What are the reasons why a gas boiler does not start?

The reasons that a gas boiler does not light well are divided into external and internal. External ones include:

- chimney problems;

- low fuel pressure in the line;

- voltage fluctuations;

- draft, reverse draft.

Internal causes include breakdowns of components or sensors - they are usually reported by error codes displayed on the display or indication. When a fault code appears, the user can always take the instructions and see what it means, as well as read recommendations for eliminating the identified problem.

Insufficient ventilation

The reason that a gas boiler ignites and goes out may be a lack of oxygen in the boiler room. This is due to poor ventilation in it. After all, for high-quality combustion of the burner of an atmospheric unit, a good air flow is necessary.

The problem is solved in the following ways:

- organizing good ventilation in the room;

- installing ventilating valves on windows;

- opening the window in the furnace room.

Problems with the chimney: backdraft, blowing, blockage

Due to drafts or errors when installing the chimney, a backdraft problem may occur. Then the wick of the gas boiler does not ignite, since the flame immediately goes out under the influence of a powerful air jet.

Blowing and backdraft mainly occur when there is strong wind or improperly organized ventilation. If the pipe height is insufficient, it burns out, or its width is too large? this problem may also appear.

The optimal chimney width is calculated using special formulas. Only specialists should do this.

Solve the problem of backdraft using the following methods:

- reduce the width of the pipe;

- install a deflector on the head of the chimney;

- redo the ventilation;

- chimney repair.

It happens that the burner of a gas boiler does not ignite due to a complete lack of draft in the pipe. A common cause of this is a clogged chimney. It is easy to check the presence of draft - just bring a lit match to the hole in the pipe: if the flame deviates, then there is draft; if the fire burns evenly, there is no draft.

If the pipe is clogged, it should be cleared of debris and dirt as quickly as possible.

Low fuel pressure

This problem often occurs in dual-circuit units. The burner does not ignite well if the fuel supply is unstable. First of all, you should check the following:

- joints of the pipe connecting the main line to the boiler for gas leaks;

- the performance of the meter - noise and crackling may indicate its malfunction.

If a leak is detected or the meter is broken, you must turn off the unit and call a gas service specialist.

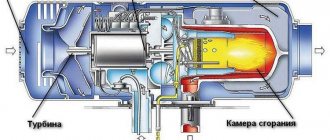

Broken coaxial chimney fan

In all gas units with closed combustion chambers, flue gases are forced out using a fan. If, when you turn it on, you hear a suspicious noise from the blades or you don’t hear anything at all, then you should check the functionality of this unit. If the fan is faulty, it needs to be replaced.

The pilot light is on, the main burner does not light up, “AOGVK boiler”

If you buy goods in bulk, you can save money by importing them directly - the site helps you find suppliers. For example, you can find suppliers for sleds for downhill sledding

. Because there is a problem with the gas supply or the pump has failed, for some reason I don’t see any other option.

... the aluminum corrugation on the chimney of a gas boiler needs to be played with a little...

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The pilot light comes on, but the burner does not

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The boiler pilot light is on. I open the main burner tap. Gas hisses but doesn't ignite

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

boiler KChM-2 with RGU-1M the igniter lights up but the main burner doesn’t why

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The pilot light lights up, but the main burner does not, which means there is a problem with the gas itself or the valve, you need to look.

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

aogv 12 “dani” the wick is burning, the burner lights up but not at full power although the gas pressure is normal, the maximum temperature is 45 degrees on the thermostat, it burns weakly and does not turn off

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The main burner does not light because there are problems with the gas, you need to check if everything is in order, look at the sensors, what they have on them, if everything is working as expected.

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The pilot light comes on but the burner does not

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The pilot light comes on but the burner does not

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The pilot light is on but the main burner is weak

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The Baxi 24F double-circuit boiler lights up and after a few seconds turns off, written E01: how to relieve pressure in the system of a double-circuit boiler

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

Boiler KChM-2 with RGU-1M, the igniter lights up but the main burner doesn’t why

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

The boiler pilot light is on. I open the main burner tap. Gas hisses but doesn't ignite

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

Hello! I have an AOGV 11.6-3 boiler, yesterday the main burner suddenly went out and won’t light up anymore, what should I do? what is the reason. Thank you.

