Russian stove makers mastered the technology of Dutch oven laying more than two hundred years ago. During this time, the stove has established itself as a reliable, economical and efficient heating unit. At the same time, the Dutch woman has an extremely simple design. After studying the following guide, you can post it yourself.

DIY Dutch oven

What does a Dutch oven look like and why is it so popular?

Appearance of a Dutch woman

This seemingly simple structure has many advantages:

- “Dutch” is capable of quickly heating up from the smallest portion of fuel. At the same time, its excess consumption during heating after a long period of inactivity is very small.

- The design of this furnace involves the use of a relatively small amount of material, so it is relatively light. For comparison: a large Dutch oven is built from 650 bricks, while a large Russian one is built from 2500. Moreover, the heated area for a “Dutch oven” is 60 m2, while for a Russian one it is only 45 m2. In addition, the “Dutch” design principle makes it possible to significantly reduce the original dimensions - down to 0.5x0.5 m in plan. This advantage allows you to safely place the “Dutch” on the interfloor ceiling.

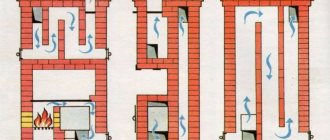

- The channel labyrinth in the body of the stove provides great resistance to reverse draft, so smoke almost never occurs when wind blows into the pipe.

- Although the Dutch oven was originally created as a purely heating oven, it can easily be equipped with a hob - the combustion mode will not be disturbed.

- The channel part of the furnace can be extended up to 2 floors (and some extend up to 4), while its efficiency will remain at the same level.

- The design features, combined with the small thickness of the walls, eliminate the development of significant temperature deformations in the masonry, so the Dutch is undemanding to the quality of materials. A good brick (fire-resistant) will only be needed to construct the firebox. The rest is sometimes even laid out from burnt or hollow bricks.

- In the duct part you can easily find an area with the optimal temperature for installing an oven or water heat exchanger.

- Irregular use does not cause any harm to the oven. At the same time, it can be heated without passing the accelerating phase - this will not cause the masonry to crack.

As you can see, the list of advantages of this stove is very impressive. But despite this, it cannot be called ideal. Here is the price at which these benefits were achieved:

- "Dutch" has a very low efficiency - within 40%. For comparison: a Russian stove absorbs more than 80% of the thermal energy contained in the fuel.

- If you hesitate even a little in closing the view after heating, the stove will immediately be chilled by cold air. It is drawn through the chimney by a channel labyrinth, which acts like a siphon.

- “Dutch” is not designed for the use of waste fuel, which burns completely in a short time. It should not be heated, for example, with reeds, straw, brushwood and similar materials: the lion's share of the heat produced will evaporate through the chimney. With maximum effect, the stove operates on long-lasting fuel (wood, coal, peat), and in smoldering mode.

- When using inexpensive fuels with high ash content, the chimney quickly becomes overgrown with soot.

If the fire is too intense, a Dutch oven can release carbon monoxide into the room.

See also our material with step-by-step instructions and ordering of a brick stove-fireplace:.

Foundation arrangement

Despite the relatively light weight for a brick oven, the Dutch oven still needs a high-quality and reliable foundation. An excellent option is a monolithic slab. An important nuance: the foundation must be reinforced both in area and in volume, i.e. deep down. The dimensions of such a foundation must be at least 1.2 x 1.2 m. The Dutch foundation cannot be connected to the base of the main building.

How to make a foundationFoundation for a brick oven

The procedure for arranging the foundation is as follows.

First step. We outline the boundaries of the foundation being developed.

Second step. We dig a pit about 60 cm deep.

Pit for casting the foundation

Third step. We fill the bottom of the pit with a 15-centimeter layer of crushed stone. Carefully level and compact the backfill.

Crushed stone

Fourth step. We lay a mesh of reinforcing bars. The recommended cell size of such a mesh is 100-120 mm.

