Solid fuel boiler As a rule, those who install autonomous boiler equipment in their home for the first time face problems with its operation. Not everyone, for example, knows how to properly heat a boiler with coal or what type of solid fuel to choose for the designated purposes. Experts point out that any stove must be handled with extreme caution, carefully observing all fire safety standards. It is also useful to familiarize yourself with the operating features of the selected equipment in advance.

Tips from experienced stove makers

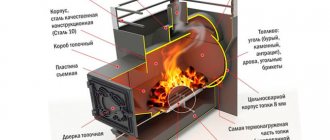

If you have a stove or boiler in your home that runs exclusively on coal fuel, you will still have to light the heating device using paper and firewood.

Only after the required temperature has been reached in the firebox can the coal itself be poured. If you don’t know what volume to take, then you need to focus on a layer of about 5-6 centimeters. When this volume of material burns well, it will be possible to add the remainder in such an amount that the layer is already 15 centimeters. With this approach, you can be sure that the stove will light up well and there will be sufficient temperature in the house.

When kindling, the pipe valve should be moved back slightly, and the coal itself should be placed on the grate. At the moment when the fuel has already ignited well, it is necessary to open this valve to the maximum.

At the next stage, you should add a portion of small coal (if it is large, you will have to split it). Its layer will be approximately 5-8 centimeters, and the area should correspond to the grid. When the filling is completed, the firebox door should be closed, and at the same moment the ash pan should be opened. After the material flares up, the volume is increased to 12-20 cm.

As for subsequent portions of coal that will be added after the batch of material burns out, some rules should be followed:

- A new bookmark is made only when you are convinced that the previously filled coal has already flared up well enough.

- Before adding a new portion of coal, if the firebox doors are opened at this time, it is necessary to cover the ash pit.

- You should not allow the material to burn out right up to the grate; combustion should be uniform throughout the entire layer.

If you pay attention, you will notice that purchased coal comes not only in large pieces. It may contain small particles, as well as typical dust. To prevent it from combining into a single layer during combustion, the material should be moistened with water before laying.

To prevent it from combining into a single layer during combustion, the material should be moistened with water before laying.

The same applies to those who use fatty coal of the PZh or Zh brands. However, the volume of water should not be large, because the material burns better in a dry form. When lighting a stove, fuel of the PS and SS grades, where small elements predominate, must be moistened with a slightly larger volume of liquid.

There is also skinny coal, which is marked with the letter T; it is this that should be moistened generously, but long-flame material is only sprayed to remove dust. As for the “Anthracite” brand, it does not need to be wetted at all, only if it is dusty, it is lightly irrigated with water.

When the combustion process itself is underway, the combustion chamber door must be closed. It should be opened only when it is planned to throw in a new batch of coal. Unlike firewood, this material does not need to be turned over as often, otherwise the firebox will cool down and some of the material will fall through the grate.

Now it becomes clear what is the best way to heat the stove and how to do it correctly. Of course, the process may not work out the first time, but don’t despair, because after two or three attempts all actions will be performed automatically, and the house will be filled with comfortable warmth and the pleasant crackling sound of burning coal or wood.

What to do if the coal in the boiler does not burn well?

It is difficult to say in absentia why coal burns poorly or does not burn at all, because this happens for many reasons, but some of them are more common:

- reduction in draft due to clogging of the chimney and grate;

- using the wrong grade or simply low-quality coal;

- the boiler power is too high, which does not correspond to the area of the house;

- loading a large volume of coarse coal, without preliminary kindling;

- malfunction of the automatic forced air supply system;

- violation of the integrity of the structure (the flame often goes out + smoke).

In the case of the latter options, a boiler repair specialist will be required, but other problems can be completely resolved by proper operation and cleaning.

What kind of coal is used to heat your home?

Anthracite coal for home heating

When deciding which coal is best for heating, the first thing that comes to mind is anthracite. This type of coal has the best fuel characteristics in terms of parameters such as minimum consumption, maximum heat transfer, uniform and long burning of each loaded batch, and a minimum amount of slag formed during combustion.

This grade of coal contains less than 1% sulfur and only about 10% ash, which suggests minimal harm to the environment (min sulfur dioxide emissions) and a significant increase in the service life of chimneys and boilers. Sulfur and water vapor, when interacting, form sulfuric and sulfurous acids, which negatively affect the design of chimneys and heating boilers.

Anyone who chooses coal for heating, despite all the advantages of anthracite listed above, cannot definitely recommend it, since anthracite has two disadvantages that play an important role for owners of private houses. Firstly, anthracite is the most expensive type of coal. Secondly, it is extremely difficult to light it.

