General characteristics and operating principle

A radiator heating element is a device that can be used as an additional or main heating device. The device consists of a cylindrical metal body. A copper spiral or steel wire is mounted in the middle of it. Internal parts have an insulating coating.

The heating element intended for radiators is equipped with a thermostat. Thanks to this, the device can be used both for heating and for temperature control.

The operating principle of such electrical appliances is quite simple:

- a tubular electric heater is installed in the battery;

- the heating element is connected to the electrical network;

- The coils are heated, causing heat to flow to the coolant.

What does a heating element for a radiator look like?

Setting the required temperature is allowed if there is a regulator in the device. When the level of the specified mode is reached, the electrical circuit opens and the heating element turns off. When the temperature drops below the set upper limit, automatic heating occurs. You can connect the heating element to almost any battery.

Types of heating elements

You can find various models of tubular electric heaters on sale. They differ in the structure of the body and the material of manufacture. Devices are also divided according to power and purpose:

- from 2.5 to 4 kilowatts - household;

- from 4 to 6 kilowatts - industrial.

There are both single heating elements and devices with two heating coils. Such devices are also made with right-hand or left-hand threads. Many models are equipped with additional options:

- Antifreeze. The function protects the heating system from possible defrosting at low temperatures. At the same time, the permissible minimum temperature is automatically maintained. During this operating mode, a completely insignificant amount of electrical energy is consumed.

- Turbo heating. This option will allow you to maximize the temperature in the room. For turbo heating to work, a thermostat is required, which makes it possible to change the heating mode.

Heating elements for radiators are produced in various lengths and with distinctive design characteristics.

Criterias of choice

When selecting a heating element for a radiator, you should take into account its technical characteristics, as well as the parameters of the battery. The main factors influencing the choice of device are:

- Power. In rooms with good thermal insulation properties, heaters from 2 to 3 kilowatts can be installed. In older buildings, it is best to use heating elements with higher power.

- Length of the electric heating tube. It is recommended to purchase heating elements ten centimeters shorter than the battery. Correct selection of the length of the heating device allows you to evenly heat all sections of the radiator.

- Battery Type. In order for the heating element to optimally fit the radiator, you should carefully study its technical data sheet. It specifies which types of batteries the product should be used with.

- Automatic control. Not all models have this option. For ease of use, it is best to purchase heating elements with automation, which are equipped with a thermostat.

The heating element should be ten centimeters shorter than the radiator.

The diameter of the electric heater is also taken into account in accordance with the cross-section of the plug on the radiator. It is important to correctly determine the placement of the thread.

It is necessary to purchase only high-quality heating elements from trusted manufacturers. Before purchasing an electrical appliance, you should check its integrity and serviceability.

Advantages and disadvantages

Tubular electric heaters contribute to uniform and complete heating of the heating system. Installing such devices has many advantages:

- safety of use;

- ease of installation;

- economical use;

- the ability to install additional options;

- reliability;

- long service life;

- relatively low price for the product.

Along with their advantages, heating elements for radiators have their disadvantages:

- When connecting a heating element, the high speed of liquid circulation in the radiator does not allow increasing the level of heat transfer. Thus, the operation of the heating system prevents uniform heating of the device.

- When using a heating element as the main heating device, the cost of electrical energy increases significantly.

Among the advantages of heating elements for radiators is their low cost.

The cost of the heating element itself is low, but when purchasing the necessary additional equipment to automate the work process, costs increase significantly. The complete set has a price several times higher than a convector operating on electricity.

The mechanism for changing the heating element in a homemade electric boiler where the heating elements are on top. Advantage

The operation of the hot boiler stops, the supply and return valves are closed. The water cools, the liquid decreases in volume, and the pressure drops. We unscrew the heating elements and take them out. We replace the burnt heating element with a new one. The loss of system coolant is minimal, practically none.

If the heating elements are located at the bottom, then you yourself understand that you will have to drain all the liquid from the vessel through the bottom tap. This is very inconvenient and you will need to add Anti-Freeze to the boiler.