4dcea99db3f3602135ea3504b9c812d5.jpe 7b0d81e1200f1b1fcb273b87a5c7c53b.jpe 2a7b8137d64e2e40f0cc3440dc3714d7.jpeFoundation pit with formwork and reinforcement

Fifth step. We install vertical reinforcement at the intersection of the rods. We tie all the joints of the elements of the support system with wire.

Sixth step. We install the formwork for pouring the foundation. We cover each wall of the formwork with roofing felt or treat it with resin for waterproofing.

Seventh step. We pour concrete.

Poured concrete

Eighth step. We “iron” the surface of the base. To do this, sprinkle the fill with a small amount of dry cement.

Let the foundation gain strength. It is better to leave it for a month, but many craftsmen begin laying it within a week. At this point the decision is yours.

Construction device

The design of the Dutch oven can rightfully be called simple-minded. The main feature is that the firebox communicates with the chimney not directly, but through a labyrinth of channels (that’s why stoves of this type are called duct stoves), passing through which the flue gases manage to give off more heat to the brickwork. A classic Dutch oven is shown in cross-section in the figure.

Dutch oven design diagram

No complex calculations are required when designing a “Dutch” and it is almost impossible to significantly disturb anything in it. Therefore, there is no specific order that must be strictly followed. It is enough to maintain the ratio of the main dimensions within certain limits.

The rapid heating of the furnace is due to a combination of two factors:

- the area of the internal surface of the flue has been increased (due to the installation of a channel labyrinth);

- the material consumption of the furnace has been reduced.

Note that the volume of materials used is reduced within reasonable limits - the heat capacity of the furnace is quite sufficient. However, it will not be enough for a whole day - the stove will have to be heated at least twice.

The smoke outlet channel is not directed upward, like many other stoves, but to the side, that is, the presence of a mounted pipe is not provided. This feature makes it possible to connect several stoves to one attached (main) chimney. For ancient Holland this was fundamentally important, since the tax there was levied precisely on the number of chimneys.

The arch of the firebox is not arched, but flat, which makes the stove even easier to manufacture.

This is interesting. In Russia under Peter the Great, there were frequent fires due to the burning of Russian stoves in black. Intending to prevent such incidents, the king, by a special decree, demanded that stoves be built in the Dutch manner. But stove makers often carried out the royal decree only partially, building stoves only externally similar to Dutch ones. The emphasis was on decorating with tiles, which was typical of the “Dutch”. As a result, confusion arose that continues to this day: stoves with a design that is not at all typical for them are often called “Dutch”, for example, bell-type stoves and even some varieties of Russian stoves.

Some inventors modified the Dutch oven for one purpose or another. For example, I. G. Utermark gave it a round shape.

Utermarkovka

The diagram shows a simplified smoke circulation consisting of 3 channels, but in some types of utermarks their number could reach 12. The oven is equipped with a steel casing, which makes it possible to reduce the wall thickness to ¼ brick. This has sharply reduced the cost of unmarking, which is why it has firmly established itself in the “budget” segment. But at the same time, the heat capacity has also decreased significantly - such a stove has to be fired quite often. In addition, due to the design features, it has low efficiency, smokes heavily and quickly becomes overgrown with soot.

The Dutchwoman of the Soviet inventor V. E. Grum-Grzhimailo has higher technical characteristics. Unlike the utermarking, it is equipped with a grate, and there is a cap in the firebox part. The bell-type version turned out to be very economical - in terms of efficiency it was almost equal to the Russian stove (over 80%).

Grum-Grzhimailo stove

In accordance with the needs of owners of houses in garden plots, a large Dutch oven was transformed into a small country oven, and there are several varieties of such ovens.

An example of a country Dutch oven with a hob

We will learn how to build one of them - equipped with a hob - ourselves.

A little history

There are several versions of the appearance of the Dutch woman in Russia. But they all agree on one thing - the laying of such stoves began in the 18th century, when Peter I issued a decree on the construction of stoves like the Dutch ones. The decree did not prescribe specific instructions for construction, so ordinary Russian stoves were often only lined with tiles or tiles imported from Holland. This is where its other name arose - gallanca. Some scientists are of the opinion that a stove was called a gallanka if it had a chimney structure typical of a Dutch stove.

