Today, gas boilers are the best solution for heating almost any private house or apartment, both in terms of reliability and practicality, and in terms of purchase cost and operating costs. Every year, one can more and more clearly observe a trend towards a preference for wall-mounted models: less universal, exclusively energy-dependent, but more efficient, compact and, in practice, according to statistics of service calls, almost as reliable.

In the article we will look at how to wisely choose an even more interesting option - double-circuit wall-mounted gas boilers, which allow, with the same size and efficiency, to provide the house with hot water. The cost of dual-circuit models is only 10-15% higher, so this is the cheapest way to organize hot water supply at home.

What are wall-mounted double-circuit gas boilers?

Modern wall-hung double-circuit boilers have an excellent design, a minimum of communications around them and operate almost silently, so they can be installed in any room that meets the requirements.

Gas mounted double-circuit models with the same dimensions and heating technical characteristics combine the functionality of two devices at once - the boiler itself and a flow-through (less often storage) water heater. The coolant from the heating circuit in dual-circuit models does not mix with sanitary water from the hot water supply (DHW) circuit.

It is advisable to install wall-mounted double-circuit models in small and medium-sized residential buildings with an area of up to 350-400 m2, in which the distance from the boiler to the points of consumption is not too large (7-10 m). Otherwise, preparing and heating running water will take too much time, 20 seconds or more, which negatively affects not only comfort, but also water and fuel consumption.

Another important point is the number of people living in the house, or rather the number of points of simultaneous consumption of hot water. Most dual-circuit models operate on the principle of DHW priority, i.e. when the consumption point opens, the heating circuit is preheated. Less often, usually in more expensive models, where the distribution of performance is implemented using a three-way valve, the heating of the heating circuit does not stop completely, but the performance is still reduced.

In practice, this means that if you use several hot water consumption points at the same time, the performance of the DHW circuit may not be enough, not to mention the heating circuit. Therefore, the total number of rooms with hot water consumption points (bathroom, guest bathroom, kitchen, etc.) should not exceed three.

Design and principle of operation

A visual principle of operation of double-circuit boilers with priority for hot water supply (DHW).

Double-circuit wall-mounted boilers differ from single-circuit boilers only in the presence of an additional heat exchanger and devices for distributing productivity between the circuits. The technical device may vary from model to model, but the standard design is simple and clear: a burner to which gas is supplied and its igniters → a primary heat exchanger, inside of which there is a heating circuit coolant and a secondary heat exchanger, inside of which sanitary water from the DHW circuit circulates → product removal system combustion into the chimney.

All well-known and common models are already equipped from the factory with all the elements and components necessary for the heating system: expansion tank, circulation pump, automatic air vent, safety valve, pressure gauge, set of sensors, etc. This means that for a standard heating scheme it is enough to just connect the supply and return lines to the boiler, as well as a water source for the DHW circuit (for example, a water supply).

To clearly understand the operating principle of dual-circuit models, let’s consider the functionality of each circuit separately:

- heating - a basic circuit in which the coolant continuously circulates, heating up in the heat exchanger and releasing heat through radiators in heated rooms;

- water heating - activated only when the hot water consumption point is opened, redirects all or a certain part of the heating circuit coolant to water heating.

After closing the consumption tap, the boiler switches back to the heating circuit and heats it up if the coolant has cooled down, or goes into standby mode (background heating) if everything is fine with the temperature.

Traditional double-circuit boilers are always characterized by a delay in the supply of already heated water (from 5 to 15 seconds), but there are models without such a delay, with a built-in boiler, operating on the principle of a storage heater, which we will talk about when describing the selection criteria. In any case, there is also a delay in the supply of hot water, independent of the boiler, associated with the length of the pipeline between the boiler and the point of consumption, where the cooled water is located.

The device is based on the example of the famous dual-circuit BAXI ECO-4s 24F: compact classic layout, optimal materials, all modules are placed down for convenience.

How to choose a room thermostat and save up to 30% per month on heating

Baxi and Vaillant quality control

Vaillant boilers, water heaters and other equipment are the embodiment of the concept of “German quality”. The manufacturer uses a unique multi-stage quality control system using the “one piece flow” method. Each piece of equipment is assembled by one master, who bears personal responsibility for his work. Next, the equipment is sent to test benches, where it undergoes a detailed check on many parameters. Only after this the products are shipped to the intermediate warehouse.

