You can heat your house using a water heating system. To do this, you will have to install an electric heating boiler or a boiler that runs on solid or liquid fuel.

You will also have to lay out a heating circuit and install radiators. You can take a different route and build a stove or fireplace in your house. Both options for organizing heating will provide warmth and comfort in the house. However, they suffer from two significant disadvantages: they are expensive and labor intensive.

An alternative to the two heating options listed are cast iron stoves for summer cottages, which are gaining great popularity. In this material we will try to talk about the types of cast iron stoves, their advantages and operating features.

What is a cast iron stove?

The simplest cast iron stoves are not much different in design from the notorious potbelly stove. They consist of fuel and ash chambers, which are separated by a grate. Air is supplied inside the furnace unit and the flow rate is adjusted either by the ash chamber door or using a special damper.

Smoke is removed through a pipe adjacent to the fuel chamber. Heat transfer to the environment is mainly carried out by convection. A small part of the thermal energy is transferred through infrared radiation.

Without disputes

Of course, there was some controversy. The author of the discussion also posted a photo of the stove he made in a bathhouse - with heat-resistant bricks. Another FORUMHOUSE user, Alexey Telegin, said that this fireplace was made incorrectly. There is a risk of fire. He pointed to the boards above the portal that either needed to be protected, or better yet, gotten rid of.

Alexey Telegin

An absolutely wrong decision! As well as feeling the surfaces with your hand (cheek, thermometer) to look for heat. Ignition is quite possible not only from heat, but also from a spark, including accumulated dust in a ventilated portal, or stuck on a board, or a burr formed... And if heating occurs up to 70 degrees, it is very dangerous!

I’m sure you yourself understand that heating and igniting dust or wood chips will require significantly less energy! So it’s better to replace the boards with any fireproof materials! It's easier and cheaper. Take care of yourself!

He advised raising it by 2-3 rows of masonry and pushing it forward like a shelf to deflect the hot air flow from the wall. In response to criticism and wishes, Ansushkov showed photographs of the finished fireplace stove and explained that in order for the stove to heat up, a heat removal shield and the Geyser included with the stove were installed. He clarified that he followed the instructions and information given in the product data sheet.

ansushkov

For a general understanding, I’m adding a photo of the inside view. Where there is doubt that it will “heat up”, a factory heat removal panel is installed, which comes complete with the Geyser stove. In addition, the view from the inside is made of brick with a large thermal gap.

However, each of the discussion participants remained unconvinced.

Advantages and disadvantages

The industry offers two types of metal furnace units. Country wood stoves are made of steel or cast iron. Cast iron heating devices are more expensive, but have a number of advantages that cannot be achieved when making steel products. Cast iron wood stoves for summer cottages have:

- long service life, which, with proper operation, can reach 30–40 years;

- high heat capacity and therefore retain heat longer compared to steel stoves;

- greater corrosion resistance compared to steel products; they practically do not rust with frequent “cold” fires;

- Due to the low coefficient of thermal expansion, cast iron stoves are not subject to warping and deformation.

It should be said that cast iron has an attractive appearance. Often, manufacturers' design solutions make it possible to turn an ordinary heating device into a real work of art. Many cast iron stoves become a decoration of the interior of the room in which they are installed.

Cast iron is a fairly fragile material and is susceptible to sharp impacts, which could cause it to crack. Cast iron is also “afraid” of heat shock. Cold water spilled on a hot stove can cause the metal to crack. Therefore, a cast iron stove with a hob must have a design that prevents direct contact of the flame with the stove.

When choosing a heating method for a country house, you must proceed from the fact that using a cast iron heating apparatus it is impossible to heat the air evenly in all rooms.

A cast iron stove can provide full heating in only one room. Fire safety regulations prohibit installing cast iron stove units in such a way that they heat several rooms.

Compared to brick stoves and fireplaces, cast iron heating devices have one important advantage. With comparable thermal power, cast iron units weigh an order of magnitude less. If a brick stove weighs one ton, then the weight of a cast iron stove will be about 100 kilograms.

Therefore, the installation of a cast iron heating apparatus does not require the construction of a foundation. It can be installed directly on the floor. Naturally, for fire safety purposes, it must be installed on a metal sheet or platform made of non-combustible material.

