Today, almost no piece of household engineering equipment can do without a functional control system. Boilers, heaters and underfloor heating systems especially require efficient and accurate means of monitoring and adjusting operating parameters. Moreover, this task is not always achieved through electronics. Even if in partial form, the mechanical thermostat is fully justified. Firstly, this is a familiar configuration of a control tool, and secondly, in some versions it benefits from reliability and cost.

General information about mechanical thermostats

Most often, such devices are small-sized devices with one or more control elements. The latter can be buttons, levers and round knobs in the form of washers. The panels also provide indicators that display basic information about performance indicators. As for the areas of operation, a mechanical thermostat is usually positioned as a universal device, but there are separate modifications designed for special application conditions. For example, equipment that must be installed on the outside is additionally protected by insulating coatings. Special versions also include combined two-zone models, which can be used to service several pieces of equipment.

Thermostat

A device for regulating and maintaining a certain temperature in heating and cooling equipment is called a thermostat. They are widely used in various fields. such as monitoring heating devices in small and large rooms, for example, apartments, or industrial facilities. The devices are installed on freezing, cooling, and heating devices of varying power. Despite the fact that the products are different, the devices that are installed on them have an identical design, and the essence of their work is the same.

Purpose and principle of operation

Turning on, off and switching the temperatures of heating devices and systems is the main purpose of the thermostat. Thanks to this, the user can maintain the necessary heat in air, water, and various surfaces.

Devices designed for these purposes operate on the same principle: due to the built-in temperature sensor, they receive data on the external temperature, after which they automatically determine when to turn on or off. In order to avoid malfunction, the device should be installed away from the direct influence of devices in the room that are equipped with heating elements. Since they will mistakenly create a different temperature near the sensor, which will cause malfunctions.

Types of devices

Manufacturers classify regulators according to the nature of installation, place of operation and the presence of a programmer function. Installation can be carried out by insertion or overhead method. The place of operation can be the floor, walls or suspended structure. Programmers, in turn, are rarely used in mechanical devices, but there are such modifications. In addition, the mechanical thermostat differs in stylistic properties. So, according to their shape, we can distinguish round, rectangular and triangular models. From the point of view of installation possibilities and ease of use, the choice according to this criterion is of little importance. Most often, attention is paid to external features when assessing the design suitability of the device for the place of use.

Main characteristics

Different models are distinguished by a wide range of operational characteristics, including the number of working zones, load power, range of temperatures available for coverage, etc. The number of working zones or channels in standard models can reach 2, but there are also highly specialized modifications in which servicing more than 10 separate objects. In terms of power, mechanical thermostats for heating have a potential in the range of 3-4 kW. Typically, as the number of zones increases, the load also increases. An important operating parameter is the temperature spectrum. For simple regulators, it is a narrow corridor on average from 5 to 30°C. However, when operating powerful boilers with high heat output, a wider range should be provided - up to 60-70°C. Also, to determine accuracy, pay attention to the error of the regulators. It is important to understand that mechanical devices are initially inferior to electronic digital analogues in this indicator. On average, deviations can reach 2-3°C.

Device with remote sensor

Today, thermostat manufacturers are adapting to consumer needs and preferences. If 20 years ago the choice was limited to mechanical devices with manual control or with a primitive display, today these are truly complex and “smart” devices that monitor any changes in air heating.

For radiators “hidden” from view by curtains or screens, you can buy a mechanical thermostat with a remote sensor. It will also be irreplaceable in rooms with high humidity, for example, a kitchen or bathroom.

In devices of this type, the working part is mounted directly into the battery, while the sensor can be located a few meters away from it. This will open up access to the settings, which would be difficult to do if they were covered in a decorative box along with the battery. In addition, if in conventional mechanical thermostats all data on changes in the environment comes directly to the thermal head, then in the case of a remote sensor it becomes a transmitter that detects a decrease or increase in temperature and sends the corresponding signal to the working part with a bellows.

If a surface-mounted mechanical thermostat is installed, it is mounted directly on the wall. Such devices are necessary to regulate air heating when the “warm floor” system is running or any electric or infrared heaters for heating boilers.

Reviews of the T6360 model from Honeywell

One might say, a basic model representing the middle class of devices of this kind. Users note the versatility of its use in terms of combination with various executive systems. For example, the regulator is connected to pumps, boiler units, valves, home heaters and other equipment. As for reliability, the model as a whole receives more positive reviews. The fact is that the mechanical thermostat from Honeywell, in its design, is focused on sensitive perception of the slightest changes in the environment. This allows you to activate the currently necessary automatic safety systems that prevent device failure. The user learns about functional processes through a panel with indicators. Owners emphasize the ergonomics of the interface and the strength of the case.

