The Viadrus Hercules D modification differs from the Viadrus Hercules C in that the D has a large firebox and a large loading door, which allows you to load quite large logs. Accordingly, modification D is intended for burning with wood, and modification C is for coke and coal.

Another interesting point relates to the design of flue gas removal. This boiler is very undemanding in terms of draft; some owners manage to operate their heat generator with a chimney 4 meters high, although the minimum boiler height recommended by the manufacturer is 6 meters.

And one more thing, the Viadrus Hercules U22 boiler can be used in a heating system with natural coolant circulation.

It is believed that this boiler can be easily converted to gas or diesel fuel, you just need to install the appropriate burner. However, it is worth considering how much you need such a replacement. And isn’t it worthwhile to hang a separate gas wall unit, and leave Viadrus as a backup boiler in the heating system in case the gas in the main goes out?

The difference between Viadrus boilers

Modern solid fuel boilers Viadrus are popular heating devices. Their installation does not require consent from certain services. As with other solid fuel units, in order to install a boiler of this brand, you will need to equip a boiler room and a fuel storage room.

The main advantages of Czech boilers are as follows:

- High efficiency.

- Very easy maintenance.

- Long service life.

To ensure stable operation of the device for many years, it is necessary to clean the combustion chamber from ash and soot twice a week and carry out full maintenance at the beginning and end of the heating season.

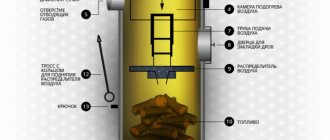

Principle of operation

The Viadrus solid fuel boiler uses wood, coke or coal as fuel. The model range includes pellet boilers, characterized by automatic fuel supply. This type of heating units is the most convenient and therefore does not require much attention from the owner.

Some type of fuel is loaded into the firebox, then the lid is sealed. This minimizes heat loss and increases equipment efficiency.

Operating principle of the Viadrus boiler

Experts recommend using coke with a grain size of 40-60 mm as fuel, while the manufacturer guarantees effective operation on the following types of fuel:

- Walnut 1. Fuel (coke or anthracite) with a fraction size of up to 40 mm.

- Nut 2. Fraction size of non-caking coal is up to 50 mm.

Detailed information about the types of coal and its characteristics can be read here.

Please note that if the draft in the chimney is good (that is, at least 20 Pa), then lump coal with a grain size of up to 80 mm can be used.

Almost all models also use wood as fuel. It is important to use only dry logs with a maximum moisture content of 20%. If this indicator is higher, then it is quite possible that the efficiency of the boiler will decrease. It is possible to use firewood with a diameter of up to 100 mm; the length is chosen based on the size of the combustion chamber.

According to the instructions, the use of the following type of fuel is not prohibited:

- wood chips;

- sawdust;

- pellet granules.

If you decide to pour wood chips or sawdust to heat the device, it is recommended to place firewood at the bottom of the chamber. This way, you will prevent small particles from falling into the ash chamber.

When using automatic pellet boilers, the fuel is poured into a special bunker, from where it is fed autonomously into the combustion chamber.

terms of Use

Owners of Viadrus solid fuel boilers note the ease of operation of the device. But still, before starting the equipment, you need to read the instructions.

Before starting the Czech boiler:

- Take readings from the thermomanometer and make sure that there is enough fluid in the system.

- Open the valves that are installed on the system pipes.

- Check the cleanliness of the smoke channels, grates and ash chamber. If there is soot, everything needs to be removed.

- Lay the firewood on the grill.

- Open the damper and close the loading doors.

- Fuel is ignited through the combustion door.

- Close the firebox door and open the muffler to allow air to flow.

- The main fuel is poured onto the burning firewood and distributed evenly.

- When the flame turns dark red, use the key to open the flaps on the loading doors.

- When the light turns yellow, the door flaps close.

- After the coolant reaches the required temperature, the volume of incoming air is reduced. Using a muffler, the air supply is controlled to allow the boiler to operate in the specified mode.

- If necessary, fuel is also reported. The time between approaches to the heating unit to add fuel depends on the type of fuel and combustion intensity.

Boilers with automatic fuel loading

In order to add fuel less frequently, a bunker is installed next to the boiler, from which fuel is automatically supplied to the firebox using an auger. The hopper can be located on the left or right, there are two sizes. When purchasing a boiler with automatic fuel supply, it is worth considering that the fuel is subject to fairly stringent requirements regarding humidity, size, and ash content. They are exactly indicated in the passport, but they must definitely have certain dimensions and a moisture content of no more than 15% for coal and 20% for firewood.

