As a rule, those who install autonomous boiler equipment in their home for the first time encounter problems with its operation. Not everyone, for example, knows how to properly heat a boiler with coal or what type of solid fuel to choose for the designated purposes. Experts point out that any stove must be handled with extreme caution, carefully observing all fire safety standards. It is also useful to familiarize yourself with the operating features of the selected equipment in advance.

How does a coal boiler work?

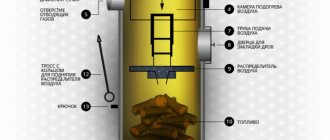

What is a coal boiler? This is a simple installation that consists of two compartments. Coal is placed in the upper firebox. After it burns out, ash and slag remain, which fall into the lower compartment and are removed from there as necessary. Between the chambers there is a regular grate made of durable cast iron.

Such furnaces can be additionally equipped with sophisticated automation, which allows the unit to switch to offline mode and control the draft. If there is no automation, coal stoves operate using natural circulation. The first type of device has several operational advantages, but long-burning stoves cost much more than simple devices .

Automation works extremely simply. Thanks to it and the operation of the fan, it is easy to control the flow of oxygen into the firebox. The more it is, the hotter the coal burns, and the faster the fuel burns, giving off the maximum amount of heat. Restricting oxygen access leads to the opposite effect. The fuel burns more slowly, the amount of heat released decreases, but the burning time of the coal increases.

The heating temperature is regulated by a special temperature sensor. The boiler operating modes can be programmed. If the set temperature is reached, the sensor is triggered and turns off the fan. At the same time, the oxygen supply decreases and the furnace burns out more slowly. When the temperature drops, the fan turns on and begins to intensively pump oxygen into the firebox. The coal is actively burning again. If you take into account such features of the operation of a solid fuel boiler, it becomes clear when and how to put coal in the stove.

Popular models

The Dymok model has a hob.

The most common models are the following. They have gained popularity due to their technical characteristics and properties.

Zota Dymok

Zota electric boilers of the Dymok series are direct-burning solid fuel appliances. The air supply can be adjusted manually using a damper. The boilers are non-volatile.

The combustion chamber is made of steel and is also equipped with a cast iron hob.

The company offers two modifications - KOTV and AOTV. The difference is that the AOTV series has a hob. The power of KOTV boilers is offered in two versions - 14 and 20 kW. The power of the AOTV series is divided into 3 levels - 12, 18, 25 kW.

The boiler system makes it possible to configure many parameters, which will ensure autonomous and safe heating operation.

Zota Lux

Zota Lux boiler for an apartment or private house, wall-mounted

Electric boilers Zota Lux series are intended for autonomous heating of industrial premises and residential buildings. The area of the heated building is from 30 to 1000 m2.

The user can adjust the temperature from +30 to +90 degrees, which allows the devices to be used in a “warm floor” system without auxiliary control equipment. The boiler will automatically maintain the set temperature.

The tunic has small dimensions and weight. The manufacturer has made it possible to easily connect to external circuits, such as sensors or pumps.

Other

List of other popular models:

- Zota MK – medium power devices;

- Zota Smart – high-tech models with a wide range of functions;

- Zota Topol-M – products with a gas-tight insulated body;

- Zota Master - models whose body is lined with basalt wool;

- Zota Econom are economical devices that perform optimally.

What coal to choose for the fire?

What is coal? This is a product of plant origin, which contains carbons and non-flammable impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is this, as well as the “age” of natural fuel, that determines the grade of coal. Experts distinguish several varieties.

The “youngest” type of coal is lingite. It has a rather loose structure. If you pick up a lump of lingite, it will quickly crumble and lose its shape. This type of coal is most often used in thermal power plants, but lingite is not suitable for heating a home.

In addition to lingite, brown coal, hard coal, and anthracite are also mined - the most ancient carbon deposits. All varieties have different humidity levels. In brown coal, for example, humidity is 50%; in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal/kg. Coal has a lower figure - 5.5 kcal/kg. The brown variety has a specific heat of only 3 kcal/kg. Considering all this, it is easy to understand what type of fuel to purchase for heating the house.

How to use solid fuel units correctly?

The operating principle of a solid fuel boiler is known, and the issue of choosing the type of coal has been resolved. All that remains is to learn how to properly light the stove. There are several simple rules that everyone who chooses the described installations for organizing heating of a country house must learn.

Remember! First, the stove must be prepared for lighting, then fuel must be correctly loaded into it. During its combustion, the installation must be closely monitored, removing combustion products in a timely manner.

Let's look at all these points in more detail.

Preparing the stove for lighting

If the stove in a country house is used occasionally, before starting its operation, for safety reasons, it is necessary to exclude the presence of cracks inside the masonry.

Why are they dangerous? Through them, combustion products and carbon monoxide can enter the room, which must be removed outside using drafts. If such a defect is discovered, it must be eliminated before kindling by covering the cracks with a mixture of clay and sand. Otherwise, when heated, the cracks may increase in size even more. And this will lead to dangerous situations.

When inspecting the stove from the outside, we remove flammable objects away from it and clean it inside. We remove the ash and slag with a shovel, freeing the internal compartment. It is advisable to wipe the inner walls of the firebox with a dry cloth. If this is not done, then during kindling the dust will begin to burn, filling the room with an unpleasant odor.

The coal stove needs to be lit several times a day. The duration of one fire should not exceed two hours. For loading, it is better to use well-dried medium-fraction coal.

Note! Wet fuel produces steam when burned. It forms condensation, which settles inside the chimney. Mixing with soot, condensate forms coke, which gradually clogs the chimney passage, narrowing it. And this leads to problems with traction.

Do not use household waste or flammable liquids such as gasoline or kerosene to ignite coal. Do not leave the stove unattended while it is burning. This rule must be observed especially strictly if there are small children or animals in the house.

How to properly melt coal?

The stove must be lit as follows:

- First, we place sheets of newspaper or any other dry paper on the bottom of the firebox. On top of it we place a layer of small wood chips. And on them we stack small firewood, for example, birch logs. To make them burn faster, they need to be folded in the form of a well or a small hut.

- Set fire to the paper. We close the oven door and open the ash pan. Using it, it is easy to control the intensity of fuel combustion. The stronger the air flow, the faster the stack of firewood burns out.

- After the firewood has completely burned out and only a pile of smoldering ash remains, you need to lay a 15-centimeter layer of fine coal directly on it.

Note! When opening the door to load fuel, be sure to close the vent.

- When the 15-centimeter layer of coal burns out well, we place larger coal directly on it and build a cushion 60 cm high. It is useful to stir the burnt fuel thoroughly beforehand, which will improve air circulation and prevent caking of the coal mass. Coal can be placed by opening the firebox door.

Note! Low-quality solid fuel tends to coke. Therefore, experienced stove makers advise laying a layer of coal with layers of firewood. Such a multi-layer cake will allow the unit to burn well and give off the maximum amount of heat.

- To properly light the stove, it is better to do this - open the ash pan and let the paper with the wood chips burn out using natural circulation. This will allow the chimney to warm up well. As the fuel burns, the draft will increase, so you then need to close the ash pan and turn on the fan.

