A parapet gas boiler is a chimneyless, energy-independent unit, which in most cases is installed in country houses. It is the absence of the need to install a chimney that makes such equipment very popular among residential property owners, including city apartments.

First of all, parapet boilers differ from alternative heating equipment in that the combustion chamber is completely insulated, which completely eliminates the possibility of smoke entering the rooms. This plus will be appreciated by owners of small spaces, since air for more efficient combustion is not taken from the apartment. Where does it get into the system from?

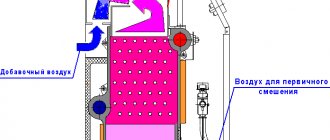

A parapet gas individual boiler still requires air intake and smoke removal. This means that you cannot do without a coaxial chimney mounted horizontally in the adjacent external wall. The design of the chimney is quite simple - two pipes inside each other. With the help of the outer tube, air is drawn into the combustion chamber, and the inner tube is intended to exhaust smoke. This design is simple and efficient, which makes it the optimal solution for installing heating equipment in living rooms.

The undoubted advantage of parapet models is the covering of the convection hole, due to which it is possible to heat the room where the device is installed without installing a traditional heating radiator. This makes the equipment even more compact and functional.

Parapet gas boilers have a rectangular shape, which greatly facilitates their installation in limited space. Depending on the characteristics of a particular location, it is possible to purchase equipment with one or another arrangement of automation and pipes.

There are two main types of parapet units - single- and dual-functional. The latter are equipped with a tubular water heater installed in the unit body, which is necessary for heating water for technical purposes. In most cases, the tubular heater is made of copper, which has decent thermal conductivity.

A gas parapet boiler can be installed in a variety of places under any conditions, since it does not need to be connected to a chimney. In a living room, it is most often installed in the window sill, where it fits perfectly despite its small dimensions.

Such units can operate on both natural and liquefied gas. This allows them to be installed even in those country houses that do not have a gas pipeline.

How to choose?

Before you start choosing a model, you need to determine the functional purpose of the boiler and its power.

Double-circuit units should be selected if you plan to equip not only heating, but also hot water supply. Particular attention should be paid to the heat transfer coefficient of the device, which is especially important when calculating the power of the heating system in regions with cold climates. Convection models have the highest efficiency. This type of design is presented in many Danko floor-standing appliances and is recommended for use in northern regions

This type of design is presented in many Danko floor-standing appliances and is recommended for use in northern regions

This type of design is presented in many Danko floor-standing appliances and is recommended for use in northern regions

This type of design is presented in many Danko floor-standing appliances and is recommended for use in northern regions.

Judging by the reviews of the owners, it was convection boilers that showed their best performance when heating a private home in harsh conditions. In addition, floor-standing devices are non-volatile. In the event of a power outage, they will not leave the house without heat. The most popular model among floor-standing appliances is the Danko 18BC model. The boiler has dimensions of 41x85x49.7 cm, weighs 81 kg and is designed to heat a room up to 170 m².

For heating country houses or when installing a heating system in southern and temperate latitudes, wall-mounted and parapet units are quite suitable. These devices can effectively warm a medium-sized room and provide residents with uninterrupted hot water supply. The disadvantage of such devices is the presence of electronic ignition, which does not allow the boiler to light in the absence of electricity.

Many models are equipped with frost protection, which is important when operating the device in conditions of temperature changes in the absence of owners, when it is not possible to force the device to turn on or off

When choosing equipment, you should also pay attention to fuel consumption. Single-circuit appliances consume significantly less gas than dual-circuit models

For example, a floor-mounted single-circuit unit of the Danko 8 brand, having a heat transfer coefficient of 92% and capable of effectively heating a room of 70 square meters, consumes only 0.9 cubic meters of gas per hour, while some double-circuit boilers consume 2.5 and more than cubic meters of fuel

For example, a floor-mounted single-circuit unit of the Danko 8 brand, having a heat transfer coefficient of 92% and capable of effectively heating a room of 70 square meters, consumes only 0.9 cubic meters of gas per hour, while some double-circuit boilers consume 2.5 and more than cubic meters of fuel.

Every detail must be taken into account! Installation of a gas boiler in a private house

Gas heating systems are effective, but require strict adherence to installation standards , since gas entering an open flame source (an ordinary spark) will lead to its ignition.

Therefore, when installing a gas boiler, you need to be extremely careful, and it is best to resort to the help of a specialist.

Installation of a single-circuit, double-circuit gas boiler in a private house

Installation of a gas boiler in a private house is carried out according to special rules.

Who installs one or two heating devices

Independent installation of the gas pipeline and boiler is impossible, so the participation of engineers is necessary.

The owner of the house enters into a contract with the city or regional gas service to install a gas pipeline and supply natural gas to the house.

After which he pays for the work: project development, pipe installation, materials and control of specialists - everything should be handled only by employees of the installation team of the local gas service.

When the work is completed, the controller-engineer checks the site and grants permission to supply gas if everything is in order (he is personally responsible for this). The installation of the device itself is also carried out by Gorgaz employees, since the gas pipeline and boiler are a single system, the tightness of which must be monitored by qualified people. Of course, the homeowner’s premises must meet the technical requirements for installing such a heating system.

Requirements for the premises, installation of a floor or wall-mounted boiler in a wooden house

Installation of gas heating in a wooden house is possible , moreover: it is one of the most popular solutions for heating private houses. But the owner of the premises will have to spend a lot of time in technical authorities to obtain the necessary documents and permits, as well as arrange for an inspection by a gas service employee to his home for consultation and check the possibility of installing the boiler.

Photo 1. Boiler room in a private wooden house. There is a window in the room to allow access to sunlight.

The basic requirements for installing gas heating in a private wooden house are as follows:

- The boiler and the equipment necessary for it (generator, uninterruptible power supply, etc.) will be located in a separate room: it should not be a basement, bathroom or living room. In some cases, with the permission of the inspector, it is possible to install a boiler on the basement floor, but this is determined on an individual basis. It is best to make an extension to the house - a boiler room, so that the inspectors have fewer questions and comments.

