Pellets are wood and other waste from wood processing or agricultural enterprises, which are small pressed cylindrical granules. They are used as fuel for pellet boilers. These boilers, like any other types of solid fuel heating equipment, are one of the few reasonable solutions if the house is not connected to a gas pipeline.

What are pellets

The production technology was invented in the thirties of the last century. The birthplace of the invention is Idaho, USA. The essence of the method for producing pellets is to compress preheated wood waste. When heated, sawdust, wood chips or shavings release lignin. This substance has the ability to bind small wood particles together.

Under high pressure they are compressed into smooth granules. The finished product has high density and heat transfer during combustion.

No chemicals are used in the production of pellets. This makes them an environmentally friendly fuel. Granules are produced according to the DIN plus standard.

Agricultural waste can be used as a raw material for the production of pellets: corn cobs, husks, etc. The most common type of granules in the country are pellets, with a diameter of 6-8 mm and a length of up to 50 mm.

The efficiency of heating solid fuel boilers largely depends on the quality of the pellets: humidity, density, ash content. When burning 1 ton of pellets, thermal energy is released equivalent to 1.6 tons of firewood.

Device, principle of operation

Solid fuel equipment can have partial or complete automation of operating modes. Pellet units differ from boilers running on coal and wood in their smaller firebox size and lower exhaust gas temperature.

Manufacturers produce two types of pellet boilers:

- highly specialized - work only on granules;

- combined - pellets, firewood and coal can be used as fuel.

A feature of pellet boilers is the ability to achieve the highest possible heating temperature of the heat exchanger by heating the air in convection channels.

This significantly increases their efficiency. The operation of such equipment is based on the principle of pyrolysis. The combustion process occurs with a lack of oxygen.

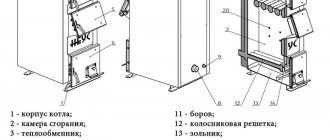

The main components of the boiler design are:

- combustion chamber (furnace);

- convective part;

- ash pit.

The granules are fed into the firebox using a special auger from the fuel hopper. Control of the combustion process is provided by an electronic control unit. The boilers have automatic setting of operating modes.

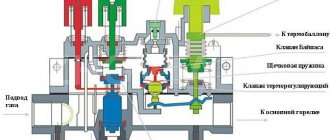

Burners are an important structural element. They come in two types:

- flare;

- retort.

They differ in the way they supply fuel and air. All burners are equipped with automatic equipment that allows you to regulate the supply of air and pellets, which helps achieve maximum equipment efficiency. Its average is comparable to gas boilers and is 92%. Foreign models of pellet boilers are equipped with fans to force air into the combustion chamber.

From the furnace, flue gases enter a heat exchanger designed to transfer the thermal energy of hot gases to the coolant of the heating system. This could be water or antifreeze.

Heat exchangers are classified according to the type of design:

- horizontal and vertical;

- flat and tubular;

- linear and multi-turn.

The most effective are models with vertical two- or three-pass heat exchangers. In such units, almost all the thermal energy obtained from the combustion of granules is spent on heating the system coolant. Fully automated boilers can be programmed for 7-10 day duty cycles. Seasonal consumption of granules is 3-4 tons.

Which burner is on your pellet heating boiler?

FlareRetort

Advantages and disadvantages of a pellet boiler

One of the main advantages of pellet boilers is their efficiency; in this indicator they are second only to gas main heating. This is due to the high efficiency of the equipment, the high calorific value of pellets, and their affordable cost. The second aspect that attracts consumers is process automation. Unlike other solid fuel boilers, pellet boilers do not require constant monitoring and regular manual fuel supply. It also wins over units running on diesel fuel in terms of environmental friendliness - no odors or black smoke.

The main disadvantage of these units is their substantial price - these are the most expensive solid fuel units, the cost of an automated station made in Europe is measured in hundreds of thousands, domestic ones are slightly cheaper. Not every private owner can afford such investments into the heating system of their home. However, with equipment longevity now approaching two decades, it is a wise investment in the long term.

