High-quality heating of your own home is one of the most important issues facing its owner. And when it is resolved, a dilemma very often arises as to which heating unit will be optimal under the current conditions. Of course, if a gas main is connected to the house, then preference is given to boilers running on natural gas - such equipment has no equal in terms of operating costs. But in the case when such an opportunity is absent (gasification of a populated area is not expected in the near future) or its implementation requires absolutely “cosmic” expenses (and this often happens when it is necessary to carry out a connection from a highway to a specific building), one has to involuntarily look for other solutions.

Liquid fuel boilers - principles of operation and calculation of fuel consumption

One solution could be the use of liquid fuel - most often diesel fuel is used in this capacity, but options with used engine oil or fuel oil are possible. This option, of course, requires specialized equipment, which you need to be able to select, and at the same time, also correctly predict operating costs. Therefore, the topic of today's publication: liquid fuel boilers - principles of operation and calculation of fuel consumption.

Gas boilers

Gas boilers are heating appliances that run on gas. The gasification network is quite widespread, so such equipment is most popular among consumers.

Gas appliances are divided into wall-mounted and floor-mounted. The first ones are equipped with a circulation pump and an expansion tank, which saves space in the room. Wall-mounted boilers are single-circuit and double-circuit (they heat the coolant and provide the home with hot water for domestic needs). Equipment with two circuits is the best option for heating private houses: it is compact, easy to install and maintain.

Floor-standing gas boilers most often have one circuit and an open combustion chamber. They require a specially equipped boiler room.

A significant drawback of these boilers is the constantly increasing cost of gas.

Solid fuel equipment

Boilers operating on solid fuel (wood or coal) have a simple operating principle. The fuel is placed in the combustion chamber and ignited. Combustion products exit through the chimney.

The main advantage of such equipment is its independence from the power grid and completely autonomous operation. The downside is the preparation of firewood or coal, high fuel consumption.

Firewood costs

Firewood

On average, the cost of this natural solid fuel is influenced primarily by the type of wood, delivery rates and prices set for firewood by logging companies, as well as the packing density per cubic meter.

A densely packed cubic meter of this solid fuel will weigh 650 kilograms and cost about 1,500 rubles.

In order to get 1 kW of heat, you need to burn only 0.4 kilograms of firewood, which comes out to an average of about 0.92 rubles.

Thus, 0.92 * 50400 and we get 46368 rubles per year.

Important: When using solid fuel, you must remember that during operation it will be necessary to regularly clean the equipment from accumulated soot, and you will also have to build a chimney.

Electric heating devices

Electric boilers are a convenient option for heating small buildings. Most often they are used as additional heating devices. For example, if firewood burns in a solid fuel boiler. As the main source of heating for a private home, electric boilers are used in areas where there is no gas supply. To install them, you do not need to obtain special permits or approvals.

The main advantage of such units is their ease of operation, they do not require frequent maintenance, and are equipped with electronic sensors and temperature programmers.

Liquid fuel units

Diesel boilers (liquid fuel) are an ideal option for areas where there is no gas pipeline. Using such equipment, houses can be heated with diesel fuel, fuel oil, kerosene, stove and biofuel, and waste oil.

Advantages

These heating devices are gaining popularity not only because they can run on diesel fuel. They also have other advantages:

- Such equipment has a replaceable burner (nozzle), which allows you to change the type of fuel in it (for example, if it becomes possible to supply gas, you will not have to dismantle the entire unit);

- they are easy to operate, do not require frequent maintenance, the main thing is to take care of the diesel fuel supply;

- work autonomously for a long time;

- Efficiency is about 95% (provided that a high-quality burner is equipped and proper diesel fuel is used), such a boiler produces more heat than a gas or solid fuel one;

- when operating, these devices do not violate environmental standards;

- installation of the unit can be carried out without special permission;

- Almost all models have an automatic system; they are independent of external communications.

Flaws

The main disadvantage of boilers running on liquid fuel is the large expenses for purchasing diesel fuel. This will especially hit the wallet when such equipment is used intensively.

Such units require a separate room with plenty of free space. They emit soot, so you need to install a hood. In addition, the increased noise that such boilers emit requires the creation of high-quality sound insulation.

To operate them and transport fuel, you must have special components.

Diesel fuel must be stored in a separate building or equipped with a warehouse in the ground, in containers made of steel or opaque plastic, so that the sun's rays cannot harm it.

Some features of this oven

The features of a homemade diesel stove can be divided into two categories:

- manufacturing features;

- Features of application.

Manufacturing features are determined by the choice of design of such a stove. This will require the selection of a certain material (appropriate steel: sheet, angle, pipe), certain finished products or home-made production (nozzles, pipes, chimneys and air ducts), containers for diesel fuel. The need to use appropriate tools and metalworking equipment (drill, grinder with a set of cutting wheels, welding machine) and hardware for attaching individual parts of a homemade stove.