Interesting: The tall chimney is a Dutch heritage. In order to save space, buildings in Holland were built tall. In order to avoid paying high taxes on chimneys and to heat more rooms, the Dutch began to build stoves with a chimney of several floors.

In encyclopedias, the concept of a “Dutch stove” is defined as a rectangular-shaped heating device that has a channel system of vertical smoke circulation and a side exit to a chimney lined with tiles.

Calculation of parameters

The main parameters of the stove are the heat transfer power and the dimensions of the chimney.

To calculate power, you need to know the specific calorific value of the fuel.

Table: wood calorific value indicators

| Wood | Value (kW*h/m3) | ||

| At 12% humidity | At 25% humidity | At 50% humidity | |

| Poplar | 1856 | 1448 | 636 |

| Fir | 1902 | 1484 | 652 |

| Spruce | 2088 | 1629 | 715 |

| Birch | 3016 | 2352 | 1033 |

| Oak | 3758 | 2932 | 1287 |

| Aspen | 2181 | 1701 | 747 |

During flaming combustion, a portion of fuel burns in about 1 hour, so the power of a stove operating in this mode will be:

W = Vt x Eu x 0.63 x 0.4 x 0.8, where:

- W is the heat transfer power of the furnace, kW;

- Vt—furnace volume, m3;

- 0.63 — combustion chamber load factor;

- 0.4 - furnace efficiency;

- 0.8 is a coefficient showing what part of the fuel is burned in full.

Let's assume that the furnace firebox has dimensions of 400x300x400 mm. Then, in the case of using birch logs of average humidity (25%) as fuel, we obtain the following power:

W = 0.4 x 0.3 x 0.4 x 2352 x 0.63 x 0.4 x 0.8 = 22.76 kW.

In accordance with the calculated power, the chimney cross-section is selected:

- with thermal power less than 3.5 kW: 140x140 mm;

- between 3.5 and 5.2 kW: 140x200 mm;

- between 5.2 and 7.2 kW: 140x270 mm;

- between 7.2 and 10.5 kW: 200x200 mm;

- between 10.5 and 14 kW: 200x270 mm;

- more than 14 kW: 270x270 mm.

If the chimney used has a circular cross-section (it can be made from sections of steel pipe or concrete blocks with round holes), then it must have the same area as the specified rectangular sections.

It should be noted that when operating the furnace in smoldering mode, its power ranges from 10 to 30% of that calculated for flame combustion. But the cross-section of the chimney should be selected according to maximum power.

Do-it-yourself Swedish stove with three firing modes

Swedish stoves differ from other heating and cooking stoves by the presence of a heating panel in the rear part. This brick panel has a system of gas ducts: vertical or horizontal. The smoke passing through them heats up the structure, and from it the rooms are already heated. The system turns out to be efficient and economical: the heat that went into the chimney in a traditional Russian stove is used to heat the premises. But both shield construction systems (vertical and horizontal) have disadvantages.

With a horizontal arrangement of gas ducts, the entire shield is heated evenly. But such a system requires a large number of cleaning holes and, accordingly, doors on them. Considering that furnace casting is not cheap today, these doors significantly affect the final cost.

Heating panel of a Swedish stove with horizontal and vertical flue channels

If the gas ducts in the swedish are arranged vertically, there can be only one cleaning hatch. But there is another problem: while the stove is heating, in the first channel, on the side where the hot gases from the furnace enter, the shield will be noticeably hotter than in the third - at the exit. Since the shield is usually located in two rooms, one of them will be much warmer than the other.

There is also a third type of shield device: bell-type. It combines the advantages of both systems: one cleaning window is required, the entire surface is heated evenly, and less bricks are required for construction. Moreover, with this design, the oven cools down more slowly: the warmest air stays in the tops of the hoods for a long time, and the “draft” from the doors passes only through the center.