Solid fuel boiler

Solid fuel boiler with automated fuel supply Viadrus Hercules DUO

Boiler with automated fuel supply Hercules DUO works with hard or brown coal and pellets. Combustion occurs using a retort burner; a controlled fan is installed at the rear to supply combustion air.

Recommended fuel:

- Dimensions: fine fraction coal - diameter up to 25mm, pellets with a diameter of 6-8mm. The sizes, fractions and grades of coal are written here.

- Humidity: hard coal and pellets – 12%, brown coal – 20%.

- Volatile matter content: 28-40%.

- Low caking.

Pellet boiler Viadru Woodpell - Ash content of pellets is 1.5%.

Pellet boilers Hercules ECO and Woodpell

For normal operation of the unit, pellets with a diameter of 6-10 mm, humidity up to 12% and ash content up to 1.5% are required. Minimum power ECO – 24 kW, Woodpell – 16 kW.

To read about pellets, their types and characteristics, follow this link.

Increasing productivity occurs by increasing sections (up to 10 pieces). Fuel bunker - any type and size (not necessarily factory-made, homemade is also perfect). The operation is controlled automatically, but it is possible to switch to manual mode.

In ECO boilers, the heat exchanger is separated from the ash pan by ceramic plates, which regulate combustion and also act as a catalyst, increasing the efficiency of the boiler (83-84%). Turbulizers are inserted into the smoke pipes, which reduce the temperature of the smoke at the boiler outlet, thereby facilitating more complete heat transfer to the heating circuit. The screw fuel supply device is connected to the hatches located on the rear panel. The heat exchanger is cast iron. Its service life is 5 years.

The Woodpell boiler features a heat exchanger based on the proven design found in the Hercules U22. Operation control is automatic, the temperature is controlled using a thermostat located in the room. The package includes protection against overheating of the coolant, which turns off the burner when the coolant reaches 95°C. It is possible to program the boiler operation by day with setting the temperature at each time interval (from 5°C to 30°C in 0.5°C increments). Built-in protection of the system against freezing (when the temperature in the system drops below 5°C, its heating is automatically turned on).

The process of assembling and installing the Viadrus U22 boiler was filmed on video by one of the campaign service representatives.

Different operating modes

In order for the solid fuel boiler to switch to night mode, I perform the following steps:

- Clean the grate.

- Add fuel and wait for it to warm up.

- Turn the smoke damper and reduce the boiler power.

In the morning, open the damper and the holes on the doors, then screw the grate through the open ash doors. After completion of work, the doors are closed.

The ash chamber needs to be cleaned two to three times a week; heat-protective gloves are required for this work.

Solid fuel boiler Viadrus U22 C/D

Boiler Viadrus U22 c/d

Viadrus U22 C/D is a heating boiler capable of operating on different types of solid fuel, including coal, logs, fuel briquettes, pellets. The only difference between modifications C and D is that the model with index D is characterized by a wider opening of the loading chamber door, and this makes it possible to load thicker firewood into the boiler when lighting it.

The basis of the design is a sectional heat exchanger made of cast iron. In addition to the front and rear sections, solid fuel boilers of different sizes have several internal sections. Accordingly, the more sections there are, the more powerful the model. The range includes nine standard sizes of the C series and seven of the D series.

The heat exchanger sections connected to each other are a single volume filled with liquid. The internal space is reserved for kindling and an ash chamber. The rear section has a chimney outlet, in the upper part there is a supply pipe, and in the lower part there is a return pipe. The front section has doors for the loading chamber and ash pan. The size of the heating unit affects the structure of the internal sections.

For more convenient regulation of the opening of the chimney damper, the handle is installed on the front panel. There are also two air supply channels to the boiler. The first is the damper on the ash chamber door. The force of its opening, as well as the volume of air supplied to the combustion chamber from under the grate, is adjusted either by an automatic draft regulator or manually using a screw. On the door of the loading chamber there is also a hole for air supply directly into the combustion chamber of the heating unit. The force of its opening is regulated by the owner.

To be able to monitor the temperature and pressure of the liquid in the system, there is a thermomanometer on the top cover of the solid fuel Czech boiler. Its sensor is immersed in the rear section, and the device itself is located in the control box.