Solid fuel heaters

The Krasnoyarsk manufacturer supplies the market with solid fuel heating units of the following series:

- Carbon. There are 7 models with power from 15 to 60 kW;

- Master. The series includes 6 models with powers from 12 to 32 kW;

- Topol M. There are 4 models with powers from 14 to 42 kW;

- Mix. The series has 4 options with power from 20 to 50 kW;

- Dymok-M. Five variations with a power range from 12 to 25 kW;

- Boxing. There is one model in this series with a power of 8 kW.

Advantages of Carbon heating boilers:

- The small circuit is made of high quality boiler steel;

- Fuel is loaded from the top;

- Ease of cleaning the heat exchanger.

Zota Carbon scheme

- Large diameter loading opening;

- Using a draft regulator with adjustment of the tertiary air flow;

- Moving grate;

- The design of the heat exchanger ensures the combustion of fuel particles contained in the exhaust gases;

- Designed for a pressure of 3 atm;

- Adjustable chimney pipe included;

- The ash pan is mounted on a water-cooled surface, which increases efficiency;

- Possibility of using an additional heating element.

An additional heating element increases the operating time. When solid fuel runs out, the boiler does not stop working. If necessary and desired, it is possible to convert the boiler to gas (liquefied or natural).

Additional advantages of the Master series include the following:

- Combined heat exchanger;

- Insulation with basalt cardboard;

- The air damper ash pan on the door adjusts the flow of incoming primary air;

- Possibility of installing a mechanical draft regulator (optional);

- The combustion chamber allows the use of coal and logs up to 70 cm long as fuel.

Installation of an additional gas burner is allowed on Master-20.

Mix series boilers are equipped with an X-shaped heat exchanger, which allows for the largest area of contact with the flame. The outer body of the heater is coated with wear-resistant powder paint.

Dymok-M heaters are distinguished by a water jacket, the structural strength of which is increased due to the use of channels. This design allows them to be used in heating systems with a pressure of up to 3 and even with a short-term increase of up to 4 atm.

Zota Dymok-M device

Sold as a standard set with a removable chimney pipe and an adjustable damper. A significant plus is tightly closing doors that do not allow gases to pass through and increase combustion duration and efficiency.

Coal heating boiler ZOTA “Carbon”

The ZOTA Carbon boiler has been produced since 2013. The device is made of high-quality steel and is intended for heating residential and industrial premises with an area of up to 600 m². The line includes 7 standard sizes with power from 15 to 60 kW.

Photo 1: Domestic heating boiler ZOTA “Carbon”

ZOTA "Carbon" has a unique design. Let's carefully examine its main advantages:

- The main feature of the Carbon series is a large firebox with top loading and adjustable air supply. It is convenient to replenish the boiler with a new portion of fuel, and its battery life increases to 11 hours.

- The steel body is made of corrosion-resistant steel. This reduces the cost and also eliminates the main disadvantage of steel boilers - the tendency to corrosion.

- The combustion chamber is designed in such a way that combustion occurs in a certain area, which in turn makes a significant contribution to increasing the duration of operation on one load. With the help of fireclay, you can burn out the exhaust gases, which turns the device into a kind of pyrolysis heating boiler using coal.

- The three-pass heat exchanger and the location of the ash pan within it significantly increases heat removal, thereby increasing the operating efficiency of the solid fuel boiler and its efficiency.

- The design of the heat exchanger and the movable grate make cleaning extremely convenient and fast.

- In addition to working on coal, it is possible to install a heating element with a power of up to 9 kW with a control unit.

Photo 2: Electric heating elements for Zota boilers

Let's look at the main technical characteristics of those listed on the official website:

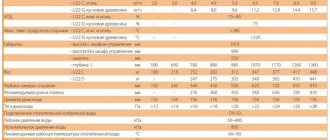

| power, kWt | 15 | 20 | 26 | 32 | 40 | 50 | 60 |

| Room area, m² | 150 | 200 | 260 | 320 | 400 | 500 | 600 |

| Efficiency, % | 80 | ||||||

| Chimney cross-section, mm | 150 | 180 | |||||

| Chimney height, m | 5 | 7 | 8 | 9 | 11 | 13 | 15 |

| Heat exchanger capacity, l | 48 | 55 | 66 | 78 | 93 | 102 | 121 |

| Price, rub | 37 200 | 44 500 | 46 800 | 49 900 | 62 900 | 69 900 | 79 500 |

Here's what home owners say about their experience:

For a house of 150 m² (siding + polystyrene foam (10 cm) + tuff block), I installed a 32 kW model with a reserve, since I heard that a power reserve is necessary. The boiler maintains a comfortable temperature even in the most severe frosts. The bunker can easily accommodate 2 buckets of coal. The maximum consumption per day was 5 buckets. I use it around the clock, at night I connect the heating elements at the night rate. I noticed that in non-stop mode it works much more efficiently. So, I only stop it to clean it once every week or two.

Vladimir Sergeevich, Krasnoyarsk

The ZOTA “Carbon” boiler is an excellent budget solution for those who are looking for an inexpensive but effective coal boiler for their home or cottage. The ability to install a heating element makes the device universal and makes it possible to heat the room with both solid fuel and electricity in extreme cases.

Return to contents

Recommendations for installation and operation

Installation of the Zota boiler and its use are carried out strictly according to the instructions for the specific model. For installation, select a closed room with functioning supply and exhaust ventilation.

The unit is placed on a non-combustible base or concrete foundation. If the floor surface is combustible, the place under the device and in front of it (0.5 m) is covered with a steel sheet on top of an asbestos or basalt gasket.

1 m of free space is left in front for easy maintenance of the boiler. From the side to the walls - at least 0.5 m, the interval at the back - 0.4 m. The joints with the chimney and heating pipes are carefully sealed to avoid leaks and smoke in the room.

Diagram of the heating system with the Zota “Topol” boiler.

- Security group.

- Ball valve with drive.

- Circulation pump.

- Coarse filter.

- Expansion tank (expansion tank).

Basic operating rules:

- Store fuel and flammable materials at a distance of more than 0.4 m from the boiler surfaces;

- do not allow the coolant to overheat (over 95 °C), otherwise the housing will be deformed;

- do not let the water in the system freeze during the cold season;

- as waste accumulates, clean out the ash compartment;

- once every 2-3 months, scrape off resin deposits from the internal cavities, which reduce thermal conductivity;

- If there is overheating and knocking in the heating system, stop burning and allow the coolant to cool. Find out which heating radiators are best using this link.

The boiler cleaning process using the Zota Magna model as an example is shown in this video.

Combined heating boiler ZOTA “Mix”

The main feature of the ZOTA “Mix” boiler is its versatility. It mainly runs on wood and coal, but in a pinch gas, diesel and electricity can be used. This flexibility is achieved by a special design that allows you to install different types of burners and operate equally efficiently on different types of fuel.

Photo 3: Combined heating boilers using solid fuel Zota Mix

Let's look at what other advantages the Mix solid fuel boiler has:

- The heat exchanger has an unusual X-shape, which ensures maximum heat removal, which in turn ensures high efficiency values.

- Operating efficiency is also improved by insulating the water jacket. Heat loss due to its use is reduced, and therefore efficiency increases. In addition to improving efficiency, insulation also improves fire safety.