Classification of thermostats

There is a large assortment of thermostats on store shelves, which allows the buyer to choose the appropriate device for any heating system. The devices differ in purpose and design and are combined with various heating systems and heating systems. Devices are classified according to several criteria, including:

- Technical capabilities, depending on them, the unit is divided into simple, designed only to maintain the set temperature, and programmable. One of the most expensive types are considered programmable; they provide several modes and programs for control. They allow you to constantly monitor heating systems in order to create comfortable conditions and be able to save energy resources. Such devices are equipped with a Wi-Fi system, which makes it possible to control and manage them via mobile devices.

- The number of channels can be single-channel, these are suitable for automatic control and temperature setting, and are light in weight. Multichannel suitable for standard sensors used in manufacturing and agriculture.

- Sizes: Devices come in compact, large and large sizes.

- Purpose: to maintain the degree of heat of the floor, air, or both at the same time.

- Mounting methods, wired, are connected by wires that transmit a signal from the thermostat to the device. Wireless models are radio-controlled, and their cost is considered the highest. Such regulators do not have extra wires and are ideal for those who do not want to spoil the situation with extra cables, as well as additional sockets. The models are endowed with certain functions, which makes them excellent assistants in creating a suitable microclimate in the house and more.

The classification does not end there; thermostats are also divided according to the type of sensor:

- mechanical;

- electronic.

Mechanical

The simplest, but despite this, the most reliable models with mechanical control. All settings are carried out manually, are intended for setting up heating systems and differ in the contents of the bellows. So, there are several types of mechanical devices:

- liquid;

- gas-filled.

The first type is characterized by low cost, and the second type is reliable. Gas-filled regulators are endowed with good speed and smoothness in changing temperature indicators. And mechanical ones are endowed with greater accuracy when transmitting pressure to the rod. By their design, such devices are considered the simplest, and are found on most household appliances, such as:

- Cookers, irons, heaters, the design of the devices is simple and consists of a bimetallic plate and a contact group. The working process is that when heated, the plate bends and opens the group, after which the electricity stops flowing, then when it cools down it returns to its previous position, closing the contact back.

- Boilers and other electrical appliances with a more complex design. The principle of operation in them is slightly different; the property of expansion of materials under the influence of temperatures is taken as a basis. More precisely, such regulators consist of a tube with a substance inside, which is placed in water; after heating, it transfers heat through the tube to the substance inside, then it expands under the influence of elevated degrees, closing or opening the contact group.

This category of thermostats has some advantages:

- reliable;

- resistant to possible voltage interruptions;

- not susceptible to malfunctions in the operation of the device itself;

- work at low degrees and their sharp changes;

- easy to operate;

- have a long service life.

And the cons:

- since the setup is done manually, regular adjustments will be required to clarify the data;

- small amount of function;

- there is an inaccuracy in the readings, which is approximately 4-5 degrees.

Models in this category are not only easy to use, but also have an affordable price.

Electronic

Electronically controlled designs have a higher cost, but there is no need to adjust their operation. Such regulators smoothly change parameters independently even when weather conditions outside change. For greater ease of use, manufacturers have provided a control panel, and on the device itself there is a small display on which all the necessary information is displayed. The electronic display itself can be push-button or touch-sensitive.

The advantages of such models include:

- wide choice of installations;

- products are produced in different design solutions;

- allows you to save electricity;

- has high accuracy;

- effective work;

- safe to use.

The disadvantages include:

- the cost is an order of magnitude higher than that of mechanical ones;

- and the possibility of electronic malfunctions.

Electronic regulators are often an integral part of a smart home system.

Temperature regulators can be installed not only inside, but also outside the room; outdoor or weather models are called thermostats.

Reviews of the thermostat DAIRE TR-TA2

This option is more likely to suit those who use low-power heating equipment in the apartment. In the line of entry-level thermostats, this is one of the best representatives. The development from DAIRE, according to many users, is beneficial in that it not only allows you to adjust the temperature to a certain level and maintain it with a high degree of accuracy, but is also able to optimize energy costs. On the other hand, the model is not characterized by a large coverage of operating temperatures. Therefore, if you need a mechanical thermostat for a heated floor or a small convector, then this purchase will justify itself, but it will hardly be useful in servicing a massive boiler installation. This disadvantage is compensated by convenient control and a high resource of the control elements, which is also confirmed by users. According to the manufacturer, the device can withstand about 10 thousand clicks.

Feedback on the Heat-PRO RTC-70 model

This is a special device for controlling the operating parameters of electric heated floor coverings. As practice shows, the model copes well with network loads, provides relatively accurate heating indicators, requires minimal power supply and is durable. However, many owners point to modest functionality and a minimum of regulation tools. For a typical heated floor system, this mechanical thermostat is suitable, but it may not fully reveal the capabilities of expensive, powerful systems. But there are no complaints about physical reliability - despite its laconic shape and compact dimensions, the model has a durable body and tightly integrated regulators.

What they say about the Caleo UTH-130 model

One of the premium models, which, although it does not offer special functionality, is noticeably different in basic performance characteristics from the analogues presented below. First of all, many owners point out the possibility of using the device in combination with powerful heating equipment. This is the optimal mechanical thermostat for a solid fuel boiler or a productive water heating installation. Again, the owners of the device testify that over a wide temperature range it shows high accuracy of regulation. As for other advantages, communication capabilities are also noted. In particular, the user can control the device using a remote sensor with an indication on a two-meter wire.