The body of the Viadrus solid fuel boiler has a special type of thermal insulation, which reduces heat losses and thus increases the performance of heating equipment. The body is covered with wear-resistant and heat-resistant paint over the insulation.

Review the table to understand the main technical characteristics of the Viadrus U22 C.

| Technical characteristics of Viadrus U22 C | |||||||||

| Number of sections | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Power (coal), kW | 11,7 | 17,7 | 23,3 | 29,1 | 34,9 | 40,7 | 46,5 | 52,3 | 58,1 |

| Heated area, m² | 120 | 180 | 230 | 290 | 350 | 410 | 460 | 520 | 580 |

| Fuel consumption, kg/h | 1,9 | 2,9 | 3,8 | 4,7 | 5,7 | 6,6 | 7,5 | 8,5 | 9,4 |

| Efficiency % | 75-80 | ||||||||

| Chimney diameter, mm | 156 | 176 | |||||||

| Cost, rub. | 49 200 | 52 000 | 55 900 | 60 150 | 64 550 | 71 800 | 76 250 | 81 200 | 89 850 |

As well as the parameters of the Viadrus U22 D boiler.

| Technical characteristics of Viadrus U22 C | |||||||

| Number of sections | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Heated area, m² | 220 | 270 | 330 | 380 | 440 | 490 | 530 |

| Fuel consumption, kg/h | 6,4 | 8,0 | 9,6 | 11,2 | 12,8 | 14,4 | 15,7 |

| Efficiency % | 75 | ||||||

Heating with reserve: review of the solid fuel boiler Viadrus U22D-4

Heating “with reserve”: review of the solid fuel boiler Viadrus U22D-4For the majority of the population, the term “solid fuel boiler” is associated with stoves, firewood, felt boots and a hut with smoke coming out of the chimney. In fact, modern TT boilers are quite technologically advanced products that can serve as the “heart” of a heating system along with gas and electric boilers. Actually, a properly designed and executed heating system does not care what kind of fuel the boiler uses - the main thing is that the required amount of coolant with a given temperature is at the entrance to the system.

When building a house, I thought for a long time about ensuring maximum reliability and efficiency of the heating system and settled on the option of parallel connection of two boilers: gas and solid fuel. At the same time, the system implements the possibility of both alternate and simultaneous operation of two boilers.

Selecting boilers for the heating system

Before starting work, it was necessary to select the brand and model of boilers. While there are dozens of different manufacturers on the market for gas boilers, solid fuel boilers are manufactured by fewer factories and companies, and the choice of models is not very large. For gas boilers the following list can be given:

- from the highest price and quality category - gas boilers Viessmann, Buderus, Wolf, Vaillant, Bosch (all from Germany), CTC (Sweden);

- average in cost and quality Beretta, Ferroli, Ariston, Baxy SPA, Fondital, Sime (all from Italy), Dakon, Mora, Viadrus (Czech Republic), Protherm, Eleko (Slovakia), Roca (Spain), Kiturami, Olympia (North Korea ), Rinnai (Japan);

- the cheapest are domestic boilers and boilers from CIS manufacturers.

As for solid fuel boilers, the list includes the following manufacturers:

- among the expensive ones - boilers of the Viessmann, Buderus, Junkers brands (all from Germany);

- of the optimal ones - Viadrus, OPOP, Dakon (Czech Republic), Demrad (Turkey), Roca (Spain);

- among the inexpensive ones - Russian multi-fuel boilers of such brands as “Don” (produced by LLC “KChM-5” (produced by OJSC “Kirov Plant”, Kirov), “Ochag” (produced by LLC “Gazstroy”, Ulyanovsk), “Yaik" (produced by JSC Novosergievsky Mechanical Plant, Novosergievka village, Orenburg region).

One of the world leaders in the production of heating equipment is the Viadrus company, which was founded in the Czech Republic back in the century before last, back in 1885. The company began producing cast iron products in 1888 - these were parts for the railway; in 1890, the production of heating equipment - cast iron radiators - began. And the first Viadrus cast iron boilers appeared in 1920. Now the Viadrus production is a modern iron foundry, which since 1993 has had a quality certificate of the ISO 9001 series, and since 1997 - a certificate of the environmental production management system of the ISO 14001 series. Thus, the high-quality material used and modern technologies of its own production are a guarantee of high efficiency, reliability and durability of Viadrus boilers and radiators.