Baxi factories annually produce hundreds of thousands of boilers, water heaters and other equipment. Assembly of one unit takes just a few minutes. Despite this, the equipment is tested for leaks, operability of main components and electronics, safety for humans and the environment, and so on. There is a testing laboratory capable of simulating maximum loads for “stress tests” of boilers selectively selected from the assembly line.

Both manufacturers have their own research departments that allow them to develop technologies and introduce innovations.

Reviews of domestic wall-mounted models with a DHW circuit: advantages and disadvantages

| Advantages | Flaws |

| Favorable price - double-circuit models are only 10-15% more expensive than single-circuit models, so this is the cheapest way to organize hot water supply in the house, compared to installing a gas water heater, electric boiler, etc. | Higher probability of failure - double-circuit models can operate without problems for 10 years or more, but statistically the probability of failure is higher compared to single-circuit ones, due to their more complex design and additional features. nodes |

| Compactness - double-circuit boilers only in rare cases differ in size from the same single-circuit analogues from the same manufacturer | Relatively long delay in the supply of hot water - can be solved by more expensive models with a built-in boiler |

| Simplicity of connection - a minimum of communications connected to one point, in contrast to the installation of separate devices for heating water | Limitation in productivity - on average, the DHW productivity of common modern models is within 8-12 l/min, which is enough for a maximum of three, and according to owner reviews, often only for two points of simultaneous consumption |

| Availability of relatively inexpensive models with a built-in storage tank, solving problems of comfort and, to some extent, performance | Energy dependence - all heating gas wall-mounted double-circuit boilers require connection to the electrical network, despite high demand, non-volatile models do not exist due to the specific design |

| Restrictions on the use of antifreeze - most models are not designed to use antifreeze as a coolant, and only some manufacturers allow the use of a certain brand of liquid, as indicated in the operating instructions |

Network of service centers

Baksi has more service centers in the Russian Federation than Vaillant. Most of Vaillant's authorized service centers are located in the western part of Russia. Baxi has a wider geographic coverage, making it easier to find a specialized company.

Baksi service centers in the Russian Federation

Vailant service centers in the Russian Federation

Whatever boiler you decide to buy, you should make sure in advance that there is a service center of the selected manufacturer nearby. This will simplify both equipment installation and further maintenance.

You can always view the current list of official service centers on the official websites of manufacturers.

How to choose a wall-mounted double-circuit gas boiler for a private home

Convection or condensation

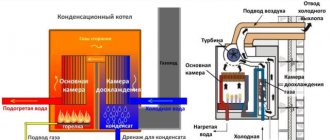

The operating principle of conventional convection (efficiency 88-92%) and condensing (efficiency 104-109%) gas boilers.

The first thing you need to decide is the type of boiler, which affects the principle of its operation and, accordingly, efficiency:

- convection - a traditional boiler that accumulates thermal energy exclusively from the combustion of gas in the combustion chamber, while some of the heat goes into the chimney along with the combustion products;

- condensing - a more advanced, efficient and expensive design with another additional heat exchanger that accumulates the heat of condensate formed from exhaust gases. The temperature of the exhaust gases with this operating principle is 30-50 degrees or more lower, and the thermal energy accumulated by the additional heat exchanger is directed to heating the return line.

Of course, in the second case, the efficiency of the installation is much higher; fuel savings, depending on the design, can reach 15-20%. The real element of condensing boilers is a low-temperature heating system (large radiators, constant burning at low power, coolant temperature up to 50°C), in which case the higher costs pay off after 3-5 years of operation. Otherwise, in modern Russian conditions, the payback period for condensing models is from 7 to 12 years.

The cost of condensing models starts from 50 thousand rubles, but more often it is 65 thousand rubles or more, with the exception of Korean and Chinese models costing about 30 thousand rubles. Such a high price is explained by the high requirements for the materials of the additional heat exchanger, which must be resistant to the acidic effects of condensate. Another disadvantage of condenser units is the need to dispose of condensate, which is not ordinary water. We have already described all the features in detail in the corresponding article.

All the differences and selection criteria for condensing gas boilers

If you do not plan to organize a low-temperature heating system, we do not recommend bothering with condensing models; today, for now, it is enough to choose a traditional convection boiler.