When using the bell-type principle of constructing the shield, heat is retained longer

From all that has been said above, it follows that the most economical and effective are Swedes with shields built on the bell-type principle. They are also easier to manage: it is possible to organize “summer” and “winter” operating modes, in which only a small part of the panel is switched on (in summer) or the entire heating power is turned on: in winter. There is even a version of a Swedish stove with three combustion modes: an “autumn” mode is added, in which a little more than half of the chimney channels are involved in the smoke circulation.

Required materials and tools

The oven is lined with two types of bricks.

Firebox walls - fireclay bricks

It is yellow in color and can withstand temperatures up to 1600 degrees.

Fireclay brick

Note! Externally, fireclay bricks look like acid-resistant bricks, which is sometimes used by unscrupulous sellers. When purchasing, ask to see a certificate.

The dimensions of fireclay bricks may vary depending on the brand. Thus, ShB-8 brand brick has the same dimensions as ordinary building bricks - 250x124x65 mm. Fireclay brick grade Sh-5 is slightly reduced: 230x114x40 (65) mm.

Signs of high-quality fireclay bricks are:

- fine-grained structure;

- absence of visible pores and inclusions;

- clear ringing sound when tapped with a hammer;

- when dropped, it breaks into large pieces (low-quality ones crumble into small crumbs).

When it comes to the appearance of the brick, darker color does not always mean higher quality. It all depends on the clay deposit: it also happens that lighter fireclay bricks have better characteristics.

It should be noted that since the thermal regime of a Dutch oven is not stressful, its combustion chamber can be lined with M150 ceramic oven bricks, capable of withstanding temperatures up to 800 degrees (not to be confused with ordinary building bricks).

The walls of the firebox can be laid out of clinker bricks, which have high strength and heat resistance. It is much more affordable in cost than fireclay.

Furnace body

The remaining parts of the stove, except the firebox, can be lined with ceramic stove bricks, or with medium-quality bricks with slight cracking.

Ceramic stove brick

Use of used material is allowed.

Materials for clay mortar

Sand

You can use river sand with grains 1 mm in size, preferably angular. But if you want to get a durable stove that can last more than 10 years, you should use sand without organic impurities. Previously, only very expensive mountain sand had this quality, but today, more affordable brick sand can be used instead. It is ground fireclay or ceramic brick.

The first option is used in mortars for fireclay masonry, the second - for ceramic masonry.

Clay

Mortars for laying fireclay bricks are best prepared using white kaolin or fireclay marl. Ceramic bricks can be laid on a mortar of any ground clay with fire-resistant properties; Cambrian clay (blue or gray) and gray kaolin are considered the most suitable.

Advice. Before buying, you need to smell the clay. If you can clearly hear any smell, even a pleasant one, it means that the material contains a large amount of organic impurities and you should not purchase it: such a solution will very soon begin to crumble.

Clay varieties with medium fat content are preferred.

Tools

Among the tools, it is worth noting the order - a flat strip with a cross-section of 50x50 mm, on which marks are applied corresponding to the rows of bricks. Four rows are fixed in the corners in a strictly vertical position (nails are driven into them, which need to be inserted into the seams), after which it will be very easy to make the masonry even.

Tools

Other tools are the usual builder's kit: a hammer-pick, a trowel, a level and a plumb line.

You may also find this article useful on how to properly make a brick chimney:.

More about tiles

Glazed painted ceramics with baked-in designs (majolica) have been known since prehistoric times. Already in Sumer and pre-dynastic Egypt, highly artistic works of art were made from it.

Ancient Greek, Arabic and Turkish tiles

The ancient Greeks were the first to produce standard size majolica tiles (pictured on the left). In Byzantium, this art received further development, and from the Greeks it was adopted by the Arabs, who called the tiles rumi al-Zulaish (rumi means Greek) in the east of the Arab world, and in the west, in the Maghreb - az-zillij.