Having decided on the manufacturer, I studied the range of solid fuel boilers and settled on the Viadrus Hercules U22 C/D model. One of the most common and best-selling models of the brand has been produced since 1977, and during this time the design has undergone numerous changes and improvements, but has not yet lost its relevance, while at the same time proving its highest reliability - after all, more than a hundred thousand units of boilers of this model. The boiler is available in both a standard version (letter C in the name) and version D - with increased space for putting large pieces of wood into the firebox (pieces with a diameter of up to 220 mm can be burned). The fuel that can be used to heat a boiler is quite varied - coal, coke, wood, wood briquettes.

Advantages of Viadrus Hercules U22:

- advanced production technology is confirmed by certificates (ISO 9001, ISO 14001);

- durability of the cast iron heat exchanger and time-tested design;

- high efficiency of the boiler and increased volume of the combustion chamber increase the time between fuel loadings;

- simplicity of design allows for easy maintenance and care;

- the large chimney diameter ensures low smoke draft requirements;

- It is possible to convert the boiler from burning solid fuel to burning gas or liquid fuel, and vice versa.

Description of the boiler

Having ordered and paid for the boiler, I was glad that the price included delivery - after all, the boiler has considerable dimensions (HxWxD 974x520x750 mm) and weighs more than 250 kg, which is no wonder, because the “insides” of the boiler are made of cast iron. The boiler is supplied on a special pallet, which can be removed with a forklift, but we carried it into the combustion room with four of us by hand. The rated power of the boiler is 20 kW, the approximate heated area is 200 sq. m.

The appearance of the boiler after assembly (the boiler is supplied with a fully assembled body, but without mounted thermal insulation and external cladding, which must be screwed on separately from a cardboard box) is quite strict and laconic - the body is black and red, the doors of the combustion chamber and the ash compartment are located on the front panel , and in the upper left corner there is a handle for the smoke damper of the exhaust pipe, which can be used to regulate the exit of combustion products from the boiler into the chimney. To control the temperature and pressure in the heating system, a thermomanometer located on top of the boiler is used. A screw with a draft regulator on top and a chain attached to the ash door (muffler) regulate the supply of burned air under the boiler grate: the smaller the hole for the air supply, the longer the firewood will burn in the chamber, but the lower the coolant temperature will be achieved at the outlet boiler

The boiler can operate in heating systems with natural or forced circulation of heating water with an operating pressure of up to 4 bar. The efficiency of the boiler when burning coal and coke is 80%, when burning wood - 71-78%.

There were no problems during the installation of the boiler; all the pipes were in the right place and of the required diameter (according to the installers, with Chinese and domestic boilers there are often cases when the boiler has to purchase additional parts necessary for normal installation).

Organization of a heating system with parallel connection of two boilers

I’ll say right away that when calculating and designing a heating system in a house, Internet experience (reading websites, forums and user reviews) did not help - in this particular case, the task was given to an experienced heating engineer-installer to solve. It was he who, having calculated the heat loss of the house, the heated area and volume, taking into account our wishes for the heating system (for example, we decided to heat the entire first floor of the house using heated floors), was able to design a heating system and calculate the required boiler power.

Or rather, boilers, since we decided to install both gas and solid fuel boilers in the system as heat sources. At the same time, with the help of calculations for balancing the pressure at the inlet and outlet of the boilers, we were able to both alternately and simultaneously operate boilers in the system. In practice, it looks like this: by default, a gas boiler is running in the system, but if you wish, you can load a solid fuel stove with firewood, and the gas boiler will turn on less often, and if you turn on the heat higher, the TT boiler will stop working altogether. But only until the firewood burns out and the water in the return of the heating system requires additional heating.

General view of a boiler room with two boilers in the system

Of course, the system also provides other heat saving elements, which can be briefly listed:

- the house must be insulated in accordance with the requirements of the given climatic region;

- it is necessary to exclude or minimize drafts and other movements of air masses inside the heated volume of the house;

- At the supply (input to the system) there should be a weather-dependent regulator that changes the temperature and volume of coolant supplied to the system depending on fluctuations in the external temperature. An alternative to such a device can be temperature controllers in rooms, which ensure heating of room air to a given temperature and automatically turning on and off the heating system for each room or zone;

- An important element could be connecting daily timers to different zones: for example, during the day in bedrooms on weekdays, high temperatures are usually not needed, but in the kitchen and living room, on the contrary, the batteries can be “screwed on” at night.