- Easy access to the flue and a spacious ash tray make cleaning and maintenance very convenient.

- The optimal pressure for a heating system is 3 atm. In emergency cases, the device can withstand a pressure surge of up to 4 atm, without the danger of explosion as is the case with the installation of a cast iron solid fuel heating boiler.

- The operating power is adjusted by a built-in draft generator and a draft control damper in the chimney. Temperature and pressure are controlled via a thermomanometer on the front panel.

The ZOTA “Mix” model is available in four sizes with power from 20 to 50 kW. Their main characteristics are as follows:

| power, kWt | 20 | 31,5 | 40 | 50 |

| Room area, m² | 200 | 315 | 400 | 500 |

| Efficiency, % | 80 | |||

| Firebox volume, l | 35 | 45 | 63 | 79 |

| Heat exchanger capacity, l | 50 | 70 | 120 | 140 |

| Chimney diameter, mm | 150 | 180 | ||

| Chimney height, m | 6 | 7 | 8 | 9 |

| Price, rub | 34 900 | 38 700 | 49 900 | 54 500 |

Feedback from a real owner of the ZOTA “Mix” boiler about the experience of use:

I use a Zota Mix 20 kW boiler to heat my ecopan house of 75 m². The device fits perfectly into the boiler room. At first I thought of installing Buderus at 12 kW, but it is significantly more expensive. I use sawdust briquettes as fuel. For the winter, 3 tons are enough, which in terms of money comes out to 16,000 rubles. I've been using it for three seasons now, so far no complaints.