Pros and cons of cast iron stoves

Cast iron is a durable and heat-intensive material; a wood-burning stove for a summer cottage made from it retains heat for some time after the wood burns out in the firebox. In addition, cast iron heaters have other advantages:

- Durability (25-30 years). The property of the material to resist corrosion for a long time gives cast iron stoves a great advantage over metal ones. They do not rust from the effects of condensation that occurs during cold kindling, and therefore can easily withstand periodic use during the cold season.

- The walls of the cast iron firebox do not corrode or collapse under the influence of condensation mixed with soot and ash. This mixture contains acids that corrode products made from ordinary metal.

- Wood stoves designed for heating country houses and cottages are distinguished by their aesthetic appearance and original design.

- Thick cast-iron walls of heating and heating-cooking units contribute to long-term heat retention.

Branded potbelly stove from the Norwegian brand Jotul for 290 euros

The thick walls of the cast iron firebox are a double-edged sword. They take a long time to cool down, that's true. But they also require more time to warm up, which means that a cold stove at the dacha takes longer to heat up.

A significant drawback of heaters that scares away many users is their price. To buy a cast iron stove to heat your home, you will have to pay 50-100% more than a wood-burning steel heater costs. The remaining disadvantages are not so significant:

- the heat source has a decent weight, which should be taken into account when placing and installing it;

- when using a cast iron cooking stove, do not spill water on the hot surface, otherwise it may crack due to temperature shock;

- The material is fragile and can crack under a strong impact.

Stove-fireplace with an original design from the INVICTA brand (France) for 2800 USD. e.

For reference. Cast iron will not crack if the unit accidentally falls during transportation. This means a strong blow with a hard object or tool, such as a hammer.

What is the efficiency?

It must be said that the simplest cast iron stoves for the home have a relatively low efficiency factor (efficiency factor). Usually it does not exceed 40%.

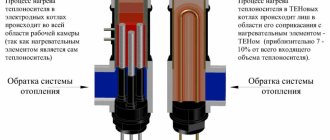

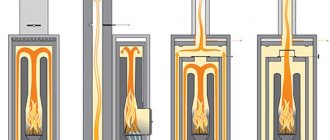

Long-burning furnace units have higher efficiency. To increase heat transfer, they are equipped with a chamber in which pyrolysis gases (flammable gases formed during smoldering wood) are burned. The air supply to this chamber is adjusted separately.

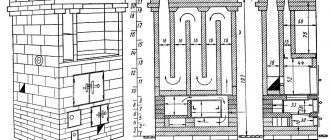

Experts are constantly working on the problem of how to improve the heat transfer of a cast iron stove. One way to increase heat transfer is to add so-called “smoke circulation” to the stove. Passing through the smoke circulation, hot smoke travels a longer distance and gives off an additional portion of thermal energy.

Sometimes, in order to increase the heat transfer time of a cast iron stove and increase the efficiency, ceramic heat accumulators are installed on chimneys.

Which design to choose for a country house

What cast iron heating stoves exist for a country house and how do they differ? By function, all structures can be combined into three large groups - heating, heating and cooking, fireplaces. Heating units are intended exclusively for heating rooms. They are designed to maintain temperature for as long as possible. There are models with advanced functions.

Diagram: operating principle of a gas generator stove

Long-burning heating stoves

Among heating stoves, convection and gas generator stoves are of particular interest. The former ensure the circulation of warm air between the walls of the firebox and the body, due to which they warm up the room faster, and gas-generating furnaces operate on the principle of double combustion of fuel. The design of gas generator furnaces differs from traditional models. In the first chamber of this design, the fuel burns slowly. The pyrolysis gas released during the combustion process enters the second chamber, where it is burned, and the heat is used to heat the room.

In temperature maintenance mode, gas generator models can operate for several hours. They use fuel economically and rationally, and their efficiency reaches 80-85%. There are models with automatic fuel supply. This is an expensive pleasure, but the home owner does not have to constantly monitor the consumption of firewood.

Drawing of the Buleryan stove for making it yourself

What types of cooking and heating models are there?

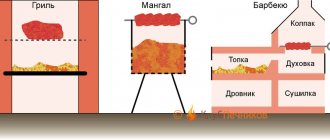

The upper part of such structures is a cooking surface - solid, with one or more burners. They are designed for cooking, heating food, and drying fruit. If desired, you can find designs complemented by a barbecue and/or oven.

Models of this type successfully combine two functions, but they cope with heating worse than “highly specialized” designs. They are best installed in small houses. For spacious rooms, it is worth choosing powerful long-burning heating stoves.