Tiled decoration in the harem

The Arabs also had contact with the Chinese, and from them they learned about the excellent qualities of white clay - kaolin. By the 8th century. the Arabic tile acquired its final form (in the middle in the figure), and by the 14th-15th centuries. Turkish tiles became widespread, on the right in Fig. Their design was softer, but still, the Koran strictly prohibited images of people and animals as idols. In both cases, cool tones, mainly blue, dominated. The sun-baked sons of the desert valued coolness above all else.

It seems surprising that Europeans learned almost nothing about tiles during the Crusades; they are not mentioned in the Book of Marco Polo. In fact, the Arabs used tiles, as a particularly refined and elegant decoration, primarily to decorate the harems of the highest nobility (see figure), where not only the damned Ferengi, but even their own access was strictly prohibited under pain of painful, shameful execution. Individual tiles, of course, fell into the hands of the “Franks,” but it was useless to talk about technology with the rude, ignorant crusaders.

Portuguese azulejo tile panel

Europeans became thoroughly acquainted with tiles on the Iberian Peninsula during the reconquista of Moorish Spain. The local Muslim rulers of the Baghdad caliphs considered their overlords no more than Benjamin Franklin and George Washington did King George and did not keep az-zillij behind seven castles; on the contrary, they traded tiles briskly, and the az-zillij masters willingly hired conscientious Christian apprentices.

The Portuguese were the first to adopt and improve the tile technique and began to create their azulejos - large artistic panels from tile fragments, see fig. higher. Courtiers of Spanish monarchs of Dutch origin in the 15th-16th centuries. became more interested in piece tiles and brought them home. The neat Dutch az-zillij, which they called kahel in the German (more precisely, Upper Dutch) manner, really liked it, and the Netherlands very soon established its own production, see next. rice. The technique remained almost the same, only the plots were taken on their own.

Dutch tiles

Kakhel, which was quickly renamed tiles here, was brought to Russia, as already mentioned, by Peter I, but mass production of world-class products was established only under Catherine II in Gzhel, using Arab-Dutch technology, on the left on the trail. rice. In the 19th century They tried to make tiles of this type in St. Petersburg (in the middle in the figure), but by that time a national school of tiles of world cultural significance had already developed (on the right in the figure), and in terms of artistic level, St. Petersburg tiles were inferior to Gzhel ones, and the enterprise was not successful. Nowadays, the old Pereburg tile is a desirable exhibit for the connoisseur collector.

Russian tiles

Preparatory work

Furnaces with a volume of up to 500 bricks can be laid without a foundation, as long as the floors in the room are strong enough (capable of bearing a load of up to 250 kg/m2). A small country Dutch oven with a hob, the construction of which we will further consider in detail, satisfies this condition.

But if the floor in the room clearly does not have the required strength, then it must be installed on a reinforced concrete foundation.

Scheme of the foundation for a heavy furnace

Its depth is usually 400–600 mm, and the edges should extend beyond the outline of the stove by at least 100 mm on each side. It is impossible to connect the structure to the foundation of the building - due to different shrinkage, distortion may occur.

After pouring the foundation, it must be ironed - sprinkled with cement.

Concrete foundation

When the concrete has matured - this takes about 1 month - it needs to be covered with two layers of waterproofing (roofing felt or roofing felt), after which it will be possible to begin building the furnace.

Foundation waterproofing

Before proceeding directly to installing the bricks in place, you need to prepare a clay-sand mortar. The correct ratio of sand and clay depends on the fat content of the latter. To determine it, proceed as follows:

- After soaking the clay for a day, stir it until it forms a dough, after which 5 portions of a solution are prepared with different sand contents: 10, 25, 50, 75 and 100% of the clay volume.

- After twisting each portion into a 30-centimeter sausage with a diameter of 10–15 mm, it is wrapped around a blank with a diameter of 40–50 mm and left to dry at room temperature for 2 weeks.

One way to determine the quality of clay

In the presence of:

- a fine network of cracks or their complete absence, the solution is considered suitable for any part of the furnace;

- large cracks, but not exceeding 2 mm in depth: the solution is suitable for furnace elements with a temperature not exceeding 300 degrees;

- For deeper cracks and breaks, the solution is considered unsuitable.