Eldar Vladimirovich, Irkutsk

Solid fuel boilers Zota - Adjustments and settings

___________________________________________________________________________________________

- Electric boilers Zota

- Roca boilers - Malfunctions and repairs

- Defro boilers - Adjustments and maintenance

- Solid fuel boiler settings Energy

Solid fuel boiler Zota Topol M 14. Sometimes after the damper closes, it seems to stick and then does not open automatically. And accordingly the temperature drops. When you come, push it, it will open. What kind of trouble is this? And about the chimney sandwich. It warms up in the tee and above. Not hot, but very warm. The hand endures and does not burn. This is fine? The tee on the street exits horizontally from the boiler room through the wall. Do you have a thermometer not in the boiler, but in the system? There is a combined pressure and temperature sensor. Why am I asking, it happens that the sensor on the unit lies by 10 degrees. For example, mine shows 70 degrees, and on the second thermometer 60. Adjust the pump according to the fact. Set it to three, the coolant will circulate faster in the system, but the unit may not have time to heat it. Sometimes I turn it on to three to quickly warm up the system. And so it’s worth 1. The condensate must be periodically removed to drain. The pipe does not have to be cold. I installed a Zota Mix 20 kW boiler. Leningradka heating system (single-pipe, pipe 40, bimetal batteries). The house is 130 square meters, 2 floors, the pipe from the boiler goes to the 2nd floor, along the 2nd goes to the 1st and returns to the boiler. The problem is that when the temperature in it is 90-100 degrees, the return barely reaches 55 degrees, and if there is terrible heat on the 2nd floor, on the first floor the temperature does not rise above 15 degrees. At a temperature of 100 degrees, the pressure begins to rise to 3 bar and above, you have to monitor it. I burn with wood. Actually the question is, is this normal or will it get better with connecting a circulation pump? I think that the system should be direct, i.e. with a pressure pipe and a return pipe, and of course a circulation pump. A dual-circuit system would be much better. But it is necessary to ensure that during a power outage there is natural circulation with slopes. It’s easy in theory, but I haven’t done it in practice yet, I’m just getting ready to do it. Zota Magna 15 kW. Recirculation works, the supply may periodically heat up, but it takes a very long time to heat up. We tried changing the fuel but to no avail. Everything is in order regarding the piping, the problem lies in the unit reaching the operating temperature of the flue gases. There are three possible causes: fuel, lacing mechanism position, and draft. Based on this, I had a question: will it work normally (without attenuation) if the diameter of the chimney is increased. The small diameter of the chimney will not allow the unit to reach full power, only half the power, but there should be no attenuation. Bring the diameter and height of the chimney in accordance with the passport data, insulate the chimney. I talked about recirculation, it will not allow it to reach normal operating mode, you need a thermostatic mixing valve for the return, preferably in your case with a bypass that cannot be switched off. Check and clean the heat exchanger, horizontal and vertical sections of the chimney, dry coal with no stumps. I bought a Zota Carbon 20 solid fuel boiler with the expectation that it would be unpretentious, economical, and would burn for a long time. I burned a choice nut with coal. The temperature once reached 80 degrees, and mostly 50-60. The batteries are barely warm. It smokes terribly. Coal hangs. I constantly had to push something through. It is heated if the top lid is slightly open. The coal flies away, you just have time to add it, but there is no heat. If you close everything, it goes out. It gets clogged very quickly, I cleaned the boiler completely every week. It doesn’t hold the temperature at all, in the morning it’s 20 degrees on the unit itself. What to do? Let's try to name the problems why the unit does not work. The chimney does not meet the required parameters. The chimney must be insulated and at least 9 meters high from its exit (internal radius 150 mm). There is no air supply to the unit. It is done as follows: a hole is made at the top of the boiler room for a 110 plumbing pipe and lowered down to the floor. You need to check the “clean-out hatch cover” (the corner, let’s say). It is necessary to open the cooled boiler in its upper part (there are 2 bolts there) and make sure that the corner is in its place and not to the left or right. The Zota Master 20 solid fuel boiler heats up quickly and consumes less than a stove, but there is one unpleasant effect. When loading coal, I open the loading door, and smoke comes out, although the wood burns well and the gate and damper are fully open. Pipe D-150 8m, good draft, unit hums. How to fix this, tell me, maybe I’m lighting it wrong? Here is the T2 boost. Three-way or four-way. The simplest option. You can install automation in the form of a thermal head. You can install real automation with a controller. Just not in this version. You can install a hydraulic arrow. There are many options. The main thing is to raise the temperature above 55, remove the dew point. Help me to understand. Solid fuel boiler Zota Topol M 30 kW. Sandwich pipe 7 meters, 150 internal and 250 mm external diameter. The problem is that after one or two fires the chambers become clogged quite well. Balakhtinsky coal. I'm tired of cleaning already. It happened - soot in the chimney caught fire. Now I'm afraid of a repeat. The horizontal section of the pipe behind the boiler gets very hot. Is this supposed to be like this or what? I constantly clean the unit. The damper is in the third position. What am I doing wrong? And when loading the next portion of fuel, sometimes a flame flies out of the ashpit. There is a draft regulator. Sometimes the gate door slowly twitches and starts whistling. This all really stresses me out. If the temperature of the return flow (return pipe to the boiler) is below 55 or 60 degrees, then the unit will become heavily overgrown from the inside. If there is no thermometer on the return, then you can determine the approximate temperature by touch by comparing it with the supply. Set the damper damper to maximum and do not touch it; adjust the temperature using the draft regulator. You also need to periodically monitor the chimney sump (if there is one) and clean it. It is necessary to install a draft stabilizer on the chimney, limit the draft to 25 Pa, then the exhaust will not fly out into the chimney, there will be no need to reduce combustion with a damper, and dirt will not be deposited on the walls of the chimney. Today's use of the Zota Magna 20 boiler was not encouraging. In the evening I threw in 2.5 buckets of Balakhta coal, and in the morning I looked into the firebox and some of the coals were still red. Just to be sure, I added some firewood and poured in half a bucket of coal to heat it up a little, turned on the fan and left. Upon arrival, I saw that smoke was coming out of the fan and from other cracks. The fan stopped, the wood and coal began to smolder and all the smoke was inside. When the fan started, everything became normal. Adjust the boost fan valve. The boost fan valve should close when it stops. If there is no draft in the pipe and the valve is not closed, then the smoke will go through the fan into the room; if the draft is excellent, then the unit would continue to burn and boil, which should not happen either. Read the passport, configure it before you launch it. Owners of Zota Mix, please tell me. What model did you have, with or without heating elements? What is the actual size of the firebox? What actual log size was included, and how many logs at a time? How many stacks of wood do you need to burn, and for how long, to warm up your house at night? Solid fuel boiler Mix 20 kW. I bought it with a 6 kW heating element and a control unit, but I hardly used it. As for the firebox - there were dimensions in the passport, I won’t tell you now, but a sawn standard birch log is not included. I sawed the log into 3 parts about 10-15 cm. It took about the same as now. I will say about coal, since the information about firewood is currently not relevant for many reasons. 2 buckets of coal were thrown in, the house warmed up from 18 to 27 degrees in about an hour. Tell me, what power should I take the Zota Carbon solid fuel boiler, 15 or 20? The house has 2 floors with a total area of 105 square meters. The system will be open to antifreeze. And in what mode does 20 work? How much area? How many radiators? How many liters of water? Closed or open? How often do you toss? If the pump turns off, will it not boil? Opening hours: from December to April without stopping. Area 110 sq. m., 2 floors. Radiators 3 pcs. and everything is on the first floor. I don’t remember exactly the displacement, it seems to be 120 liters. The system is closed. We throw up to -5 degrees once a day, to -15 - 2 times, two buckets each, if more than -15, then a full load. By pump - If the temperature rises, of course, but not to a boil, I usually maintain the temperature at 60 degrees. The house is +19 to +23 depending on the temperature outside, in which case there is a security group. Tell me, please, what is the problem? We heat the Zota Master 18 boiler with coal (Kuznetsk), the draft regulator was adjusted, it worked well. Something strange has been happening over the last few days. We set the regulator to 70 degrees, it reaches 92. We set it to 55, it still gives out under 90. The coal placement is the same. The door is completely closed, but the unit accelerates as it wants. The regulator was adjusted again as soon as the pipe was increased to 5 meters. Everything worked well. It’s true that in recent days the temperature “overboard” has been -30, maybe this has an effect? Tell me, what could be the reason for such a discrepancy in temperature between the sensor and the draft regulator? Yesterday my device also accelerated to 100 degrees, the regulator was set to 70 as always. I think it’s due to the fact that before that I cleaned it well, and the water became hotter, besides, it got colder to -35, and in the cold the draft is stronger, and I didn’t touch the damper on the chimney, but I had to cover one hole gate The question is, which Zota boiler is best for heating with wood? Long burning is desirable. And why is Topol M not quite suitable for firewood? Topol-M's operation on wood is less efficient than on coal, because it was originally designed as a coal boiler (mainly for brown coal). Coal and firewood, fundamentally different types of fuel, burn differently and require quite different principles and combustion modes for efficient combustion. In addition, the calorific value of firewood, the density of firewood and bulk density are much lower than that of coal, and the design of the firebox does not allow loading a sufficiently large amount of firewood into it - hence the operating time on one load is 2-3 times shorter. For firewood, the Magna model is best suited. This is a semi-automatic unit. Work on one full load of firewood from 4 to 15 hours depending on the operating mode (nominal / minimum power). But I would like to immediately note that the requirements for the moisture content of firewood are quite high - 12-15%. Magna boiler 26 kW. In fact, the coal burns, but the temperature of the gases drops below 100 degrees, and it records the attenuation. But the hydraulic part is of little concern for now; it is important for me that it burns and the