- Wooden walls in the boiler room must be treated with a thermal protective compound , and the use of flammable materials, false ceilings and false floors is prohibited. If this is an extension, then it is better to make it from concrete blocks or bricks, although this is not necessary, but inspectors will certainly appreciate the responsibility of the homeowner. In a wooden room, first of all, a protective panel is fixed against the wall for the boiler (both wall-mounted and floor-mounted) made of a layer of basalt insulation and a steel sheet.

- The height of the boiler room ceilings is from 2.5 m , the minimum volume of space inside is 8 cubic meters. The door width is from 0.8 m without a tight fit to the floor for additional ventilation.

- Mandatory access to fresh air: at least one opening window and holes of the required width (calculated individually) for air circulation.

- Correct chimney design: with fire breaks, without decorative elements and, preferably, with a deflector; horizontal sections of the chimney should not be more than three meters long, and along its entire length there can be no more than two couplings to create a bend.

Important! In a wooden house, the ceilings will most likely also be made of wood, a flammable material, so when installing a chimney you need to use safe heat-protective basalt gaskets.

Second group with a steel heat exchanger:

The Conord boiler with the design of a steel cylindrical heat exchanger made of cold-rolled metal is offered by the plant in single- and double-circuit versions. The service life is reduced compared to cast iron to 15 years. The designs use two automation options.

The first option: SIT automation from an Italian company known for its quality throughout the world. It is installed in the vast majority of all manufactured boilers in the European Union, such famous devices as: IMMERGAS, Fondital, Vaillant, Bosch and many others. The SIT valve allows you to guarantee a stable set temperature.

In addition, automation controls stable operation with a reduced gas pressure in the city pipeline. So the nominal value provides for operation with a pressure of 1.3 kPa, but a drop to 0.6 kPa is not a big problem and the Conord gas boiler continues to operate steadily, despite the fact that this is 46% less than required.

Single-circuit, with automatic SIT – heating only:

KSts-G-8S Heating capacity =8 kW KSts-G-10S Heating capacity =10 kW KSts-G-12S Heating capacity =12 kW KSts-G-16S Heating capacity =16 kW KSts-G-20S Heating capacity =20 kW KSts-G-25S Heating capacity =26 kW KSts-G-30S Heating capacity =30 kW KSts-G-40S Heating capacity =40 kW KSts-G-50S Heating capacity =50 kW

Single-circuit, with thermohydraulic automation

The second option is more budget-friendly, equipped with domestically developed AGU-T-M automatic equipment. AGU is an automatic gas burner device, consisting of nozzles and safety automation. The main manufacturers are Mimax and Tagonrog. ASU automation consists of:

- temperature sensor;

- igniter with thermo-bimetallic plate;

- adjusting screw with lever;

- gas valve;

- block crane;

- connecting parts.

Ignition order:

- We check the draft, move the damper, light the igniter.

- Press the gas valve and light the wick. We fix and do not release the button until the bimetallic plate heats up.

- While continuing to hold the button, follow the lever. It will creep onto the inscription “on the button”, we need to wait for the moment when it is fixed.

- Release the gas valve and set the required temperature using the control knob.

Domestic automation makes it possible to buy a Conord boiler a little cheaper. In contrast to European analogues, it has the simplest design. It is non-volatile - no power supply is required. The starting process is carried out manually by igniting with matches or a lighter. By the way, thermo-hydraulic automation type AGU-T-M is widely used in Russian gas boilers

According to customer reviews, such automation is completely unpretentious, and the Conord floor-standing boiler equipped with it is not “capricious.” In addition, it is not difficult to find spare parts on the market even far from city centers. The prices are also not satisfactory, for example, one of the frequently requested parts - a bimetallic plate - is found everywhere for no more than 100 rubles.

KSts-G-10N Heating capacity =10 kW KSts-G-12N Heating capacity =12 kW KSts-G-20N Heating capacity =20 kW KSts-G-25N Heating capacity =25 kW KSts-G-30N Heating capacity =30 kW

Double-circuit with DHW and SIT automatic control system

The Conord floor-standing gas boiler, when equipped with two circuits, copes with the task of heating buildings and at the same time is capable of preparing hot water used for household needs. The design uses the proven modulation function. Burner operation using modulation significantly increases the efficiency of hot water supply.

KSts-GV-8S Heating capacity =8 kW KSts-GV-10S Heating capacity =10 kW KSts-GV-12S Heating capacity =12 kW KSts-GV-16S Heating capacity =16 kW KSts-GV-20S Heating capacity =20 kW KSts-GV-25S Heating capacity =25 kW KSts-GV-30S Heating capacity =30 kW

Double-circuit with DHW, with thermo-hydraulic automation

KSts-GV-12N Heating capacity =12 kW KSts-GV-20N Heating capacity =20 kW KSts-GV-25N Heating capacity =25 kW KSts-GV-30N Heating capacity =30 kW

Boiler Conord decoding

- K – boiler

- C – steel material for the heat exchanger

- C – cast iron, heat exchanger material

- G – gas

- B – DHW circuit

- C – cylindrical.

Design and operating principle

A distinctive feature of this type of gas equipment is a closed combustion chamber. The convenience of this design is obvious:

- There is no need to arrange well-functioning ventilation. This will be especially true in old buildings.

- There is no need to take care of the chimney, which must be taken outside the roof of the house. In this case, a coaxial type chimney is used. In order to install it, a hole is made in the wall to match the diameter of the coaxial pipe. By the way, it will not be visible from the side of the room, because the output is made behind the boiler in a horizontal direction. Experts recommend installing a parapet boiler near a window so that it is possible to inspect and repair the chimney.

- The design of the heating device contains convection holes. With their help, the heating of the room where the boiler is installed is carried out. That is, it turns out that the unit works both as a device for a water heating system, heating the coolant, and as a regular oven or convector.

If we talk about technical characteristics, it should be noted that parapet boilers operating on gas are produced with a fairly large power range, where 7 kW is the minimum, and 40 kW is the maximum. True, today manufacturers have also offered more powerful units that can be used to heat a very large multi-story building. But statistics show that the most popular are boilers with a power of 7-15 kW. Such units are most often installed in small cottages and city apartments.