Models stylized as hearths, fireplaces, and tiled stoves look very beautiful. They often become the main detail of the interior. Stoves with glass doors and decorative elements look especially romantic. They are multifunctional - this is a plus, but the disadvantages include lower productivity, because... models hold heat worse.

Cooking and heating model with oven

Fireplace stoves - heating and romance in one bottle

Wood stoves with glass doors have remained popular over the years. On the contrary, they are increasingly in demand among buyers who pay special attention to the aesthetic aspect in home design. The sight of flames creates an atmosphere of romance, warmth, and intimacy. The doors are made of high-quality heat-resistant glass. The material is reliable, safe, and does not emit harmful substances. Designs of this type are more practical and fireproof than open fireplaces. In addition, they do not require major modifications to install a chimney, which will inevitably have to be done if you build a traditional fireplace.

The main function of such models remains heating the room, but aesthetics also play an important role. The reflections of fire on glass and pieces of furniture are unique light-color effects, the beauty of which lies in their unpredictability. There are corner structures, and there are also those that can be placed in the middle of the room. It all depends on the needs and wishes of the buyer.

Decoration of the stove-fireplace

Types of models

Manufacturers offer several types of heating units made of cast iron. Conventionally, they can be divided into:

- conventional cast iron stoves;

- fireplace type stove units;

- heating and cooking stoves made of cast iron;

Fireplace-type stove units are equipped with transparent combustion doors and side heat shields made of heat-resistant glass. When such “fireplaces” are heated, a unique cozy atmosphere is created due to the warmth and sight of burning logs.

A cast iron stove with a cooking burner will not only provide the room with heat, but will also allow you to boil water for tea and make coffee. Not every housewife will regularly cook food on it. For this, it is more convenient to use a compact gas stove. However, this option may also not be superfluous.

The need for a foundation for a metal furnace

If the stove weighs more than 750 kg, it is necessary to build a foundation for it. Often a cast iron heater with a three-dimensional mesh weighs 900 kg. With a weight of 600 kg, it is also recommended to make a foundation, since over time, under the weight of the unit, the floor will deform and the stove may warp.

Types of foundations for a furnace

The most reliable foundation for a metal furnace is a monolithic one.

A weight of 750 kg or more as a load for the foundation is not that great. However, the specifics of the design itself limits the choice. There are 3 options.

- Monolithic is the most popular. The depth should be below the freezing point, in most cases 50 cm is sufficient. The dimensions of the base exceed the dimensions of the furnace body by 30 cm around the perimeter. Such a foundation ensures absolute stability of the apparatus. In northern latitudes, the depth can reach 2 m. In this case, most of the pit is filled with sand and crushed stone and compacted, and the slab itself is made ordinary.

- Tape - involves digging a trench around the perimeter of the base and constructing formwork. In this case, less materials are consumed, but the need to construct complex formwork and reinforcement eliminates the advantages of a lightweight foundation.

- Block - a hole for the foundation is dug as for a monolithic foundation, but filled with bricks or, more often, large ready-made blocks. The cheapest option.

It is possible to install a stove on a foundation in a finished building, but to do this you will have to first disassemble the floors.

Principles of foundation installation

Sand and crushed stone are compacted at the bottom of the pit.

The construction technology is the most common.

- A pit is dug under the stove with a depth of about 50 cm or more and dimensions exceeding the dimensions of the body by 20–30 cm.

- A layer of sand and crushed stone at least 20 cm thick is compacted onto the bottom.

- Formwork is made from boards or plywood and secured inside the pit.

- Lay out the bottom layer of large pieces of rubble 30 cm thick and fill the voids with small crushed stone.

- Fill the formwork with liquid cement-sand mortar.

- Lay out the next layer and fill it with cement again. The operation is repeated with your own hands until 6–7 cm remains to the floor surface.

- Fill the last layer with concrete screed. Until the concrete sets - 3 weeks, it is periodically moistened and covered with polyethylene.

Foundation waterproofing is often done with roofing felt.

Types of fuel used

The long service life of a cast iron stove is ensured by using the “correct” fuel. It is best to fire with dry hardwood firewood (oak, hornbeam, birch, etc.).

They have high heat transfer with relatively low fuel consumption. Coniferous species are less suitable. Damp wood is difficult to light, it burns “reluctantly” and does not emit enough heat.