temperature of the gases does not drop. The heat exchangers are dry. If 200 degrees is the power rating, then what power will it give when running on coal at a temperature of 150? The unit does not return to normal operating mode, the supply temperature should not be lower than 65 degrees, the return temperature should not be lower than 55 degrees. You need a thermostatic return valve. I have a Zota Mix 50 solid fuel boiler. Why does the steel on my exhaust chimney glow (the area in the room up to the vertical chimney)? What temperature is this? At this rate it will probably burn out soon. I threw in a couple of buckets of coal and have an extra night light. The boiler is 95 degrees, there is a TA. Maybe there is a damper switch in the unit itself? Or just reduce the thrust by using a damper at its outlet? This model has a damper switch. The secondary air also needs to be closed; in general, as a rule, it is for firewood or until the coal flares up. On the top right of the bottom door there is a “secondary” one. By dismantling the cover. Just pry the decorative (gray) one with clips (latches) or gently pull it towards you. Behind it is the shaft cover on 4 x 6 studs (unscrew the nuts with a 10 x wrench). Solid fuel boiler Carbon 20, chimney height 9 meters, cross section 150 (regular water pipe). The pipe is half insulated, there is no canopy. The problem is that a deposit (such as tar) forms on the walls of the firebox. How to get rid of it? The fuel does not burn through completely and freezes. The unit is in the garage (what temperature should it be in the boiler room?). Now in the garage it’s +5+8 degrees, outside -30 and below. During operation, if the valve is moved to ignition, it burns well. Firstly, you need a unit for 150 square meters of 15 kW, maximum 20, but no more. There is not enough heat removal. Secondly, check the cleanout hatch cover. Thirdly, the entire chimney must be insulated. Fourthly, if there is no stitching, you definitely need to do it. I doubt, of course, that anything will help you with such a model for such an area. The temperature in the boiler room does not affect the operation of the unit, since it is completely insulated. I read the passport of the Zota Master 20 boiler, it says that when the device cools below 30 degrees, condensation may appear. Which apparently leads to clogging. I heat it in the evening after work, and turn on the heating element at night, turn it off in the morning, and it doesn’t work until the evening, so it cools down and condensates. It is necessary to increase the return temperature. As stated in the passport. Or in other ways. There will be less dirt. And longevity is determined by the fact that from laying to laying the temperature in the unit does not fall below 55 degrees. It can be increased using a four-way valve. But then you need a second pump in the circuit, with lower characteristics than the boiler pump. Then in general everything works more stable. But for some reason some manufacturers don’t like four-way ones. You can also raise it with three moves. There are many ways. You can also use a hydraulic gun. And the temperature on all units is the same. If it is not written, it means by default. Boiler Zota Topol M 20. Whistling in the ash pit. And now a question has arisen. I don’t touch the valve on the pipe. It stands almost completely open. I leave one division. But then it turns out that there is not enough for the night. The electric boiler turns on. But due to the fact that it is connected to solid fuel, the temperature is low and somewhere from the middle of the night the electric heats up constantly. If the temperature does not rise then this is normal, I also have a whistle, but after reconfiguring the draft regulator, now everything is fine, it whistles, but the temperature remains at the set level. Solid fuel boiler Zota Magna 26. After two days, the holes are halved and gases begin to escape from the loading door. Maybe someone has similar problems. How to fix it? Clean with the brush included in the kit. I installed a Zota Mix 31.5 kW boiler and fired it with European wood. I didn’t raise the temperature above 65 degrees, because it’s very hot and you can’t touch the batteries. I didn’t even climb into it or clean it, but recently it began to choke. It turned out that the chimney hog was completely clogged. We disconnect it from the chimney and what we see: pipe d120 is completely clogged and plus the outlet from the boiler. The pipe was cleaned, but I don’t know how to get inside the unit. If anyone has taken it apart, please tell me. Remove the front (gray part) panel, then 4 nuts on d6 key 10, unscrew and clean. Very easy. Tell me, there is a hum in the Zota Master 12 boiler, this seems to be the norm when warming up, but sometimes I have a very strong hum and even vibration and either smoke or steam is emitted from somewhere behind. This is when the door in the ashlar is fully open. I quickly cover it to a minimum, and everything is fine. This happened a couple of times during the month of use. Why could this be and has anyone else had it? Install a draft stabilizer on the chimney. The Zota Carbon 15 boiler does not reach a temperature of more than 60 degrees, and even then in 4 hours, the brick pipe with a cross-section of 240/160 reaches the attic, above 2 m of the sandwich it is without a circulation pump and I tried to turn off the supply valve, it cannot heat itself. What should I do? Most likely, you do not have an inlet. It is done as follows: a hole is made at the top of the boiler room for a 110 plumbing pipe and lowered down to the floor. Tell me how to adjust the fan boost damper on the Zota Magna 15 boiler. The instructions say that you need to find the position of the rod, with the fan turned off, at which the damper will be closed. How can you tell if the damper is closed? By sound? Is this somehow visible? Now I regulate, in fact, at random. Either it’s overheating or it doesn’t flare up. I caught, by chance, some position in which it burns and does not overheat, but at the same time it flares up very slowly and gains the temperature of the coolant, it takes 1.5-2 hours until the coolant reaches 65-70 degrees. It's easy to determine by poking the nut with your finger. If you unscrew the nuts until they melt, sometimes the damper is lifted by the rod. How long is a full fire of wood, and what temperature is it? Does the unit body get hot? Can the Zota Mix boiler be installed in the kitchen? A full firebox lasts for about 4 hours if you already have the boiler heated and water in the heating system. You can put it in the kitchen, you just need to carefully remove the ashes. The body heats up, but not much; the chimney hog gets very hot. It can be used, but it makes sense to use it in conjunction with a heat accumulator. And at what power will the efficiency of Zota Carbon 15 be maximum? What addiction? This depends on the design of the unit. The relationship is usually not linear. There is a peak at nominal and drops at minimum and maximum powers. Zota Topol M 30, aluminum batteries 80 sections, PP pipes 20, at the entrance and exit 40, metal piping. The house is 80 sq. m., 1st floor is brick, 2-frame, everything is insulated. We heat 2-3 times, 5-7 buckets of coal per day, it’s cold in the house, 15-19 degrees. We can't understand the reason. The unit is gaining temperature, but the batteries heat up unevenly, the bottom is warm, the top is hot, the supply pipe is hot, and the return pipe is slightly warm. It seems to me that the return flow in the boiler room is less than 55, my hand is tolerating it. It also seals the pipe. Check the filter in front of the pump (if worth it), there was such a problem a month ago, the filter was clogged with rust. Washed - now everything is fine. On the batteries, lower the air. I have a solid fuel boiler Master 20 with electricians (additionally). When you twist the handle of the air temperature regulator, the heating elements are turned on, and when the handle of the water regulator (to the maximum), then no. It seems that the water temperature sensor failed or what? Try to push the air sensor a little, and the adjustment of the water temperature should earn. The question is for those who use the boiler of the tycoon 20 kW on firewood. How much is enough and how often do you have to clean? It all depends on firewood, the moisture of the breed. Sroped with pine, scraps after construction, damp. The heat exchanger was poorly overgrown, the full load of the clock was enough for 8 hours, a weak heat, and the coals are burned out very quickly, and the desired size should be sawed and laid with clearances. Once in the grates, the log was stuck after Shurovka. Tell us about the furnace of the boiler mix with wood angle. What is the load, consumption? Combustion time? Wood is not the best. For 3 months, about 6 tons were burned, portions of about 8-10 kg, burning in 1.5-2 hours. Later he switched to stone coal. The temperature is gaining faster, burns 2.5 times longer, respectively, the consumption decreased noticeably. The only negative is more slag. Can clarify the situation with the secondary air. Why is it needed and where does the Karbon 20 Zota 20 live in this canal on the back wall of the boiler? Secondary air is needed for furnace with wood so that smoke burned out. For coal, primary air is needed. What recommendations can you give by operation of the boiler Topol M 20 kW in the summer? Do I need to turn off the pump or not? There is only one recommendation - do not operate it in the summer. I just did not understand a little for what purpose to operate it. If for the hot water, then this is economically not beneficial compared to electricity (namely in the summer). If for periodic burning of garbage - please use, the main thing is to provide traction in a chimney, a tributary and heat discharge from the coolant. The pump needs to be disabled if the unit does not work for you. Tell me why in the furnace of the boiler the master 18 on the walls as if a layer of bitumen. When burning firewood, plaque does not go away, but only melts a little. The area has increased, and the unit itself will drop below. So, after all, how does the return temperature affect this raid? This also happens if the return comes to the boiler cold. There is a certain condensation on its walls. In general, the return temperature of the solid fuel unit should not be lower than 50-60 degrees. Usually, when it works at full power, resin formation does not occur. To get rid of this, you need to raise the return temperature. Solid fuel boiler of the SLAGE MALLS 20. Tell me how often you need to clean the horizontal heat exchanger? When working on coal or other fuel. So that there are no problems I clean once a week (it takes a couple of minutes), I used to clean 3-4 weeks, there were problems with cleaning. Now I drown with brown coal, with a stone plaque there was more. Tell me, please, we want to put the Mix 31.5 zot in a separate boiler room. The house is wooden, the total area of 190 square meters. m, 2 floors. Is it worth it or not? You have 190 squares, respectively, you will have to run to the unit at least once every 4 hours and throw coal in a bucket of coal (in your case 2 buckets). I have a smaller area (77kv), but the essence is the same. There was a 20 kW mix, it cools over the night and that's it, in the morning it is cold. In the coldest period (-35 degrees during the day), 6-8 buckets per day came out. And so these models are not bad, I would even say universal, and most importantly, their dignity is absolutely omnivorous, and if someone is constantly in the house, then the unit is certainly good, I also had a 6 kW -on, but the cost of electricity did not allow To use it for a long time.