Application features include: the specifics of igniting such a stove, organizing the removal of combustion products. Using diesel fuel as fuel will require periodic maintenance of the existing nozzle and burner. This is caused by the presence of sulfur in diesel fuel.

If you use a diesel fuel stove in which the fuel flows by gravity, it is necessary to place the diesel fuel tank at a certain distance above the burner itself to prevent its uncontrolled heating.

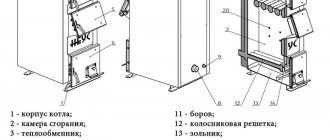

Construction of liquid fuel boilers

Liquid fuel boilers are made of cast iron and steel. The service life of the first is approximately 50 years, the second is no more than 10.

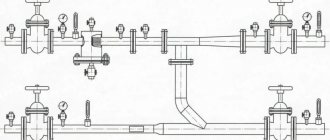

The liquid fuel unit consists of a combustion chamber, burner, heat exchanger, fuel purification filter, control system, and chimney.

Burner

The burner is the main element of the boiler. It mixes air with fuel in certain proportions and delivers this composition to the combustion chamber. During its operation, the energy carrier is heated, which then goes into the pipeline. Combustion products exit through the chimney, before partially giving off heat to the heat exchanger, thereby increasing the efficiency of the unit.

Burners for liquid fuel boilers can be purchased separately. A heating system with such equipment can be assembled in accordance with the preferences of the home owners. Today, boiler models with universal burners suitable for several types of fuel are sold, but the cost of these units is high.

The design of the burners is compatible with many types of water heaters and heat generators. When switching from one type of fuel to another, you need to completely clean the boiler of combustion products.

Injectors

There are several types: one- and two-stage, ventilation and diffuse.

The former operate with constant power; it can only be changed by stopping the boiler.

Two-stage nozzles operate in two modes, which allows the unit to gradually increase power.

Ventilation burners used in liquid fuel boilers force air. Diffuse ones receive the air necessary to maintain the combustion reaction from the environment.

Control

The automation of the heating device makes it possible to maintain the set temperature, ensures its proper functioning and protects it from dangerous operating conditions.

An oil-fired boiler depends on electricity. It must have an independent source of energy: then the equipment can operate autonomously.

Fuel tank

Such units have an additional capacity of no more than 50 liters (if the heating device is located in one of the main rooms of the home) for diesel fuel; it is often installed near them.

Tanks with a volume of up to 1000 liters are installed in a specially equipped room.

Types of liquid fuel equipment

Depending on different parameters, several types of units are distinguished.

By the number of heating system circuits

An oil-fuel boiler can be single-circuit or double-circuit. The latter are equipped with two heat exchangers, which allows not only to heat the house, but also to provide its residents with hot water for domestic needs. Naturally, their fuel consumption is higher than that of single-circuit ones.

By type of injectors

Boilers operating on liquid fuel are divided into units with built-in and mounted nozzles. The first ones usually run on diesel fuel. The latter are universal equipment; their design is similar to gas heating appliances.

Changing the type of fuel is accompanied by installing another burner. The main advantage of mounted boilers is the ability to operate on 2 or more types of fuel.

Depending on the type of installation

Depending on the installation method, liquid fuel units can be mounted or floor-mounted.

In the first case, the equipment is light in weight, but does not have high performance. Floor heating devices are more convenient; the area they can heat reaches 350 m2.

Review of models from leading companies

A worthy niche in the heating equipment market is occupied by liquid fuel boilers from foreign manufacturers: ACV, EnergyLogyc, Buderos Logano, Saturn, Ferolli and Viessmann. Among domestic companies, Lotos and TEP-Holding have proven themselves well.

Universal boilers ACV Delta Pro

The Belgian company ACV sells models of the Delta Pro S line - double-circuit boilers with a built-in boiler. The power of heating units ranges from 25 to 56 kW.

Delta Pro S boilers are supplied with a burner of the buyer’s choice - either model BMV1 for liquid fuel or BG2000 for propane and natural gas

Technical and operational features:

- heat exchanger material – steel;

- polyurethane foam insulation of the body;

- operation on diesel fuel or gas;

- control panel with thermometer, control thermostat.

The liquid fuel boiler “adjusts” to the season - a “winter/summer” switch is provided.

The efficiency of Delta Pro S boilers is 92.8%. The water heating time for the DHW system depends on the power of the installation and ranges from 16 to 32 minutes

EnergyLogyc units – intelligent automation

Waste oil boilers from the American company EnergyLogyc differ from their analogues in the automated processes of setting up the burner and burning fuel.

The fuel used is waste oil, diesel fuel, vegetable oil or kerosene.

