Gas-firewood

The advantage of universal gas-wood heating boilers is their autonomy: a smooth transition of the system to burning wood in the event of a lack of gas. Also, if desired, you can connect a “warm floor” structure, because the necessary connections and pipes are included with the boilers.

Such universal gas-wood boilers can be single-circuit or double-circuit, so connecting a boiler to heat water or heating water using a flow-through method is not difficult.

The disadvantages include the large dimensions of such units. Most often, they require a separate room for installation, and involve complicated maintenance. Typically, such boilers are produced only of the floor-standing type.

Combined gas-wood boilers for the home imply increased requirements. Norms and rules of operation are described in PPB, SNiP and SP.

A gas-wood combination boiler for a private home includes the following elements:

- Fire chamber. It is made of cast iron or steel. The boiler can have one firebox or two (more convenient). In the double version, wood is burned in the upper section, and a gas burner is installed in the lower section.

- Hot water supply and heating circuits. They are produced by companies specifically for heating, or for heating the production of hot water (double-circuit). Heating of hot water using a flow-through method.

A universal gas-wood heating boiler implies savings. You can verify this by looking at the following table.

| Type of fuel | Approximate cost of 1 kW of energy, $ | Approximate cost of 1 m³, $ | Approximate cost of heating a house with a volume of 450 m³, $ |

| Gas | 0,01 | 0,00047 | 0,2115 |

| Firewood | 0,02 | 0,0094 | 0,423 |

| Coal | 0,055 | 0,002585 | 1,16325 |

| Electricity | 0,03 | 0,00141 | 0,6345 |

| Diesel fuel | 0,04 | 0,00188 | 0,846 |

High-quality equipment using wood and gas is produced in Russia: “Zota MIX”, “Kupper PRO” (“Teplodar”), “Karakan” (“STEN”), “PARTNЁR” (“KOSTYOR”), “STS” (“Steel Solid Fuel Systems"). As well as foreign companies: Austria and Germany (“Wirbel”), the Finnish concern “Jaspi” and others.

It should be noted that in foreign analogues it is less common to notice shortcomings in the assembly and automation of the unit. They boast reliability and quality. However, the domestic manufacturer is constantly improving in accordance with the wishes of customers.

Prices for combined wood-gas heating boilers depend on the country of origin and the popularity of the brand. For example, the model (“BONTER”) will cost an average of 23 thousand rubles. Much will depend on the configuration, power and other indicators. But “Jaspi” will cost 130 thousand rubles. The run-up is large, however, unlike the Finnish one, where everything is regulated automatically, in the Russian analogue you will have to carry out all the boiler settings yourself.

Reviews of universal solid fuel and gas boilers: advantages and disadvantages

| Advantages | Flaws |

| Significant space savings, which is especially important for small houses with an area of 40-80 m2. The dimensions of combined models do not differ from single-fuel models | Primitive automation or its complete absence (mechanical traction control) |

| Availability of single-circuit and double-circuit models | In more than 95% of cases, a gas burner is not sold complete with the boiler |

| Almost all models are non-volatile (do not require connection to the mains) | Owners often note the rather high noise level of the burners, which is not comparable to the standard burners of gas boilers. |

| In combined models, durable cast iron heat exchangers are often used, while budget solid fuel and gas heat exchangers almost always use steel ones that are vulnerable to corrosion. | Higher requirements for chimney draft, which complicates calculations. If the design is incorrect, the thrust may not be sufficient for complete combustion of gas. |

| Small selection of multi-fuel combined models, especially foreign ones |

Coal-gas

The universal gas-coal boiler is environmentally friendly and easy to maintain. However, when choosing this type of design, you will have to constantly monitor the availability of solid fuel, because coal runs out quickly. If you suddenly come to the conclusion that “two in one” is not suitable for you, then you can always replace the burner - and the boiler will already operate on natural gas.

You can read more about the features of a pellet boiler here.