___________________________________________________________________________________________

___________________________________________________________________________________________

Repair of gas boilers AOGV Borino, ZhMZ, Siberia, Alfa Kalor, Termotechnik. Adjustment of gas automatic equipment Eurosit 630. Replacement of thermocouple and maintenance of pilot burner.

Troubleshooting and repair of Baxi boilers Models Luna, Luna 3 Comfort, Luna Duo Tec (F / Fi). Double-circuit, turbocharged. Recommendations for eliminating errors and malfunctions. Settings and adjustment of operating modes.

Bosch gas heating boilers Models ZWC, ZSA, ZSC, ZWR, Gaz 5000, Gaz 3000 W ZW, WBN 6000. Wall-mounted, double-circuit. Repairs, adjustments and malfunctions. Settings for functions and modes.

Navien repair recommendations Deluxe Coaxial, Deluxe Plus, GA models. Errors and problems. Working with Xital remote control. System control. Adjustment of work by temperature and pressure.

Buderus floor-standing boilers Repair of Logano G124, G125, G215, G234, G334 models. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions.

Operation of Vailant boilers Models Turbotec Atmotec pro/plus VU/VUW INT. Components and operating functions. Programs for adjustment. Gas system. Installation and installation. Maintenance and prevention.

Floor-standing boilers Protherm Repair of Bear models KLOM, KLZ, TLO, PLO with power from 20 to 50 kW. Breakdowns and problems. Operation, maintenance. Recommendations for setting operating parameters.

Lemax - repair and adjustment Models of gas floor-standing boilers Premium, Leader, Patriot. Performance characteristics. Prime, Wise models. Adjustment of automation Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward.

Wall-mounted boilers Protherm Repair of Panther, Cheetah, Jaguar, Lynx, Leopard models. Breakdowns and malfunctions. Operation and service. Recommendations for adjusting operating modes.

Beretta - repairs and adjustments Repair and operation of Ciao, City, Novella, Exclusive boilers. Wall and floor models. Malfunctions and error codes. Operating functions and setting up service modes. Maintenance.

Boilers Teplodar Kupper PRO Operation and adjustment of solid fuel boilers with a capacity of 22, 28, 36 kW. Installation of automatic pellet burner APG-25, 36, 42. Operating mode settings.

Repair of gas boilers Oasis Models of wall-mounted boilers ZRT, ZRN, BM. Malfunctions and error codes. Troubleshooting tips. Operating modes and setting up service parameters. Maintenance.

Heating boilers Alfaterm Description of floor-standing boilers of the Beta model and wall-mounted gas boilers Sigma. Malfunctions and error codes. Repair and troubleshooting questions. Basic maintenance work.

Wolf - faults and repairs Wolf boiler installed. I noticed that over time the pressure in it gradually decreases (by about 1 in 2 days). I checked all the pipes for leaks, but found nothing. What else should I check?

Junkers gas boilers After 7 years of operation, the Junkers ZW-23-KE gas boiler developed the following problems. When the hot water supply starts working, it either turns off or stops working...

Boiler repair Neva Lux Neva Lux 8224 (Baltgaz), discovered the following problem: the post-circulation pump does not turn off, and it does not matter what the temperature is. To make sure this is so, I raised the temperature to...

Boiler ZOTA “Topol M” on coal and wood

The ZOTA “Topol M” model is an improved modification of low-power household solid fuel boilers of the Topol series. In addition to the new design, the device has undergone a number of other significant changes:

- The body insulation is made of basalt cardboard, this reduces heat loss and increases operating efficiency.

- An additional horizontal heat exchanger was added inside the firebox, making the boiler a three-pass one.

- The firebox door opens both vertically and horizontally for convenience. It is convenient to load firewood up to 58 cm long through the scoop door.

- The ash pan is equipped with a damper, the degree of opening of which is regulated either mechanically or using an automatic draft regulator.

- As an option, it is possible to install a heating element and a gas burner in place of the screw door.

Photo 4: Zota boiler “Topol M” wood, coal, gas, electricity

In total, three standard sizes of the “Topol M” series are produced, here are their characteristics:

| power, kWt | 14 | 20 | 30 |

| Room area, m² | 140 | 200 | 300 |

| Efficiency, % | 80 | ||

| Firebox capacity, l | 36 | 46 | 53 |

| Heat exchanger volume, l | 46 | 54 | 64 |

| Chimney diameter, mm | 150 | ||

| Chimney height, m | 6 | 7 | 9 |

| Price, rub | 26 900 | 29 900 | 34 200 |

Review from the owner of ZOTA “Topol M”:

It’s been a month and a half since I installed “Topol M” 14 kW in a wooden house of 60 m². Of course the insulation is not very good, there are a lot of holes. There were frosts down to -35 °C, the boiler copes well. Regarding the loading mode, I will say the following: if you set the draft regulator to 70 and throw in a bucket of coal, then after 11 hours the temperature will be 30 ° C. The screw grid raises questions, because... When it gets red hot, it quickly burns out.

Zota "Topol M" is perfect for those who are looking for a small universal solid fuel boiler with good efficiency. It is precisely because of their high efficiency, low price, and ease of use that they are so popular on the Russian heating equipment market.

Return to contents

Main models

Zota pellet boilers are presented on the market in two model ranges - Zota Pellet and Zota Pellet Pro. Also on sale is the universal Zota Optima model, which can operate on ten types of solid fuel. All equipment presented for sale is manufactured by LLC TPK Krasnoyarskenergokomplekt. All products are certified and meet strict quality standards.

Zota solid fuel pellet boilers are used to heat buildings for various purposes - residential cottages, outbuildings, industrial hangars, warehouses and much more. They are equipped with spacious bins for storing pellets and are equipped with convenient control panels. Let's look at this equipment in more detail.

Pellet boilers Zota Pellet

This series is represented by seven models with power from 15 kW to 100 kW. The equipment is equipped with screw fuel supply systems and forced-air fans. It operates in automatic mode, focusing on the specified temperature indicators and regulating the supply of fuel to the combustion chamber. Ignition is carried out automatically using a small heating element.

Structurally, the Zota Pellet pellet boiler consists of two parts. The first contains a combustion chamber and a heat exchanger with an ash pan, and the second part consists of a burner and a spacious hopper. The system uses an electronic control system with the ability to control via a GSM module - this provides remote monitoring of various indicators.

Other features of Zota Pellet pellet boilers:

- Left or right arrangement of the hopper with burner according to the customer’s request;

- Possibility of working on fuel wood and briquettes - during a power outage;

- Possibility of installing a block of heating elements - ensures maintenance of the coolant temperature when the supply of pellets in the bunker is depleted;

- Built-in weather-compensating control;

- Safe design that prevents fires and ignition of fuel reserves;

- Water cooling jacket.

Zota Pellet pellet boilers use deciduous and coniferous wood pellets as fuel. The equipment is designed to operate in heating systems with forced circulation of coolant.

If necessary, the capacity of the bunker can be increased by retrofitting it with additional modules for fuel. The standard volume is 293 liters.

Pellet boilers Zota Pellet Pro

This series includes high power models - from 130 to 250 kW. Productive vertical heat exchangers and air automatic ignition systems are used here. The standard capacity of the bunkers is 560 liters, which is enough for a long time. Fuel is supplied to the burner using two screws.