You should not use coal as fuel. Coal has a higher combustion temperature compared to wood. Therefore, there is a high probability of overheating the stove. When cast iron is heated above 450°C, the structure of the metal irreversibly changes, causing its heat capacity to decrease. After the stove overheats, the unit will work noticeably worse.

Choosing a good cast iron fireplace: all the rules and secrets

In recent years, you can see a returning fashion for fireplaces. Russia has not remained aloof from such trends. The most popular among such heating systems are cast iron fireplaces.

This is due to the fact that they significantly increase the comfort in the house, create an atmosphere of calm, home and protection, and therefore people are so drawn to quiet gatherings and a burning flame. They also perfectly perform their purely practical functions - they heat the room, which also largely determines the comfort and coziness in your home.

An undoubted advantage of this type of heating will be your own energy independence - from now on, the warmth in the house will be influenced not by weather conditions or decisions of city heating enterprises, but only by your desire.

Such a firebox is most often installed in a country house, but the scope of application of a cast iron fireplace is practically unlimited. The choice of this device should be approached seriously, because not every option will be able to consistently provide comfortable temperatures with optimal resource consumption. This means you can start purchasing only when the topic has been thoroughly studied!

Why cast iron and not steel?

A large number of craftsmen advise installing cast iron stoves: steel fireplaces are in many ways inferior to this option. A cast iron firebox has the following advantages:

- smaller in size than steel, but at the same time much heavier, since cast monolithic parts are used to create it;

Fireplace installed in a brick niche

- it is heat-resistant, it is not afraid of prolonged exposure to high temperatures, which will help avoid deformation and other negative effects;

Cast iron fireplace portal

- with proper operation, a long service life (in some ancient houses and estates in Russia, the age of the firebox exceeds 100 years);

Cast iron wood burning fireplaces

- The significant efficiency of such stoves is that cast iron quickly heats up and at the same time cools down extremely slowly, which provides incredible heat transfer and allows you not only to significantly warm up the room, but also to maintain a high temperature there.

Stylish cast iron fireplace

However, when choosing a stove for your dacha, you should also take into account possible difficulties in working with such heaters. In particular, the disadvantages include:

- intolerance to sudden temperature changes (the material can simply burst);

Cast iron fireplace portal

- heavy weight, which means certain difficulties in delivery, installation and subsequent transfer (if necessary) of such a firebox;

Cast iron portal

- rather limited appearance, because everything depends on factory standards, and the massiveness of parts and components limits the scope for design activity.

Note: In a word, there are both pros and cons in the operation of cast iron fireplaces, and therefore the final choice depends only on the personal priorities and wishes of the client.

Note that steel options are better suited for those who are very interested in the appearance of the fireplace or its large dimensions. If your priority is efficiency and efficiency, then a cast iron fireplace is best suited.

How to choose a fireplace from a design point of view

How it works: look “under the hood”

When choosing any device, it is always recommended to at least briefly become familiar with its basic operating principles: then the subject will no longer seem abstract and incomprehensible, and therefore the choice will be easier to make. Cast iron fireplaces have a similar operating principle as other devices made from other materials. Warming up of the structure itself, and with it the room, occurs due to air circulation and combustion processes.

Fireplace stove with special finishing

We know from school that heated air always rises.

Everything happens in the same way inside the device: hot air currents rise upward, where they penetrate into the room through special grilles in the casing, heating it.

At this time, cold air enters the firebox through other cracks and the firewood, inside it comes into contact with the heated radiator, takes heat from it and travels upward until it finds gaps through which it enters the room.

Cast iron fireplace option

The process repeats in a circle, but it can be influenced in various ways. The temperature of the radiator determines the circulation speed and how quickly and intensively the room will be heated.

Additional elements allow you to regulate these processes, influence the duration of combustion, air temperature, etc. For example, a special damper, adjustable with a cable, can trap air in the firebox, heating it even more and only then releasing it, which will significantly improve the heating of the room.

The same function can be performed by the bottom air damper - when purchasing a device, you should ask in advance whether this fireplace has such a function.

Cast iron fireplace

Chimney

Note: This important element of any firebox for a summer house and beyond deserves special attention, not only based on its important function in the fireplace system, but also based on the installation features. After all, thinking about where, how and what kind of chimney will be installed is not an easy task, but it is the most important.