In addition to the high cost, the disadvantages include energy dependence - the automation requires electricity, and if a shutdown of several hours (on average up to 10) is acceptable and will not disrupt the settings, then a longer shutdown will stop the operation of the boiler. The station must be equipped with an independent energy source, which will further increase the cost of the system.

Classification

Most models of pellet boilers are intended only for heating buildings, but there are designs that can also provide hot water. The units produced by manufacturers are classified according to various criteria.

Boilers are classified according to the method of fuel supply:

- automatic;

- semi-automatic;

- mechanical.

Automated models work according to a given program. When servicing semi-automatic boilers, you have to perform some functions manually. Mechanical units are fully human-serviced.

Analysis of reviews on the Internet

For this work, two dozen reviews were collected on various resources. The main impression among consumers is good - the boilers are really economical and are not particularly difficult to maintain. But there are also a number of recurring complaints - frequent repairs of cheap equipment. In some reviews, there is a mention of environmental friendliness - they are practically “smokeless”, as the happy owners of the equipment say - there is not as much soot and burning as when burning coal.

What else to read:

The best automatic models

If there is a warehouse for storing granules, equipped with a supply system, the units can operate for a long time without human intervention. The fuel supply system requires careful installation. It must have ideal geometry. The granules should not get stuck in the plug, disrupting the process of their uninterrupted supply to the fuel bunker.

SVETLOBOR

Country of origin: Russia. The brand produces three lines of equipment: ECO, AUTO, BIO. All models are fully automated. The devices can operate automatically without human supervision for up to 1 month.

The cost of the units depends on their power and ranges from 230,000 to 1,460,000 rubles.

Boilers are used for heating residential and industrial buildings. The power of industrial heat generators is from 90 to 320 kW. In terms of automation level, the equipment is comparable to the best German and Austrian analogues. Models have an automatic heat exchanger and burner cleaning system.

Pellet machines have a vacuum supply of granules. Efficiency – 95%. Granules with any ash content can be loaded into boilers. An alternative type of fuel is wood chips. The operation of the units can be controlled remotely using SMS.

Advantages:

- are not inferior to foreign analogues in quality at a lower cost;

- unpretentious to the type and quality of pellets;

- high efficiency.

Main disadvantage:

- high cost of equipment.

Review

| Evgeniy Ch. |

| I heat the house with a Svetlobor 32 kW boiler. It has been working since 2013 without failures. I use gray granules as fuel. I'm happy with the model. |

FROLING P4 PELLET 25

Country of origin: Austria. Average cost 1.1 million rubles. The model is considered one of the most advanced in the world. It is distinguished by high quality assembly, functionality and a high level of automation.

The Lambdatronic P 3200 control unit is equipped with a large touch display. The design has good sound insulation, so it works quietly.

FROLING P4 is thought out to the smallest detail. Once a week, a person must empty the ash pit; all other operation of the equipment is controlled by automation. The design allows it to be connected to low-temperature heating systems. For example, to a warm floor. The model is considered the most effective in its class.

Advantages:

- ease of maintenance;

- double fuel fire protection system;

- automatic diagnostics of equipment before each switch-on.

Main disadvantage:

- high price.

Review

| Leonid M. |

| Expensive unit, but completely worth the money. Works no worse than gas. Sometimes you need to clean the ash pan and do preventative maintenance once a year. |

SOLARFOCUS PELLETTOP

Country of origin: Austria. The average cost is 700 thousand rubles. The design of the model allows you to create a fully automated heating system in your home. Unit efficiency is 94%. The supply of granules from a remote storage is carried out using a vacuum method.

Advantages:

- long manufacturer's warranty period (10 years);

- full automation of the house heating process;

- long period of autonomous operation without human intervention;

- modern design.