The control in Zota Pellet Pro pellet boilers is electronic, with the ability to connect GSM modules. There is also weather-dependent automation on board that monitors the weather outside and adjusts the operating parameters of the units. The electrical network is used as a backup heat source - heating elements units are purchased and installed separately.

Universal boilers Zota Optima

These units are universal. They can work on brown coal, fuel briquettes, firewood, as well as wood and sunflower pellets. Depending on the selected fuel, manual, semi-automatic and automatic operating modes are supported. Buyers have a choice of models with a power of 15 and 25 kW, which is enough to heat buildings up to 250 square meters. m.

Zota Optima boilers, which can operate on pellet fuel, are equipped with built-in thermostats and weather-compensating automation. It is possible to install a block of heating elements with a power from 3 to 12 kW. The units are easy to clean and have a spacious ash pan for storing ash.

Domestic boiler with hob ZOTA “Master”

ZOTA “Master” is an ideal option for those who need a small but practical and economical boiler for their country house. The main feature that distinguishes the Master series from other solid fuel boilers is the presence of a removable hob. Other advantages include:

- High efficiency is achieved due to good thermal insulation and heat exchanger design, which ensures maximum heat removal.

- The dimensions of the combustion chamber make it possible to use wood as fuel.

- A mechanical draft regulator is optionally available, allowing you to automate the operation of the device.

- It is possible to install a heating element or a gas burner in a 32 kW boiler.

Photo 5: Solid fuel boiler with hob ZOTA “Master”

High build quality, a large heat removal area and excellent thermal insulation turn the Zota “Master” into a full-fledged, modern, inexpensive, long-burning solid fuel boiler. Here are the main parameters of the Master series:

| power, kWt | 12 | 18 | 20 | 25 | 32 |

| Room area, m² | 120 | 180 | 200 | 250 | 320 |

| Efficiency, % | 73 | 73 | 75 | 73 | 73 |

| Loading chamber volume, l | 32 | 38 | 40 | 52 | 61 |

| Chimney cross-section, mm | 150 | ||||

| Chimney height, m | 5 | 5 | 5 | 6 | 7 |

| Price, rub | 23 500 | 26 900 | 26 500 | 30 500 | 33 900 |

Here is one review from the forum:

I would like to talk about the experience of using a 12 kW Master solid fuel boiler. The first thing I want to say is that it copes with the heating task well, but there are some inconveniences in use. Because The device is low-power and has rather modest dimensions. The result is a very small firebox and ash pit. Only one bucket of coal fits, and the ash pan overflows quite quickly. The easiest way to load coal from a bucket is to remove the burners from the cooking surface.

Sergey Nikolaevich, Ekaterinburg

As you can see, Zota Master boilers are very versatile. They can run on coal, wood, gas and electricity. Perform not only a heating function, but also serve as a stove for cooking. Combined with a low price, ZOTA “Master” is ideal to buy for a small country house or village house.

Return to contents

Types of boilers operating on solid fuel

All equipment of this class can be divided into 2 groups:

- Automatic fuel supply

- Manual loading

The first are pellet boilers. In them, granules play the role of fuel; they are loaded into special bunkers and from there they enter the furnace. Such devices have high efficiency and can operate automatically for weeks, without human intervention.

The latter, depending on the design features, are divided into 3 types:

- Classic

- Pyrolysis

- Long burning

They can use firewood and wood waste as fuel.

A traditional or solid fuel boiler using wood has been produced for a very long time, and its design has remained virtually unchanged. In it, the combustion chamber is located at the bottom and is considered the hottest part. Most often it is made of cast iron or steel. However, such heating of a wooden house with a solid fuel boiler is used quite rarely, as it requires frequent maintenance.

Pyrolysis devices are a new step in the field of solid fuel equipment. Their work is based on the principle of decomposing wood into solid residues and gases and burning the latter. The advantages of this device include high efficiency, minimal formation of ash and soot. Among the disadvantages is the need to burn dry wood with a humidity of no more than 20%.

Long-lasting combustion - their operating principle was developed in Russia and has no analogues in the world yet. It is a new generation boiler not only in terms of design, but also in its operating principle. Its main advantage is the simplicity of its design and the ability to service it once a day when operating on fuel with natural humidity. A solid fuel wood boiler has the most precise power control and can produce a given amount of heat.

Floor-standing combi boiler ZOTA “Dymok M”

"Dymok M" is an inexpensive and reliable solid fuel boiler that has long been popular among owners of country houses. The manufacturer is already producing the fourth generation of these heaters in this series, introducing more and more innovations that make it even more efficient. Let's look at them in more detail:

- For most summer residents and owners of private houses, firewood is the main fuel. The firebox is modified in such a way that makes it more spacious and allows you to load more long firewood.

- The insulation of the loading and ash door has been improved, which makes the boiler more gas-tight, and therefore reduces losses and increases efficiency.

- Heating elements can be installed on all standard sizes.

- Low-power models of the Dymok M series are equipped with a hob.

Photo 6: Combined heating boiler ZOTA “Dymok M”

The technical characteristics of solid fuel boilers “Dymok M” are as follows:

| Model | AOTV-12M | AOTV-18M | AOTV-20M | AOTV-25M |

| power, kWt | 12 | 18 | 20 | 25 |

| Room area, m² | 120 | 180 | 200 | 250 |

| Efficiency, % | 70 | |||

| Loading chamber volume, l | 34 | 60 | 70 | 80 |

| Chimney cross-section, mm | 150 | |||

| Chimney height, m | 5 | 5 | 5 | 6 |

| Price, rub | 17 800 | 20 800 | 20 400 | 23 900 |

Here's what real owners say about Dymok M:

I will say one thing, Dymok is worth the money they ask for it. A simple and inexpensive solid fuel boiler, naturally without super characteristics. I liked the heating elements, you don’t have to jump to the boiler at night if the stash burns out. The main drawback is, of course, the burning time; I would like it to be longer.

As you can see, “Dymok M” is a budget, but quite practical device for heating a small country house. Its use will make your heating system inexpensive, but quite efficient.

For more information about ZOTA boilers, watch the video:

In this review, we looked at ZOTA steel solid fuel boilers. All heating devices have many similar features, but each is unique in its own way. We hope our review will help you choose the best solid fuel boiler for your home.

The use of autonomous boiler equipment has a number of features that inexperienced owners may simply not know about. For example, with solid fuel boilers running on coal, a lot of questions may arise, since such boilers have rather unique behavior and characteristics. This article will discuss how to heat a boiler with coal.

Features of the Zota brand

The products described have been produced in Krasnoyarsk since 2007. . Despite the registration date (2007), the company began its activities much earlier - back in 1999, introducing heating devices into domestic homes that could provide users with hot water. It was this niche that was chosen by the company’s management for further development.

Today the company specializes more in the manufacture of Zota boilers operating on solid fuel. Such devices are capable of heating premises (both residential and industrial) with a total area of 30-4000 square meters. All models are divided into several model series, which we will talk about a little later. In addition to heating units, the company produces additional devices and accessories. These include, for example, tubular heating elements, automatic systems - all this is actively used in a variety of fields.

Note! The plant's production lines are constantly updated, thanks to which each new generation of heating equipment becomes more durable and advanced. The process uses sheet metal folding machines, laser cutters and other mechanisms.