Advantages of a manual thermostat

Although some consumers consider these devices primitive, they have a number of very attractive and useful properties:

- Manual thermostats are small in size and therefore hardly attract attention.

- On devices with an indicator screen it is easy to set the desired temperature parameters.

- Their installation takes only a few minutes, and operation does not require any additional preventive maintenance or maintenance.

- Even such a simple device with a minimum number of functions can create comfortable living conditions, minimizing heating costs.

- The temperature range from +5°C to +27°C allows you to set the thermostat to minimum when residents leave or fix it at medium settings when they are away from home all day.

- A mechanical thermostat creates a uniform supply and ensures equal heating of all radiators in the circuit heating circuit.

These devices can be used both in a working heating system with old or new batteries, and can be added to the plan when installing autonomous heating.

Connecting the thermostat

In general, the operation of installing a thermostat is similar to installing conventional sockets. At least this applies to the physical integration of the device into the wall. There are also overhead models that do not require intervention in the wall niche. The direct connection is made through three lines - this is the power wire, the cable from the heating actuator and the circuit from the sensor that monitors the air temperature. When connecting a mechanical thermostat, it is important not to confuse the types of wires. Typically, white or black markings indicate phase, blue markings indicate zero, and grounding is performed through yellow-green wires. True, to be sure, you should still refer to the instructions with the diagram attached to the thermostat of a particular model.

How does a mechanical thermostat work?

Cheap heat is not a utopia at all, since today there are special devices that can take control of its distribution and save energy resources. The market offers models from the most primitive manual designs to complex programmers with built-in Wi-Fi and remote control.

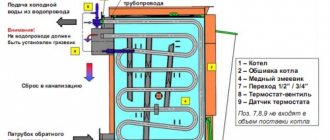

A mechanical temperature controller is an automatic device for heating radiators, the job of which is to monitor the heating of the air in the room. The device contains:

- Bellows, or as it is also called, thermoelement. It is shaped like a cylinder with corrugated inner walls that allow it to stretch to a certain length.

- A valve that fixes the supply and shutdown of coolant circulation.

- A special liquid or gaseous medium that reacts to air temperature fluctuations.

- The function of the transmitting rod is to “reach” the valve and close it or, conversely, release it, depending on the degree of heating of the room.

- A scale with divisions allows you to set the manual thermostat to the required temperature.

The operating principle of the device is simple:

- When the air in the room is heated to the required level, the working medium in the bellows expands under the influence of heat, which causes the cylinder to straighten. The rod connected to the bellows rushes forward and presses on the valve, pressing it tightly against the through hole. In this case, the supply of coolant to the radiator stops.

- After the media remaining in the heating battery has cooled, the liquid or gas in the thermoelement is compressed, causing its walls to contract, which leads to the opening of the valve. Hot coolant enters the system and the process starts all over again.

If the first manual thermostats had a limited lifespan and were highly dependent on the type of heating system, then the mechanical temperature controller for a new generation heating radiator is designed for a million operations of closing and opening the valve, which is an average of 50-70 years of operation. In addition, this inexpensive device is easy not only to adjust using a scale, but also to install in a heating system.

It is enough to unscrew the radiator cap and fix a mechanical thermostat in its place, but this must be done taking into account the type of heating system. Thus, in single-pipe systems without a bypass, installing a thermostat is not recommended, since the coolant requires free circulation through the heating circuit at the moment when the valve blocks its access to the radiator.

When installing the thermostat, make sure that it is screwed in horizontally. As a rule, arrows on the body of the device indicate the movement of the coolant.

In many ways, the quality of operation of a mechanical thermostat depends on factors such as:

- Circulation of warm air currents in the room.

- Direction of the sun's rays.

- Outside air temperature.

- Additional sources of heat or cold.

Unlike its more “advanced” electronic counterparts, a mechanical thermostat for radiators does not respond as quickly to changes in the air temperature outside the window, but quite effectively copes with the task assigned to it of maintaining a certain microclimate in the room.

How to choose the optimal model?

Before purchasing, you should draw up a list of mandatory requirements for the regulator for the installed equipment. First of all, the choice is made based on the load power - it should be sufficient to work with a specific heating equipment. Next, the connection features are taken into account. It is important to evaluate the conditions under which the installation will be carried out - for example, using the overhead principle or through insertion. Thus, a mechanical thermostat for a heated floor is usually installed in the wall, but if we are talking about a boiler station, then additional devices for wall-mounted installation may be required. You should not ignore possible threats in terms of external influences on the device. Both the risk of physical damage and the likelihood of moisture entering the housing are taken into account. Accordingly, to ensure safe operation of the regulator in conditions with such risks, it would be useful to turn to models equipped with protective insulating layers in the housing.