Most often, a combined coal-gas boiler can also be heated with wood. For example, in the technical characteristics of the dual-circuit model “Beryozka V”, in the “fuel” item it is indicated “natural gas / coal” (see table). However, buyers use such a boiler for heating with wood.

| Manufacturer and model | Characteristic |

| ATEM (Zhytomyr, Ukraine) Berezka V | The boiler is made of steel, is universal and completely independent of electricity. It acts as a budget solution for heating cottages, utility rooms, and outbuildings. Units of brand “B” are created for the production of consumer hot water. Fuel - natural gas / anthracite (coal). The area of the heated room is 125 m². Rated thermal power - 12.5 kW. Maximum gas flow is 1.5 m³/h. Nominal gas pressure (min/max) - Pa 1274+100 (635/1794). Working water pressure is 0.1 MPa. Efficiency when using solid fuel is 78%. Efficiency when using natural gas is 90%. Weight - 119 kg. DHW water consumption - 280 l/h. The combustion chamber is open (chimney). Number of circuits: double circuit. |

Gas-coal-wood

The advantage of a gas-wood-coal boiler is that it does not depend on electricity. This allows you to create autonomous heating systems. Fuel for such a unit is available in any locality and, moreover, at a low price. The wood-coal-gas boiler from the manufacturers listed in the table below is easy to service and has an attractive design.

| Manufacturer and model | Characteristic |

| Outbreak KSTG-10 (Russia) | This company has been on the market since 2003. It is a dynamically developing and reliable manufacturer. Boiler type: single-circuit. The combustion chamber is open. Installation - floor. Heating area - 200 m². Power - 20 kW. Gas is natural. Type of solid fuel - firewood, coal. Operating temperatures - 95 ºС. Heat exchanger material is steel. Efficiency - 77%. Weight - 70 kg. |

| Outbreak KSTGV-12.5 (Russia) | This “coal-wood-gas” boiler model is energy-independent and stable when operating at reduced gas pressure. Due to the optimal design of the combustion chamber, the boiler has high efficiency. Built-in water heater that provides hot water. Includes gas pressure regulator. The boiler body is resistant to temperature changes. Type - double-circuit. The combustion chamber is open. Installation - floor. Heating area - 125 m². Power - 12.5 kW. Gas is natural. Type of solid fuel - firewood, coal. Boiler - built-in. Operating temperatures - 95 ºС. Heat exchanger material is steel. Efficiency - 83%. Automatic shutdown - no. Weight - 120 kg. |

| Raton KS-T-12.5 (Belarus) | The boilers are designed for heating individual residential buildings, buildings and structures equipped with continuous water heating systems with natural coolant circulation and an open expansion vessel. Type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 130 m². Power - 12.5 kW. Type of solid fuel - firewood, coal, peat. Display - no. Heat exchanger material is steel. Ignition is mechanical. Efficiency - 77%. Weight - 138 kg. The service life of boilers is at least 15 years. |

| Brestselmash KST 12.5 kW (Belarus) | Based on the type of fuel, boilers produced by Brestselmash OJSC are multi-fuel boilers designed for burning solid and gaseous fuels through conversion that does not require dismantling the boiler. Installation - floor. Heating area - 125 m². Power - 12.5 kW. Gas is natural. Type of solid fuel - firewood, coal, peat. Display - no. Operating temperatures - up to 95 ºС. Heat exchanger material is steel. Efficiency - 90%. Weight - 180 kg. Designed for heat supply and hot water supply of residential buildings and public utility buildings equipped with water heating systems with natural circulation, with operating water pressure up to 0.1 MPa (1.0 kgf/cm²) and maximum water temperature at the boiler outlet up to 95 C°. |

| Boiler PARTNЁR 24 (Russia) | The advantages of this company's products lie in its own innovative, unique design developments. The manufacturer provides guaranteed quality components, raw materials and materials. This is a stable, high-tech production facility. The combustion chamber is closed. Installation - floor. Power - 24 kW. Type of solid fuel - firewood, coal. Efficiency - 80%. Weight - 108 kg. Height - 79.5 cm. Width - 42 cm. |

Solid fuel boilers: operating features

The prices for solid fuel boilers can hardly be called low, but in the case of a house located remote from a populated area, there is often no other choice. Naturally, solid fuel boilers are practically not used in the city or in holiday villages, since there are a lot of other, cheaper ways to provide a home with heat. However, it is sometimes simply impossible to gasify a private house, which is why solid fuel boilers become the only heating option. It is also worth buying a solid fuel boiler because it has a fairly high efficiency at a relatively low cost of fuel.

For a long time, solid fuel boilers were not very popular due to the impossibility of automating their operation process. Today, this problem has been completely solved, and models capable of operating in autonomous mode for a long time have entered the market. The use of such long-burning solid fuel boilers makes it possible to provide the house with the necessary amount of heat without spending time on constant reloading of fuel. It is enough to load fuel once, and the boiler will operate efficiently throughout the day.