Device and design

Let's add to all of the above that this type of heating units includes both single-circuit and double-circuit options. All manufacturers, without exception, in the second type use heat exchangers made of 3 mm thick stainless steel or copper to heat the coolant. The second option is more effective, this must be taken into account when choosing.

The lineup

The line is represented by five series:

- Wall-mounted. Two modifications - 23 ZKE and 23 VKE. Double-circuit modifications. Each circuit has its own heat exchanger. For heating - copper, for hot water supply - steel.

- Parapet. 8 modifications - 7, 10, 12.5 and 15.5 kW. They are compact. Single-circuit. No smoke. Can be installed in apartments with an area of 140 square meters. Heat exchanger – steel.

- Steel. 22 models differ in power, number of circuits and location of chimneys.

- Cast iron. All have an open chamber. Cast iron radiators last approximately 25 years.

- With pump. 4 modifications. They work to heat the room and heat hot water. Steel heat exchangers. Related security systems.

Boiler requirements: selection criteria

For safety and ease of use, the correct choice of the main component of the heating system is necessary. To do this, you need to familiarize yourself with its varieties, since differences can be both in functionality and in the filling of the device.

The main criteria are:

- permissible installation location;

- device power;

- materials from which the heater is made, number of circuits;

- automatic auxiliary devices for safety;

- need for an interface device.

All of the above criteria are interdependent. The unavailability of the required area leads to the installation of a unit with less than necessary power. The need to heat additional volumes of water for household needs forces the purchase of a double-circuit boiler.

When choosing, it is important to consider the need for maintenance. If there are no special workshops nearby, you will have to look for additional options or install one that is easier to maintain

Functionality becomes the main condition for choosing equipment.

Floor-standing boiler "Danko"

produces floor-standing boilers with high-quality, thick and high-temperature-resistant ISOVER insulation, which maximizes thermal energy retention. A 50mm thick layer of thermal insulation covers all the walls of the heat exchanger and flue. Floor-standing boilers can be either single-circuit or double-circuit (have a DHW function).

- Single-circuit boilers are used to heat relatively small buildings, apartments or rooms up to 300 m2.

- Double-circuit boilers are capable of heating not only the room, but also the water. Thus, there is no need to purchase an additional water heating boiler.

Varieties in design and material

At the moment, there are various models. Externally, they are not particularly different, except in size and installation method: wall-mounted and floor-mounted. To know which one to choose, you need to understand the filling.

Single and double circuit

There are single-circuit and double-circuit devices. The difference is that the single-circuit heats water only for heating the house; in order to have warm water for domestic use, an additional water heater is installed.

A double-circuit boiler immediately heats water for batteries and household use. This smart device responds to the actions of its owners. While water is needed only for heating, he takes care of it. As soon as you open the tap to wash dishes or take a shower, water begins to flow into the tap using a special valve.

It is necessary to provide the required power of the device. The more people will take a bath or shower, the more powerful the device needed to heat it.

Typically, consumers choose double-circuit boilers. They are more functional, you do not need to buy an additional boiler, but they are also more expensive than single-circuit ones.

Floor and wall mounted

The next difference is the method of installing the boilers. There can be two of them: floor-mounted and wall-mounted.

Mounted ones are more compact, the requirements for their installation are less extensive. They do not need a separate chimney; such elements are installed even in the kitchen; it is enough to simply ensure safety during operation.

Floor-standing ones have large volumes, high power and weight. A separate room must be allocated for them; they require a lot of free space around. It will be necessary to build a separate chimney for a floor-standing boiler, since they produce noise, unlike wall-mounted ones.

For a small house or apartment, a wall-mounted heater will be sufficient. When heating a large house, you need to look after a floor-standing unit. Such models are dependent on constant voltage in the electrical network, so during surges the equipment may fail.

Combustion chamber view

The combustion chambers in these boilers are of open and closed types. The former take oxygen for combustion from the room in which they are located, so they require ventilation. But at the same time, they have a simple design, are more reliable, easier to install and cheaper.

The second type is more modern. These boilers are parapet, they provide safety, but are more expensive and more difficult to install. It is worth considering that these boilers, if properly installed and equipped with an air duct, do not pose a risk of poisoning to residents in the event of a malfunction, which cannot be said about units with an open chamber.

The choice in this case depends on the equipment room. A closed-type boiler is safer and more convenient, but only if it is possible to equip an air duct. If there is a power outage and the ventilation does not work, the heating will also turn off.

Safety system

Gas-powered appliances require serious monitoring. It is provided either by a person or an automation system. The latter is capable of providing multi-stage protection that prevents dangerous situations and increases equipment safety. The main task of the protection system is to turn off the device in time by stopping the fuel supply.

Let's look at the stages of protection using the example of the floor-standing boiler "Wolf KSO". These modern devices have multi-stage protection. One of the stages is an ionization sensor that controls the flame. If the fire goes out, a signal will be sent to the control unit, it will shut off the fuel supply and prevent an accident.

The combustion chamber has a temperature sensor that monitors the heating of the coolant and prevents the firebox from quickly burning out. “Wolves” are equipped with a KTD system - chimney draft control. It prevents the accumulation of carbon monoxide. If there is no draft, combustion products begin to accumulate in the chimney, and the thermostat heats up. When the temperature limit is reached, the thermostat contacts open and the flow of fuel stops.

Automatic protection

Modern heater models are equipped with electronic control and measuring instruments that generate signals for the control unit. Automation, receiving signals from sensors, coordinates the work of all nodes. Elements that prevent various types of malfunctions and problems are safety valves, expansion tanks, air valves, smoke detectors and other devices.

What is a parapet boiler

The boiler body is made of 3 mm thick steel, painted with a special fire-resistant anti-corrosion coating, which ensures its resistance to mechanical and corrosive influences.

Main elements of the boiler:

- closed firebox;

- gas burner device with igniter;

- coaxial chimney;

- two heating circuits with independent boilers made of copper and steel.

