The German company Rehau has been producing pipes and various fittings since 1948. The company's products are recognized all over the world. For the manufacture of pipes, the latest material is used - cross-linked polyethylene, which ensures the durability and reliability of the products. In addition, experts note that not only professionals, but also ordinary people can install Rehau pipes. What does this require? Read on.

Types of pipes for various systems from Rehau

Features of Rehau pipes

The production of pipes using new technology determines the fundamental features of the products, which consist in the following aspects:

- increased sound insulation. Cross-linked polyethylene is able to absorb sounds produced by water flow;

- Rehau pipes are installed using a unique method that allows you to create the most durable connection;

- the material from which the pipes are made is universal. Pipes can be used to create hot and cold water supply and heating systems, and can be used to install heated floors. The maximum liquid temperature in the pipe is 95ºС;

- pipes are practically not subject to cracks and deformation due to mechanical damage, so they can be laid under plaster or covered with other structures;

- high degree of thermal insulation, which helps to save natural resources;

- any pipe can withstand changes in liquid temperature and internal pressure;

- complete safety for humans. The company's products are certified;

- A special coating on the inner walls of the pipes prevents the formation of plaque and a reduction in throughput.

Materials that give Rehau pipes unique qualities

From Rehau pipes and various fittings, pipelines of any complexity and purpose can be constructed.

The only drawback of Rehau pipes is the high cost of products and fittings.

Areas of application of metal-plastic elements

Pipes made of metal polymers are widely used in the construction of individual houses, in industrial construction and agriculture.

The main areas of their use are:

- transportation of liquids, gaseous agents;

- laying drainage systems, water pipes, heating;

- in structures involving the transfer of compressed air;

- supplying heating components to radiators, installing heated floors;

- installation of air conditioning circuits;

- protection and shielding of wires (primarily power);

- construction of irrigation systems.

Metal-plastic is not recommended for use:

- when organizing central heating systems with the proposed construction of elevator units;

- in places with an assigned fire safety level “G”;

- with the expected supply of hot liquid in the pipeline with a working pressure >10 bar;

- in rooms where it is planned to place sources of thermal radiation with a surface temperature of over 150 degrees C.

In addition, it is undesirable to use metal-polymer pipes in safety, signal, overflow, expansion circuits and in fire-fighting water supply systems.

Metal-plastic products are widely used in private and industrial construction. This photo shows pipes used for laying heating systems

Pipe installation

To install Rehau pipes with your own hands, you need:

- purchase the necessary tools;

- Please read the pipeline assembly instructions first.

Tool required for installation

Before you begin installing pipes, you must:

- purchase the required number of pipes, connecting fittings and adapters. To calculate the necessary materials, a water supply diagram is drawn up;

Approximate layout of hot and cold water pipes in a city apartment

- prepare a tool for installing Rehau pipes:

Expander for pipe installation

press clamp with additional nozzles of different diameters. Since the installation of the type of pipe in question is somewhat different from conventional welding, the procedure requires such a specific tool for installing Rehau pipes;

Manual press used for connecting pipes, REHAU RAUTOOL

pipe cutting tool. Standard pipe cutter, used for all types of plastic pipes;

Plastic pipe cutting tool

tape measure, marker for marking pipes.

Standard measuring tool used in construction

All tools can be purchased individually or as a set. The average cost of a set is 2,500 rubles.

Pipeline assembly process

Installation of Rehau cross-linked polyethylene pipes begins with pipe preparation. Preparation consists of two steps:

- pipes of various sizes are cut according to the previously prepared drawing;

The process of cutting a pipe to the required size

- the fittings necessary for assembling a certain section of the pipeline are prepared.

If heating is being installed using Rehau pipes, then it is more advisable to immediately prepare all sections of the system, and then first check the correctness of the sections according to the diagram.

To check, all pipes and fittings are placed on the floor in a certain order. This is especially true for heating in city apartments, since it is necessary to turn off the heating in the entire house.

When cutting pipes, you should be guided by the old Russian proverb - “measure seven times, cut once.” Errors in pipe cutting may result in the inability to install a piping system indoors.