Over the years of operation of a homemade boiler, the heating element rarely needs to be replaced. You select the power of the heating elements yourself. You can install a time relay to operate the heating element during low electricity tariffs.

The described homemade electric cylindrical boiler is recommended to be used as an additional one to support the heating system in country houses and cottages. And if the main one, then you need to install limit and working thermostats in it. One of them maintains the temperature at the required level, the other prevents the boiler from boiling if there is a failure in the automation.

As the main boiler, it is better to use another boiler based on the one described above, but modernized. An improved boiler is welded from three or more cylindrical pipes parallel to each other. For an average house or cottage, 3 such links are enough. Each cylinder contains a heating element. Heating elements are also inserted from above. Water drains from below. You can also change the controls in the boiler. Add a limit thermostat and instrumentation. And in this boiler you can integrate the DSM-module Xital system to turn on and off the module via SMS. This control is very convenient: when you are away, you can reduce the temperature to 5 - 7 degrees Celsius, and when you return home or to the dacha, send an SMS and increase the temperature of the boiler so that the house warms up to 16 degrees Celsius or higher when you arrive. This is very convenient for cottages and country houses. You save your resources when you are not in the building.

In general, a homemade electric boiler is completely satisfactory for those who already use it. He has proven himself on the positive side both in work and in service. If you have the desire and opportunity, you can try to make an electric boiler yourself.

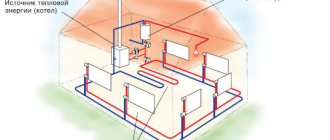

How are they used for heating radiators?

The main function of tubular-type electric heaters for radiators is to heat liquid in an autonomous or centralized heating system. The device is used as a secondary or main heat source.

As an autonomous system and the only coolant heater, heating elements are used in the following cases:

- The need to heat rooms where there is no other type of heating. This could be a workshop, garage or agricultural building. The main condition for installing a radiator electric heater is the small size of the building. It is more effective to fill batteries with oil of low viscosity, since it has a fairly low freezing point.

- Subject to periodic heating of the room. Most often, such structures are dachas with no main heating system. At the same time, the number of installed heating elements, their power must correspond to the volume of the room.

As an additional device to the main heating, a tubular electric heater can be installed:

- In multi-storey buildings. Heating elements are installed in radiators in apartments if the main heating is not particularly efficient. The device helps create and maintain the necessary indoor microclimate. But its installation requires limiting the access of water that circulates through the heating system of the entire house. In this case, the use of a heating element is completely impractical, since you end up paying twice for heating - for the operation of the electric heater and to the housing office for the use of the coolant.

- In private homes. A heating element is installed if it is not possible to regularly add firewood to a solid fuel boiler. In such a situation, the tubular heater does not allow the coolant to cool completely and the required temperature is constantly maintained in the room.

A heating element for a radiator is installed in both private and apartment buildings.

Using a heating element for gas boilers does not make sense, since such units cope well with heating due to an automated system.

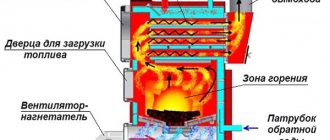

How does a boiler work with electricity or with solid fuel?

Mixed heating boilers for solid fuel and electricity operate on the principle of using a backup heat source. In practice, this means that after the coolant stops heating from burning wood, coal, etc., the electric heating element turns on, continuing to maintain the required temperature in the heating system.

A hybrid combined solid fuel boiler with electric heating, heats the coolant through a “water jacket” and has a special technological hole for installing a tubular heating element. In the basic configuration, the hole is covered with a plug. At the request of the customer, the boiler is equipped with a heating unit.

How does energy carrier switching occur?

There are two ways to switch from one type of fuel to another, differing in the degree of automation:

- Manual switching - in a solid fuel boiler with an electric heating element that uses manual switching between types of fuel, there is no thermostat or temperature sensor. In the basic configuration, almost all models of dual-fuel units have exactly this method of turning on the electric heating element. This solution is extremely inconvenient and does not solve the main problem. After the flame in the boiler has died down, the user’s personal participation will be required to turn on the heating of the coolant.