Control unit: pressure and draft sensors, thermometers and thermocouples, they protect the boiler from overheating. When the draft in the firebox drops to 0 mm.w.st., the boiler instantly begins to overheat the water; when the temperature rises above 65C, a signal from the plate will be sent to the cut-off valve, it will shut off the gas, and combustion will stop.

The thermocouple, when exposed to heat from the gas flame, creates a small voltage that controls the gas valve. During the absence of combustion, the voltage in it drops to 0 V, the valve instantly cuts off the gas supply to the boiler.

Range of Danko gas boilers

Danko's product range includes:

- parapet gas boiler;

- wall;

- with circulation pump;

- cast iron;

- steel.

The special characteristics of each type of unit lie in some important aspects.

Features of parapet devices of this brand:

- They have the ability to connect a hot water supply circuit.

- There is a closed combustion chamber, so the boilers can be used to heat an apartment.

- Gas enters through micro-flare burners, and this significantly increases the productivity of the system.

- Heat exchanger material – steel (3 mm thick).

- The maximum efficiency is 90%.

- Possibility to heat areas up to 140 m².

- This type of equipment is represented by the following models: parapet boiler Danko 7 U, 7VU, 10 U, 10 VU, 12.5 U, 12.5 VU, 15.5 U, 15.5 VU.

You can find out more about the design features of parapet gas boilers here

Wall-mounted devices of this brand differ:

- Modification 23ВКЭ with a closed combustion chamber.

- Modification 233KE with an open combustion chamber.

- Built-in automation units that control electric ignition and flame level of the burner device.

- The Danko wall-mounted gas boiler has a steel heat exchanger for supplying warm liquid.

- Heating circuit with copper heat exchanger.

- The efficiency of the equipment is 90%.

- Heating of a room up to 210 m².

Models installed on the floor are characterized by the following parameters:

- These are devices with two circuits (for heating and hot water).

- They have high-quality steel heat exchangers (3 mm thick).

- With circulation pump.

- The Danko floor-standing gas boiler allows the owner to sleep peacefully, since the heater has a safety system that controls the flame, draft level and boiling point of the liquid.

You can find information about energy-independent wall-mounted and floor-mounted gas boilers at this link

Gas devices made of cast iron differ:

- Single circuit circuit (heating only).

- Open combustion chamber.

- Cast iron heat exchanger.

- Manufacturing automation in foreign countries: Italy, Poland, America.

- Efficiency 90%.

The line of steel boilers from the Ukrainian manufacturer includes 22 models of devices, which are characterized by the following parameters:

- chimneys can be both horizontal and vertical (it all depends on the model);

- built-in automation for safety;

- possibility of system regulation.

Choosing a place to install a parapet-type boiler

Parapet-type boilers are installed only in non-residential and non-service premises, i.e. they cannot be installed in living rooms and offices, but they may well be located in kitchens, halls, corridors and other utility rooms.

Gas boilers of this type do not require constant monitoring. Parapet gas boilers are installed only on the outer wall of the building in such a way that there are no combustible structural elements near their installation site. If the wall includes combustible elements, then the distance from the pipe to such elements must be at least 20 cm, and these elements themselves must be protected with fire-resistant material on the side of the pipe and the gas boiler. On the facade itself there should be no combustible elements closer than 30 cm from the pipe. If such elements exist, they are either removed or protected with fireproof material.

The pipe should not go into the loggia, onto the balcony, under the canopy, and especially into the entrance or arch. You should immediately make sure that the pipe does not disturb passers-by if the boiler is installed at a low height relative to the ground, and does not throw combustion products out the window to neighbors.

Figure 3. Diagram of a parapet boiler.

For boilers with a power of up to 7 kW, it is allowed to place the pipe 25 cm from the window in any direction and 50 cm to the sides if the boiler power is higher. If the boiler is located on the ground floor, then the installation height of the pipe above the ground should not be less than 0.5 m, if there is no passage of people at the pipe outlet, but if there is passage of people, and the boiler power exceeds 7 kW, the height of the pipe should not be less than 2.2 m. Also, the pipe should not go under the supply vent closer than 2.5 m or next to it closer than 0.6 m for boilers with a power of 7 kW and no closer than 1.5 m - if the power of the gas boiler is over 7 kW. Under balconies and other elements protruding by more than 0.4 m, it is allowed to place a parapet-type boiler pipe no closer than 2 m (if the power of the gas boiler is over 7 kW - 3 m), cornices and other elements protruding less than 0.4 m - no closer than 0.3 m (if the power of the gas boiler is over 7 kW - 1.5 m).

Since the coaxial pipe requires periodic monitoring and maintenance, the installation location of the gas boiler should be chosen in such a way that it is possible to organize access to the pipe.

There should be no flammable interior elements (curtains, curtains, draperies) near the gas boiler indoors; furniture and electrical appliances should not be installed close to it or closer than 30 cm.

The controls of the gas boiler itself, the control and shut-off valves of the pipelines connected to the boiler must be accessible for inspection and control, for which there must be a passage at least 1 m wide in front of the front panel.

User manual

After starting the boiler unit, before the heating system warms up, condensation collects on the walls of the combustion chamber, which begins to flow into the firebox and the main burner on the hearth.

In this case, the coolant temperature should be increased to 70C in this mode; the condensation process will stop. It is also not allowed to take water for hot water supply from the heating system.

During operation of the boiler, the temperature of the coolant and its pressure are monitored. It is necessary to periodically check the vacuum in the boiler and the combustion quality of the nozzle.

For long-term trouble-free operation of the boiler unit, before supplying the mains power to the device, place a water purification filter, and from time to time the heating circuit is flushed with clean tap water.

Temperature adjustment is carried out in operating mode, according to the user’s own feelings. The boiler is started either using a piezo ignition system or manually using the principle of a gas stove. To turn on the boiler using piezo ignition, you need to turn the knob to the ignition position.

The thermostat knob must be turned until it aligns with the “asterisk” icon and at the same time pressed in all the way.

Press the piezo ignition button several times to light the burner, but hold the thermostat knob for another 10-15 seconds. If the attempt is unsuccessful, repeat the procedure.