The joining of pipes and fittings to each other is carried out using sleeves, which are fixed as follows:

- A nozzle is selected for the expander, the diameter of which fully corresponds to the diameter of the pipe used. In this case, the handle of the tool must be fully extended (the ends of the handle are located at right angles to each other);

- the nozzle on the expander should hold firmly and sit on the pin until it stops;

- A sleeve is placed on the section of pipe that needs to be connected to the fitting. The diameter of the sleeve used must also correspond to the diameter of the pipe;

Each sleeve has a chamfer. When installing, it should be directed towards the future connecting seam.

- a pipe is put on the other end of the nozzle installed on the expander. When the expander handle is compressed, the pipe expands;

The process of expanding the pipe for further installation

- the extended end of the pipe is connected to a fitting that must be installed in this place;

Inserting the fitting into the prepared end of the pipe

- a previously installed sleeve is supplied to the fitting;

- Using a press clamp, the sleeve is pushed into the fitting until it stops. A strong and reliable connection is ready.

Fixing the fitting with a press clamp

When arranging the connection of pipes and fittings, even the slightest distortions should not be allowed. All connecting parts must be positioned strictly horizontally to each other. Otherwise, the connection will be unreliable.

Step-by-step diagram of working with a press clamp

Installation of Rehau pipes for heating, gas or water supply must be carried out in compliance with all safety standards. First of all, you need to take care of protecting your eyes (using a mask) and hands, which are not recommended to be inserted into moving elements.

The video below of installing Rehau pipes will allow you to observe the process from the outside in order to more accurately clarify all the most important aspects.

Anyone can install pipes from the German manufacturer Rehau. The main thing is to have the necessary tools and strictly follow the instructions above.

Are they really better?

To understand whether the installation of REHAU pipes can really completely replace everyone’s favorite polypropylene and metal. It's worth starting with the material of manufacture. Cross-linked polyethylene is used for REHAU pipes. At the molecular level, a three-dimensional network is formed, which ensures the connection of all links. The end result is a bay that is uniform throughout its entire length. The advantages of this solution can be considered:

- non-toxic. The polyethylene itself in the product does not release harmful impurities into the water;

- no noise when passing water;

- versatility of the material for various systems;

- unique and simple pipe installation system “REHAU”;

- resistance to deformation and ruptures;

- high plasticity;

- minimal heat loss;

- resistance to pressure and temperature changes;

- special design and coating of the internal walls, which prevents plaque.

From the above, it becomes clear that installation of REHAU pipes is possible both in old houses and in new buildings. The products do an excellent job of transferring hot and cold liquids. This means that not only heating is easy to do using REHAU pipes, but also plumbing. Moreover, they can be laid in any configuration. REHAU pipes are easy to adjust to the line of walls and openings.

The company has developed several types of products, which allows you to quickly make a choice and determine the best price-quality ratio for a particular object. The “HIS” line is suitable for supplying any non-aggressive liquids with temperatures up to 70º. Used for heating systems with tight media control. The “REHAU Flex” subtype is also suitable for laying heating and water supply, the maximum possible pipe diameter is 63 mm. "REHAU Stabil" is able to hold its shape better, therefore it is used when installing water collection points. The peculiarity of this REHAU pipe is explained by the small layer of aluminum. The pink series “REHAU Pink” is used exclusively for heated floors or general wiring of the heating system. They are very plastic and require fixation with fasteners. They feel great under screed and plaster. Withstands temperatures up to 90º and pressure up to 10 atmospheres.

Before installation

To provide everything for the user of REHAU pipes, the company has also developed special pipe installation tools and fittings

This means that it is important to familiarize yourself with the product range in order to improve efficiency and use recommended components, which will only increase service life. Tools you will need:

- expander or expander;

- REHAU press;

- specialized scissors;

- roulette;

- marker for marking.

The REHAU expander is a device similar to a rivet gun. Only its tip is a sharp cone, which is inserted directly into the pipe. His role matches his name. It increases the diameter of the pipe ends or flares them for ease of interaction with fittings. The kit can be supplied with a set of nozzles for different diameters of REHAU pipes.