The function of the chimney is to provide draft in the fireplace. Firstly, it promotes air circulation, that is, in fact, it provides the main function of any firebox. Secondly, it prevents smoke and other substances hazardous to humans from entering the room.

Cast iron fireplace with chimney

Care should be taken in advance to insulate the chimney from precipitation and moisture. For such purposes, it is customary to use foam concrete and special sealant.

Galvanized caps are also often used, which are very successful in preventing precipitation and debris from entering the pipe.

However, when installing protection on the chimney, it is important not to overdo it, otherwise you can accidentally block its access to the outside world, and then the air circulation will stop, and dangerous smoke will pour straight into the room.

Fireplace stoves with chimneys

The combustion process itself and the provision of traction depend on a number of factors. You should not make the pipe too wide - the wider it is, the harder it is to heat the fireplace to the level where it is able to maintain heat on its own.

The location of the chimney relative to the cast iron stove or fireplace itself will also have a beneficial effect: if it is located vertically, then the draft will be maximum. If there are no possibilities for such placement, then installation of the pipe can be done with your own hands and at a distance.

In this case, the main thing is that the angle of inclination for open chimneys is at least 45 degrees, and at least 30 for closed ones.

The optimal pipe length is within 5-10 meters. Anything higher will contribute to faster burning of wood, which means more waste. This option will be extremely uneconomical.

How to choose a fireplace

Types of devices

Various devices for summer cottages in Russia help to implement different functions, and therefore the choice of a specific heating device depends on your goals and needs. There are three types of fireboxes:

Heating stove

- heating and cooking stove;

Heating and cooking stove

Stove-fireplace

The first option implies that the main focus is on heating and heating. Manufacturers are trying to provide them with good thermal conductivity and conservation of hot air, which allows them to work longer with less use of resources. This usually includes lightweight, compact devices that are easy to install and do not require complex maintenance rules.

Stove-fireplace in the interior

The second group includes stoves that, in addition to heating, also allow cooking.

And although many criticize such cooking stoves due to their low efficiency and high costs, nevertheless, there are still buyers, and companies continue to produce such products.

However, the function of cooking outside the city, where power lines are not installed or not fully installed, will be important, and then cooking over a real fire from a cast-iron pot will become a real mini-extravaganza.

The third group consists of fireplace stoves that combine the best qualities of the two previous options. They allow you to both cook efficiently and heat all the necessary rooms just as well.

Installation Tips

You can install a stove, firebox, fireplace or other heating device yourself, but to prevent problems it is better to contact specialists. But knowledge of the basic installation rules will be useful not only in the process of direct work, but also for determining the location or making preliminary calculations.

Fireplace installation

Due to the large weight of such fireplaces (when assembled, they can weigh hundreds of kilograms), a strong floor with a concrete screed is a prerequisite. When facing, the fireplace should be at the level of the finished floor, so consider this point in advance.

Important attention is also paid to the wall, which is located behind the fireplace. It must be free from communication lines, consist of fireproof materials, and if it is external, it must also be thermally insulated.

In Russia, as in other countries, thermal insulation is produced using foil-coated mineral wool.

The installation of a chimney, as we noted earlier, can occur with the pipe placed vertically relative to the fireplace, or a little further away and at an angle - it all depends on your needs and objective capabilities.

How to choose?

The main criterion for choosing a heating device is its thermal power. Thermal power is selected based on the area of the room or its volume. Typically, manufacturers in the technical documentation indicate the volume of the room that can be heated using a particular model.

Having decided on the power of the stove unit, you need to decide on its type: a simple stove, a “fireplace” or with hobs. When choosing a stove for heating your home, you need to focus on reputable, reputable manufacturers.

Among the well-known brands we can recommend:

- Belgian heating units EFEL,

- products from the Polish manufacturer EUROKOM,

- Russian-made products from ARDENFIRE META,

- Italian EdilKamin.

Shiber

Another important element of such a fireplace stove is a damper installed above the starting convection pipe. Ansushkov recommends making the chimney straight, since such a chimney has better draft and heats up faster. In addition, this is also a safer way to install a fireplace stove in your home.

ansushkov

The gate was placed immediately above the starting convection pipe. It is a must to install. Enlarge the photo and you will see it. A straight chimney is really better, the stove is very powerful, the draft is strong, it heats up instantly, and therefore it is safer with a straight chimney. And after one full charge, I don’t recommend charging the second one right away, it heats up like hell, my volumes are large, although one floor has a 3.8 m ceiling, the living room and kitchen are combined, it gets hot. The convector at the starting point also helps distribute the flow. The stove itself holds heat for a long time - cast iron.