To service and repair the boiler, you should call a technician from the service center. Independent tampering with the structure will automatically void the warranty agreement.

Types and prices

The advantage of such boilers is a large selection of models with different mountings: floor-mounted and wall-mounted. When choosing a boiler, real connection conditions are taken into account.

Boiler equipment from European factories, Russia, CIS countries and China is quite widely represented on the construction market. It is clear that the quality of equipment from the EU is higher than that of boilers from China, but the price is also much higher.

Popular parapet boilers:

- TERMOMAX-C are non-volatile compact boilers for individual heat supply of single-storey and multi-storey buildings, equipped with a flue gas exhaust system through a coaxial channel, horizontally built into the external wall. Structurally, they are carried out in both single and double-circuit versions with markings E and EB and thermal power from 7 to 16 kW. For heating systems with high hydraulic resistance, a circulation pump is provided. Control, protection and start-up are carried out through the gas valve EuroSit 630. The burner is started using piezo ignition. TermoMax C 16EB has an efficiency of 90% and is capable of heating rooms measuring 120 m2, the cost of the unit is 20,100 rubles.

- Another Russian model of a parapet boiler is Lemax Patriot 20 with a closed firebox. The steel heat exchanger is treated with an inhibitory compound and covered with an enamel coating to resist corrosion processes. Mounting type: wall-mounted. The range of thermal loads of Lemax boilers is from 6 to 20 kW. Gas burner equipment from the Italian concern “SIT” with an injection flare burner “POLIDORO”. There are special holes on the front panel to create a convection effect and increase heat transfer in the room. Features include: removable cladding elements, igniter, coaxial smoke removal system, non-volatile installation option. The cost of the unit is 25,820 rubles.

- The double-circuit boiler “Slim 2.300 Fi” is produced by the Baxi brand with a heat load from 14.9 to 29.7 kW, capable of heating objects measuring 140 -160 m2. The boiler is made of high-quality materials, with a price from 120.0 to 140.0 thousand rubles.

- EcoCompact VSC D INT 306/4-5 190L, boiler of the German brand Vaillant - a highly efficient unit, can heat 160-180 m2, price 240.0 thousand rubles.

- The Danko parapet boiler, with a power from 7 to 18 kW, is equipped with a cast iron boiler with a wall thickness of 3 mm and a closed combustion chamber. The universal design allows for two-way connection of utility networks; the control unit is located on the operating panel of the boiler. The units are equipped with Honeywell gas automatics, piezoelectric ignition and a micro-torch burner, heating area up to 160 m2, price – 21 thousand rubles.

- Eurotherm KT TSY (P2) for individual heat supply in systems with natural and forced circulation of the heating circuit, with water heating temperature up to 90 C, thermal power 10 kW, gas consumption 1.13 m3/hour, efficiency 92%, weight 59 kg, warranty period 24 month, heating area 100 m2, price – 24 thousand. rub. Steel boilers are equipped with a copper recovery system with a bypass channel. A specially designed copper coil is placed in a water cavity to produce hot water. Design features: heat recovery system with a receiving tank, housing, control and protection unit, air duct, flue, wind protection cover. The design allows you to install the unit at floor level near the wall. The DHW circuit connecting pipelines are made on one side. The air intake duct passes through the outer wall with a thickness of 200 - 500 mm. Mounting on walls in a wooden house is not allowed without fire protection measures.

Pros and cons of Danko gas boilers

The Danko solid fuel boiler runs on wood, coke, and coal.

The advantages of these units include:

- use of advanced technologies and high-quality components;

- long service life of equipment;

- economical fuel consumption and quiet operation;

- relatively low cost of the product.

The advantage of boilers in this series is also their compactness and attractive appearance. Like most heating units powered by natural gas, Danko products have characteristic disadvantages.

- It is necessary to periodically service the unit, be sure to clean the chimney.

- During operation, the flame may go out due to external factors.

- Danko wall-mounted models have power limitations, while floor-mounted ones have an increased noise level.

The listed disadvantages do not have a serious impact on the overall assessment of the purchased equipment. Technical indicators are usually used as criteria for choosing the right model. Among them, the following factors stand out:

- average gas consumption for the allocated period of time;

- placement method;

- energy efficiency;

- functionality and warranty period.

Often, to the listed criteria, an assessment of equipment based on the heated area is added.

Gas heating in a wooden house: rules and regulations

Heating a wooden house with gas has a fairly large number of advantages. However, when using this type of heating of a wooden room, special attention should be paid to fire regulations, since if used incorrectly, this can lead to tragic consequences.

Main characteristics

Important elements of the house that need to be taken into account when choosing such heating are:

- Floor material. As a rule, the floor is made of boards, plywood or OSB, which are laid over the foundation beams. Such a base is quite movable, which eliminates the possibility of installing a water-based underfloor heating system, because it must be mounted with a screed.

- Insulation of walls and windows. Basically, such surfaces are made of logs or beams, which have a high level of thermal insulation. The coldest place is considered to be the opening, both window and door. That is why heating of a wooden house should be centralized in such places.

It is also important to note that a large amount of heat is also lost through the roofing areas, so the surface of the floor and attic should also be carefully insulated.

Moreover, a material such as wood has good flexibility, which allows the entire system of pipes and air vents to be installed without much interference.

Types of structures

Gas boiler

This design consists of a centralized boiler that heats the heating compartment. In this case, the gas is liquefied and distributed through the pipes, thereby releasing thermal energy. The radiators themselves, being heated to a safe temperature level of 80 degrees, heat the room. The safest solution in this case would be to use main gas, since it is located in a special room - the boiler room - and does not need to be carried through all rooms of the house.

However, heating a wooden house with gas using a gas boiler has some features that must be taken into account:

- It is necessary to choose a boiler that operates on the convection principle, since condensing boilers, although they are less expensive, require a low temperature of the pipeline system, which cannot be done while maintaining the optimal level of heat. The heated floor system can operate at low temperatures, but it is difficult to install it in wooden houses (for more details: “Warm floors in a wooden house are the key to comfort”).