The REHAU press is like an enlarged and modified pliers. It allows you to press in the consumable material, as well as pull the pipe to the required fixation mark. It also has attachments for different diameters. Such a device can be equipped with a motor and run on a battery, which further facilitates and speeds up the process of installing a pipeline in an apartment or private house.

You can use standard scissors that are suitable for metal-plastic or polypropylene. The quality will not suffer from this. But if you plan to closely, at a professional level, install heating or other systems, then it is recommended to acquire specialized ones that have greater functionality and allow you to process the insulation faster.

Important! Use only tools recommended by the manufacturer. Otherwise, damage to the pipe or a loose joint may occur, the repair of which can cost a lot of money.

Preparation for installation work

The collector outputs should be the first elements that require increased attention. Only their correct processing will ensure complete tightness in the system.

Before installation, the workplace must be completely free of dust and debris, as well as the equipment. Welding, threading and gluing are the methods that are most widespread during installation. You just need to purchase the appropriate type of fitting, depending on the installation method you choose.

Watch video: Bir Pex systems

Absolutely all parts used during installation must be intact and clean. A visual inspection is required before purchase. This will ensure the quality of the finished product. Their transportation deserves special attention.

Guide to using the pressing tool

If you will use a pressing tool in your work, then at the first stage you need to use it to grab the connection and switch the lever to the upper position. This will allow the elements to be compressed. The expander handles must be moved, and then the sleeve must be inserted to the flange. The next step is to bring the tool lever to its original position, with the lever at the bottom on the side.

When using the Rehau pipe pressing tool, the next step is to bring the handles together. The movable handle must be sharply raised by 90° to bring the tool to its original position.

What are the dangers of unprofessional installation?

Installation of Rehau pipes in an apartment, which is carried out by non-specialists and without the use of professional equipment, can lead to the most disastrous consequences. If pipes burst, flooding of the living space and all areas adjacent to it is ensured.

If the gust occurs on the heating system, then in winter you are faced with complete defrosting of the system and the difficulty of restoring it. If you order the Rehau pipeline installation service in, then you will not encounter any of the unpleasant consequences.

The work performed by professionals has several distinctive characteristics:

- the pipeline laying scheme is the most optimal and does not interfere with other systems and normal life processes for the owners of residential premises;

- each pipeline connection is of high quality and has smooth seams;

- for installation, the correct type of pipes has been selected, which is compatible in parameters with the system being installed;

Prices

The cost of Rehau products depends on the series of channels and their sizes.

To see the average price per meter of these products, see the table below.

| Pipe type | vendor code | Packing size | Price (€) |

| 2.2x16 mm | 136042-120 | 120 m | 2,12 |

| 2.2x16 mm | 136042-006 | 60 m (6 m each) | 2,42 |

| 2.8x20 mm | 136052-120 | 120 m | 2,76 |

| 2.8x20 mm | 136052-006 | 60 m (6 m each) | 2,97 |

| 3.5x25 mm | 136062-050 | 50 m | 4,13 |

| 3.5x25 mm | 136062-006 | 30 m (6 m each) | 4,47 |

| 4.4x32 mm | 136072-050 | 50 m | 5,74 |

| 4.4x32 mm | 136072-006 | 30 m (6 m each) | 6,21 |

| 5.5x40 mm | 136082-006 | 12 m (6 m each) | 9,64 |

| 6.9x50 mm | 136092-006 | 6 m | 12,63 |

| 8.7x63 mm | 136102-006 | 6 m | 18,25 |

You can find out more about the prices for the products in question on the websites of the company’s official dealers. There you will find comprehensive information on this issue. We strongly do not recommend purchasing products from resellers or companies with a dubious reputation. There are quite a lot of fakes sold on the market. Therefore, you should not take risks to save money. It’s better to buy quality materials once than to spend money, time and energy on correcting mistakes later.

Be sure to ask for certificates of conformity. This will allow you to protect yourself from purchasing low-quality products. Here you can find this documentation.

The cost of installing Rehau pipes depends on the scale of the project. For a small one-room apartment, this figure in Moscow and St. Petersburg can be from five thousand rubles. In Kyiv, these works will be cheaper. The minimum cost of installing Rehau pipes in the Ukrainian capital can be about one thousand hryvnia.

