The most optimal and economical source of heating for a country house is still a gas boiler.

There are a huge number of manufacturers of these products on our market - Bosch, Buderus, Viessmann, Vaillant, Baxi, Navien, etc.

In addition, there are single-circuit and double-circuit models, traditional and condensation, wall-mounted and floor-mounted, with an open and closed chamber. Which one should you choose and what technical issues should you pay attention to in addition to the brand?

Let us help you understand this matter in order to avoid irreparable mistakes when purchasing.

Power calculation

At present, no one questions the project for power supply to the building. This is taken for granted.

Mistake #1

At the same time, not everyone orders the same heating project.

This leads to problems, first with the correct selection of the power of a gas boiler, and then with its operation.

Mistake #2

You cannot select power based on some average parameters.

The most popular way of them is to divide the total area of the house into 10 m2. As a result, the calculated value is supposedly obtained.

In this case, the thickness and material of the walls, dimensions, number and type of windows, doors, the presence of an attic, etc. are not taken into account.

If you want to find out the average power without a project, at least use online calculators. You should choose those that require you to enter the maximum number of parameters.

For example, this one is TYTS.

But still, for a comfortable and quiet life, initially include in your expenses a separate amount for the heating supply project. It should also include a diagram of the entire heating system and calculate the heat loss of the house.

Features of natural gas for home heating

“Natural” gas flows through the pipes, in quotation marks, because it has a very distant relationship with nature, a little more than modern gasoline. It is a mixture of methane with various impurities. About 50 years ago it was mined straight from the ground, but now, after extraction, it goes through a series of rather complex purification and dilution processes, as a result of which its characteristics are squeezed within the boundaries of the standards.

Red cylinders sold on the markets usually contain a mixture of propane and butane. Once upon a time it was a by-product of oil refining, which they did not know what to do with! Now, with the development of catalytic petrochemical technologies, on the one hand, a refinery can distill it into gasoline, but on the other, it has to be made or imported as a separate product, since the oil refining industry is going through hard times.

The first mention of people's use of this fuel dates back to the end of the 18th century, that is, more than two hundred years ago, when city streets were illuminated by gas lamps. But industrial extraction of natural gas from the ground is less than 100 years old.

Combustible gas can be of several types:

- Generator - air blast. 800 – 1000 Kcal/m3;

- Generator - oxygen blast. 1600 – 2000 Kcal/m3;

- Water - steam blast. 2800 Kcal/m3;

- Domain;

- Coke.

That is, with “natural” gas “the light has not converged like a wedge” - you can burn other gases too! Is it profitable? The answer is definitely yes! And then we will tell you why.

Electrical and thermal power

When people first see a boiler plate with a power of 24 kW or more, it makes them dumbfounded.

Mistake #3

Wow, how much electricity will such a boiler “reel” in?

Do not confuse the electrical and thermal power of heating devices. In the worst case, a gas boiler consumes no more than 150-200 W per hour from the outlet.

Therefore, to power it during a blackout, conventional batteries with an inverter or so-called UPS are sufficient.

We are not talking about any kilowatts here.

Service life of a floor-standing boiler

Floor-standing gas units last 5-8 years longer than wall-mounted ones. So, according to actual data, a steel heat exchanger can last 11-12 years, and a cast iron one can last 12-18 years.

Floor-standing devices practically do not function at full load, which prolongs the service life. And if the owner of a double-circuit heating boiler carefully carries out all routine maintenance and preliminary water purification, then such a gas boiler unit will serve him for at least an additional ten years. Many people remember Soviet cast iron boilers with a service life of 50 years.

At temperatures below 55 C, the condensation process begins in them, with the formation of acid, which penetrates the boiler heating surfaces and “eats away” everything in its path, from the chimney system to the firebox.