Structural design and material of the heat exchanger

Double-circuit boilers have two heat exchangers, which can be combined or separated:

- bithermal heat exchanger is a heating circuit and a domestic hot water circuit combined into one inseparable structure; they are combined according to a “pipe-in-pipe” scheme, in which sanitary hot water is located in the inner pipe, and the heating circuit coolant is in the gap between the walls of the inner and outer pipes

- monothermic heat exchangers are two separate traditional heat exchangers, in one (primary) the coolant of the heating circuit circulates, in the other - sanitary water of the DHW circuit.

Differences between boilers with one bithermic heat exchanger and two separate monothermic ones.

If in the case of a heating system, even the hardest, but not replaced water practically does not form scale that impedes circulation, although such cases do exist. Then in the DHW circuit the water is constantly changing, and when heated in the heat exchanger, it settles on the walls in the form of scale, significantly narrows the diameter of the coil, and over time completely clogs it.

But if two separate heat exchangers can be cleaned without problems even mechanically, then a bithermic (dual) heat exchanger is almost impossible to clean and if it becomes clogged with scale, it must be replaced. However, models with a single design are more compact and cheaper to manufacture than more reliable and durable boilers with two separate heat exchangers.

The bithermal heat exchanger cannot be cleaned mechanically and is quite difficult to rinse. When scale forms, it clogs faster.

No less important, affecting durability and reliability, is the material from which the heat exchanger is made:

- steel – steel heat exchangers are inexpensive to produce, lightweight and flexible, and are not afraid of sudden thermal changes, but they are highly susceptible to corrosion, even despite good anti-corrosion coatings. Their service life is usually 10-14 years;

- copper - copper heat exchangers are more expensive, but also more thermally conductive, more resistant to corrosion, their service life is about 14-17 years.

Availability of a storage tank

The photo shows Buderus Logamax plus GB172-24 with a built-in storage tank of 48 liters.

Modern mounted boilers can have various methods of preparing hot water:

- flow-through – the previously described principle in which water begins to heat up when the point of consumption is opened;

- storage – the principle in which a certain volume of heated hot water is constantly available in the built-in storage tank of the boiler.

If you use hot water intensively, we recommend choosing a boiler with a storage tank, the capacity of which can be from 30 to 60 liters. A storage tank means eliminating the 5-10 second delay in preparation, a certain supply of already heated water, and a more uniform temperature. Please note that formally such boilers are usually called “single-circuit boilers with a built-in boiler”; when searching in the product catalog of an online store, they may be located in this category.

Combustion chamber design and types of smoke removal

According to the method of supplying the oxygen necessary to maintain combustion and removing combustion products, all double-circuit gas boilers can be:

- with an open combustion chamber (atmospheric boilers) - combustion air is taken from the room through openings in the housing, and combustion products are discharged through a traditional vertical chimney;

- with a closed combustion chamber (turbocharged boilers ) - air for fuel combustion is taken from the street, through a coaxial chimney, and with the help of it the combustion products are removed.

The type of combustion chamber determines the cost and ease of installation, the cost of the boiler itself, as well as the requirements for the room for its installation.

Open combustion chamber and natural draft

Atmospheric boilers are cheaper, but often have slightly lower technical characteristics. Combustion products are discharged through a traditional vertical chimney using natural draft. To ensure this, a pipe with a diameter of 120 mm and a length of 4-5 m is required; detailed requirements are usually specified in the boiler documentation.

In addition to more complex installation, the disadvantage of atmospheric models is their faster contamination and the need for periodic cleaning of the burner, ignition electrodes, etc. It is also not recommended to install them in residential premises (in corridors, kitchens, etc.), since they take oxygen for combustion from the same room; when placed in a boiler room, proper ventilation must be ensured.

Closed combustion chamber and forced draft through a coaxial chimney

Boilers with a closed combustion chamber are equipped with a forced-air fan (turbine), which forcibly removes combustion products and helps draw fresh air into the combustion chamber. The efficiency and economy of turbocharged boilers is higher, due to the fact that the turbine rotation speed is automatically adjusted; the boiler always maintains optimal combustion due to the optimal ratio of fuel and oxygen.

A serious advantage of boilers with a closed combustion chamber is the absence of the need to organize a full-fledged traditional chimney. Air is taken in and gases are removed through a coaxial (side) chimney, in which the inner pipe serves to remove combustion products, and the gap between the inner and outer pipes serves to take in fresh air. The coaxial chimney comes complete with the boiler and is mounted very simply into a hole in the wall.