In my system, these principles are implemented in this way: each floor has its own separate heating zone, controlled by an internal temperature sensor (for bedrooms the optimal temperature is set to 21 degrees, for the first floor - 19). In addition, a weekly timer is installed on the supply of the first floor, which stops supplying heat at night and during those periods of time while no one is in the house.

An alternative to the system described in the description can be the organization of an intelligent “smart home”, in which all these and many other functions will be implemented through the control of electrical, electromagnetic and other devices through a central control device (controller or computer). However, the cost of a “smart home” system is quite high, and its installation is possible either at the stage of construction or major renovation of the entire house (wiring for power and control must be connected to each section of the system and device that must be controlled).

After installation and commissioning of the system, we started both boilers to make sure that they were functioning properly at the same time. In practice, the need to heat a solid fuel boiler arises either in extreme cold, when the need for heat increases sharply, or during periods of gas saving (for example, to fit into the annual limit). In addition, in four years, once the gas supply was suspended for two days (a gas pipeline accident), but it was these two winter days that showed us that an alternative source of heat is not only a pleasant, but sometimes a vital addition.

Experience in using and maintaining a solid fuel boiler

As for the features of the installation and operation of solid fuel boilers, special attention should be paid to the safety of using such units. In the photo on the left is a safety group for a solid fuel boiler, which includes a pressure gauge and a tank device, which, when the maximum temperature is exceeded (usually 100 degrees), opens the emergency valve and releases water into the return line or into the sewer until the temperature drops below critical.

I confess that one day I unknowingly tested this security system: I set fire to the wood in the TT boiler without opening the supply tap (which is strictly prohibited!), and went about my business. After 30-40 minutes, I heard from the boiler room a series of impacts of metal on metal and the hissing of steam and water. I run into the boiler room: the pressure on the safety group pressure gauge is 3.2 bar, the supply pipe has heated up above 100 degrees, the drooling finger hisses when touched, and the sounds of blows are the operation of the safety group valve, which was releasing steam and hot water into the sewer with a roar. But if there were no safety group, overheating of the solid fuel boiler could cause not only its failure, but also an explosion and fire. To avoid such unpleasant consequences, entrust the design and installation of the system to professionals and adhere to the rules for operating solid fuel boilers.

Another important aspect of the operation of TT boilers is fuel. In particular, boilers can be fired with coal, peat, sawdust or special pellets (small granules of sawdust), but my boiler is designed mainly for firewood. The best firewood for heating is oak - they burn longer and produce more heat compared to other types of wood. Birch firewood is also good; it also has a high calorific value.

But coniferous firewood (pine, spruce, larch) can throw up an unpleasant surprise, especially raw firewood - when burned, it leaves a layer of resin and soot inside the combustion chamber and chimney, which worsens the draft in the chimney and requires subsequent cleaning of the combustion chamber. At the beginning of the operation of my boiler, I made several stacks of undried pine firewood, which I later regretted: the boiler needed cleaning of the loading chamber from resin (after which I was convinced with my own eyes that the expression “dirty as a stoker” has a deep and difficult to wash rationale), and the chimney elbow from the boiler to the transition to the brick chimney had to be removed to clean the inside. By the way, I decided to clean out the soot accumulated in the chimney by burning it from the inside - and I saw how soot and tar could burn inside the chimney (clouds of suffocating smoke and flames escaping from the pipe on both sides with a roar). Since then, I have never forgotten to add a special powder to the firewood every 5-6 loads for preventive maintenance - a chimney soot cleaner.

By the way, depending on the temperature and intensity of firewood burning in the boiler, one full load of good oak firewood is enough for 2-6 hours of burning, after which, of course, the firewood needs to be added. In my case, if the stash burns out, the gas boiler will simply be connected. Very, very convenient - especially at night, because you no longer need to get up in the morning and go to the furnace room, and warmth in the house is guaranteed.

Conclusions and Conclusions

In general, modern solid fuel boilers are quite technologically advanced and allow the use of such heat sources as both main and additional ones. However, TT boilers are associated with some inconveniences in use - in comparison with their gas or electric counterparts, of course.

Such disadvantages include the complexity of adding fuel and subsequent cleaning of the boiler from ash and soot, the need to store a supply of fuel (with my mode of use, I had enough firewood for the season, but even this car needs to be stored somewhere - optimally in the yard under a canopy, not far from the entrance to the furnace room). The next disadvantage is the need to constantly monitor the operation of the boiler and add firewood - sometimes you are too lazy to do this, and sometimes it is physically impossible (for example, if everyone has left home for several days). Well, the last disadvantage is the increased fire and operational hazard of using solid fuel boilers.