Firewood-coal-pellets-gas

Currently, these units are offered by: the manufacturer of the universal boiler “Cooper” “gas-wood-coal-pellets”, and others.

A large selection (pellets, firewood, coal, gas) gives such a boiler a great advantage. In the absence of one type of fuel, you can always switch to another type and stay warm.

| Manufacturer and model | Characteristic |

| Teplodar Kupper OK15 (Russia) | Boiler type: single-circuit. The combustion chamber is closed. Installation - floor. Heating area - 150 m². Power - 15 kW. Gas is natural. Type of solid fuel - firewood, pellets, coal. Display - no. Efficiency - 78%. The diameter of the chimney pipe is 150 mm. Weight - 98 kg. Double-turn heat reservoir formed by a removable visor, which ensures complete flame extinguishing in the tube sheet. In addition to the standard water jacket, the firebox has a heat exchanger. Power adjustment from 30 to 100% (a combustion regulator can be installed on boilers). A spacious firebox that allows you to load firewood 400 mm long horizontally and 500 mm vertically, or two buckets of coal. The presence of a tubular electric heater allows you to maintain heating systems after the end of the fuel combustion process. |

| Raton KS-TG-35U (Belarus) | Boiler type: single-circuit. The combustion chamber is open. Installation - floor. Heating area - 340 m². Power - 35 kW. Gas is natural. Type of solid fuel - firewood, pellets, coal, peat. Display - no. Ignition is electric. Operating temperatures - 95 ºС. Heat exchanger material is steel. Efficiency - 77%. The boiler is intended for heating residential buildings that are equipped with continuous heating systems with natural or forced circulation of coolant. |

| Teplodar Uyut-10 (Russia) | “Uyut” are budget heating boilers for rooms up to 100 square meters. m. The firebox is in a horizontal position, which allows you to heat the boiler with wood up to 0.5 m long. The high efficiency of the boiler is ensured by the original design of the water circuit: stagnant zones are excluded, and the heat-removing surface area is increased to 1.1 sq.m. Possibility of installing a gas or pellet burner. Boiler type: single-circuit. The combustion chamber is closed. Installation - floor. Heating area - 100 m². Power - 10 kW. Gas is natural. Type of solid fuel - firewood, pellets, coal. Display - no. Ignition is mechanical. Efficiency - 72%. The diameter of the chimney pipe is 115 mm. Weight - 67 kg. |

Gas pellets

A pellet gas boiler is equipment that easily changes its operation from heating with one type of fuel to heating with another. This usually happens in about 15 minutes.

Here it is also possible to replace the burner in case of conversion. Many models have a tubular electric heater.

It is allowed to connect a liquefied gas cylinder.

The efficiency of a pellet gas boiler reaches 90%.

The unit has several combustion chambers. The kit includes two burners, as well as many control and shut-off devices. Has a high degree of security and automation. But despite this, a gas-pellet boiler, like any combined gas boiler, requires compliance with the standards of PPB, SNiP (some excerpts are described at the beginning of the article).

Don't forget to clean the boiler from time to time. During the maintenance process, it is necessary to remove accumulated wood dust and soot from the electric drive and moving elements.

What do you need to work with pellets?

To convert the boiler to fuel pellets, you need to install a pellet burner, which is connected to the fuel hopper. After all operations, the boiler operates as follows:

- granules are supplied to the burner via a conveyor from the fuel bunker;

- electric ignition occurs immediately via a piezoelectric element;

- a built-in fan is activated in the burner, which increases the pressure, and the pellets burn at a high temperature, raised artificially.

Typically, gas-pellet boilers are made of cast iron, and due to their large dimensions and weight, the structure is placed on a concrete base.

What do you need to work on gas?

Pellet boilers with a gas burner are connected, first of all, to cylinders and gas holders. Such units are gaining popularity in the construction of houses and sites where natural gas is planned to be installed soon.

To connect a gas burner, you first need to close the unused firebox with an airtight hatch. Then you need to install a burner device in a place specially designated for gas equipment. After everything, set the switch to gas consumption. All. The modification took no more than 15 minutes.

Combination boiler Wirbel ECO-CK 20

Boiler "Kupper PRO-22" with pellet burner

Boiler "Kupper PRO-22" with a pellet burner

Instead of a gas burner (as in the previous version), a pellet burner is installed, on top of the boiler there is a bunker with automatic control for a standardized supply of fuel pellets from the bunker.