But even in this case there are disadvantages:

- When operating at high speeds, the turbine creates a certain noise, in some models it is quite noticeable, and in others it operates almost silently;

- a coaxial chimney can negatively affect the aesthetic appearance of the house;

- turbocharged boilers consume 20-50 W more electricity.

- in cost they are 3-5 thousand rubles more expensive.

We recommend choosing models with a closed combustion chamber: they are more efficient and safe, easier to install, and do not require ventilation.

All necessary communications (piping) of a mounted double-circuit model with a closed combustion chamber.

DHW performance

Almost all modern double-circuit wall-mounted boilers produce about 8-12 l/min of hot water, regardless of their power. This volume is absolutely enough for two points of consumption, open to the maximum, so focusing on the DHW performance indicator should be done at one of the last stages and paying attention only to serious deviations from the average values.

But in order to roughly imagine how much boiler performance is sufficient, you can calculate the maximum consumption.

For example, the throughput of an average mixer in a bathroom or kitchen is in the range of 3-5 l/min; of course, the value depends on the diameter of the pipe, pressure and efficiency of the mixer (ratio of air and water at the outlet).

Efficiency

The efficiency factor (efficiency) is the ratio of the volume of fuel consumed to the volume of heat generated, that is, the efficiency of the boiler. The optimal indicator for a modern mounted boiler is 89-92%. However, you should also pay attention to efficiency last, having decided on the previous parameters, since a difference of 1, 2 and even 3% will be expressed not in hundreds, but in tens of rubles per month.

It is worth paying attention only to indicators below 86%; in 2022 these are unacceptable indicators for a good mounted gas boiler, indicating technical imperfection, and the difference in operating costs compared to models with an efficiency of 90% and above will be noticeable.

How to replace a gas boiler in a private house without violating the law

Minimum required power

It is reasonable to select the power after deciding on the model, since all modern models have a wide selection of versions with different heating capacities (usually the range is from 12 to 35 kW and wider).

For an average uninsulated or poorly insulated house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power of heating equipment is calculated based on the rule: 1 kW for every 10 m2 of heated area. We also recommend setting aside a power reserve of 15-20%, and in the case of a double-circuit boiler - 25-30%.

For example, for the above-described house with an area of 150 m2, the minimum required power is 150/10 * 1.3 (30% reserve) = 19.5, that is, 20 kW.

In non-standard cases, if panoramic windows are used and the glazing area is much larger, the ceilings are high, the house is well insulated, and is located in the extreme southern or northern point of the country, correction factors are taken into account that can change the result by 15-30% up or down. You can make a detailed calculation using the calculator below.

In conclusion, it is worth mentioning the criteria that increase the comfort of operation, but, accordingly, the price of the boiler:

- the presence of a sound insulation layer that seriously reduces the noise level of the boiler;

- the presence of a programmer that allows you to set the boiler operating pattern for a day or a week;

- the ability to send fault notifications via SMS, using a GSM module, as well as control via Wi-Fi.

Which boilers break down more often: Baxi or Vaillant?

Judging by consumer reviews and search query statistics, Baxi boilers lead in the number of problems.

The most common error in Baksi boilers is e01. The error is that the ionization sensor does not detect the burner flame (either there is no flame, or there is one, but it is too weak). This problem leads to the boiler blocking. There are also common errors:

- e10 (water pressure in the heating circuit is too low, loss of contact between the control board and the relay, failure of the pressure switch);

- e03 (critical reduction in the speed of exhaust gases in the chimney or problem with the draft sensor).

Internet users search for Vailant boiler errors less often. Among the common errors, the most popular is f28 (indicates several unsuccessful ignition attempts due to problems with the gas supply, pressure drop, faulty grounding elements and supply voltage, or due to boiler failure). Errors with codes often occur:

- f75 (Vailant’s self-diagnosis checked the start of the circulation pump and did not record a pressure surge, which is why the system concluded that there were problems with the pump; in order to prevent overheating, the boiler is blocked);

- f20 (indicates overheating, can be caused by a malfunction of the signal circuits or the overheating sensor; false alarms occur due to instability of the electricity supply, a stabilizer can be a solution to the problem).

