Traditional wood stoves are the main source of heat in individual country houses. Moreover, many owners do not plan to exchange them for modern heating devices. This is partly easily explained by the following: today there are many alternative types of fuel - briquettes. Compared to the firewood that many are accustomed to, they are much more efficient, more convenient to use, but at the same time their cost is higher. In general, each fuel material has its own advantages and disadvantages. Therefore, the decision to choose firewood or wood briquettes always remains with the home owners. They usually assess the situation from a practical point of view and make a more profitable choice for themselves.

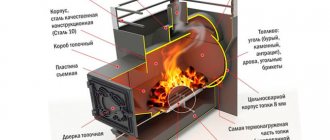

Stove heating with wood or other modern materials remains relevant today for many owners of country houses Source o-vannoy.ru

Fuel briquettes or firewood – which is better?

It is advisable to start comparing different types of fuel with the cost of materials. If we analyze their price indicators, 1 m3 of Euro firewood will cost approximately twice as much as the same amount of ordinary logs. Moreover, the former are made from raw materials of varying value; the price of firewood is determined by the type of wood.

There are different products on the market. First-class briquette products have a denser structure, do not contain cracks or chips, and most often they are fired on the outside. Low-quality products are multi-layered, have lower density, and are vulnerable to mechanical damage. Such fuel burns faster and produces less heat.

The cost of fuel briquettes is approximately twice as much as regular firewood Source pankornik.pl

Homemade briquettes - pros and cons

The reasons why this type of fuel is very attractive are clear. When a person has his own wood production or the opportunity to cheaply buy sawdust for briquettes, then thoughts about making them at home are quite natural. The fact is that not every heating equipment is suitable for burning sawdust. As a rule, fine wood in a conventional stove or boiler burns quickly and gives off little heat, and even half will spill into the ash pan.

To successfully burn wood waste, you need a special shaft-type or top-burning boiler. It’s quite difficult to make this; the prospect of pressing sawdust into fuel briquettes seems much brighter.

It turns out that not everything is so simple here either, and here’s why:

- Buying factory drying and pressing equipment is an unreasonably expensive undertaking. It is cheaper to purchase ready-made European firewood.

- You can make a briquette press yourself and make them in an artisanal way. But the products will be of low quality and will provide little heat, and will take a lot of time.

After squeezing out the water and subsequent drying, the briquette becomes quite light.

Point two requires clarification. Due to the impossibility of following the technology, the “bricks” after drying are light due to their low density. Their specific heat of combustion is three times lower than that of wood, which means that for heating they will need three times as much. The whole process will take a lot of time and consume a lot of energy. And it is very difficult to store such a volume of fuel so that it does not accumulate moisture.

Educational video for enthusiasts who want to start manual briquetting of various household waste:

What to choose: coal or firewood?

Coal is perfect for heating boilers located in a separate room. It is not at all recommended to use it in a stove located in the home. This is due to the fact that such fuel burns for a long period and does not burn completely. For this reason, it is unacceptable to leave the chimney closed so that carbon monoxide does not accumulate in the room. At the same time, ordinary firewood always burns completely, releasing enough heat. This means that you can safely close the valve without fear for your health or heat leakage through the chimney.

Lighting charcoal without the right wood is a difficult task. Therefore, all those who use it are forced to purchase material for ignition.

Coal dust is considered quite harmful to human health. When throwing such fuel into the stove, you must try to prevent dust from rising into the air. Firewood contains almost no dirt, making it much safer.

As opposed to coal heating, traditional wood heating is more environmentally friendly: when burned, dry wood emits a small amount of carbon dioxide and therefore does not damage the natural environment. The latter is not typical for coal.

Unlike firewood, coal is not recommended for heating stoves located in residential premises Source tektarif.ru

What are wood briquettes made from for heating stoves?

I call this type of fuel Eurowood, I was prompted to come to this conclusion by modernity and ease of use; such elements appeared relatively recently, but are already the main competitors to generally accepted logs made of natural material, which all people have known about since ancient times.

Such products can be made from known surplus production and not only, I will describe this point in detail, there are such types of raw materials as:

- Tree. Non-format materials include shavings, sawdust and bark; they are pressed on special equipment, giving each element a convenient shape. During operation and transportation, products of this type do not lose their presentation, this is due to the substance that produces natural material, it is called lignin. The liquid is similar to glue, after hardening with its help the briquettes hold their shape perfectly, the calorific value is at a high level and amounts to 5000 kcal/kg.

- Straw. The manufacturing method is similar to the previous one, I noticed that the characteristics are slightly lower, they are 4740 kcal/kg.

