Coal is one of the most sought-after minerals, the extraction of which requires enormous effort and occurs in very unsafe conditions. Its deposits are located deep underground and are formed as a result of plant decay caused by lack of oxygen. In everyday life and industry, various grades of coal are used, corresponding to the accepted classification based on quality characteristics.

Coal grades vary. at least in terms of quality

Description and purpose of the mineral

In wetlands, plants are converted into peat under the influence of many bacteria, then into brown coal, which, in turn, turns into stone after many years. The latter is characterized by a higher calorific value and is therefore used as fuel. The areas of its consumption are:

- electric power industry;

- thermal power equipment of industrial enterprises;

- chemical plants;

- Department of Housing and Utilities;

- heating systems of private houses.

Depending on the marking of coal, it can be used as a solid fuel for modern heating boilers and conventional stoves in old houses. Despite their external similarity and even belonging to the same type, fossils may differ, for example, in sulfur content, heat of combustion, humidity, etc.

In this video you will learn about the specifics of USSR grade coal:

The cost of each grade of coal is determined separately. Their characteristics affect how much a ton of fuel will be priced for an industrial or private facility. The study of properties and features is carried out in several directions:

- elemental analysis (detection and calculation of oxygen, hydrogen, organic sulfur, carbon and nitrogen in the total mass);

- technical research - analysis of quality indicators that must meet the requirements established by regulations (humidity and sulfur content, ash content and heat of combustion, yield of volatile components);

- mechanical analysis - the ability of a fossil not to crack or collapse, not to change size under the influence of friction or impact (important for foundry and electrode production);

- thermal tests - allow you to determine the strength of coal under the influence of high temperatures (grades intended for furnaces, semi-coking);

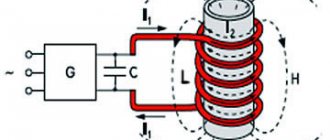

- determination of electrical properties - depending on the stage of transformation, coals can be dielectrics and semiconductors in the initial stages, and conductors in the later stages.

Special laboratories examine absolutely all types of coal. Their characteristics make it possible to sort pieces by size (size), as well as by other properties that affect quality.

Coke coal (K)

This is a very valuable type of coal due to its low abundance. This brand produces very high quality coal coke, as the name suggests. Such coal is formed at a fairly large depth (5500 m), where there is high pressure. The color of this coal is gray with a glassy sheen. It has a very uniform structure and a minimal number of pores. The content of volatile substances is moderate (22-27%), and carbon reaches 88-90%, which has a positive effect on heat transfer, although such coal is rarely used as fuel. Coke coal is mined in the Kuznetsk coal basin, in Anzhersky, Tom-Usinsky, Prokopyevsko-Kiselevsky and other areas.

Classification and properties

In the Russian classification, it is customary to distinguish 8 groups. This division does not coincide with the labeling adopted in Western countries. Coal is available in several grades with the corresponding letter designation:

- brown (B) - with a calorific value of 7000-7500 kcal/kg;

- skinny (T) - from 7300 to 8700;

- long-flame (D) -7500-8000;

- gas (G) - when burning, it releases heat from 7900 to 8600 kcal/kg;

- anthracite (A) - 8100-8750;

- fat (F) - 8300-8700;

- coke (K) - 8400−8700;

- lean-sintered (OS) - 8400-8780.

The most common in private households and industry are long-flame coal (labeled DPK or DPKO, popularly called “fist” or “nut”), skinny coal (labeled TPK and TPKO, sizes 50-200 mm and 25-50 mm) and Anthracite coal (used most often in the energy sector).

Read also: about the main types of coal and their purpose.

Lean-caking coal (OS)

This grade of coal is not very different from coking coal: the content of carbon and inorganic impurities is approximately at the same level. Its main advantage is its high calorific value. It is 36 MJ/kg, so it is sometimes used as fuel in power plants. But its main use is in the coke industry. True, this coal is difficult to coke, so it has to be used in a mixture with other types of coal. This mixture of several grades is called coal charge. Mining of lean-caking coal is mainly carried out in the Kuzbass, in the Kemerovo region and in the South Yakutsk coal basin.

Characteristics of groups

Stone minerals of grade D are considered the most suitable type of fuel, which ensures the operation of furnaces and heating boilers. It is a long-flame coal that gets its name from the high flames it produces, like firewood. It supports a long combustion process and releases a large amount of heat without sintering. This type of fuel can be used in almost any system (even those not equipped with a natural draft system or forced air injection). It flares up very quickly and allows for efficient heating of private homes and medical institutions, as well as administrative buildings.

The second most popular type of coal can be considered grade T. It is called “lean”, is characterized by the release of volatile substances in the range of 9-17%, does not sinter, and practically does not emit a flame when burning. It contains about 90% carbon, so this coal is considered the richest. It is indispensable in the fuel industry, chemical production, gas generating plants, housing and communal services and mobile power plants.