Therefore, most often, for heating a house with coal, preference is given to long-flame coals (LFC), which are well suited for almost any heating boilers operating on solid fuel, as well as for classic fireplaces and stoves. As additional advantages of coals of this grade, it should be noted that they:

- Convenient to light, easy to use;

- Demonstrate the most optimal quality/price ratio;

- They burn with long tongues of flame, similar to burning wood;

- The combustion process of one bookmark takes quite a long time and is accompanied by the release of large volumes of heat;

- For stable combustion, no additional ash pit is required.

That is why long-flame coal is purchased not only by owners of private houses, but also by boiler houses of schools, administrations at various levels, hospitals, etc.

The specified coal in stationary boiler plants has proven itself to be effective both in pulverized and layer combustion. Therefore, consumers are in demand for almost all commercially available coal fractions of the specified grade: from “P” to “M”.

Types of coal

Coal is of plant origin. For the most part, this fossil consists of carbon and non-combustible components, which turn into ash during combustion. Coal mined in different regions contains different amounts of such impurities. When ignited, the sulfur in the rock forms oxides that form sulfuric acid in the atmosphere. The largest proportion of sulfur comes from lignite. Based on its characteristics, coal comes in several types.

Coal is classified by age as follows:

- Lignite (youngest);

- brown (subbitominous) coal;

- coal;

- anthracite (the oldest deposits).

According to the content (B) of moisture and volatile impurities (MP):

- brown (subbitominous) coal: B=30-40%, LP > 50%;

- hard coal: B=12-16%, LP=40%;

- anthracite: B=5-7%, LP=5-7%.

Specific heat of combustion:

- brown coal – 3000-5000 kcal/kg;

- hard coal – 5000-5500 kcal/kg;

- anthracite – 7400-9000 kcal/kg.

A set of measures before starting the fire

For the normal passage of the entire combustion process, it is necessary:

- carefully inspect the stove structure, starting from the firebox door of the stove and ending with the chimney. If cracks are found in the brickwork or chimney pipe, they must be sealed with a sand-clay mixture. Otherwise, the room will instantly fill with smoke, a large amount of carbon monoxide may appear, and small cracks will turn into large cracks and can actually damage the masonry;

- whitewash the pipe if you have not used the stove for a year or more;

- clean the chimney structure, including chimney channels, pipes from soot (if you have not used the stove for 3-4 months);

- clean slag and ash from the furnace. To avoid the appearance of dust in the room, combustion waste must first be filled with water, then raked out and taken outside;

- check for traction. To do this, insert a newspaper folded lengthwise into the firebox, set it on fire, and if smoke goes up the chimney, then everything is fine;

- use a dry cloth to wipe the outer part of the heating structure, otherwise an unpleasant odor will appear during the fire;

- Heat a little at a time 2-3 times a day, if the unit has not been heated for a long time, to prevent overheating of the stove.

Stable combustion stage

The stable combustion stage lasts about 5-9 hours. The main technique on how to properly heat a boiler during this period is to uniformly supply fuel to the firebox. Usually, if at the first filling ¼ of the fuel is used, then during the period of maintaining stable combustion, the remaining fuel is divided into 3 equal parts. After adding anthracite through the vent grate, the burning mass is stirred to prevent slagging of the firebox.

Combined heating boiler ZOTA “Mix”

The main feature of the ZOTA “Mix” boiler is its versatility. It mainly runs on wood and coal, but in a pinch gas, diesel and electricity can be used. This flexibility is achieved by a special design that allows you to install different types of burners and operate equally efficiently on different types of fuel.

Photo 3: Combined heating boilers using solid fuel Zota Mix

Let's look at what other advantages the Mix solid fuel boiler has:

- The heat exchanger has an unusual X-shape, which ensures maximum heat removal, which in turn ensures high efficiency values.

- Operating efficiency is also improved by insulating the water jacket. Heat loss due to its use is reduced, and therefore efficiency increases. In addition to improving efficiency, insulation also improves fire safety.

- Easy access to the flue and a spacious ash tray make cleaning and maintenance very convenient.

- The optimal pressure for a heating system is 3 atm. In emergency cases, the device can withstand a pressure surge of up to 4 atm, without the danger of explosion as is the case with the installation of a cast iron solid fuel heating boiler.

- The operating power is adjusted by a built-in draft generator and a draft control damper in the chimney. Temperature and pressure are controlled via a thermomanometer on the front panel.