Before going on sale, each new development is run in and tested at special sites. This means that the likelihood of marriage is practically reduced to zero, as well as “weak” points.

https://youtube.com/watch?v=lHnrvInfaKg

As a small conclusion

So we found out what kind of Zota heating boilers there are. As it turned out, there are a great many of them - many electrical appliances and devices that operate on solid fuel, there are also models that consume pellets (of any origin) as fuel. Do not forget about automatic and semi-automatic units. All of them are in considerable demand among consumers, as over the years of existence they have earned trust and a certain status.

Coal selection

To have an idea of how to properly heat a long-burning boiler, you must definitely consider the fuel used for this. Coal is a natural material containing carbon and non-combustible elements. When burned, the latter become ash and other solid deposits. The ratio of components in the composition of coal can be different, and it is this parameter, coupled with the duration of occurrence of the material, that determines the grade of the finished fuel.

The following grades of coal exist:

- Lignite, which has a rather loose structure, has the shortest period of occurrence among all types of coal. It makes no sense to consider this material, since it is not suitable for heating private houses.

- More ancient deposits are brown and hard coal, as well as anthracite. Anthracite has the highest heat capacity, followed by hard coal, and the least efficient is brown coal.

When deciding what kind of coal to heat a boiler with, you need to evaluate the characteristics of a specific brand of raw material. Good coal for heating has a fairly high heat transfer and a long period of complete combustion - one load of fuel can burn for up to 12 hours, which allows you to reduce the number of loads per day to two. The presence of different types of coal on the market allows you to choose the most suitable material, depending on your financial capabilities.

The specific heat capacity of anthracite is about 9 thousand kcal/kg. This is quite a large value - the heat capacity of hard coal is almost two times lower, and brown coal is three times lower in efficiency. If you take these parameters into account, then the choice of the most suitable fuel for heating is obvious - but do not forget that you have to pay much more for the most heat-intensive coal for heating the boiler.

Preparing for kindling

To ensure that coal heating equipment is safe and efficient, you need to pay attention to the following points:

- If the boiler or stove is rarely used (for example, seasonally), then before use you need to make sure that there are no masonry cracks. Even small cracks in the structure of the furnace provide a wide path for carbon monoxide to escape into the room, where it can seriously harm people present there. To get rid of this problem, all cracks must be covered with a mixture of sand and clay before heating the solid fuel boiler.

- Before lighting the boiler with coal, you need to inspect it visually. There should be no flammable objects near the heating equipment. The internal surfaces of the structure must be cleaned. It is advisable to wipe the firebox with a dry cloth so that the burning dust does not emit an unpleasant odor that will enter the room.

- Coal stoves need to be heated several times a day, and the duration of each kindling should not be more than two hours (for more details: “How to heat a stove with coal and which coal is better”). Dry coal of medium fraction is best suited for heating.

- To ignite coal equipment, you cannot use various flammable wastes and liquids such as kerosene. In addition, the stove must be supervised during the combustion process, especially if there are animals or children in the house.

The described points are not particularly difficult and make it possible to make the operation of boiler equipment safe.

Options for connecting the boiler to heating system lines

Connecting gas boilers

When it comes to gas heating boilers, it is possible to implement their connection to CO in several ways.

a. Direct connection of a gas boiler

Most often used in simple RMs. This assumes that the boiler has all the equipment necessary for this (safety group, expansion tank, circulation pump).

b. Connecting a gas boiler through a hydraulic separator

If you plan to install a complex heating system in your home, including low-temperature (warm water floors) and high-temperature (radiator) elements, then it is necessary to eliminate the “mismatch” in the movement of the coolant that occurs during operation. To do this, a hydraulic separator must be included in the piping, which performs the necessary hydraulic isolation. In fact, two coolant movement circuits are formed in the CO: the boiler circuit and the general CO circuit. Each of them has its own central control center. c. With additional heat exchanger

Installation of said element ensures waterproofing of said heating circuits from each other. The need for such a solution is due to:

- • use of different types of coolant (antifreeze and water) in circuits;

- • when combining closed and open systems within a single SO. Each of the circuits is equipped with its own central pump, make-up and drain taps, and safety groups.

d. Connecting a gas boiler using indirect heating boilers

The presence of the mentioned element in the CO allows you to constantly have a certain supply of hot water in the house, which is heated by the heat taken from the coolant operating in the CO. As a rule, these boilers are connected through special priority valves (three-way). If the house is large and the CO is multi-circuit, then this boiler is connected after the hydraulic separator.

Connecting solid fuel boilers

A specific feature of the mentioned types of boilers is their lack of a heat supply control function. It is impossible to interrupt the combustion of fuel. This, in the event of a power failure and the central heating unit stopping, can lead to the fact that continued heating will cause an increase in pressure in the lines, which can damage the CO.

To eliminate such a situation, several options for emergency schemes are being implemented to dump excess heat:

- • Connecting pumps to the battery;

- • Prompt supply of cold coolant (water);

- • The presence of a circuit operating in the mode of gravitational circulation of the coolant;

- • Connection of an optional emergency circuit.

Double-circuit solid fuel boilers are not recommended to be used in conjunction with gravity circulation systems.

Connecting electric boilers

If the boiler is an electrode model, then it is required in the heating circuit. Install: pressure gauge, air vent, non-return safety valve.

If the system is open, then in the pipeline, immediately behind the expansion tank. It is necessary to install shut-off valves.

Technology for lighting a coal boiler - how to fire it correctly

Coal boilers are operated using the following technology:

- First of all, dry kindling material - rolled up newspaper or paper - is placed in the firebox. A small layer of wood chips is placed on top, and even higher - small firewood (for example, birch). It is best to lay out the firewood in a hut or in the form of a well so that it burns better.

- The paper placed in the firebox is set on fire. The boiler door closes and the ash pan opens. Using a blower, you can regulate the intensity of combustion - increasing the supply of oxygen directly affects the rate of burning of wood.

- A layer of small coal is placed on top of the completely burnt wood, which has turned into smoldering ash. The thickness of the coal layer is about 15 cm. Each time the door is opened, the ash pan must be completely closed.

- After the first layer of coal burns out, another layer is laid directly on top of it, but a coarse fraction is used for it. The thickness of the main fuel layer should be about 60 cm. Before laying a new batch of fuel, it is better to stir up the previous one a little to increase the intensity of air movement and prevent the coal from sintering into one large piece.

- Low-quality fuel may coke during combustion. To avoid this phenomenon, it is advisable to dilute the main coal layer with small layers of firewood - this will give the boiler the opportunity to warm up normally and ensure maximum heat transfer. The presence of a layer, among other things, will also greatly simplify the process of cleaning the boiler after fuel combustion.

- Proper lighting of the boiler requires that natural circulation is used to burn out the paper and wood chips, which is achieved if the ash pan is open. Due to this effect, the chimney will warm up, and the draft will increase gradually, and at a certain point you will only need to close the ash pan and turn on the fan.

This technology includes a number of fairly simple nuances, and when they are implemented, questions about how best to heat a boiler with coal will not arise. All these subtleties are very easy to remember with the constant use of coal equipment, and it becomes incredibly easy to follow them in the future.