Water-heated floors are gaining increasing popularity among residents of private houses, becoming a full-fledged alternative to traditional radiator heating. Installation of such a heating system is very complicated. It requires not only certain knowledge and skills, but also the use of high-quality materials that can last for decades.

Installation of water heated floor Rehau

For this reason, experienced installers, who have already encountered problems caused by incorrectly selected materials or errors during system installation, prefer to purchase products from trusted manufacturers. One of these manufacturers is the Rehau company, which began its work in the middle of the last century.

Thanks to its experience, the company is able to offer consumers Rehau heated floors - a system with all the components that greatly facilitate the work process.

Features of Rehau pipes

The main heating element in water-based floor heating options produced by Rehau is the Rautherm pipe. This element of the system is made of high-strength cross-linked polyethylene, the outer part of which is coated with an oxygen-protective material. Thanks to this combination, these pipes have certain advantages.

Characteristics and prices for Rehau pipes

- Rehau pipes are characterized by increased resistance to mechanical damage that occurs both during installation of the system and during its operation.

- Cross-linked polyethylene has high thermal conductivity, so it perfectly warms the floor surface.

- The pipes are very flexible, which eliminates the formation of kinks during their installation.

- This heating element is highly resistant to corrosion and internal deposits.

Rehau pipe structure - Cross-linked polyethylene is not exposed to chemicals, so during operation of the system, not only water, but also antifreeze can be poured into the pipes.

- The hydraulic version of floor heating, installed using a Rehau pipe, is not afraid of high temperatures and increased operating pressure.

This company produces pipes of the following diameters (wall thickness is indicated in brackets):

- 10.1 mm (1.1 mm);

- 14 mm (1.5 mm);

- 17 mm (2 mm);

- 20 mm (2 mm);

- 25 mm (2.3 mm);

- 32 mm (2.9 mm).

Rehau pipes

About the manufacturer

The history of the Rehau company begins back in 1948. Initially, the organization employed only three people. In the 60s, the main focus was on the production of PVC profiles and cross-linked polyethylene pipes, and this became a fundamental point in the development of the company.

Currently, Rehau is a leader in the production of energy-efficient systems for the construction of industrial and private facilities. The brand is known to domestic buyers thanks to the metal-plastic windows and warm water and electric floors offered by the company.

Additional items

Installation of the Rehau water heated floor pipeline is carried out using special fasteners.

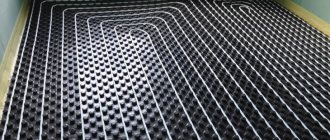

- Varionova mats are made of polystyrene foam and are equipped with clamps designed for securing pipes. In addition to the main function of facilitating installation, these elements are equipped with heat and sound insulating properties. The mats are fastened together using a connecting strip using the seam method. Mats with clamps and thermal insulation Rehau Varionova

- The Varionova panel is a film equipped with bosses and fasteners. Installation of the pipe on the film panel is carried out by laying it between the bosses. Panel with Varionova fasteners without insulation

- RAUFIX tires are made of rigid polypropylene and are an alternative to the previous elements, reducing the cost of the hydraulic floor heating option. The underside of the tires is equipped with special brackets that allow these elements to be securely fastened to any floor surface. The busbars are connected to each other by a locking connection. The advantages of using Raufix tires lie in their design features

Rehau water heated floor is a ready-made system, equipped with all the necessary fasteners designed for fixing mats and pipes on mats and panels. These include:

- harpoon clamps designed for fixing pipes; Tece harpoon bracket for heated floors

- clips for fixing mats. Insulating nails and clips for underfloor heating

Hydraulic underfloor heating from Rehau is controlled using a distribution manifold, available in various modifications. The most popular among consumers is the assembled manifold, equipped with a thermostat and a flow meter.

Fasteners

To secure the pipeline transporting the coolant, fastening systems are used. There are several such products.

Varionova fixing mats

The rigid polymer material from which they are made provides the mats with excellent mechanical stability. For example, they are able to withstand the load from the weight of an adult man, even if the top layer of the screed has not yet been poured. They provide greater speed of installation of Rehau floors compared to models from other manufacturers. Each product is equipped with clips designed for installation over pipes. Mats can be cut along special lines into individual fragments. They are then joined together using connecting elements. Pipes ø 14–17 mm are laid with a minimum step of 5 cm.