If you purchase goods in bulk, you can save by importing them directly - the site helps you find suppliers, for example, you can find suppliers for sleds for downhill sledding

Hello! I have an AOGV 11.6-3 boiler, yesterday the main burner suddenly went out and won’t light up anymore, what should I do? what is the reason? Thank you. The gas flows normally, I tried to turn off the propeller, turned it off - the igniter went out, turned it on - the igniter lit up. A gas stove nearby works fine. I didn't have any pump.

Answer or clarify the question

Good to know

... column element, hence the igniter does not light up. For good measure, regardless of...

I have a signal-10 boiler. There are no signal repair specialists in the city! stopped holding...

Problem starting the boiler, help solve it! I turn on the boiler and the pilot lights up...

Why does the Mimax 7 agu t m 9 boiler not turn off the main burners when the temperature is reached...

You can hear the automatic click when gas is supplied to the main burner, but ignition...

boiler with piezo ignition, pilot burner burns but when I increase the gas supply...

... there is no thermostat for a gas boiler. They are in a large...room thermostat for gas...

...I support your friends. Gas boilers "Rinnai" are used...and safety...

Other reasons

If the circulation pump fails, you can hear noise in the boiler, and the flame in the burner will go out. In this case, you will have to replace the pump.

If the igniter of the gas boiler does not light, it means that the unit’s protection system is triggered. This is due to poor pressure regulation. In this case, you will have to correctly adjust the gas supply.

Read here about possible gas boiler malfunctions and how to eliminate them

It happens that the problem is in the burner. Over time, it becomes contaminated. Eliminate the problem by cleaning the burner nozzles from dust and soot. It is also advisable to clean the photocell of the flame sensor and repeat ignition.

Features of breakdowns and their approximate classification

Whatever the problems: minor or larger-scale, they must be eliminated efficiently and quickly, because a breakdown of a gas boiler can cause not only an accident, but also an explosion. Many faults can be fixed by users themselves, without waiting for a mandatory preventive inspection. For example, it can be seen that the water takes too long to heat up, unusual sounds are heard, or some small part is faulty. This is a signal that you don’t need to go to extremes and start repairs in time. The result will be less disastrous and costly.

Equipment experts classify gas boiler malfunctions based on the following points:

- breakdowns dependent or independent of each other;

- intermittent or final (an intermittent fault occurs when some parameters go beyond the norm, and then, when they are restored, the activity resumes: for example, a decrease in voltage in the network, after which the system resumes its operation);

- hidden or obvious faults (hidden faults, for example, such as malfunction of heat exchangers or various types of leaks, are quite difficult to find and will require calling a specialist);

- appeared after a long service (gradual) or suddenly appeared.

Almost all problems, with the exception of ten percent of one hundred, can be determined by visual inspection by heating system specialists.

Why doesn't the boiler start?

Often problems are shown as an error code on the display. All modern models Vaillant (“Valiant”), Baxi (“Baxi”), Ferroli (“Ferroli”) are equipped with a self-diagnosis system. Each brand has its own codes and their meanings. If the display does not show symbols, then you need to look for the cause of the problem yourself.

Problems with wall and floor units can be caused by external and internal factors.

External ones include:

- Insufficient gas pressure in the main;

- Chimney problems;

- Power surges in the network;

- Draft, low temperature in the room/boiler room.

Internal factors include breakdowns of electronics - sensors, wiring, as well as individual components - pump, heat exchanger.

Check the display and error codes first

Modern boilers are usually equipped with a screen that displays an error code if a malfunction occurs. You can decipher these codes using the boiler operating instructions. Knowing the error code and the essence of the problem will greatly facilitate troubleshooting the heating system, as well as simplify communication with service specialists.

How to deal with problems

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Proterm”, “Navien”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

Problems with the chimney part

This is excess, deficiency or backdraft. All this leads to the fading of the wick and automatic shutdown of the equipment.