- Seed husk. The calorific value is quite good, 5151 kcal/kg; such elements are produced from the residues of sunflower seed processing. The oily components included in the husk can increase efficiency, but I advise you to be careful with this point, because in addition to a good flame, deposits will form on the walls of the chimney.

- Cereal waste. Similar specimens are created from rice husks, the heat transfer is not the best, it is 3458 kcal/kg.

- Peat. Briquettes of this type must be dried before pressing, and only then they are shaped. The products are small, which affects ease of transportation. When burned, such fuel can release 5000 kcal/kg. Ash of this type of form, after cleaning the tank, is often used to fertilize the land on a personal plot, which bears fruit.

- Coal dust. The waste is sifted before compacting and then shaped. I do not recommend comparing this type of product to the stone type, because it does not produce as much smoke and is much more convenient to use.

How to make briquettes with your own hands

If firewood or briquettes are not available, you can try to make the latter yourself. The main principle of Euro-firewood production is the compression of crushed wood waste until lignin begins to be released. This substance subsequently glues small particles into a monolithic product. For the production of fuel briquettes it is allowed to use: agricultural residues, sawdust, shavings, and other woodworking waste.

Procedure:

- Grind raw material.

- Dry to 10% moisture content.

- Using a hydraulic press or auger device, briquet the prepared raw materials.

Making at home

It is clear that purchasing such powerful equipment to press briquettes at home is a fool’s errand. Even if you have the funds and free raw materials, you will be able to recoup its cost only if you press firewood from sawdust for sale. This means that it will not be possible to maintain traditional technology for lignin extraction.

Clue. Waste from winter tree pruning is perfect for briquetting if it is first crushed with a crusher. Read about the process of assembling such a branch chopper in a separate material.

Instead, home craftsmen have adapted to using different binders to form “bricks,” for example:

- wallpaper or other cheapest glue;

- clay;

- paper, corrugated cardboard.

In order not to buy expensive drying and pressing equipment, fuel briquettes are made at home as follows. Sawdust is soaked in water and thoroughly mixed with clay in a ratio of 1:10, or soaked cardboard or wallpaper glue is added. The resulting mixture for making briquettes is placed in the form of a homemade manual sawdust press and compressed by hand. Then the “brick” is removed from the mold and placed to dry naturally, outside.

For reference. Using this technology, savvy owners press briquettes from any available materials that can burn: straw, paper, cardboard, leaves, seed husks, and so on.

Methods for storing briquette fuel

Pressed briquettes for heating must be stored in compliance with strict rules. It is necessary to monitor the humidity level in warehouses. Its indicator should not exceed 80%. For this there is no need to build insulated hangars. It is enough to update the roof over the canopy. Due to the fact that the fuel has a high density, a small area of the room allows you to store significant reserves of briquettes. One cubic meter can hold up to 2500 kilograms of fuel.

There is no need to equip warehouses with strict adherence to safety regulations, since the fuel in briquettes will not ignite. There is also no release of foreign gases or other toxic substances.

Fuel in briquettes does not absorb excess moisture, therefore it is able to maintain high performance for a long time.

Briquetted fuel has received excellent reviews and is widely used for heating suburban real estate, heating baths, saunas. Ideally keeps the air temperature at the specified values in fireplaces and stoves. It is also recommended to use it for heating greenhouses and outbuildings. This type of fuel can be used to light boilers for any purpose. As you can see, briquetted fuel is not only an economical, but also an effective source of heat.

Composition of briquetted fuel

Dense bars of fuel are made from waste wood, that is, in fact, they are compressed sawdust. Before being put under the press, the raw material undergoes special preparation: it is crushed to the required size and dried.

Important! Sawdust binders are organic compounds that are safe and do not contain glue.

When pressed, hard briquettes are formed from the raw materials, ready for use. The manufacturer can additionally process them by firing, if such a stage is provided for in the fuel manufacturing process.

The resulting material for heating stoves is delivered to the consumer, who can safely heat his home, non-residential buildings or light a fireplace in the country. Briquettes will replace firewood when traveling outdoors. They will ensure the fire burns evenly, the coals will not fly away and spark.

Cost of wood briquettes

In Moscow and the region, you can purchase forms of this type from various tree species, often when ordering from 5 tons, the price will be changed, this is a kind of discount for a wholesale buyer.

I can only give approximate numbers, but they are worth a look. The package consists of 12 pieces, often the weight does not exceed 10 kg, which is quite convenient. I would like to highlight the following types:

- Birch sawdust – 6500 rub. per ton.

- Oak dust – 8500 rub. per ton.

- Wooden specimen made of oak – 9,700 rubles. per ton.

It is better to find out all the exact prices directly from consultants; I advise you to take a closer look at specialized sites, where you can find all the important information without leaving your private home.