Specifications:

- The thickness of the coating is 2 mm; it is possible to choose products with or without a thermal insulating foam backing.

- Designed for laying pipelines with a diameter of 14 to 17 mm.

- The minimum laying step is 5 cm.

- To optimize installation, the surface of the mats has cutting lines and connecting elements for joining individual parts to each other.

RAUFIX tires

This is the best way to install an inexpensive heated floor. Tires made of rigid polypropylene, thanks to special brackets on the underside, are attached to almost any base. Such products have a small thickness, which is why the floor height increases by only 5 mm. The installation of the main line is carried out in increments of multiples of 5 cm. The tires are 1 meter long and 4 or 5 cm wide. The tires must be mounted on top of the thermal insulation layer.

How to install a Rehau underfloor heating system

Before installing a Rehau water heated floor, it is necessary to draw up a project, which includes calculating the system power for each specific room, and choose a pipe laying method - snail or snake.

Pipeline layout diagrams

The floor structure must be installed in such a way that temperature changes are not felt during operation. The optimal step is the distance between the loops equal to 11-18 cm.

Depending on the diameter of the pipe, the maximum length of the circuit should not exceed 120 meters. Otherwise, the coolant will reach the farthest sections of the pipeline already cooled, which will directly affect the quality of heating.

Overview of installation of heated floors using Rehau technology

[ads-mob-1][ads-pc-1]

Advantages of Rehau products

- Warm hydraulic floors from Rehau release heat energy as much as possible, reducing its losses in the room to nothing.

- Advanced developments provide exceptional reliability of the pipes used, which, in turn, guarantees the integrity and productivity of the system for a long time.

- Rehau

flooring does not require specialized maintenance or care. He is completely independent. - Allows you to design a system both for the entire room and in its individual sections.

- Timely and economical installation provides an excellent opportunity to use different installation technologies, for example, the use of liquid screed or pipe laying at an acute angle.

Installation process

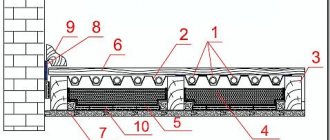

To prevent such heating from causing trouble in the future, its installation should begin with leveling the subfloor by applying special solutions and laying a damper tape, or a special profile for an expansion joint around the perimeter of the room and between the contours of the water-heated floor. In this way, it will be possible to compensate for the expansion that occurs during the heating of the pipe and avoid cracking of the concrete screed.

Laying scheme for water heated floors

When the base dries, thermal insulation in the form of sheets of expanded polystyrene is laid on it. And a polyethylene film is laid on top of it, on which the functions of waterproofing will be assigned. Moreover, thermal insulation is required only if the Rehau heated floor is planned to be laid on a film panel or tires. If mats are purchased, then the need for additional thermal insulation disappears.

Now you can begin installing the distribution manifold, which is connected to the heating boiler. Next, mats or panels with tires intended for securing the pipeline are laid. Pipes begin to be laid by connecting to the collectors. During the installation process, the pipes are secured to the mats using special fasteners.

Characteristics and types of pipes

Pipes made of cross-linked polyethylene are divided into four groups according to the type of production:

- PEX-a - peroxide;

- PEX-b - silane;

- PEX-c - treated with fast electrons;

- PEX-d - nitrogen.

They are produced with diameters from 10 to 110 mm, operating pressure from 8 to 25 bar. They are designed to operate in a temperature range from 0 to 95 °C and do not react with acids and alkalis.

They are used in devices:

- warm floors;

- heating of domestic and industrial premises;

- cold or hot water supply;

- air conditioner piping.

They withstand freezing of the coolant without breaking connections, and quickly restore their previous dimensions after defrosting the water.

RAUTITAN pink

These are specially designed PEX-a pipes for creating heating systems in private homes and industrial premises. To protect against dissolved oxygen in water, an intermediate layer of ethylene vinyl alcohol is used.

RAUTITAN pink is used in pipelines with a working pressure of no more than 9 bar and a maximum temperature of up to 95 °C. For a short time, polyethylene pipelines will withstand an increase in coolant temperature up to 110 °C. Pipes with nominal bore diameters from 16 to 63 mm are produced, supplied in coils or individual six-meter pieces.