Please note that a common cause of problems with a heating system (of any brand) is improper installation or design errors.

Even if you bought a high-quality boiler from a good company, unprofessional installation can lead to numerous malfunctions, including complete failure of the boiler.

The best known manufacturers and models: characteristics and prices

All the models listed below are the most well-known and widespread, one of the most trouble-free and proven, optimal price-quality ratio double-circuit wall-mounted boilers. It is quite difficult to sort them into a rating based on reliability or quality, since most of them are the most successful models on the competitive market, almost identical when assessed based on a set of parameters, but clearly having their own characteristics.

BAXI ECO-4s 24F

The most common and “favorite” in Russia is the Italian double-circuit boiler with a closed combustion chamber (prefix F in the name). It is highly efficient and economical, its efficiency is one of the highest in the price segment - 92.9%, maximum gas consumption - 2.73 m3/hour. At the same time, the boiler is perfectly adapted to domestic conditions: unstable gas and water pressure, as a rule, is not the cleanest coolant, the automation and pump tolerate minor voltage drops.

The primary heat exchanger is copper, there are almost all protection systems available today: from overheating and freezing, blocking the circulation pump, auto-diagnostics. A water filter is also pre-installed. The quality of assembly and layout is excellent; after operating for more than 6 years, the boiler is known for its trouble-free operation. Owners also note almost silent operation. Among the shortcomings, only slight instability of the temperature of the heated water can be noted.

Vaillant turboFIT VUW 242/5-2

Despite its less popularity, in our opinion this is one of the best wall-mounted double-circuit gas boilers for heating a private home. TurboFIT VUW 242/5-2 is one of the German reference models with a closed combustion chamber. It is distinguished by excellent efficiency, efficiency – 93.5%, and maximum gas consumption – 2.66 m3/hour. The heat exchangers in it are separate, the primary one is copper. The performance between the circuits is carried out using a three-way valve, which allows you to maintain the temperature of the coolant when hot water consumption points are open. DHW performance is at the level of analogues.

The model has been on the market for only a few years (since 2022) and so far there are no known cases of service failures. However, the manufacturer has long been known for its high reliability and durability. Judging by the layout, this model is no exception: all pipes are copper, not rubber, connections are threaded, excellent build quality. All necessary protection systems are present. The turbine, servo drive and ignition operate almost silently.

Its only drawback is its higher price; in fact, it is a budget model from a well-known premium manufacturer. It is also worth considering that it is advisable to connect the boiler through a voltage stabilizer to prevent failure of the electronic control board.

Viessmann Vitopend 100-W A1JB010 24

Another reference German boiler with a closed combustion chamber, slightly inferior in performance to the Vaillant turboFIT. Efficiency – 91% at maximum gas flow – 2.77 m3/hour. The heat exchangers are separate, the primary one is made of steel, although with thick walls, designed for an operating pressure of up to 3 bar; during operation in Russia, no problems with burnout or leakage are known. The distribution of performance between the circuits is also through a three-way valve, and there are all protection systems.

A special difference is the presence of a programmer that allows you to set boiler operation settings for a day or a week, which, with proper operation, can significantly reduce consumption. A built-in programmer is a rarity in boilers in this price category.

The disadvantages are standard for most Viessmann models: vulnerability to voltage surges (the protective mechanism is designed for 170-253 V, which is not always enough); again, we recommend connecting the boiler through a voltage stabilizer. Also, in rare cases, the flame sensor and the burner module as a whole may become clogged, causing the automation to display error F4. It is imperative to regularly clean the boiler (at least once every 3-4 years) and monitor the condition of the gas filter.

Bosch Gaz 6000 W WBN 6000-24 C

A budget model from a well-known manufacturer, not the most outstanding in terms of characteristics, but proven in operation. Maximum gas consumption – 2.8 cubic meters. m/hour, separate heat exchangers, the primary one is copper, the distribution of productivity between them is carried out by means of a three-way valve. It operates almost silently, at the level of the reference Vaillant, in particular thanks to the smooth ignition technology, without the characteristic pop.

The device and materials used are not very different from previous analogues, but some connections are not threaded, but use rubber. In general, there are no serious complaints about technical reliability, but the boiler is very demanding on the presence of grounding, preferably dedicated specifically to the boiler, otherwise it will constantly generate an EA error.