Therefore, if the manufacturer specifies a lower temperature limit for the return coolant, it must be maintained. In addition, when the condensation process occurs, it is necessary to additionally install condensate traps at the bottom of the chimney, which will significantly increase the service life of the floor-standing gas boiler.

Boiler with power reserve

Mistake #4

The greater the power reserve of the boiler, the greater the gas consumption will be.

Therefore, it is not economically profitable to take a gas boiler with a reserve. This is not always true.

First of all, this problem concerns “dumb” floor-standing and obsolete wall-mounted boilers.

This is what the operating schedule for a 20 kW and 30 kW device looks like.

Vertically we have gas consumption, horizontally we have operating time. Two modes, the so-called clocking, are drawn at the top. Bottom – comfortable operation mode with constant power in cold weather.

Positive and negative qualities

This type of equipment is optimal if you have access to liquefied or main gas.

Advantages of a gas boiler

- Economical.

- Reliability.

- Autonomy.

- Durability.

- Easy to use.

- High performance.

- Possibility of placement in small rooms.

Disadvantages of a gas boiler

- Compliance of the premises with technical requirements.

- The need to obtain special documents permitting installation.

- Installation, connection and maintenance are carried out by specialists.

- For smooth operation, constant access to fuel is required.

Timing and solution methods

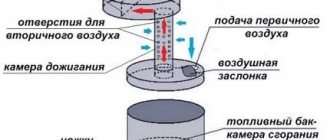

Typically, clocking is observed during the off-season, when there are no severe frosts and there is no need to warm up the system for a long time.

In this situation, the boiler starts at maximum, quickly heats the water and turns off. Next, the pump removes the coolant throughout the system, the temperature drops, and the burners start up again.

In this mode, both 20kW and 30kW boilers operate. What's the difference?

And the difference is that the first one will consume gas during the launch intervals, conditionally 2m3, and the second 3m3. When the boiler cycles, it does not have time to evaluate anything and reach optimal power.

It starts at maximum and stops at maximum. But all this applies to old, “dumb” models.

In modern wall-mounted appliances with modulating burners (1:10) and smart electronics, the boiler’s operation is designed in such a way that if the automation initially detects overheating of the coolant, the next switching on will occur at a lower power, or you can reduce it yourself.

The only problem is when the minimum power of the boiler is not so minimal.

Therefore, check the instructions and ask the seller whether the gas boiler has a modulation function or not. And the more frequent the adjustment step, the better.

Mistake #5

But there is no need to overdo it with the so-called “brains”.

90% of consumers never use weather-dependent automation or GSM modules in their lives. It's not worth overpaying for them.

It’s better to install a couple of smart and inexpensive room thermostats.

More details

Most people solve the age-old problem with clocking in this way.

How to choose a single-circuit gas boiler

First, let's look at the key characteristics of boilers that you should pay attention to when choosing.

Number of circuits

- this is the most obvious parameter that determines the very purpose of the boiler. If the task is to provide both heating of the room and heating of water, a double-circuit boiler is needed. Relatively inexpensive models work alternately - when hot water is turned on, the boiler switches to water heating mode, and heating of the room is temporarily suspended. At the same time, 2-circuit boilers with a built-in boiler operate in two modes, where there is always heated water, but these are mainly expensive models with floor installation.

But if you need a boiler only for heating, a single-circuit one will be enough, and these are the options we will consider. Such models are on average more compact than double-circuit ones, can often be easily placed on the wall, have a generally simpler design, are less demanding, less vulnerable and, all other things being equal, are cheaper than double-circuit ones.

Power

The second key characteristic is power.

. It determines how much area of the room the boiler can handle. The larger the house, the greater the power should be. The approximate ratio is 1 kW per 1 square meter of heated room. But this is only an approximate correlation that allows you to estimate the price. To accurately select a boiler based on power, it is advisable to contact a specialist who will inspect the room, determine its features, take into account insolation and climatic factors, and make recommendations based on the data obtained.