RAUTITAN his

Rehau Rautitan His 311

Rehau RAUTITAN cross-linked polyethylene pipe is used to supply hot or cold water to residential and industrial premises, and for piping process pipelines. It is produced from cross-linked polyethylene of the RAU-PE-Xa brand with the addition of peroxides under pressure. Produced with a nominal bore from 16 to 63 mm in coils or individual pieces up to 6 meters long and with wall thicknesses from 2.2 to 8.6 mm.

The use of this brand of polyethylene ensures stable operation of pipelines at an operating coolant temperature of up to 90˚C. It has a small thermal elongation of 0.15, has flexibility (bending radius is equal to 8 diameters), wear resistance, and a service life of more than 50 years.

RAUTITAN stabil

These pipes are used in heating and water supply systems. RAUTITAN stabil is a multi-purpose pipe with several layers. Between the inner and outer shells there is an intermediate protective aluminum layer. It plays the role of an insulator of the outer layer of non-crosslinked polyethylene from the diffusion of oxygen into it from water.

In water supply systems for drinking water, the pipelines must be designed for an operating pressure of up to 10 bar. In heating systems, RAUTITAN stabil pipelines are installed on lines with an operating pressure of up to 10 bar and a coolant temperature of up to 95˚C.

During emergency situations, it can withstand a short increase in water temperature up to 100 degrees Celsius.

RAUTITAN flex

Rehau Rautitan flex

RAUTITAN flex pipes supply hot and cold water, install heated floors, and use cast iron radiators or bimetallic radiators in rooms for heating.

The intermediate protective aluminum layer not only prevents the penetration of oxygen from water into the inner layers of cross-linked polyethylene, but also promotes better heat transfer. Therefore, these pipes are recommended for use when installing heated floors under: ceramic tiles, laminate, porcelain stoneware.

RAUTHERM S

RAUTHERM S pipe is used for installing heated floors. Due to its low price, a cross-linked polyethylene pipe with a diameter of 17×2.0 mm has become most popular among consumers.

The pipeline is protected from the penetration of dissolved oxygen from the intermediate layer of ethylene vinyl alcohol copolymer. Thanks to the three-dimensional internal structure, products made from cross-linked polyethylene are tear-resistant and do not form cracks throughout the entire period of operation.

The guarantee for the use of pipelines without breaking connections from exceeding the operating pressure by no more than seven times is 10 years.

Pouring concrete screed

To ensure that the system works flawlessly and the floor warms up evenly, the pipes are filled with a cement-sand composition. To increase the strength of the structure, a reinforcing mesh is laid on top of it.

Scheme for pouring a concrete screed for a water heated floor

Before you begin finishing the floor, you need to wait until the screed has completely dried and gained strength. This process lasts 28 days. All this time the heating system must be turned off. Otherwise, the concrete may crack.

Installation of a water version of floor heating is much more expensive than its electric counterparts. However, its installation allows you to heat the room more evenly and create a healthier microclimate. In addition, the operation of such a floor is much cheaper than electric options. And after a few years, such heating completely pays for itself. [ads-pc-2][ads-mob-2]

Carrying out installation work

Regardless of whether you want radiator heating or heated floors, installation work involves a number of simple operations. Efficiency is ensured due to the fact that Rehau fittings are very functional.

The stages of installation work are as follows:

- Prepare all the necessary products and additional elements, make sure that they are free of any defects. Damaged parts will need to be replaced, otherwise problems may arise when operating the heating system.

- Separate the pipes into sections.

- If necessary, clean the ends.

- Place pipes where necessary.

- Secure the fittings.

- Assemble the products and fittings together using slide nuts.

- Tighten the nuts and make sure the pipeline is in good condition. It is necessary to check whether the system is working and whether anything needs to be fixed.

The procedures described above are standard - they are necessary in all cases. However, it is worth noting that when installing a heated floor you will have to spend more time than when working with radiator heating. The products will need to be laid in a spiral structure, but thanks to the flexibility of the pipes you can handle this very easily.

When carrying out installation work, connections can be welded or threaded. You can create even a very complex communication system, while the pipeline will be as strong and reliable as possible. These floors go very well with a wide variety of screeds. You don't have to worry about any emergency situations.