority tasks of any developer is the question: “How to heat the home?” It is well known that heating with main gas is convenient and cheap. But what if there is no pipe with “blue fuel”, but you don’t want to switch to solid fuel? How else can you heat your house? The topic of our material is diesel heating.

Based on the experience of FORUMHOUSE participants, we will tell you about the advantages, disadvantages, and features of diesel heating in a country house.

Advantages of diesel heating

- Low equipment installation costs. Installation of other heating systems is more expensive than installation of heating using diesel fuel;

- Unlike a gas boiler house, the installation of a diesel boiler does not require obtaining permits;

- There is no need to install a complex chimney system. A hole is made in the wall, and a chimney is led out of it;

- Possibility to fully automate the operation of a diesel boiler. The boiler automatically maintains the desired water temperature in the heating system. If the water has cooled down, the burner turns on itself and turns off when the water has reached the required temperature;

- Availability of fuel.

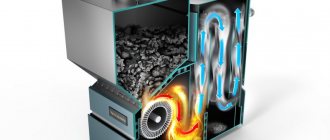

Oil burner

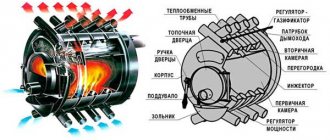

For liquid fuel heating units, fan (pressurized) burners are used. They atomize liquid fuel entering the burner under pressure with the required atomization ratio. Air is also forced into the burner, which is correctly called forced air.

The fuel mixture is ignited by electrodes. Further operation of the boiler is ensured by built-in automation.

Here it’s time to note that the design of boilers contains a lot of electronics and equipment powered by electricity (fans, pumps). This makes diesel boilers electrically dependent and this must be taken into account when purchasing and installing. If your home has frequent electrical problems, then you need to take care of a backup power supply.

Disadvantages of diesel heating

- High heating costs. Due to the constant increase in the cost of diesel fuel, heating with diesel fuel is more expensive than gas, coal, firewood and pellets;

- Energy dependence. The boiler requires a constant power supply to operate;

- Since diesel fuel may contain various impurities, it is necessary to use high-quality fuel to power the boiler;

- Smell of fuel and noise during burner operation. The solution is to additionally soundproof the room where the boiler is installed.

Advantages and disadvantages

The main reason why diesel is replaced with heating oil is the lower price, although the characteristics of petroleum products are very similar. The cost is favorable because cheap raw materials are used in production, and the finished petroleum product has a different, more favorable taxation. The tax on diesel fuel is high, which is why the price in Moscow and other cities is comparatively higher than that of stove fuel.

Other advantages of PT:

- good fluidity;

- economical consumption;

- the ability to reduce the pour point due to additives (expands the scope of application).

The disadvantages of PT include the following:

- higher sulfur concentration than in diesel fuel;

- production in accordance with technical specifications, and not GOST (some characteristics do not have standard values that manufacturers must adhere to);

- high pour point (without additives).

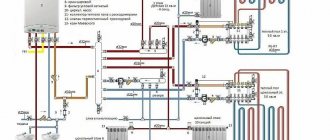

Diesel heating system, where to start?

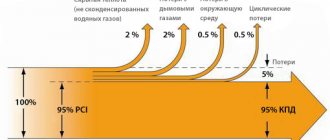

Today on the market there is a huge list of companies offering diesel boilers. The efficiency of a diesel boiler, depending on the manufacturer and design features of the model, ranges from 75% to 85%.

Double-circuit boiler models not only heat the home, but also provide the house with hot water supply.

The question that most homeowners first ask is: “What will be the fuel consumption when operating a diesel heating system?”

Konstantin FORUMHOUSE user

Diesel fuel consumption during constant operation is 0.9 liters per hour. On average, 0.5-0.7 l/hour. But such consumption is achieved only in a very well insulated house. The average consumption of diesel fuel is 1 l/hour per 100 m2.

But before you go and buy a boiler, you first need to decide on the place where it will be installed - the boiler room.

Another FORUMHOUSE user (nickname on the Hortek SPB forum) advises that when installing diesel boiler houses, one should focus on the standards for gas boiler houses, namely:

- Ceiling height - not lower than 2.2 m;

- Area - at least 4 square meters. m for each boiler;

- Doorway - at least 80 cm;

- Window - for every 10 cubic meters. m of room - 0.3 sq. m windows;

- Supply ventilation - 8 sq. cm per 1 kW of rated boiler power or 30 sq. cm per 1 kW, if the air flow is from the interior;

- The cross-sectional area of the chimney should not be less than the boiler outlet cross-sectional area;

- Natural supply channel at a distance of 30 cm from the ceiling;

- Power supply located on a separate machine;

- Ground loop bus;

- The supply of diesel fuel in the boiler room is no more than 800 liters.

Hortek SPB FORUMHOUSE user

Since the requirements for diesel boiler houses are not as strict as for gas ones, in practice they install containers of 2000 liters each, and make smaller windows or don’t make them at all. The main thing is that there must be an air flow and a place for servicing the boiler.

When installing a diesel boiler room, you should pay attention to such an important fact that the operation of boilers with a turbocharged burner does not require the expensive installation of a special chimney. It will be enough to purchase a coaxial chimney and bring it out through the wall. Such a pipe effectively removes combustion products into the atmosphere and at the same time takes clean air from the street.

Models of diesel boilers are also produced that allow you to dismantle the diesel burner and install a gas burner at any time. Purchasing this type of boiler will save you money if you intend to connect to the gas main in the future.