Floor or wall

For wall installation, as a rule, models of low and medium power of no more than 30 kW are suitable. High-power options are often only floor-mounted, especially those with a built-in boiler. Our review will present mainly wall-mounted options with a power of less than 30 kW, but there will also be two examples with a power of over 40 kW, and also wall-mounted.

Burner type

Boilers are also distinguished by the type of combustion chamber

- open or closed. Open ones use room air to burn gas, and combustion products are removed naturally through a chimney and are usually not equipped with an active fan. This gives a plus in terms of price and energy independence - no connection to the power grid is required.

Boilers with a closed burner use air taken from outside, from the street, and the combustion products are removed by a built-in fan. Such boilers do not need a chimney, but they are relatively noisy, depend on electricity and are on average more expensive.

Heat exchanger type

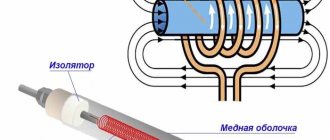

Gas boilers can use different heat exchange schemes. The simplest and most affordable option is with a bithermal heat exchanger. It is used in both single-circuit and double-circuit boilers. To complete the picture, we will inform you about both types, not only for the single-circuit circuit.

In schemes where both circuits are closed to one heat exchanger, there are no complex components, the equipment is less vulnerable and the cost of such models is lower. The downside is that the coolant (water) does not circulate in one of the circuits when the other circuit is running, but it still heats up. This contributes to the overgrowing of the heat exchanger channels with scale, which requires more frequent and responsible maintenance.

There is also an important point related to safety. If for a long time the boiler worked only for heating, and then turn on hot water, then literally boiling water may come from the tap for some time. This is the same heated coolant. You need to remember this when installing a boiler of this type.

A more advanced scheme involves the presence of two heat exchangers - the main and the secondary. The main one is located directly above the burner, and the secondary one is in another part of the boiler. The secondary heat exchanger is heated not by the flame, but by already heated water circulating through a small circuit. This approach increases the durability of the boiler, maintainability and safety of use - the water does not heat up on its own to extreme temperatures.

Heat exchanger material

The heat exchanger in the boiler is the most vulnerable part, since it bears the entire workload - thermal, mechanical and chemical (water composition, scale formation, temperature deformations). It is also the most expensive, since the efficiency of heating and the accuracy of temperature control depend on the efficiency of heat transfer. The materials used here are different, each has advantages and disadvantages:

- Cast iron

. Such heat exchangers are durable - they last for decades without burning out, are not subject to corrosion, and are heat-intensive. But they are heavy and are used only in floor-standing boilers. In addition, they are quite noticeably afraid of sudden temperature changes. - Stainless steel

. These heat exchangers are also quite strong and reliable, but they are still susceptible to corrosion at the welding points. This is the most common type, including for wall-mounted boilers. - Aluminum.

This is a good option for weather-controlled heating, as aluminum has extremely low thermal inertia. This metal is also not afraid of corrosion. - Copper.

Excellent heat transfer, low susceptibility to corrosion, but high price.

Manufacturers often indicate a certain established durability of the heat exchanger, but these data are most often conditional, and in fact this part lasts much longer without any problems. In addition, modern boilers are often equipped with additional add-ons such as weather-dependent units, all kinds of electronics and automation, which in total can significantly offset the disadvantages of one or another type of exchanger.

Condensing boilers

It’s worth saying a few words about a special type of boilers - condensing boilers. This is a relatively new technology; mainly convection-type boilers are on sale.

Condensing boilers are characterized by the highest efficiency due to the extraction of latent energy released during the condensation of water vapor. It makes sense to choose this type of boiler for a home where it is expected that there will be panel radiators or a “warm floor” system. Condensation models are significantly more expensive than convection models, but in the long run they provide significant savings and pay for themselves.

Water volume and gas consumption

Mistake #6

The greater the volume of water in the heating system, the greater the power of the gas boiler should be.