When it is not possible to connect to a gas pipe, a boiler of this type will be the optimal solution in terms of automation of the heating system. And of course, as you already understand, when civilization reaches you and it becomes possible to connect to the natural gas pipeline, there is no need to change the entire boiler - only the burners.

Speaking about heating boilers, we cannot, of course, ignore electric boilers; in some cases they are also in great demand.

Firewood-pellets-gas

If you are interested in the design of this type of heating, the table below describes the manufacturer of gas, solid fuel and pellet boilers, its most popular model and a brief description.

| Manufacturer and model | Characteristic |

| Atmos DC 18 SP (Czech Republic) | The new series of combined boilers "ATMOS" DC 15EP(L), DC 18SP(L), DC 25SP(L), DC 32SP(L) allows for ecological combustion of wood using the principle of generator gasification in combination with a burner for pellets, natural gas or extra light fuel oils (depending on which burner is built into the boiler). Boiler type: single-circuit. The combustion chamber is open. Installation - floor. Heating area - 300 m². Power - 20.5 kW. Type of solid fuel - firewood, pellets. Display - no. Boiler - external (optional). Boiler volume: 78 l. Heat exchanger material is steel. Overheating protection - yes. Frost protection - yes. Thermostat - yes. Ignition is mechanical. Efficiency - 92%. Weight - 429 kg. The advantage of this model is that the boiler takes up less space compared to a large number of boilers. Regarding environmental operation, the boiler, according to CSN EN 303-5, belongs to class 3. |

Thus, combined boilers for heating a home are an excellent option for obtaining not only heat, but also saving money. Since there is always a choice of fuel and its autonomous switching, in the absence of one specific type of fuel, your home will be heated at any time of the year. Combined boilers for solid fuel and gas are reliability, high performance and versatility.

Single combustion boilers

Combined boilers "wood/coal - gas"

| Combined wood-gas boiler | Fuel: wood-gas |

Today, there is no main gas supply to the village where the house is being built, but it is possible to use firewood to fire the boiler - a universal single-fuel boiler is selected, when instead of the loading chamber door, a gas burner can be installed in it in the future. In this case, there is no need to buy an additional gas boiler. You can choose an atmospheric burner, in which gas is mixed with air to create a combustible mixture naturally, or a pressurized one, equipped with a fan, with its help the gas burns in the chamber much more efficiently, its consumption is reduced. The disadvantages of a pressurized gas burner are its energy dependence, noise and higher cost.

| Gas burner for boiler |

According to the degree of regulation, forced-air burners are divided into:

— single-stage, when when the required coolant temperature is reached, the burner is turned off and then turned on again;

- two-stage, when in the first stage the boiler operates at 100% power, and in the second at 50-60%, and this significantly saves fuel;

- modulated, with smooth adjustment of the gas combustion flame, which allows the boiler to operate in the range from 10 to 100% of power, and gas consumption is saved by 15% or more compared to unregulated burners, if the operating mode of the modulated burner is configured correctly.

The situation may look different: gas is supplied to the house, but the gas pressure in the network is unstable, or has disappeared altogether, and there is a need in the middle of winter to urgently switch to an alternative type of fuel in order not to defrost the system. Removing the gas burner and installing the combustion chamber door of a universal boiler is not a difficult task; any man can handle it by tightening a few bolts. It is assumed that there is enough space on the territory for storing firewood in a ventilated place, protected from precipitation, or in a specially folded woodpile.

| Storage of liquefied gas in cylinders |

In houses where people do not live permanently in winter, it is sometimes economical to use liquefied gas as fuel in their dachas. For significant volumes of its storage, the installation of a tank is required, and this entails obtaining permission from the gas service, compliance with the protected zone, and other requirements, and it will be filled by special refueling vehicles. You can use gas in cylinders; they can be combined into blocks of up to 10 pieces. and one cylinder with a volume of 40 liters is enough to heat a house with an area of up to 50 m for about three days. Liquefied gas is more expensive than main gas, but for its use there are less approval costs and if the house is used infrequently, on weekends and the system is filled with antifreeze, this heating option can be used in the boiler. Cylinders cannot be installed in the same room as the boiler; a reducer is required to convert the liquid state of the fuel into a gaseous state with a volume of 1.8-2 m³/h and a gas train (proportional gas supply valve). The burner used is the same as for main gas.