Backdraft or blowing out occurs due to weather conditions: strong winds, pressure changes lead to the burner extinguishing. During installation, take into account the requirements for the height of the chimney:

- The height of the pipe on a flat roof is at least 50 cm;

- With a distance from the roof ridge of 1.5 meters - from 50 cm above the ridge;

- At a distance of 1.5–3 meters - level with the ridge.

Compliance with these parameters will help to avoid blowing and backdraft.

Excess air flow occurs with a powerful kitchen hood or ventilation. The solution is to turn off the hood while the boiler is operating.

Lack or absence of traction provokes:

- Blockages. Occurs in stationary chimneys. Clear the mine of leaves, debris, and construction debris. Fixed and coaxial pipes can become covered with ice in winter. Along with combustion products, hot steam escapes into the street, condensation forms, which freezes on surfaces. Insulate the chimney.

- Damage, burnout of the pipe. Only replacing the chimney will help.

Line pressure drop

Does the dual-circuit device “AOGV”, “Beretta” or “Vailant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Does your equipment not start after a long shutdown? It may be worth using antifreeze as a coolant. It does not freeze when the temperature drops and allows you to safely start the system after a long period of inactivity.

Fan fault

All boilers with a closed combustion chamber - such as Buderus, Wolf, Danko, Lemax - are equipped with fans. They forcibly discharge combustion products into the street. If you hear strong noises when the blades rotate or do not hear operating sounds at all, carry out diagnostics and replace the element if it breaks.

Preventive measures

Any equipment requires comprehensive care and inspection. Because it is subject to wear and tear during constant operation. To avoid constant breakdowns, calling specialists or even replacing the water heater or gas burner. Here's what you need to do to ensure a longer device life:

- Gas equipment must be serviced once a year while the warranty card is valid. And when the coupon expires - once every six months.

- To receive maintenance services, an agreement is concluded with the company that installed the boiler.

- The company usually checks the chimney, automation and leaks.

- If you smell gas and suspect a leak, you can check it yourself. Cover the suspected leak area with soap and water. If there is a leak, additional bubbles will appear. In this case, you need to turn off the gas supply and call the gas service. It is not advisable to use electrical appliances. We also advise you to leave the premises.

Preventative measures include maintenance once a year.

Of course, it is always necessary to follow all safety precautions when using a gas burner.

A gas burner is a convenient device for producing a flame by mixing air and fuel in the required proportions. But there are times when there is no flame. They do not depend on the imperfection of the device, but on improper care, manufacturing imperfections, and so on. It is always important to remember that if you have problems with the burner, you should contact a specialist.

Types of gas boilers

Before you start to deal with problems, you need to understand exactly what type of boiler is installed. They are divided into several groups.

By installation type

The gas boiler can be placed on the floor or on the wall. The first option has great power, which allows it to be used for heating large rooms. It is characterized by long service life, since the main components are made of cast iron and steel. A separate room is usually allocated for such technologies.

Wall-mounted units are smaller in size and weight. They are limited in power. In addition, they are demanding on the quality of water that needs to be heated.

By type of design

Devices are divided into single-circuit and double-circuit. The first are intended exclusively for heating. The second circuit additionally heats running water.

By type of removal of processed products

Boilers have natural and forced draft. The first option is connected to an ordinary chimney . Exhaust gases are removed naturally. In order for everything to work as it should, such a design has some installation rules. So, for example, the pipe should be at least half a meter higher than the roof. Otherwise, the boiler may go out.

The second version of the gas boiler has a so-called coaxial chimney , which in fact is a pipe located inside another one. Such a structure is led directly through the nearest wall to the street. Oxygen enters through the outer pipe to support the flame. And through the internal combustion products are discharged outside. Such boilers have closed combustion chambers.

According to the method of water circulation

He may or may not be dependent on electricity. The first uses a special pump powered by current, which creates forced pressure in the system. In most cases, such installations have a complex automation system that supports the desired operating mode.