What are the main advantages and features

- Presence of reverse shrinkage. The products are able to resist high pressure, and after prolonged exposure they return to their original shape. Other materials with similar parameters simply stretch after some time and become completely unusable.

- Increased heat resistance. Such pipes operate normally at temperatures up to 120 degrees.

- Availability of prices.

- Ability to resist freezing.

- Tolerates high temperatures and pressures.

- Convenient installation.

- Light weight.

- Bir Pex, Rehau and other companies have a high level of sound insulation. Thanks to this, the room itself is protected from extraneous sounds. Pressure surges are completely absorbed by the system itself.

- Long service life combined with high strength. You can forget about rotting and corrosion when working with this material.

- Environmentally friendly. Polyethylene does not emit harmful substances, even when it is highly heated.

- Elasticity.

Characteristics

Let's take, for example, one of the series - Raupink.

Maximum permissible values:

- Pressure (working) at ten atmospheres.

- Short-term temperature at one hundred and ten degrees Celsius.

- Temperature (working) – ninety-five degrees.

Minimum acceptable values:

- The service life is fifty years.

Another popular heating series, Rautitan, has the following characteristics:

Maximum permissible values:

- Pressure (working) at ten atmospheres.

- Short-term temperature at one hundred degrees Celsius.

- Diameter (outer) – 1.6-4 cm.

The advantages of such products:

- Pipes can be supplied pre-insulated.

- Temperature elongation is of little importance.

- Can be directly connected to a heating device.

- Retains shape when bending.

- Even if the aluminum shell is damaged, the strength properties are maintained.

- The inner PEX layer is durable.

Such pipes can operate at a maximum pressure of ten bar and a temperature of ninety-five degrees.

And only in emergency situations can products withstand one hundred degrees for a short time.

Installation process

The installation technology includes several steps.

- We screw a nozzle with the required diameter onto the expander.

- After that, we put crimp rings on the pipes themselves with our own hands. And we do this so that the place where the pipe expands is not occupied.

- An expander must be inserted into the pipe. It expands when the installer presses a special handle. The next step is to rotate the pipe itself or the expander by 30 degrees. And then press the handle again. You can repeat the operation to consolidate the result. After this, proceed to using the fitting.

- The shutter is removed from the press with your own hands. Next, pull out the pins used for fastening. The next step is to thread the nozzles, which are secured with pins. The shutter snaps shut.

- The connection takes on a finished form. The product must be removed from the press.

Do the products have any disadvantages?

There are not many of them, but to some they will seem significant.

- High oxygen permeability. Because of this, corrosion sometimes worsens in other materials adjacent to polyethylene. But this can be easily corrected by using special pollination products. They help reduce diffusion in the oxidizer.

- The anti-diffusion protection, which is located on the outside of the polyethylene pipe, has a very weak coating. It can be easily damaged if you handle the material carelessly.

- During installation, the need for additional fixation with your own hands. This is due to the absence of an aluminum layer, which is typical for similar products.

- Avoid exposure to sunlight.

There are so-called European standards for such polyethylene products. According to these standards, there are a total of 19 standard sizes for cross-linked polyethylene pipes. The maximum permissible wall thickness is 28 millimeters, the throughput diameter is 250.

Installation of cross-linked polyethylene pipe

Materials

Before starting work, prepare the necessary tools and consumables. You will need:

- Vise.

- Fittings: couplings, adapters, elbows, tees, sliding sleeves (when installing a sliding sleeve, you do not need to use rubber gaskets, which increases the reliability of the design).

- Expansion device.

- Roulette.

- Pipe cutting tool.

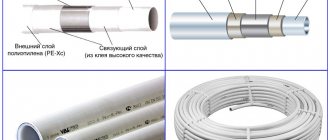

Rehau pipe - design

Video

The German company Rehau has been producing pipes and various fittings since 1948. The company's products are recognized all over the world. For the manufacture of pipes, the latest material is used - cross-linked polyethylene, which ensures the durability and reliability of the products. In addition, experts note that not only professionals, but also ordinary people can install Rehau pipes. What does this require? Read on.

Types of pipes for various systems from Rehau