Step-by-step instructions for grounding a gas boiler in a private house

Also, owners often note less convenient controls; to change the temperature of the DHW circuit and some other settings, you need to perform several actions, unlike separate buttons or “knobs” in previous models.

Buderus Logamax U072-24K

A German model with a closed combustion chamber, but with Russian localization (assembly is carried out at a Russian plant), which significantly influenced the cost of the boiler and made it possible to distinguish it from others. Efficiency – 92%, maximum gas flow – 2.8 m3/hour, primary heat exchanger – copper. The layout of the boiler is not much different from previous German analogues; the connections are threaded, but the quality of Russian assembly is sometimes inferior to European ones.

In general, this is an extremely budget-friendly, efficient, reliable and stylish model, but at the same time it has a slightly larger number of shortcomings. Firstly, in addition to the lower quality of assembly, it is a plastic water supply valve, which is easy to break over time. Secondly, the electronic board is vulnerable to voltage surges. However, the price of the boiler makes it competitive and worthy of attention.

Ariston ALTEAS X 24 FF NG

An extremely stylish, efficient and high-tech boiler with a closed combustion chamber. Efficiency – 93.7%, maximum gas flow – 2.73 m3/hour, separate heat exchangers, distribution via a three-way valve. In addition to the design and build quality, the main difference from previous analogues is the presence of a programmer and the ability to control from an application on a smartphone via Wi-Fi. Owners also note a large number of fine settings (limiting the coolant temperature, influencing the on/off frequency, etc.).

The only drawbacks are the interface, which is somewhat difficult to master, the impractical glass cover, which shows fingerprints, and the rather high price, which, however, can hardly be considered overpriced.

Undoubtedly, there are other excellent models from the same or other manufacturers, in some respects inferior to those listed, and in others superior; it is impossible to list them all within the scope of the article.

If you wish, you can also pay attention to models from such companies as Protherm, Lamborghini, MORA-TOP, De Dietrich, Wolf. Due to the increased problems and quality, we do not recommend choosing Korean models, Russian-made boilers and similar ones that are attractive for their cost: Navien, Kiturami, Lemax, Ferroli (assembled in China).

Video description

In the video, a specialist talks about the Protherm Panther KTV wall-mounted boiler:

Floor standing gas boilers

They are presented on the market from the same manufacturers, so the range is wide. And yet we have to choose the best floor-standing double-circuit gas boiler.

Vaillant atmoVIT VK INT

First place again goes to German equipment. There are several types in the model range of this unit, differing from each other in power. This figure varies in the range of 16-56 kW. Basically, a boiler is required to heat hot water, but one model has an instantaneous heater installed inside.

Boiler features:

- atmospheric injection burner without fan;

- cast iron heat exchanger;

- Efficiency 92%;

- flame, temperature and draft control sensors.

Boiler Vaillant atmoVIT VK INT Source mostszh.ru

Viessmann Vitogas 100-F 29-60

This brand is one of the most extensive in terms of model range. It contains 15 models with a power from 29 to 60 kW, which is very convenient if you need to select the required unit. Experts say that if the consumer is faced with the task of choosing an economical gas boiler, then this is it.

Moreover, all models easily cope with gas pressure differences in the main pipeline. That is, it is not a problem for them.

Design features:

- the burner is made of stainless steel, it is rod type;

- heat exchanger made of gray cast iron;

- full automation of equipment;

- gas control relay.

Viessmann Vitogas floor standing boilers Source static.wixstatic.com

Prices: summary table

| Model | Efficiency, % | Max gas consumption, m3/hour | DHW capacity, l/min at t 30°C | Cost, rub. |

| BAXI ECO-4s 24F | 92,9 | 2,73 | 9.8 at t 35°C | 43 200-47 500 |

| Vaillant turboFIT VUW 242/5-2 | 93,5 | 2,66 | 11 | 45 000-53 200 |

| Viessmann Vitopend 100-W A1JB010 | 91 | 2,77 | 11,2 | 54 000-61 000 |

| Bosch Gaz 6000 W WBN 6000-24 C | 93,2 | 2,8 | 11,4 | 39 800-42 000 |

| Buderus Logamax U072-24K | 92 | 2,8 | 11,4 | 43 500-52 500 |

| Ariston ALTEAS X 24 FF NG | 93,7 | 2,73 | 9.6 at t 35°C | 64 200-69 000 |