Combined gas/diesel fuel boilers

| Gas/diesel combined boiler |

One of the most common types of universal boilers is the combination of “gas/diesel” in the fuel used, since both substances burn in a firebox of approximately the same design and the transition by changing the burner is carried out quickly and with simple settings. In the line, for example, of German Buderus boilers there are models both in steel (the marking contains the letter “S”, they are for large objects, the power line starts from 71 kW) and in cast iron (“G”, power 25-1200 kW, these boilers are more often used in individual houses). Such models are very popular in Europe, in addition to natural and liquefied gas and diesel fuel, they can also run on biofuel - rapeseed oil, they use technologies that reduce harmful emissions of exhaust fumes into the atmosphere and various techniques to reduce fuel consumption. These cast iron boilers are low temperature. Thus, the cast iron boiler Buderus Logano G215 WS (power 40-95 kW) is manufactured according to the Thermostream principle, thanks to which it can operate stably without the use of a mixing pump or return temperature controller.

Combined boilers “wood/coal-electricity-gas-liquid fuel”

| Boiler for all types of fuel Zota |

There are quite inexpensive models, such as those of the Russian brand Zota, which can operate on many types of fuel: in normal mode using wood/coal, with the additional installation of a heating element - on electricity, and when installing the corresponding burner, also supplied as an option - on diesel or gas.

Using such a boiler as an example, we can consider options for switching from one fuel to another in a combined unit.

It should be understood that one mode will be the main mode for the boiler; it is according to this mode that the boiler power will be calculated, and other fuel sources will become backup. For example, when operating on solid fuel, the boiler produces full power, and if the firewood runs out, the device will automatically switch to heating with a heating element (if there is a special control module), but will work with a decrease in the initial power. This mode is intended to protect the house from defrosting in the event of an emergency shutdown of wood burning, but not for full heating to a comfortable temperature. Nevertheless, this is the most common way to complete a universal boiler; for small heated areas, you will not feel any difference in temperature comfort and it will allow you to significantly save on the purchase of an additional electric boiler and installation of pipes.

| Diesel burner |

Installing a liquid fuel burner will reduce the efficiency of the boiler, since heating with wood and diesel fuel has different heating principles: when burning with wood/coal, the heat rises from the bottom up when the coolant is heated, and from the burner the heat spreads horizontally in the boiler, strongly heats the back wall of the boiler, which, with prolonged exposure it may burn out. Additional thermal insulation of the rear wall will be required. Diesel and fuel oil burners are described in detail in the article on liquid fuel boilers; in this case, we are only talking about the possibility of a simple transition of a universal device to this type of fuel if necessary. Diesel fuel is stored in plastic containers either indoors, with a protective metal tray in case of leakage, or, if the composition of the soil allows it, buried next to the boiler room; a place must be provided in advance.

| Waste oil burner |

Sometimes, it is convenient for owners of car service centers located in areas remote from the main gas supply to use universal boilers with a firebox for wood/coal and a special burner for working with waste oil. According to reviews, its efficiency is not bad, but the oil consumption required varies depending on the power and you must constantly have a supply of it, which is only possible with a large turnover of material.

Changing a diesel burner to a gas burner or installing a gas burner on a boiler that was previously fired with wood is also not difficult if all the equipment is from the same manufacturer. If the transition from gas to another type of fuel does not raise any questions, then the reverse transition sometimes requires attention: when burning with diesel, for example, a significant amount of soot is formed in the chimney, and when the gas burner is turned on, soot from the walls of the chimney can crumble and block the chimney. A good burner should turn off in this case, but if this does not happen, the resulting carbon monoxide can enter the room, which is unfavorable and sometimes dangerous. Therefore, when switching from a diesel firebox to gas, it is better to invite a service specialist who will clean the chimney and start the boiler.

All of the above conditions for switching from one fuel to another are typical for single-fuel boilers, that is, when all types of fuel burn in one chamber and heat one coolant circuit. This type of universal boiler is the most economical and if you do not intend to frequently switch from one type of fuel to another, you can consider it. Universal boilers can be made of cast iron or steel. The former are more bulky and heavy, but given the difference in heating mode when changing fuel, cast iron may be preferable. Nevertheless, there are steel boilers with a bent, seamless body, which in the low power range can also successfully act as universal boilers.

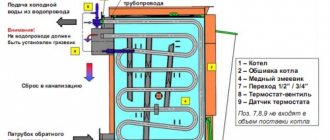

| Combination boiler operation diagram |