The ZOTA “Mix” model is available in four sizes with power from 20 to 50 kW. Their main characteristics are as follows:

| power, kWt | 20 | 31,5 | 40 | 50 |

| Room area, m² | 200 | 315 | 400 | 500 |

| Efficiency, % | 80 | |||

| Firebox volume, l | 35 | 45 | 63 | 79 |

| Heat exchanger capacity, l | 50 | 70 | 120 | 140 |

| Chimney diameter, mm | 150 | 180 | ||

| Chimney height, m | 6 | 7 | 8 | 9 |

| Price, rub | 34 900 | 38 700 | 49 900 | 54 500 |

Feedback from a real owner of the ZOTA “Mix” boiler about the experience of use:

Eldar Vladimirovich, Irkutsk

If you are looking for a solid fuel boiler that can, if necessary, operate on gas or liquid fuel, while maintaining high efficiency and remaining safe, then the ZOTA “Mix” is exactly what you need.

Consumption rates and rules for calculating the required volume of fuel

According to technical standards, 2 kg of coal is required to generate 10 kW of thermal energy. Knowing this, you can calculate its required volume using the formula:

M x =X/fuel calorific value (in this case 5 kW/kg)

- where M x is fuel consumption for a limited period of time (day, month, season);

- X – heat loss during the heating period, determined by the formula:

X = S×D×24×0.7×70

- where S is the heated area of the house, including all residential and utility rooms;

- D – duration (number of days) of the heating period;

- 24 – burning time (number of hours) of the boiler per day;

- 0,7 – average operating factor of coal boilers;

- 70 – average heat loss per hour (for a standard house in a temperate climate).

If we take the average heating period of 6 months (175 days) as a basis, then with an area of 100 m2 the heat loss will be X = 100 × 175 × 24 × 0.7 × 70 = 20,580 kW per season or 117 kW per day. Coal consumption for the same period will be equal to M1=20,580/5=4,116 kg and M2=177/5=23 kg, i.e. it will be necessary to purchase about 4.5 tons of coal.

Reference . Quite primitively, you can rely on the “living” experience of other owners of coal boilers: when the temperature outside is + 1 ... or more °C per day, 1 bucket of fuel burns, if - 5 ... - 15 °C, then 2-3 buckets, and especially frosty in winter - 20 ... and less °C, you will need to load up to 10 buckets* per day.

* a standard bucket (12 l) holds about 18 kg of medium-sized coal.

The nuances of firing stoves with coal in winter

In winter, at low temperatures, it can be quite difficult to light the stove. In addition, the special draft that is formed due to cold air does not allow smoke to escape freely. There is no way to light the stove quickly. You can improve the kindling process by using a hairdryer, which warms up the inside of the heating equipment.

Such heating of the furnace device will avoid smoke, which is typical for cold structures. The stove should be warmed up several times a day in winter so that the system does not have time to cool down too much.

Coal is considered the most efficient type of fuel. It is successfully used to kindle stoves. The level of heat transfer of such raw materials is higher than that of wood raw materials. A good result from using coal for a stove can only be obtained by following all the rules for kindling and operating the heating device.

How to remove ash?

Heating solid fuel boilers

When the stove is heated with wood, removing ash is very simple. The fuel burns out and falls into the ash pan chamber.

Coal has a much longer burn time, so it is quite difficult to remove slags in time. Laying with wood saves the situation - a layer of firewood, a layer of coal. You can cope with this problem by increasing the combustion temperature. Therefore, it is useful to learn how to regulate cravings.

About firewood

As mentioned above, the quality of the fuel is of great importance. Both for the efficiency of heating equipment and for increasing its service life. This is especially true for firewood - a very unstable type of fuel. The efficiency of the boiler depends on the uniform supply of fuel, which is equalized in its calorific value

This is most important for modern technological heating devices, burdened with automation. Firewood differs in its technical qualities - humidity, specific heat of combustion

That is why manufacturers of boiler equipment insist on choosing high-quality fuel.

Pellets and fuel briquettes are more efficient fuel for a wood boiler

Log log discord

Wood of different tree species has different densities, which means their ability to produce heat. But, besides this, other features of firewood that affect the operation of the boiler are also important: the amount of non-combustible (ballast) substances and the presence of resins that pollute the chimney and the internal structure of the device during combustion.

Birch firewood

Birch has dense wood, so it burns hot and produces a lot of heat - 3750 kcal, even if the wood is damp. It is highly flammable. But when such firewood burns, especially damp wood, tar is released - a substance useful in medicine, cosmetology or for protecting surfaces from rotting, but extremely harmful to the insides of the boiler.

Soot on the boiler heat exchanger

Alder firewood

Burning alder wood produces virtually no soot. Moreover, burning alder wood helps clean the chimney. Alder is flammable, burns well and produces a sufficient amount of heat - 2100 kcal.

Aspen firewood

Burning aspen, like alder, cleans the chimney. But such firewood itself produces a little heat when burning - up to 1650 kcal.