Main disadvantage:

- high price.

Review

| Oleg P. |

| The compact boiler has high performance. Can be left unattended for a long time. |

The best semi-automatic machines

Heiztechnik Q BIO DUO 35

Country of origin: Italy. Average cost – 190 thousand rubles. The model is equipped with a double firebox. Efficiency – 88%. The unit can operate in automatic and manual mode.

In addition to the burner, the structure is equipped with a grate for storing firewood. The pellet machine can work offline for 3 days. Designed for heating rooms up to 350 square meters. m.

Advantages:

- high degree of security;

- ability to work on pellets and firewood;

- convenient display of the control unit;

- spacious fuel hopper (300 l),

Flaws:

- large dimensions;

- high price.

Review

| Roman I. |

| You cannot heat a boiler with coal. The slag is sintered on the burner. It hangs on it like a big cake. You have to constantly clean them. |

Kiturami KRP 20A

Country of origin: South Korea. Average cost – 200 thousand rubles. The model is designed for heating houses up to 300 square meters. m. The design is equipped with an auto-ignition system. When granules burn, a lot of ash is formed, which must be constantly removed from the ash pit. The boiler has a fire extinguishing function. Fuel combustion modes are set on the control unit, but pellets must be filled in manually. Efficiency 92%.

Advantages:

- high degree of security;

- automatic diagnostics.

Flaws:

- the model does not have a circulation pump;

- no heating indicator;

- heavy weight.

Review

| Marina G. |

| The boiler has to be cleaned frequently. I do this at least once a week. |

ACV ECO Comfort 25

Country of origin: Belgium. Average cost – 250 thousand rubles. The model has automatic ignition. The fuel hopper can be fixed in the right or left-hand position. The combustion chamber is made of stainless steel. The burner is cast iron.

Advantages:

- ease of connection to the heating system;

- good thermal insulation.

Flaws:

- heavy weight;

- Suitable only for a certain type of pellet.

Review

| Yulia K. |

| Nice build. Reliable unit. |

Principle of operation

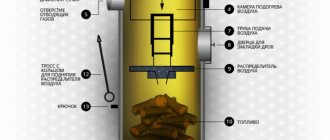

The principle of operation of a solid fuel boiler occurs according to the following cycle of supply and combustion of pressed wood pellets:

- From the hopper, an external screw conveyor delivers pellets to the preliminary combustion chamber.

- Depending on the model of the unit, fuel from the pre-furnace reaches the grate or burner nozzle through an internal auger or free fall. With the help of auto-ignition, ignition occurs.

- The primary air flow is directed under the grate, fuel is purged and the grate (retort) is cooled.

- The secondary air flow is directed to the burner, into the combustion chamber, through air channels in the boiler body or directly in the burner itself.

- In economy class units, ash spills into the ash pan through the gaps between the grates. More expensive models, with advanced functions, are equipped with movable (tipping) grates for removing ash from the firebox.

- In cheap series boilers, the ash pan is cleaned manually. To do this, you need to stop the operation of the device after filling the ash collection container. In automated analogues, waste combustion products are removed using automation. Using an auger, the ash moves from the container along the ash channel to the external ash pan. As it progresses, it is compressed, which makes it possible to produce an external ash pan with minimal dimensions.

Important: for boilers without automation: when using good quality wood pellets, the ash pan is cleaned every 6 - 7 days; when burning agropellets, cleaning must be done every 3 days; using coal requires removing ash daily.

Selection options

Manufacturers produce a large number of different models of pellet boilers. You can buy them in specialized or online stores.

When choosing the optimal model for yourself, you need to pay attention to factors such as:

- unit power;

- efficiency;

- functionality;

- fuel consumption;

- number of circuits.

Double-circuit boilers can be connected to heating and hot water systems. When choosing a pellet stove, be sure to take into account what type of room it will heat: residential or industrial. For domestic needs, a small power boiler is sufficient.