Inclusion rules

Connecting an open or closed type gas boiler is not as simple as it might seem, since this is not only a high-tech device, but also a dangerous one. There are too many connection options and circuits. The installation method and the order of connecting the highways are all individual. For this reason, it is recommended that the connection process, start-up and commissioning of gas equipment be carried out by an authorized service center.

In addition, if you connect a double-circuit or single-circuit gas boiler of an open or closed type yourself, this will void the performance warranty. However, situations are different. You should proceed as indicated in the instructions.

The algorithm for how to light a gas boiler will depend on the method of installation of the boiler. So, you can connect a wall-hung gas boiler correctly by proceeding as follows:

- Connect the device to the electrical network;

- Unscrew the gas valve and press the start button (the type with the name of this button is indicated in the operating instructions);

- Select the operating temperature using the plus and minus buttons.

Burners running on electricity are connected automatically after they have been switched to the hot water heating mode. The piezo type of ignition occurs by short adjusting the flame and pressing a special key.

Note! Switching on is blocked when air accumulates. It is enough to press the restart button and the boiler will be able to start working.

As for how to turn on a floor-mounted double-circuit or single-circuit open or closed boiler, this can only be done after the boiler room has been completely ventilated. The rest of the connection process is simple. First, you need to set the temperature selector to off mode, open the gas supply valve, and set the selector to piezo ignition. Then hold down the key for 5 seconds, press the piezo button and adjust the temperature.

Important! To prevent rupture of pipes and freezing of the system, you need to set the minimum indicator values before starting the boiler.

How to start a boiler - step-by-step instructions

It is necessary to start a single-circuit or double-circuit domestic or foreign gas boiler only if the integrity of the system with threaded connections, taps, valves and expansion tanks has been checked. If water is used as the coolant, then the heating system can be filled at above-zero temperatures to avoid the formation of plugs.

It is also important to remember about the absence of prolonged drainage, since untreated and hard water forms scale and settles inside the system. It is better to use soft water or give preference to distilled water.

In an open type heating system, it is enough to fill the coolant using an expansion tank until it is filled to the extent it should be. In a closed system, the media is filled using a specially designated drain and fill valve. As a rule, in modern units the carrier is already installed in a certain place. It is indicated in the instructions and operating instructions.

When filling the carrier, you need to take into account that the pressure there is high, for this reason the opening of the refill tap should be gradual and not full. It is necessary to stop filling the liquid when the pressure on the pressure gauge reaches the operating range. Usually it is 2 bar. It differs depending on which model, for this reason the exact values are always indicated in the manual.

It is also necessary to take care of the air exhaust system, pressure testing and flushing before lighting the boiler.

Note! Modern wall-mounted models already have an automatic air vent, which is located inside: at the top above the heat exchangers or at the bottom in the circulation pump. If there are no automatic air vents in the system, then the air is released using a Mayevsky valve. To do this, you need to take a small plate, place it under the radiator, unscrew the tap a little until the air comes out and hisses. Wait for 5 minutes and close the tap. In modern domestic and foreign advanced models, this is not required, since the air itself comes out through the expansion tank

.

As for the pressure testing procedure, this is an optional step, but necessary for the safe start-up of the boiler. In case of depressurization of the heating system, there will be a lot of hassle if pressure testing is not done. This is done using a suitable pressure testing pump. To do this, the operating pressure is set and the system is run. If the pressure drops, there is a leak somewhere.

Gas boiler malfunctions

All malfunctions of thermal units can be divided into four main groups:

- the equipment does not start;

- the burner goes out;

- does not reach the required temperature;

- does not turn off.

The equipment does not start

A gas boiler malfunction may be due to:

- problems with the ignition system;

- lack of voltage in the network;

- shutting off the gas supply;

- insufficient or, conversely, excessive fuel pressure;

- burner clogged.

Any gas equipment, including a boiler, is a complex mechanism. It has potential hazards if used incorrectly. Therefore, it is not recommended to do repairs yourself , except in the simplest cases.

To replace the ignition elements or clean the injectors, you must call a specialist who has special approvals from the relevant authorities. The fact is that damage to the burner can lead to the flame breaking away from it, which in most boilers is a sign for automatic shutdown.