Automatic switching - as an additional option, electric solid fuel boilers for heating private houses are equipped with temperature sensors and an automatic control unit. Switching between energy carriers is carried out automatically. A sensor installed on the return line controls the heating temperature. After the solid fuel burns out, the coolant gradually cools down. When the minimum permissible heating value is reached, the sensor sends a signal to the automation, and the electric heating element turns on, continuing to heat the liquid in the water circuit until the boiler is re-flooded. After the coolant has warmed up to the required levels, the temperature sensor again sends a signal, but this time to turn off the electric heating element.

Modern universal heating boilers using solid fuel and electricity, in addition to sensors installed on the coolant return, are connected to temperature sensors located in the rooms and controlling the heating of the rooms. The automation ensures operation in several modes, including “anti-freeze”, maintaining the minimum permissible heating of the coolant, preventing it from freezing.

Is it possible to install a heating element in a HT boiler yourself?

In most modern boilers, a hole is provided in the heat exchanger for installing an electric heating element. Connecting a tubular heating element, in this case, is quite simple. The water is drained from the boiler and the heating element is installed using a special threaded connection. For sealing, use heat-resistant silicone.

If a hole is not provided in the structure, the possibility of installing a heating element depends on the design, or more precisely, the material of the heat exchanger:

- Cast iron boilers - drilling a hole for the heating element is quite problematic. During cutting or subsequent operation, cracks may occur, leading to a violation of the tightness of the structure. The damage cannot be repaired; the damaged section will need to be replaced.

Steel boilers - making a hole for installing a heating element is not difficult. In any specialized workshop, the work will be completed in a few minutes. After drilling the hole, you can install the heating element of the required power.

Installation of heating elements

Before installing the device, it is necessary to make power calculations taking into account the type of battery and the average thermal characteristics that are the norm in the given area.

Making calculations

When determining the power indicator, you can use the average value of thermal data in the Russian Federation. Thus, when installing a tubular-type electric heater as the main heating device on 10 square meters, a power of 1 kilowatt is sufficient.

For radiator heating elements that are supposed to be installed as an addition to the main heating system, it is recommended to use a power rating three times lower.

The rated power of an electric heating device can be calculated according to the formula:

Q = 0.0011*M (T1-T2)/t

In this case, M is the mass of the energy carrier, T1 is the temperature indicator after heating, T2 is the temperature value before heating and t is the time required for the maximum increase in temperature.

An important factor is the technical characteristics of the electric heater itself, as well as the heat transfer of the battery. All necessary data about the device can be read in the passport attached to it. The heat output of one section of a cast iron radiator is on average 1.40 watts, and that of aluminum is 180 watts. Therefore, the power of the heating element for the same volume of batteries made of different materials will be slightly different.

Installation

Installation of a tubular electric heater is not difficult. To do this you need:

- unscrew the battery plug on one side;

- install using threaded fasteners and rubber gaskets.

The process of connecting a tubular electric heater has some features:

- When the coolant heats up, it increases the pressure in the battery. In this regard, the installation of a small expansion tank is required. You can also equip the radiator with a valve that regulates pressure in a closed system.

- The fastening connections of the heating element are quite fragile. Therefore, when installing the device, it should be done carefully, without additional effort.

To ensure maximum efficiency of the electric heater, it is best to connect it to the bottom of the battery. This is due to the fact that the coolant, when cooling, descends, and when heated, rises to the top.

Benefits of the latest technology

Infrared film is used not only for heating window sills; it is used in systems of heated floors and baseboards. Installation of this device is simple, and no special tools or skills are required.