- The heating system should, as a rule, be single-pipe, barrack-type. The main pipe runs along the entire perimeter of the house, and heating radiators are cut in the direction of this pipe. All this is suitable for a convection boiler, with heating of 60 degrees and above.

- You can purchase boilers with electronic ignition. That is, they do not need to constantly maintain the combustion mode of the main burning part, which in turn increases the level of safety. In case of frequent power outages, you can simply install an uninterruptible power supply system

About the manufacturer

The owner of the Danko brand is the Ukrainian company PJSC Agroresurs, which simultaneously produces heating equipment with several items. Danko boilers are manufactured using imported equipment from Japan, Finland and Denmark. This has significantly improved the performance quality of manufactured products, making them more reliable and durable. In the production process of boiler equipment, modern assembly and metalworking machines and a powder coating line are used.

The vast majority of technological operations are automated. All boiler units have high efficiency - over 88%. The assortment set includes modifications with a cast iron heat exchanger, the service life of which is more than 25 years.

The advantages of such units include the availability of spare parts on the market, low cost of the kit and reliability.

The assemblers note the relatively complex processes of assembly and piping with the in-house heating system, as well as increased background noise when the boiler is on, compared to Western analogues. According to responses on the Internet, Danko’s double-circuit options, with a high level of hot water supply, do not always provide the required heating rate.

The organization TD Finist LLC in Taganrog is the official representative of the company; boiler models can be found on Danko.rf. The following heating boilers are sold in Russia: “Danko”, “Danko-Breeze”, “OK”, which are certified according to Russian standards.

Installation

It is necessary to take into account the rules for installing gas equipment:

- The power is selected according to the heating.

- There must be at least 25 cm between the housing installed on a fire-resistant horizontal platform and a non-combustible wall.

- The device can be installed near fire-resistant walls if they are sheathed with steel sheets.

- The width of the passage in front of the facade is from 1 m.

- To improve water circulation, the installation should be lower than the level of heating devices.

- The expansion tank is located at the very top of the system.

- The minimum length of the chimney is 5 m.

- If the chimney is located outside, it must be insulated.

- The diameter of the smoke outlet must exceed the diameter of the smoke outlet pipe.

- At the junction of the boiler and the chimney, it is necessary to seal it with a solution of cement or clay.

How to light a Danko gas boiler

Identification of boiler control elements.

- Turn the mechanical temperature regulator counterclockwise until it stops.

- Make sure that the tap on the gas pipeline inlet is open.

- Press and hold the start button, then press and release the piezo button (several clicks may be required, repeat until the pilot burner lights up). Hold the start button for at least 30 seconds until the burner goes out when it is released. If the boiler has not been adjusted previously, it may be necessary to adjust the air supply by turning the nut on the ignition burner until the burner flame turns blue.

- Turn the thermostat knob clockwise until the main burner turns on, then set the desired power.

The startup process differs slightly for configurations with different automation; the algorithm is described in detail in the operating instructions, an electronic copy of which is attached in the description of each model on the official website.

Boilers of the Danko TN series

The Danko TN boiler is the most popular brand of boilers among our domestic consumers. Danko solid fuel boilers are characterized by the reliability of their design, thick metal of the firebox and heat exchanger (steel thickness 5mm), and excellent painting.

Danko heating boilers provide high-quality heating for your home or cottage.

Advantages of Danko TN series boilers

- Boilers of the Danko TN series have cast-iron grates, which allows the use of not only wood, but also coal, peat and fuel briquettes for heating.

- The thick-walled heat exchanger of the Danko TN series boiler, 5 mm thick, guarantees long-term heating over many years of operation of the solid fuel boiler.

- The efficiency of Danko TN series boilers is no less than 71.0%, this is due to the fact that: firstly, the entire body of the Danko TN boiler (left and right) is designed as a heat exchanger; secondly, the combustion chamber is equipped with a multi-pass horizontal heat exchanger; thirdly, the walls of the boiler of the Danko TN series are insulated on all sides with mineral wool (layer 5 cm thick);

- The main advantage of Danko-TN boilers is ease of maintenance, large and comfortable firebox. (One stack of oak firewood is enough for 4 to 8 hours of burning).

- Solid fuel boilers "Danko TN" work well in open and closed heating systems with natural and forced circulation of coolant.

- The boiler doors tightly close the firebox, there is no smoke coming out of them, and they do not become loose even after many years. The service life of boilers is tens of years.

- Heating boilers of the Danko TN series are easily installed into an existing heating system with a gas boiler and can be used together in a cascade.

- Boilers of this series can additionally be equipped with a fan and a controller to automate the operation of the equipment, or a draft regulator, which controls the amount of air entering the combustion chamber and, accordingly, the temperature of the water in the system by opening or closing the air damper.

- Does not depend on electricity;

- The power range of boilers of the Danko TN series (Danko 12.5TN, Danko 16TN, Danko 20TN, Danko 27TN) allows them to be used in dachas, garages, greenhouses, and in houses with small and large heating areas .

Operating principle of parapet gas equipment

- The burner device is ignited with a wick or igniter.

- Gas, when burned, releases heat, which heats the boiler.

- Network water, using a circulation pump or with natural circulation, heats up, leaves the boiler and enters heating devices located in residential, public or industrial premises.

- The gas combustion process will continue until the water in the heating circuit heats up to a predetermined level, after which it will be automatically turned off by a gas valve installed in front of the boiler.

- The wick continues to function and will re-ignite the burner when the mains water temperature drops.

Pros and cons of parapet boilers:

- Possibility of indoor use.

- Affordable prices.

- Small geometric dimensions of the installation.

- Speed and ease of installation work.

- Possibility of use without installing additional radiators.

- Large power range.

There is only one drawback - energy dependence.

Operation and setup

Operating requirements are detailed in the user manual, which must be carefully read before using the unit.

The key to successful operation is competent and high-quality installation. Floor-standing models are installed on a non-combustible substrate (a layer of asbestos, on top of which a metal sheet is laid), and wall-mounted boilers are hung on brackets secured with anchor bolts.

Only strong load-bearing walls are suitable for installation; temporary and plasterboard partitions for hanging are prohibited.