So, brand D is the most popular

The third group is long-flame gas DG coal, low-caking, with low fragility and high strength. Unsuitable for coke batches because the resulting coke is radioactive. The yield of volatile substances is in the range of 27-30%, refers to energy rocks.

Under the brand Zh there are two groups of fossils , the division of which is based on the yield of volatile substances and the reflection of vitrinite. This is a highly coking, especially valuable type of fuel, which, as a result of combustion, forms high-strength structural coke. For the production of cast iron or steel in ferrous metallurgy, grade Zh coal is most preferable, the characteristics of which make it possible to avoid technological difficulties associated with the combustion process.

Anthracite combines a group of coals with a VLV of about 8%, which are irreplaceable in the energy industry. Large and medium-sized specimens are used as smokeless fuel in the municipal and domestic sectors. In addition, anthracite is necessary for the production of carbide (aluminum and silicon).

Long flame coal (D)

Usually has a gray-black color. It burns with a long, smoky flame, which is what gave it its name. Contains 70-80% carbon, which makes it a slightly higher quality fuel compared to brown coal. This is also affected by less moisture and impurities. But this is not the advantage of long-flame coal. This fuel can burn without blowing, which makes it easy to use in stoves and boilers. This type of coal is very common. Its production is carried out in the Minusinsk, Kuznetsk, Donetsk and many other basins.

Intermediate marking

Labeling, adopted on the basis of quality indicators, allows you to identify several groups and select the appropriate mineral depending on your needs. Depending on the production basins, an intermediate classification has been adopted, which distinguishes:

- gas fatty (GZh);

- low-caking (SS);

- coke fatty (QF);

- coke second (K2).

When mining coal, it is possible to obtain pieces of different sizes, on the basis of which it is customary to divide them into classes. Class P (slab) includes pieces over 100 mm, large (K) includes pieces from 50 to 100 mm. Class O (walnut) is represented by stones of 26-50 mm, and class M (small) is represented by rocks of 13-25 mm. Group C (seed) includes small coals 7-13 mm in size, and a piece (Sh) refers to all remains less than 66 mm in size. The designation P (ordinary) is assigned to fossils that are not limited in size.

Coal mining

In our time, hard coal is mined in three fundamental ways. Such as:

- career method

- mining through adits,

- mining method.

The quarry mining method is used when coal seams lie on the surface, approximately one hundred meters deep or higher.

Quarries involve simply digging up the ground or sand pit from which mining is carried out; usually in such cases the coal seam is quite thick, which makes its extraction easier.

Adits mean wells with a large angle of inclination. All mined minerals are transported upward along it, without the need to use serious equipment or dig out a basin.

Typically, deposits in such places are thin and not buried particularly deep. Therefore, the method of mining through adits allows for rapid production without special costs.

Mining through mines is the most common method of extracting minerals, at the same time the most productive, but at the same time dangerous. The mines are drilled to great depths, reaching several hundred meters. However, this requires a permit confirming the justification for such large-scale work and evidence of the presence of deposits.

Sometimes the mines can reach a kilometer or more in depth, and stretch for several kilometers in length, forming interconnected webs of corridors underground. In the 20th century, settlements and small towns were eventually formed around the mines, in which miners and their families lived.

It is precisely because of the mining conditions that work in the mines is considered very difficult and dangerous, because a huge number of times the mines collapsed, burying dozens or even hundreds of people working there.

Types

- Regular charcoal

is made from peat, coal, wood, coconut shells or petroleum. - Sugar charcoal

is produced by carbonizing sugar and is particularly pure. It is purified by boiling with acids to remove any minerals and then burned for a long time in a stream of chlorine to remove the last traces of hydrogen. - Activated charcoal

is similar to regular charcoal, but is made specifically for medical use. To produce activated charcoal, manufacturers heat regular charcoal in the presence of a gas, which causes the charcoal to form many internal spaces, or "pores." These pores help activated carbon traps. - Lump charcoal

is a traditional charcoal made directly from hardwood wood. It usually produces much less ash than briquettes. - Japanese charcoal

had pyrrolic acid, which was removed during charcoal production; therefore, when burned, it produces almost no odor or smoke. - Briquette-shaped pillows are made by pressing charcoal, typically made from sawdust and other wood waste, with a binder (usually starch) and other additives. Briquettes may also include lignite (heat source), mineral carbon (heat source), sodium tetraborate, sodium nitrate (ignition agent), limestone (ash bleaching agent), raw sawdust (ignition agent) and other additives.

- Sawdust charcoal

is made by pressing sawdust without binders or additives. It is preferred to be used in the Middle East, Taiwan, Korea, Greece, etc. It is mainly used for barbecuing, as it does not produce odor, smoke, little ash, has a high combustion temperature and a burning time of more than 4 hours. - Extruded charcoal

is made by pressing untreated shredded wood or carbonized wood into logs without the use of a binder. The heat and pressure of the extrusion process holds the coal together. If the extrusion is made from untreated wood material, the extruded logs are subsequently charred.