Pine firewood

They burn well and quite hotly (3800 kcal), but pine wood is resinous and a lot of soot is formed during combustion.

Firewood in the storage meter

Spruce firewood

Spruce firewood is comparable in quality to pine, but has a slightly higher specific heat of combustion - 3900 kcal, and is also less resinous.

Poplar firewood

Poplar burns hot, but burns out quickly.

Firewood from apple and pear trees

Firewood from fruit trees - apple or pear - has dense wood, which means it produces a lot of heat, burns and smolders for a long time. But these species are usually grown for their fruits, so such firewood is not common. Another feature: the trunks of pear and apple trees are clumsy, the logs are difficult to prick, and the logs are knotty and difficult to pack tightly in the firebox.

Oak, beech, ash firewood

Oak, beech, and ash are dense wood; when these species burn, a lot of heat is released - up to 3600 kcal. The disadvantages of oak or beech firewood include their rarity on sale and the difficulty of splitting and heating a boiler with them. Considering the described qualities of wood as fuel, a good owner stores different types of firewood: some so that it flares up easily, others so that it burns long and hot, and others so that it can periodically clean the chimney of soot.

Main disadvantages

Like any other equipment, they have their disadvantages. The production process uses quite complex automation, which can significantly increase the cost of the device. As a result, the price turns out to be 2 times higher compared to conventional designs that have the same power.

Among other things, due to the fact that the combustion process is automated, the owner of the equipment cannot interfere with the operation of the boiler while the coal is smoldering. This indicates that it is not possible to extend the combustion life in such a device. Sometimes this creates certain difficulties during operation.

Algorithm of actions

In fact, everything is extremely simple:

- Initially, the furnace firebox is covered with a small amount of paper.

- It is necessary to put wood chips, small wood shavings or bark on top of it; it must be dry.

- For the next layer, take logs, but their thickness should be less than those that are already used in a burning oven. This amount of materials will be enough to warm up the heater.

- When the flame is sufficient, the firebox is filled with firewood, and its level should be 20 cm lower than the firebox. With this approach, the fuel will have time to burn out even before it enters the chimney.

- When the required amount of warm air has accumulated, you can begin to add coal, starting with small pieces and throwing in more and more.

Sahara

A steam room equipped with a Sahara stove-heater can easily turn into both a traditional Russian bathhouse and a classic Finnish sauna. The stoves have a unique ergonomic design; they embody the principle of the “golden ratio” without violating proportions or smoothing corners. This shape allows it to fit well into almost any interior.

When developing the design of the Sahara stove, the principles of maximum comfort in operation with aesthetic appearance and operational efficiency were embodied. Heating of the stones is ensured from five sides; the fastest heating is achieved due to the successful placement of the chimney parallel to the axis.

The creation of a microclimate similar to a Russian bath and Finnish sauna is ensured by installing an additional converter.

Teplodar sauna stoves can be called, without a shadow of exaggeration, a work of stove art; all products are characterized by a stylish design, high functionality, reliable operation and ease of operation.

" What

Results

Heating a house with coal is a good solution, in combination with which you can also use corner heating radiators. There is no need to worry about heat loss with such a system; such devices are placed in corners, even behind the boiler.

For decades now, coal boilers have shown that they are worthy and reliable as a heating system.

Among the undeniable advantages that determine the popularity of coal-fired boilers is, undoubtedly, the fact that you can use not only coal, but also other types of fuel - hardwood, briquettes, peat, sawdust, etc. Coal-fired boilers are economical and have high heat transfer, long-lasting combustion, and the boiler itself can be used throughout the heating season without extinguishing.

Among the disadvantages of heating with coal is the need to constantly add fuel and dispose of waste. There will also be coal dust everywhere, even if you work carefully. Coal has to be prepared.

Features of the grate

Various grates are installed in coal boilers. They differ in material and shape. Steel grates deform over time due to high temperatures.

Boiler grates

More reliable ones are made of cast iron in the form of a solid grate. You also need to pay attention to the shape of the ears. The peculiarity of modern grates is that they are made in the form of corners, which allows the ash to fall into the ash pan faster.

Criterias of choice

The main one is the boiler model. If the manufacturer has technically provided for the use of 1-2 grades of coal for normal operation, then the question of choice disappears: it is necessary to use only the types of fuel specified in the operating instructions.

In other cases, heating engineers consider anthracite to be the best option. Although there are many nuances when it is more profitable to use less expensive brands. Another determining criterion for selection is the size of the fraction: fine ignites and burns faster than large ones, but more often requires a new filling.

According to this criterion, preference is given to “nuts” (50 mm) and large ones (up to 80 mm). Such coal will burn longer and produce more heat.