Burner damping

There are several reasons that lead to attenuation of this element:

- excessive or insufficient traction;

- the corresponding sensor does not work;

- insufficient thermocouple contact;

- unstable operation of the energy system;

- depressurization of the gas system.

Problems with gas boiler draft arise with installations that have an open combustion chamber and a natural exhaust system. All of them have built-in sensors that can be triggered when the decomposition products are poorly drawn out. As a result, the automation shuts down the burner. In case of excess draft, exhaust gases are drawn out faster, which can lead to fire failure. As a result, the system shuts off the fuel supply. Sometimes the flame may go out due to strong gusts of wind.

It is easy to check the lack of draft with an open chamber - you need to bring a burning match to the holes of the atmospheric burner. If all is well, the flame will be directed inward. If excess draft occurs, the gas begins to burn quickly, unusual noise occurs, and the flame is barely noticeable. If you bring a burning match, the fire will instantly go out.

In most cases, draft problems arise as a result of non-compliance with the requirements for the installation and use of chimneys. Sometimes the cause is condensation inside the pipe. In case of sub-zero weather outside, drops may freeze, which over time leads to a decrease in clearance.

Almost all problems associated with traction can be resolved independently. First you need to determine the reason for the malfunction. For example, you can lengthen or, on the contrary, cut the chimney, remove ice or other blockages.

You can determine if the sensor is faulty by shorting its terminals and attempting to ignite the equipment. If everything works, the sensor is broken, and therefore it is advisable to replace it quickly.

To prevent problems with voltage surges, the installation is connected to the network using a stabilizer. In addition, just in case, you can create power from a gas generator or battery.

Doesn't get temperature

Sometimes there are situations when the boiler is working, but the water does not heat up to the required temperature. There are several reasons:

- Poor oxygen supply. For example, in special rooms for heaters, special holes are made in the doors to allow air to get inside.

- Chimney problems.

- Pump breakdown or failure of individual automation elements.

- Loss of pressure in the system.

- Air jams.

- In the case of a double-circuit boiler, excessive amounts of energy may be drawn from the water supply.

To correct problems in this group, it is advisable to call a specialist who will diagnose and fix everything.

Equipment does not turn off automatically

Basically, automatic units turn off when the temperature inside reaches the desired level. It is determined using an appropriate sensor. The shutdown is carried out by a processor installed in the electronic board. Usually, when the boiler does not want to turn off, the thermostat or microcircuit has failed.

Connecting a gas boiler at home is an excellent precaution that allows you to use hot water and not be dependent on the heating season. Like any other technological equipment, this too can fail. There are several main problems, the solution of which will further allow you to use the installation.

Signs that the igniter (wick) is not working properly and why does it go out?

In columns with piezo ignition, the igniter must burn constantly, because when the hot water tap opens, it must ignite the main burner. The extinguishing of the igniter disconnects the column from the gas supply so that gas does not accumulate inside the device.

The pilot light may go out if:

- It is clogged with debris or dust.

- A flow of air acted on him from outside.

- The thermocouple has burnt out or worn out.

- There is no draft in the chimney.

- The traction sensor has failed.

- The solenoid valve is broken.

- No air access.

The most common cause of igniter extinguishing is a faulty thermocouple. Its main function is to block gas access to the column if the device is operating unstable. As soon as the pilot light goes out, the thermocouple detects the lack of heat and gives a signal to turn off the gas. However, if the thermocouple itself is damaged, it causes the wick to fade.

An equally common situation is when dust or some kind of debris gets into the igniter nozzles. Their diameter is very small, so even slight contamination can prevent the igniter from burning, resulting in the thermocouple not heating up enough.

The color of its flame indicates that there are problems with the igniter and it may go out at any moment. A normally functioning wick will have a flame that is 90% blue and may include some red flecks, and the tip may be yellow. If the pilot flame is predominantly yellow or orange, the wick is not working properly and the thermocouple will not heat up enough, causing the burner to go out.

For other possible reasons for the igniter fading, see the following video.