The gas boiler Ochag KGS is part of a wide range of products. The Russian manufacturer produces gas burners, control units and gas burners. The Ochag KGS boiler is the result of the implementation of innovative strategies combined with the technical experience accumulated by the largest specialized plant over many years. Just imagine, 63 types of boilers this company can offer!

Don’t be alarmed, our review today will only cover the standard and premium versions of boiler equipment from the Ulyanovsk plant:

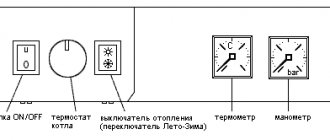

How to turn off the Proterm boiler?

Complete shutdown of the heating system is carried out differently:

- On the main panel you will have to find the on/off button and hold it down for a while until the display goes out.

- In the off position, the external two-pole control lever must be moved.

- Gas access to the boiler is blocked.

Interesting materials:

When did silk appear? When did the term Orthodoxy appear? When do last minute tours appear? When do the first boletus mushrooms appear? When do the first mushrooms appear? When do magpie chicks hatch? When do birthmarks appear? When will the Kolosoviki go? When to buy pullets? When do buyers receive the keys to the apartment?

Device and technical characteristics

Single-circuit boiler Hearth for heating a house

A heating boiler can be single-circuit, double-circuit or combined.

Single-circuit boiler

It has a cast iron heat exchanger and uses natural gas for heating. This is a complex configuration and requires a large number of parts to install. Its functions include heating only. For hot water supply, a boiler is additionally installed.

Double-circuit boiler

Equipped with two heat exchangers. Used for central heating and hot water. Natural gas is used for heating. This is a compact installation that operates automatically. To simultaneously heat the heating batteries and produce hot water, a heat accumulator is installed.

In the absence of a heat accumulator, when the hot water tap is opened, the pressure in the heating system drops and the temperature decreases. If the boiler is located far from the place of consumption, hot water will not appear immediately.

Combined installations

These are universal boilers with a steel heat exchanger (KSTG, KSTG). The unit can operate on fuel oil, solid fuel, and natural gas. Used for heating rooms with an area of 400 m2 and hot water supply, it has an internal water heater. Equipped with gas automatics, which reduces the gas supply when pressure increases.

The gas boiler Ochag has the following technical characteristics:

| Characteristics | Boiler brand | ||

| KSG-7AT | KSTG-16 | KNG 24 | |

| Type | Convection gas heating | ||

| Fuel used | Natural gas with conversion to liquefied | Natural gas or solid fuel | Natural gas with conversion to liquefied |

| Purpose | Heating | Heating | Heating and hot water supply |

| Mounting method | Floor | Floor | Wall |

| Efficiency | 85 % | 75% | 90% |

| Power | 7 kW | 16 kW | 24 kW |

| Power supply | Absent | Absent | 220 V / 50 Hz |

| Life time | 15 years | ||

| Guarantee | 36 months | ||

The parameters of three commonly used brands of Ochag heating unit are given.

Operating principle and advantages of flame sensors

Flame detection sensors are designed to effectively detect fires. Their main advantage and difference from smoke detectors is that flame detectors do not respond to the presence of combustion products in the air, but directly to the cause of an emergency situation - fire. Their effectiveness does not depend on the movement of air masses (as is the case with smoke devices), which makes the data obtained more accurate.

The operation of flame sensors is based on capturing ultraviolet radiation emanating from burning objects. Thanks to a special light-sensitive element (a thin UV indicator) built into each sensor, flame detectors are highly sensitive to electrical signals and electromagnetic rays. It is this characteristic that is responsible for the ability of sensors to recognize fires without confusing them with the effects of electric lamps and sunlight. The devices respond to UV radiation in the range from 220 to 280 nm. They are able to almost instantly determine the location and type of fire, which makes it possible to quickly localize the fire, minimizing possible risks and losses.

Flame control sensors are recommended by EEC standards and are suitable for installation both indoors and outdoors under a canopy.

Types of flame control sensors

In accordance with the technical characteristics and installation features, today you can buy the following types of fire sensors (detectors):

- ultraviolet;

- infrared;

- multi-band;

- visible range.

They can have different fire detection ranges, up to a maximum of 100 meters. This indicator is important to consider when choosing equipment.

Flame control sensors are a complex, high-tech device, the price of which varies widely, depending on the individual characteristics of the model.

One of the widest lines of flame sensors is offered by the SIEMENS SBT brand. In the company's catalogs you can buy flame sensors, fire control relays, fire detectors at the best prices.

Still have questions? Ask them now by calling 8 (800) 302-5771 or via the feedback form

Source

Boiler marking Ochag

The boiler brand has letter designations, which are deciphered as follows:

- K – boiler;

- C – heat exchanger material steel, CH – cast iron;

- T – used for working on solid fuel;

- G - equipped with gas burners;

- B – has a water heater in its design;

- M – heating elements and an expanded firebox can be mounted to it;

- The number indicates the power of the boiler, the first number is for solid fuel, the second is for gas.

For example: KSG-7AT is a boiler with a steel heat exchanger, equipped with a gas burner with a power of 7 kW, and has SABK-AT automation. Modification KCHTG-16: a boiler with a cast iron heat exchanger, runs on gas and solid fuel, with a power of 16 kW without installing automation.

Ignition sequence

Algorithm of actions for igniting the boiler.