The heating film has the following qualities:

It heats up in a very short time: one or two minutes, and it is in the operating temperature range. It warms up efficiently, evenly, affecting the entire area. Electricity consumption is striking in its economy - 20 W. Three window sill plates - three 20 W each - the energy consumption is equal to one incandescent light bulb. Excellent aesthetic appearance. It does not damage the base at all, since it does not require either a cement screed or an adhesive solution for installation: it is applied to the surface using a dry method

This is very important: if it fails, there is no need to do “dirty” work. Replacement will require about an hour of free time

Sold in kits that include all the necessary accessories and elements for its installation: special tape, mounting wires, an insulating block, several clamps. To control such a heating system, a convenient electronic control has been created

There are both simple hand-held devices and programmable ones with an LCD display. Invisible to prying eyes. It is more convenient to measure thickness not in millimeters, but in microns.

Safety precautions and operational points

A heating element is a mains-powered heater. When using the device, it is quite important to follow some rules that will ensure safe use and significantly extend its service life:

- In order for the device to operate for a long time with full heat transfer, the scale that forms on its surface should be cleaned once every three months. If a large layer of white deposits forms, it can damage the device. The intensity of scale formation can be reduced by using distilled water as a coolant.

- Do not allow the electric heater to overheat. The temperature of the radiator in the place where the electric heater is installed should not reach seventy degrees above zero. Therefore, it is quite important to choose the correct power of the heating element.

- The heater can only be turned on in a battery filled with coolant. If water enters an already heated electrical appliance, it can lead to a thermal explosion. As a result, not only the radiator, but the entire heating system may be damaged.

- If static electricity appears on the surface of a tubular device, it must be immediately turned off and all connections and the device itself checked for leaks.

- The heater power should not be higher than the thermal rated power of the battery. A load of no more than 3.5 kilowatts is allowed in one outlet.

The temperature of the heating element for the radiator must not reach 70 degrees.

Installation of the heating element in the heating radiator is carried out only using grounding. To avoid voltage drops, it is best to connect the electric heater to the network through a stabilizing device.

Internal structure of electric heaters

It is convenient to consider the device using the example of a tubular model. An electric heater is a ceramic or metal tube filled with a thermal conductor with a spiral located inside. In the place where the tube is fixed to the flange there are insulating bushings that make it impossible for the conductive spiral to contact the heating element body.

Most models of heating elements use similar components, but their durability may vary depending on the build quality

The electric heater is mounted primarily with a flange connection, which allows the internal environment of the heating device to be sealed from the external space. The disadvantage of this design is the impossibility of replacing the spiral if it burns out internally.

Efficiency mark

A heating element for a radiator is not a heating device that can be constantly used to heat a large area. One kilowatt of electrical appliance power is converted into one kilowatt of thermal energy, which is completely used to heat the room.

When using cast iron batteries, a heating element equipped with a thermostat with a heating power of 100 Watt/m² can heat no more than 25 m² of space. Electrical energy consumption for twenty-four hours will be 36 kW/h, which approximately corresponds to 167 rubles. This takes into account the average power consumption of 1.5 kW. If the heating system is well organized, installing a tubular type electric heater does not make sense.

A heating element for a radiator is most effectively used as an emergency device. If the heating system is unstable, such a device will allow you to maintain the required level of heat in the room even in severe frosts. Installing a tubular heater makes sense if its power is correctly selected and all safety rules are observed.

Varieties

There are several types of heating elements:

Tubular devices. This device is most popular among users. Heat is transferred by convection, conduction or infrared radiation.

Copper, stainless steel, ceramics and steel are used as materials for the body. Length - from 200 to 6000 mm . The tube diameter varies from 5 to 18 mm . Power depends on the model and is 0.3-2.5 kW.

- Finned device. This is a modification of a tubular heating element. This model is distinguished by a large number of thin steel plates, which are located along the entire length of the body. Advantages: high heating rate, which ensures rapid heating of the room. The device is recommended for use in air-type heaters.

- Block model. These are several tubular devices that are fixed on the basis of a single mount. The device has high power, so it quickly heats the room. It is used in everyday life and in industrial settings. The power of the device is 5-10 kW.

- Cartridge device . They are a tube with one free ring. Case material: polished steel. Such models have high power and are used mainly in industrial facilities.