As for my case, the Viadrus U22D-4 model was ideal as an additional (and in case of emergency, the only) heating source in the system. And my son and I also love the process of igniting the boiler - there is something mesmerizing about a living fire, even if you look at it through the door of the boiler loading chamber.

Owner reviews

To fully understand what a unit of this brand is, you need to read reviews of the Viadrus solid fuel boiler. Here, for example, is the Viadrus U22 D boiler. Users confirm that with care and proper operation, the device operates stably and in accordance with the specified technical specifications. The temperature is maintained within the specified error of 2-3 °C. A one-time laying of firewood is enough for 1.5-2 hours. After the boiler and the entire system have warmed up well, the user closes the damper and the fuel smolders. Thus, the logs burn twice as long, but the owners do not recommend using this mode immediately after kindling: only on a properly heated system. People note the high reliability of the Viadrus U22 D, the doors open and close easily, and the system works as it should.

Review from the owner of the Viadrus boiler The firebox of the Viadrus boiler turned out to be small and completely uncomfortable. This includes 20-25 cm of firewood. If you burn with coal, it also comes in small volumes. Well, accordingly, this whole thing burns out quickly and needs to be refilled often. In winter, our temperature reaches -40 or more, and we have to constantly be near the boiler. So no amount of benefits can completely compensate for this. Jan

Some owners of Czech boilers model U22 4D note the effective operation of the draft regulator in the device, but at the same time complain about problems with soot accumulation due to the use of damp logs, and sometimes the formation of soot in the chimney.

As a rule, reviews of the Viadrus solid fuel boiler are positive. If there are shortcomings, then they are due to improper operation or initially incorrect choice of device according to technical characteristics. In case of any breakdown and the warranty is valid, the user can contact the company’s specialists for free repairs. Therefore, Viadrus boilers can safely be called reliable.

Wood and coal boiler Viadrus Hercules U22 pros and cons

The Viadrus Hercules boiler has three main advantages:

- Firstly, this is a good heat exchanger made of high-quality cast iron, which allows us to talk about the overall durability of the boiler.

- Secondly, this is a very reasonable price for boilers from a European manufacturer. For example, a Viadrus Hercules U22 D-4 boiler (four sections, power 23 kW, fuel wood) costs from 36,000 to 42,000 rubles from different dealers. If you guess the timing and get caught up in dealer promotions, you can buy a boiler even cheaper.

- Thirdly, the Viadrus Hercules U22 boiler has fairly precise control of the combustion process, whether using wood or coal. That is, you can be sure that your system will not boil, that the boiler automation will be able to extinguish the flame in the firebox in time.

There are not many disadvantages to the Viadrus Hercules U22 boiler.

- Firstly, the recommended chimney diameters for the models are quite strange - 156, 175 mm. Non-standard pipes or adapters increase the cost of installing the boiler and chimney.

- Secondly, models with up to 5 sections inclusive have a very small firebox depth. That is, only the D-6 (power 33/35 kW) can have a log length of 45 cm. This is the standard length, which is sawn in Russia and sold on any corner from trucks.

And for models with 4 and 5 sections, the length of the log is a ridiculous 27 and 35 cm. That is, a boiler that heats a house of 200-300 sq.m. you need to heat it with such funny logs, cutting down standard firewood.

The amount of sawdust that you cut during the season can be scattered over a considerable size garden.

More on this topic on our website:

- Coal and wood boiler Dakon DOR - characteristics and reviews The coal and wood boiler Dakon DOR is manufactured by DAKON in the city of Krnov (Czech Republic). The boiler is intended, first of all,…

- Pellet boiler ZOTA Pellet / Zota Pellet reviews and characteristics When a gas pipe runs in front of the house along the border of the site and there is an opportunity to connect at state tariffs, you can build any house…

- Calorific value of wood - table of the calorific value of firewood For those owners who decide to heat their house with solid fuel, this material is intended. It’s not easy to figure out what fuel to use for heating...

- Solid fuel boiler ZOTA Mix - review and reviews from owners ZOTA boilers are produced at the Krasnoyarsk Heating Equipment and Automation Plant. The plant specializes in the production of solid fuel and electric heating boilers….