The device has increased the size of the firebox and the cross-section of the smoke pipes - this makes it possible to effectively use “working off” and reduces the number of boiler cleaning jobs

EnergyLogyc liquid fuel units are available in three modifications:

- EL-208B – power 58.3 kW, fuel consumption – 5.3 l/h,

- EL-375B – performance 109 kW, fuel consumption – 10.2 l/h;

- EL-500B – thermal power – 146 kW, fuel consumption – 13.6 l/h.

The maximum coolant temperature in the presented models is 110°C, operating pressure is 2 bar.

The EL-208B boiler is suitable for heating premises for various purposes: cottages, greenhouses, car services, production shops, warehouses, private homes and offices

Buderos Logano – German quality

The Buderos company (Germany) produces diesel boilers, nozzles, burners and other equipment necessary for operating the heating system. The range of power characteristics of the units is 25-1200 kW.

The efficiency of Buderos liquid fuel boilers is 92-96%. The equipment operates in fully automatic mode, the fuel material is diesel fuel. Heat exchanger made of gray cast iron or steel

Buderos Logano boiler systems are produced in two series:

- Buderos Logano category “G” - intended for private use, their power is 25-95 kW;

- Buderos Logano category “S” - equipment for industrial use.

The units are distinguished by a streamlined design, a convenient control system, and a built-in silencer.

Buderos Logano domestic boilers are supplied with built-in and adjusted diesel fuel burners. The device can be equipped with a pump group, a security system and an expansion tank

Boilers from the Korean company Kiturami

Kiturami Turbo series floor-standing double-circuit boilers are designed for domestic use. The power of the units is 9-35 kW.

Distinctive features of the model:

- provision of heating and hot water supply for premises up to 300 sq.m;

- the boiler heat exchanger is made of high-alloy steel;

- the additional DHW heat exchanger consists of 99% copper, which increases heating efficiency;

- Antifreeze and water are suitable as coolants.

A distinctive feature of Turbo models is the presence of a turbocyclone burner. It operates on the principle of a turbocharged car engine.

In a special metal board, secondary combustion occurs due to high temperature. This allows for economical fuel consumption and reduces the emission of harmful substances into the atmosphere.

Kiturami Turbo can operate in the following modes: “Shower”, “Sleep”, “Presence”, “Work/Check” and “Timer”. The control panel is located on the front side of the case

Fuel calculation

Fuel consumption is affected by the quality of thermal insulation and the size of the house. Oil-fuel boilers have high efficiency when they operate at maximum. Therefore, there is no need to buy such equipment with a reserve. In this way, you will be able to avoid unnecessary costs, since the amount of fuel consumed will be reduced.

It is possible to approximately calculate how much diesel fuel is needed for a house of a certain size. So, for a power of 10 kW, the consumption of diesel fuel will be 1 kg per 1 hour of boiler operation.

You can also calculate the amount of diesel fuel based on the injector power parameter; it is multiplied by 0.1. This is how the material consumption is calculated for 1 hour of boiler operation. These indicators will help to calculate the approximate amount of fuel needed to heat a house of the corresponding area. So, for a home of 150 m2 you will need a boiler with a power value of 15 kW. We multiply this parameter by 0.1, the result is 1.5 kg/hour. Accordingly, at full speed, such a unit “eats” 36 kg of diesel fuel per day. It is easy to calculate how much diesel fuel will be consumed in 5-6 months of the heating period.

When choosing a heating boiler, each person is guided by certain parameters and requirements. In populated areas where power outages occur constantly and there is no gas pipeline, liquid fuel heating boilers will prevent their owners from freezing.

Calculation of heat consumption for a 20 kW boiler

Boilers with power from 20 kW

For a cottage whose characteristics were taken as a standard, it will be necessary to purchase a heat generator with a power of at least 20 kW.

This calculation was made based on standards, according to which to heat 10 square meters of space in our climate, it is necessary to spend at least 1 kW of thermal energy generated by the boiler per hour.

So, we multiply 20 kW by 24 hours a day and 30 days a month, as a result we get 14,400 kW.

This is exactly how much heat such a boiler can produce per month if it operates at full capacity. But as practice shows, most often the boiler operates only at half power, which means 14400 can be safely divided by two, reducing the result to 7200 kW.

Every year, with minor adjustments, the heating season lasts about seven calendar months.

So, we multiply our result of 7200 by 7 - the number of months, and we end up with 50,400 kW.

The resulting amount will become the starting point for determining the operating costs that are necessary for the operation of the boiler; it is thanks to this indicator that the most optimal cost-effective heating scheme can be determined.

The main component of heating costs is operating costs.

It is worth noting that the owner of a country house will spend one time on purchasing the necessary elements and constructing utilities, but he will be faced with covering operating costs on a monthly basis.

It very often happens that in his desire to reduce the cost of constructing a heating system, the owner makes a number of strategic mistakes, as a result of which in the future he will pay almost several times more than his more prudent neighbors who were not too lazy to calculate heat costs before purchasing boiler and design of the entire heating system.