This is not true at all. The final power is affected solely by the heat loss of the building.

The volume of water affects only the speed of INITIAL warming up.

When the temperature reaches the set values, the amount of heat released from the boiler will be the same. It doesn’t matter how much water there will be in the system - 10 liters or 100 liters.

Differences between gas pipeline and liquefied gas boilers

Despite the use of one natural resource, liquefied gas boilers are very different from gas pipeline boilers:

- To convert fuel into a gaseous state, it is necessary to install special equipment (reducer); when supplying gas directly from the main line, this is not required.

- High efficiency. The efficiency of liquefied gas reaches 95-98%. Manufacturers monitor this indicator and try to increase it, since this fuel is not the cheapest, and it is necessary to use its potential to the maximum.

- Injectors.

- Lower pressure is the key difference between a liquefied gas boiler and a boiler with a gas pipeline.

Manufacturer country

Which wall-mounted gas boiler is better - Korean or European? It is between them that the struggle most often occurs in this segment.

Mistake #7

Korean boilers are more economical than European ones.

Mistake #8

European boilers are more economical than Korean ones.

All wall-mounted turbocharged boilers work approximately the same. Yes, their filling is different, but this does not affect the SAVINGS.

The efficiency of both Korean and European models is the same. Here you need to look at another parameter, namely, the availability in your city of a service for maintenance and repair of a specific brand.

Because sooner or later your boiler, no matter how reliable it is, WILL BREAK.

Based on this factor, it is worth making a choice in one direction or another. Remember a simple rule - the further you live from the service, the simpler the units you choose.

Gas tariffs in the Moscow region 2022

According to the latest data from the Committee on Prices and Tariffs of the Moscow Region dated June 20, 2018, the following tariffs for the population are established:

| p/p | Directions for gas use | Unit | Prices (including VAT) |

| 1 | Cooking and heating water using a gas stove (in the absence of other uses of gas | rub./cub. m | 6,35 |

| 2 | Cooking and heating water using a gas stove and heating water using a gas water heater in the absence of a central hot water supply (in the absence of other uses of gas) | rub./cub. m | 5,61 |

| 3 | Heating with the simultaneous use of gas in the areas specified in paragraphs 1, 2 of this Price List | rub / 1000 cubic meters m | 5 523,00 |

| 4 | Individual (apartment-by-apartment) heating of residential premises (residential buildings, apartments, rooms) in excess of the standard standard area of living premises in the absence of gas meters | rub / 1000 cubic meters m | 6 632,00 |

| 5 | Heating of non-residential premises in the absence of gas meters | rub / 1000 cubic meters m | 6 638,00 |

| 6 | Heating and (or) generation of electrical energy using boiler houses of all types and (or) other equipment that are in common shared ownership of the owners of premises in apartment buildings | rub / 1000 cubic meters m | 5 362,00 |

Notes:

- The heated area of residential premises (residential buildings, apartments, rooms) does not include the area of warm attics and basements, basements (undergrounds), cold, unheated verandas, balconies, loggias, terraces, as well as a cold attic or part thereof not occupied as an attic;

- When calculating fees for the use of natural gas in residential premises (residential buildings, apartments, rooms) not equipped with gas meters, one should be guided by the Decree of the Moscow Region Government dated November 9, 2006 No. 1047/43 “On approval of standards for natural gas consumption by the population in the absence of meters gas metering";

- In residential premises (residential buildings, apartments, rooms), in the absence of permanent residents and gas meters, payments for the use of natural gas for heating purposes are made at the prices specified in paragraph 4 of the table “Prices for natural gas sold to the public” , as well as housing maintenance organizations, organizations managing apartment buildings, housing construction cooperatives and homeowners’ associations for household needs (except for gas for tenants of non-residential premises in residential buildings)”;

- The size of the standard standard area of residential premises used when calculating payments for the use of natural gas for heating purposes is established by the Law of the Moscow Region No. 120/2009-03 “On the standard standard area of residential premises for the provision of subsidies and the provision of social support measures to certain categories of citizens for payment of housing premises and utilities in the Moscow region";

- The price for natural gas takes into account the costs of localizing emergency situations, except those that occurred through the fault of the subscriber;

- The price of natural gas does not include the cost of maintenance and repair of gas equipment in buildings and household gas-using equipment, as well as the cost of turning off and turning on household gas-using equipment;

- The price of natural gas does not include the commission charged by banks and payment systems for services for accepting payments from the public.