Boiler tuning consists of adjusting factory settings designed to increase efficiency and stability of operation.

The boiler adjustment must be performed by a specialist from the warranty workshop. Doing the work yourself can damage the unit.

In addition, unauthorized work with gas equipment is an offense and can be punished within the competence of the gas service.

Popular models of single-circuit boilers

If you are going to buy a reliable and durable heating gas boiler, and are already looking at wall-mounted models, you will find the information in our next section useful. In it we will consider the most popular models that have received excellent reviews from customers - these are domestic and foreign samples.

Buderus Logamax U072-24

Recently, this brand has become increasingly popular - references to it are increasingly found on advertising materials. It is not surprising that the economical single-circuit gas boiler Buderus Logamax U072-24 has become the most rated model. Its thermal power is 24 kW, which allows it to heat an area of up to 250 square meters. m - this is quite enough to heat most private households, including two-story ones. The device is equipped with a closed combustion chamber and a durable copper heat exchanger.

Its design already includes all the necessary casing - a safety group, an 8-liter expansion tank and a circulation pump. For more convenient control, the wall-mounted single-circuit boiler Buderus Logamax U072-24 is equipped with an informative display. It is also possible to connect external control. Built-in protection systems:

- From overheating – controls the maximum heating temperature of the equipment and heating system;

- From freezing – protects residential and non-residential buildings from freezing;

- From blocking the circulation pump.

Separately, it should be noted the presence of a flame control system.

The wall-mounted smokeless convection single-circuit gas boiler Buderus Logamax U072-24 can operate on both natural and liquefied gas. The maximum temperature in the heating circuit is +82 degrees, the pressure in the system is no higher than 3 bar. The efficiency of this unit is 92% - this is a fairly high figure. The price varies between 26-32 thousand rubles.

Baxi ECO Four 1.24

A good single-circuit gas boiler from an equally well-known brand. Its power ranges from 9 to 24 kW, fuel consumption - up to 2.78 cubic meters. m/hour, depending on the load. Operation from liquefied gas is also possible, consumption is 2.04 kg/hour. The device is equipped with a durable copper heat exchanger and an open combustion chamber - it requires a traditional chimney. Inside there is all the equipment necessary for heating operation - a circulation pump, a 6-liter expansion tank, an automatic air vent and a safety valve. Also on board there are all the necessary protection systems.

The single-circuit wall-mounted gas boiler Baxi ECO Four 1.24 received excellent reviews from heating engineering specialists and users. It has good performance, a user-friendly control interface and high efficiency - it is 91.2%. There is a system of smooth flame modulation, which ensures precise maintenance of the set temperature, low noise level and smooth ignition without pops or explosions. If necessary, underfloor heating systems can be connected to the unit.

Bosch Gaz 6000 W WBN 6000-24 H

Such a complex name hides a gas boiler from one of the world's leading manufacturers. It so happens that Bosch is a leader in many areas. And if this manufacturer produced cars, they would probably be the best cars. The presented model has a minimum power of 7.2 kW, a maximum of 24 kW. Equipment Features:

- Possibility of connecting heated floors;

- Electronic flame modulation;

- Built-in protection systems;

- Built-in harness;

- Coolant temperature – from +40 to +82 degrees;

- Expansion tank capacity – 8 liters;

- Consumption – up to 2.8 cubic meters. m/hour (2 kg/hour for liquefied gas);

- The pressure in the heating circuit is not higher than 3 bar;

- Copper heat exchanger;

- Convenient control with LCD display.

Installation of a wall-mounted boiler

Installation of gas heating boilers of this type requires care when installing fastening units that are fixed on one of the walls of the room. This boiler is very popular among owners of private or country houses, as it is light in weight and compact in size.

If the house is built from a material such as wood, then the wall on which the boiler will be installed must be covered with a sheet of non-combustible material, such as metal. Often in private homes, a wall-mounted gas boiler is installed in the kitchen. Modern devices have an attractive appearance, so they will fit into any interior and will be combined with kitchen furniture.

A wall-mounted gas boiler does not require a separate boiler room, since it includes all units and components, such as a circulation pump, shut-off equipment, automation, and others. You will need to carry out such a step as installing heating from a gas boiler.

This will help avoid mistakes that could affect the efficiency of the heating system. If you do the installation yourself, you must have certain skills and knowledge, and also take as a basis all the requirements specified by SNiP. Otherwise, the system simply will not be approved by government services and will require repair of gas heating boilers.

Recommendations

Despite the fact that Danko boilers have a long service life and reliability, some breakdowns still occur.

Therefore, all owners of gas equipment should know the main types of malfunctions and the causes of their occurrence.

- The formation of soot and soot on the internal surfaces of the boiler indicates problems with the chimney. In this case, you should clean the pipe from accumulated combustion products and wash the parts of the device from dirt.

- Unstable operation of the device and temperature fluctuations in the system indicate a malfunction of the fan or circulation pump. If you have the necessary spare parts, you can repair the device yourself.

- If the boiler's pilot light goes out or the wick does not light, the reason is most likely the absence of a special valve in the chimney system that prevents backdraft. The igniter going out may also be due to the thermostat tripping. In this case, adjustment of the device is necessary, which should be done by experienced specialists. Only single-circuit boilers are subject to attenuation. In dual-circuit devices, such problems are not observed.

- If the combustion sensor or pipe fails, the device is urgently disconnected from the gas supply and left to cool. Repairs can only be performed when the breakdown is not related to a fuel leak. For example, cleaning the pipe can be done independently, but more serious faults should only be trusted to a specialist.

- Increased fuel consumption and the presence of extraneous noise before attenuation are most likely caused by a failure of the controller. If you have the necessary spare parts, you can repair the part yourself.

In the next video you will find a review of the Danko 12.5 TN solid fuel boiler.

This is caused by the desire to save on paying for network resources, the unavailability of connecting to a central heating center in remote cottage villages, or other reasons.

There are a large number of samples of heating devices on the market, of which gas boilers are unanimously recognized as the most effective.

They are produced by all well-known companies in Europe and Southeast Asia.

Manufacturers from the countries of the former USSR are not lagging behind, their products are able to successfully compete with European models.