The passage of the pipe through the ceiling itself is made of non-combustible blocks, a sandwich chimney, the main main reduction in temperature in the first section through convection.

How to install a cast iron stove in a wooden house with your own hands?

Wooden buildings are the most fire hazardous. Installing a cast iron stove in a wooden house with your own hands requires strict adherence to fire safety rules:

- As already mentioned, heating appliances made of cast iron are relatively light in weight. Therefore, they can be installed directly on the floor. To prevent fire, place a thick steel sheet on the floor or lay out a podium made of heat-resistant ceramic tiles. If the weight of the stove unit exceeds 100 kg, then the floor is reinforced from below with additional supports. You can also build a concrete or brick foundation.

- Heat screens are installed on walls located close to the heating unit to prevent heating of wooden structures. Some furnace manufacturers include such screens in the delivery of their products.

- When installing chimneys, where they pass through wooden (combustible) walls and ceilings, thermal insulation of heating parts is performed.

Reputable manufacturers provide detailed instructions for installing stoves and fire safety measures. If all recommendations are followed exactly, the operation of stove heating will be safe.

Installation of a cast iron firebox

It is necessary to build a concrete foundation under a cast-iron stove.

Thermal equipment is a product ready for installation. Usually it is a prefabricated unit consisting of individual elements, and therefore requires the articulation of these spare parts. Despite the relatively light weight of the heater, it is not possible to simply install it on the floor unless it is a strong concrete base. In all other cases, preparation is necessary. The same applies to the pipe - it must protrude above the roof level, and its passage through the building structure must be fireproof.

Tool preparation

To install the heat generator in the right place, the following tools are required:

- Measuring tape. With its help, the distance of the product to nearby walls or reporting points is determined.

- Horizontal level. The product must be positioned perfectly straight.

- Jack. May be needed to level a heavy structure by lifting one of the corners and placing a support leg under it.

- Set of wrenches. They are necessary if the heater consists of different parts held together by bolts.

All these tools are not needed when a hired professional team is responsible for the installation. It is impossible to do without the help of workers if the weight of the product is not comparable to the strength of one person.

Installation location

Combustible materials near the stove must be insulated.

There are no serious restrictions for installing heating equipment in one place or another, it is important that the floor is strong and does not press through, the nearby walls are non-flammable or protected from heat, and the place is comfortable.

The operation of any solid fuel boiler or fireplace is accompanied by the accumulation of dust, so it is advisable to install the unit not too far from the entrance area, so as not to drag garbage throughout the room.

If the stove does not have any particular decorative appeal and can be connected to a diluted water heating system, it is better to install the firebox in the boiler room.

Foundation preparation

It is better to make a concrete base for the heavy weight of the heat generator. For a new building, it should be laid down immediately. To do this you need:

- Remove a layer of soil to a depth of 25 cm - dig a small pit with linear dimensions exceeding the dimensions of the convector itself by a couple of tens of centimeters in length and width.

- In each corner of the pit, go deep to 80 cm with pit dimensions of 25x25 cm.

- Insert 4 reinforcement bars into the resulting holes, driving them into the ground. In the upper part they should not extend beyond the pit.

- Fill the pits and foundation pit with concrete to half the height.

- Place a reinforcing mesh on the cement mortar and fill the foundation to the end.

If it is not possible to arrange the base in this way, but there is a fairly hard floor, it is enough to place a sheet of metal 3-4 mm thick on top of it, which must be secured with self-tapping screws. Steel will additionally strengthen the floor and will serve as protection against the loss of burning coals.

Installation procedure

Elements of a collapsible stove

To install the stove, perform the following steps:

- Take the spare parts out of the packaging and check the passport to ensure that everything you need is present.

- They study the diagram, where which part should be screwed, and find these elements.

- Twist the two side walls from the back using a bolted connection, fixing them to the lower base.

- Screw the support legs, fix the ash pan panel and the grate group.

- Place the partially assembled product in a permanent place.

- Install the front door with glass on the awnings and close everything on top with a lid with a hole to remove smoke.

- Insert the ash pan into the seat.

It is necessary to carefully tighten all the screws so that the fire-resistant gaskets fit tightly to the joint. If cracks are visible, it is advisable to seal them with fireproof sealant.