Heating systems of the Hearth are equipped with automation that regulates its operation and facilitates ignition. To start the unit with SABK-AT automation, perform the following procedure:

- Open the gas supply valve.

- Place the handle in the “Ignition” position.

- The “Start” button is turned on and held for 10 seconds.

- Press the piezo ignition button several times; if it is missing, ignite the gas with a match.

- The “Start” button is held for 20-25 seconds until the thermocouple warms up. In this case, a magnetic plug holds the gas valve in the open position.

- The knob of the block is turned to position 5 and stable combustion of the gas burner is achieved.

- The required temperature is set on the gas block.

The ignition algorithm for other brands may differ in the position of the block handle, which is indicated in the instructions for the automatic system.

Wolf gas boilers

Wolf GmbH was founded in 1963. During its activity, the company managed to grow into a large industrial concern engaged in the production of heating, climate control and water heating equipment.

Gas boilers occupy a prominent, although not the main place in the list of company products. A special feature of the equipment is the absence of scattered production and assembly across different countries, which is typical of other well-known European brands.

Despite the fairly widespread use of imported custom parts, the units are assembled in Germany, which ensures quality and compliance with all requirements and standards. The boilers are adapted to the technological conditions of the countries in which they will be used.

This helps to overcome a lot of problems, for example, according to manufacturers, the boiler electronics are able to compensate for voltage drops of up to 160 V.

The operational capabilities and reliability of Wolf boilers were highly appreciated by specialists and ordinary users, and were also awarded the corresponding diplomas and certificates.

The gas boiler is blown out by the wind, what should I do?

Often the reason why a gas heating boiler stops working is due to wind blowing. Its shutdown in winter is a very unpleasant surprise for the owners. This can lead not only to a sharp decrease in the temperature inside the house, but also to damage to the entire heating system. Let's deal with the problem.

If your gas boiler suddenly turns off, do not panic and first rule out such a possible cause as a sharp decrease in gas pressure in the pipeline. To do this, you can simply turn on the gas stove and look at the flame, its size, and check how quickly the water boils. You will immediately notice low gas pressure on the hob. In this case, your boiler is definitely not to blame; call the gas workers and find out the causes of the problem. Most likely, not only you have it, but also all your neighbors.

In addition, check and eliminate the possibility of gas leaks using a soap solution, which is applied with a sponge or spray bottle to the joints of pipes and parts. There is no smell or bubbles, which means there is no leakage.

However, often the reason for the gas boiler turning off is obvious - there is a hurricane wind outside, which simply whistles in the pipes. Strong gusts of wind entering the chimney cause reverse draft, the valve is activated, and the flame in the boiler automatically goes out.

You should think about preventing the risk of the boiler blowing out even at the stage of installing the chimney. It is highly advisable to take into account the wind rose in your region. A chimney that is incorrectly located relative to the wind pressure zone significantly increases the risk of the boiler burner blowing out. Incorrect chimney pipe configuration can also cause this problem.

A deflector installed on the head of the chimney pipe copes well with the problem of the boiler blowing out. This is a fairly simple design that increases draft in the chimney, protects it from precipitation and blowing. Be sure to think about installing a deflector or immediately purchase a design with such a device.

Important! Actions with gas equipment require coordination with the relevant service. Therefore, before installing a deflector or weather vane, consult with gas specialists. The cause of a gas boiler blowing out can also be the burning of a metal chimney pipe

As a result of burning, a hole is formed into which air flows - problems with the chimney appear. Only replacing the pipe will help cope with the situation. In the case of coaxial chimneys, there is no risk of burnout, because the hot gas from the boiler flows through the internal pipe, cooled by the oncoming cold air flow

The cause of a gas boiler blowing out can also be a burnout of the metal chimney pipe. As a result of burning, a hole is formed into which air flows - problems with the chimney appear. Only replacing the pipe will help cope with the situation. In the case of coaxial chimneys, there is no risk of burnout, because the hot gas from the boiler flows through the internal pipe, cooled by the oncoming cold air flow.

Two more possible reasons for a gas boiler blowing out:

Ice formation on the chimney. This often happens with coaxial structures in frosts of -10..-15 °C. Hot steam comes out of the chimney, gradually cools, turns into water droplets, condensation, which freezes, forming icicles and a thick layer of ice. This leads to a disruption in draft, the boiler automation is triggered, and it stops working. If such a problem arises, do not rush to knock off the ice build-up - you can damage the chimney itself. It is best to remove the head and upper part of the pipe and bring it into a warm room so that the ice melts naturally. Before removing and cleaning the pipe, the gas supply must be turned off! Additional insulation of the chimney helps to avoid the appearance of ice;

Poor ventilation in the boiler room can lead to problems with the operation of the atmospheric boiler. It will help to install forced ventilation in the room or holes with a fine mesh at the bottom of the boiler room door.

Manipulations with the pipe help to cope with the boiler blowing out - the diameter of its outlet can be reduced or increased in length. A chimney opening that is too large can be reduced by installing an additional inner pipe. Remember that the vertical chimney must be 50 cm higher than the roof ridge.

In this case, too long a chimney can cause excessive, strong draft, which will literally tear the flame away from the boiler burner.

We strongly advise you to call specialists if problems arise in the operation of your gas boiler! Only they will be able to accurately determine the reason for the device shutdown and eliminate it.