Model overview

If you choose the right manufacturer and model of the boiler, it will be able to effectively heat your home even without the “help” of additional equipment.

Thus, Danko gas boilers have a power of 7 to 15 kilowatts, so they are quite capable of handling a room with an area of up to 140 square meters. All devices from this manufacturer have an automatic gas supply system, micro-torch burners and piezo ignition. The walls of the heat exchanger are 3 millimeters thick.

It is characteristic that the design of this exchanger has been updated, and the right-left connection is ignored in principle. This makes installation easier. The connection in this case is two-way, which significantly saves work space. There is also a special panel that allows you to adjust the operation of the device and visually monitor it.

Video parapet boiler – Model “Danko 7U”

ROSS is one of the largest Russian manufacturers of gas equipment. Boilers from it are known to ordinary users as AOGV and have a power of up to 100 kilowatts.

Parapet boiler Aton Compact

The boilers of the Aton series are no less popular, since considerable funds have been invested in this company in recent years. The boilers are produced using modern equipment, thanks to which excellent external performance of the products is combined with high quality.

Gas parapet boiler Zhitomir

There are also Zhitomir gas boilers, which are perfect for heating a multi-storey building. The fuel combustion chamber in them is absolutely sealed and equipped with automatic process control, a temperature control device, piezo ignition and a built-in gearbox. Each of the boilers has pipes for connection to the heating system on both sides.

The manufacturer guarantees that all products are absolutely safe to use, since they are tested seven times for failure-free operation in emergency conditions. If we talk about efficiency, then it can reach 90 percent.

Video - Advantages of Zhitomir models

Attention! The cost of parapet boilers ranges from 11,250-25,000 rubles, although there are more expensive models. It all depends on the technical parameters and the manufacturer

Possible problems with the boiler

Frequent questions from users regarding malfunctions of this Ukrainian equipment include the following:

- Why does the Danko gas boiler blow out?

- Why does the unit go out?

- What causes high gas consumption?

If we summarize the practical experience of the owners and take into account the opinions of experts, we can make a small list of possible causes of these problems:

- Gas line failures (gas is supplied unevenly).

- Problems with the chimney (most likely, soot and soot have accumulated on the inner walls, which impede the proper removal of combustion products).

- Possible damage to any structural elements. For example, a malfunction of the ventilation device, which does not supply air flow to the combustion chamber.

- Electrical supply problems that directly affect the operation of boiler equipment. In other words, interruptions in the functioning of the circulation pump or blower fan, which affects poor heating of the room.

- There is no valve in the smoke structure, this does not allow the reverse draft to work normally, as a result - the system blows out and attenuates.

Experts recommend thoroughly cleaning the chimney of deposits.

How to light a Danko gas boiler?

Light the boiler using a semi-automatic method in stages:

- The mechanical regulator is brought to its extreme position.

- Press the wheel down for 5-6 seconds. Gas is supplied to the burner.

- Ignition occurs using a piezoelectric element.

- After igniting the ignition burner device, continue to hold the regulator in the down position for approximately 5-10 seconds. If, after lowering the wheel, the igniter goes out, the procedure begins again. The burner has a sensor that records the temperature on the body. If the burner device is not heated sufficiently, the gas supply valve is not opened.

Types of heating devices

To heat a private house or city apartment, boilers can be used, which differ:

- at the installation site

- by power

- according to the method of removing combustion products

- by functionality

- by cost

- by burner type

- by type of coolant

- depending on electricity

- by the presence of automation and many other parameters

Depending on the installation site, gas heating boilers can be floor-mounted or wall-mounted. Floor-standing devices are usually more powerful and are capable of heating rooms up to several thousand square meters.

Wall-mounted ones are used more in private houses and apartments, since their power does not exceed 30 kW. Naturally, there are wall-mounted boilers with greater power, but here we are talking about mini-boiler houses that combine several devices like a cascade.

Type of chimney

Aton 7-16 kW

Based on the method of removing combustion products, units with natural draft and forced draft are distinguished. In the first case, gases are discharged through chimneys in the form of a pipe that exits through the roof to the outside. In the second case, combustion products are removed through special coaxial chimneys passing through the outer wall.

In some information materials you can find mention of turbocharged devices. Essentially, these are wall-mounted parapet boilers, from which combustion products are removed using built-in fans through a coaxial chimney.

Natural draft boilers use an open burner, and the air for combustion of fuel is taken directly from the living room. With coaxial exhaust, oxygen comes from the street. Such a chimney consists of two pipes of different diameters located one inside the other. A pipe of a smaller cross-section serves to remove combustion products, and through the space between the walls of the pipes, outside air, necessary for burning the gas, enters.

It is the parapet gas boiler that is equipped with such a chimney, which has a positive effect on the environmental situation in the house. Indeed, in this case, oxygen is not consumed from living quarters, but taken from the street.

Boiler functionality

Boiler functionality

Wall-mounted heating devices, like floor-mounted ones, can have one or two circuits. With one circuit, only the house is heated; with a second circuit, it becomes possible to also obtain hot water for domestic needs.

In parapet boilers, the built-in flow-through hot water heater is usually made of copper, since this metal has the best thermal conductivity qualities.

Parapet devices can be connected to the heating system on the right, left or both sides at the same time, which simplifies the heating installation.

These units are designed to operate on natural gas, but when changing burners they also function well on liquefied gas.

Coolant

Wall-mounted gas condensing boiler

Many people do not know that they cannot use hot water from the city heating system for domestic needs. And this often happens when the supply of hot or cold water is turned off for a while. Some residents, without thinking twice, open the tap on the radiator and drain the hot water to use it, for example, for washing the floor.

This is strictly forbidden, because there are special additives in the water. They prevent the formation of scale and other deposits on the walls of pipes and radiators. The use of such “water” can have a very negative impact on human health precisely because of these additives.

When installing a gas boiler in a city apartment, you need to carefully study this issue, because not all devices are designed for a similar coolant composition. It’s a different matter in a private house, where the water quality is controlled by the homeowner himself, and any heating units can be installed without regard to the coolant.