How to calculate the boiler power?

What power should I choose for the boiler? To correctly calculate the boiler power, it is necessary to take into account several parameters:

- House area;

- Ceiling height;

- Insulation thickness;

- Number of windows.

But in order to outline milestones, you can use a table:

For ceiling heights up to 3 meters, the boiler power is calculated from the ratio of 1 kW per 10 m2. If you plan to install a 2-circuit boiler that will provide the house with heat and hot water supply, then the power should be increased by approximately 20% of that indicated in the table.

When choosing a diesel boiler, you should also take into account such a moment as the material from which the boiler heat exchanger is made. Since diesel fuel contains sulfur, when it burns, it produces corrosive condensate, which can lead to the formation of pockets of corrosion that can destroy the metal over time. Therefore, based on the experience of FORUMHOUSE users, we can recommend the use of boilers with heat exchangers made of stainless steel or cast iron.

Fuel capacity

The choice of a container for storing diesel fuel must be treated as carefully as the choice of a boiler. So what are the requirements for the tank?

Firstly, you need to decide on the storage location of the container. Regardless of whether the tank is located in the boiler room or is located next to the house, one of the main conditions must be met, namely, unimpeded access to the fuel refueling truck. And although the length of the hoses of modern tankers can exceed 30 meters, the experience of the user ar_ca is interesting.

ar_ca user FORUMHOUSE

Since the fuel tanker hose is quite heavy and dirty, if you drag it into the house you need to put something on the bends and thresholds. The diameter of the nozzle of the filling pistol is 50 mm and 1400 liters of diesel fuel were poured into me in less than 10 minutes. In case of a fuel spill, you can fill the area with sawdust.

ar_ca also advises paying attention to the following point. After refueling, approximately 50 liters of diesel fuel remain in the tanker hose, and if you do not want to “gift” it to the driver, then the fuel must be drained into a previously stored container.

What else should you pay attention to?

An excerpt from SP 41–104–2000 “Design of autonomous heat supply sources” states that the capacity of the supply tank installed in the boiler room should not exceed 0.8 m3. This volume is not enough to create a full-fledged heating system. And although many users of diesel heating often install tanks of 2000 - 4000 liters in the boiler room, the most appropriate way to store fuel is to install a fuel tank outside the living space.

This installation method promises additional benefits:

- There is no need to run the fuel tanker hose into the house. This means the absence of dirt and odor in the boiler room;

- Additional safety in case of fuel spill;

- Due to the absence of bulky tanks, the useful area of the boiler room increases.

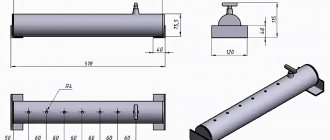

Among containers, vertically oriented tanks from 800 to 2000 liters are in greatest demand. If necessary, a large-capacity fuel storage facility can be created on their basis. To do this, the tanks are connected to each other using fuel piping elements, which allows you to increase the operating time of the boiler room at one gas station.

vlad220FORUMHOUSE user

There are different containers for tanks - plastic, metal, fiberglass. There is also one for underground fuel storage. For small storage volumes - no more than 2000 liters, it is not necessary to bury the tank. The main thing when storing fuel outside is to properly insulate the container. If the fuel line runs in an unheated area, it must be protected from freezing.

When organizing a boiler room with a tank located outside the room, it is necessary to provide an additional pump that will pump fuel into the boiler room. In this case, it will be necessary to place a small tank with a capacity of 100 to 200 liters in the boiler room, into which fuel will be pumped from the main tank.

Automation (control)

According to its characteristics, fuel can be supplied to the boiler independently; it does not need to be thrown in like firewood. Therefore, in boilers of this type, maximum attention is paid to automatic control, which minimizes the presence of a person in the operation of the boiler.

Using the example of the Kiturami boilers I came across, let’s see what is included in the boiler automation. On the body we see sensors for fuel level, temperature, and overheating. Yes, electronic remote control unit. Boiler indicators allow you to monitor the temperature of the coolant in the heat exchanger, circulation pump, burner, and power supply. Tricky buttons “Sleep”, “Shower”, also elements of universal automation. That's a plus.

Features of operating a diesel boiler house in winter

Since the viscosity of diesel fuel increases noticeably in winter, the pump may not have enough power to pump fuel through the fuel line. Therefore, if the container with diesel fuel is installed at a considerable distance from the boiler room, it is necessary to provide additional thermal insulation of the fuel line. Also, when installing a boiler room, it is necessary to remember that the quality of diesel fuel varies and therefore a fuel filter must be included in the boiler power system.

Installing a fuel tank underground is associated with large material costs and requires a large amount of preparatory excavation work and qualified installation of the power supply system.

We can say that diesel heating of a country house is a complex solution consisting of many factors that require knowledge and experience. You can learn more about the operation of a diesel boiler house from the forum thread, and here there is a discussion of liquid fuel boilers and burners.

Subscribe to our Telegram channelExclusive posts every week

Fuel storage tank

Now comes the fun part. An oil-fuel boiler requires a container for storing fuel, and I listed this as a disadvantage a little higher.

The calculations shown above indicate that a capacity of several tons is needed. There is no need to invent anything here and it is better to buy a ready-made container with all the built-in equipment: a float, a vapor outlet, a drain valve, a fuel intake kit, a pipeline for discharging fuel to the burner, etc.

Material for containers is steel, polyethylene, fiberglass.

To install the tank, site preparation, excavation, concreting and a lot of special work will be required. You need to understand this and most likely, you will have to hire specialists.