That is, the cost of natural gas will be about 5-6 rubles per cubic meter. Thus, it is not difficult to calculate that to heat a small cottage or country house in winter you will have to spend only a few thousand rubles a month, which is comparable to the cost of housing and communal services in an apartment. And in the summer, this expense item will be completely absent or insignificant.

How to check the manufacturer?

Mistake #9

Often, instead of a gas boiler with European components, you can easily buy a Chinese boiler.

In fact, there is nothing wrong with this, it’s just that sellers should be honest with you from the beginning, and not push purely European quality.

How can you avoid falling for this and check everything yourself? Elementary.

Type the full name of the model into Google and add two words – “CERTIFICATE OF CONFORMITY”. Download it and study it carefully.

Mistake #10

If you cannot find such a certificate at all, then it is better to immediately avoid this model.

Each product that is imported into the territory of the CIS countries must have a certificate. The “Manufacturer” column indicates exactly where the boiler was actually manufactured. Here are two certificates for a visual comparison.

See the “Products” column for the specific brand.

This applies not only to assembly, but also to components. Already, few manufacturers save only on labor at the expense of the Chinese.

Therefore, you should not believe the sellers that the boiler was only assembled with a screwdriver in China, and all its internals are European. Although, again, we repeat, in the modern world, Chinese components are not always bad.

Here, first of all, we are talking about the honesty of the seller.

AGV modifications

Considering the variety of modifications of gas water heating devices on the market, it is worth understanding how the AOGV differs from a gas boiler. Looking ahead a little, there is no fundamental difference between the devices; all the differences lie in small nuances.

If we talk in detail, then everything that distinguishes an AOGV from a boiler comes down to the following points:

- Glass thermometers have been replaced with modern Italian components;

- Honeywell products began to be used as automation elements;

- The design is supplemented with a piezo ignition device;

- The last difference between the AOGV and the boiler is that the appearance of modern modifications has been slightly improved, for which a higher quality coating has been used.

Double-circuit or single-circuit?

Mistake #11

If in addition to radiators at home there is also a heated floor, then you must definitely buy a double-circuit boiler.

Double-circuit boilers are needed only for hot water supply (DHW) - heating + separate hot water. The single-circuit device copes well with both heated floors and radiators.

All it does is simply heat the water. What kind of heating system you have doesn’t really bother him.

The main thing is to design and calculate everything correctly. In general, for normal hot water supply it is not recommended to buy a boiler with a power of less than 24 kW.

There are many copies on the Internet about double-circuit and hot water supply.

To briefly formulate the essence, it is as follows:

- one bathroom or two hot water points + all this is not far from the boiler room - your choice is a double-circuit boiler

- three or more water points - single-circuit and indirect heating boiler

Conclusion

For heating a private home, the ideal option is to install a boiler on a gas pipeline. But in some cases (for example, when you are rarely at the dacha in winter, or when the construction of a main gas pipeline is just being planned), such work is not carried out, since it takes a lot of time and money, or is not yet possible. An excellent alternative is to purchase a liquefied gas boiler. The main thing is to correctly calculate the required power and carry out installation in accordance with all standards. Then you will not have problems with leaks, and the comfortable microclimate in the house will be uninterrupted.

28.06.2017

Return to list

Condensing or traditional boiler?

Boilers are like people, some are traditional and some are not.