Having determined the optimal ratio of sand and clay, prepare a solution in the required volume. The clay is also soaked for a day, only after that it is further ground through a sieve. The sand is sifted and washed. The finished solution should have the consistency of sour cream.

Stage 2. Construction of the foundation

First, it is worth noting that from a structural point of view, the foundation being built should not be connected to the main foundation of the house. The further sequence of actions should be as follows.

Foundation for a brick oven

First you need to outline the outline of the future foundation

It is important that the width and depth of the base be 8-10 cm larger than the planned dimensions of the stove. At the same time, you need to check whether the foundation coincides with the location of the chimney pipe

A hole of appropriate dimensions is dug; its depth should be approximately 60 cm.

The bottom of the pit is covered with a 15-centimeter “cushion” of crushed stone. The crushed stone is carefully compacted, its surface is leveled using a mounting level.

8d842bcd869c90ef558187c4ba7d36bb.jpe

44803aff01781fa7a7abafcc9c8d1c74.jpe 183ab32f4531b623bc4a6915cb324607.jpeThen you need to build the formwork for the furnace foundation. For this you can use wood, chipboard and even thick cardboard.

Attention! If the material chosen for the construction of formwork absorbs moisture, then the inside must be lined with roofing felt (although any other waterproofing material is suitable for this). Concrete solution is mixed

To do this, dry cement is mixed with sand in a ratio of 1:3 and filled with the required amount of water. The solution is thoroughly mixed

The concrete solution is mixed. To do this, dry cement is mixed with sand in a ratio of 1:3 and filled with the required amount of water. The solution is thoroughly mixed.

The formwork must be filled with mortar and wait until it dries completely. This often takes a maximum of a week.

Step-by-step instructions with order

The oven is laid out row by row according to the order.

Layout diagram of a small Dutch oven with a hob

Particularly high demands are placed on row No. 1, since errors in its installation will lead to distortion of the entire structure. The bricks must form a perfectly regular rectangle, a sign of which is the equality of the diagonals. The top edges of all blocks must lie in a strictly horizontal plane - this is checked using a building level.

Row one

Advice. It will be easier to give row No. 1 the correct shape if, before laying it, chalk the outline of the future stove onto the waterproofing coating.

A beginner-level stove maker is advised to first lay out a row without mortar to check how well the bricks fit together. After adjustment, you can lay the blocks on the mortar.

Another trick is to start each row with corner bricks. Once they are level, it will be easier to lay the remaining blocks correctly.

In the Dutch version, the blower door is installed directly on the 1st row. The frame must first be placed in a winding of asbestos cord. It will allow the cast iron to expand freely when heated and will eliminate parasitic air suction through the gap between the frame and the brick, that is, it will act as a seal.

Oven doors

In brickwork, the door will be fixed with wire. It needs to be inserted into the box, folded in half and twisted. Next, this wire is placed in a specially cut groove in the brick (at the upper edge), bent and intertwined with the masonry.

Before continuing work, you should establish vertical guidelines along which it will be convenient to lay out the corners of the oven. This can be the order described above, or 4 nylon cords stretched plumb between nails driven into the ceiling and masonry seams.

According to the established guidelines, the corner bricks of the 2nd row are laid, and then the entire row.

Row two

Row No. 3 and some others in the order are indicated in yellow. This means that they are made of refractory bricks.

Row three

A grate measuring 300x200 mm must be laid on top of the bricks of the 3rd row.

Bricks of row No. 4 should be laid on a spoon (long end or edge). The blocks indicated in the order diagram in red are supporting for the internal partition of the chimney (see above).

One of the bricks on the back side should be laid without mortar and pulled out slightly - it will replace the cleaning door. This brick is called a knockout brick. To access the smoke exhaust duct, it will need to be removed from the masonry, and after cleaning, it will need to be replaced.

Method for cleaning a stove using a blowout brick

It is necessary to install a firebox door on the front of the 4th row. It is equipped with a seal and is fixed in exactly the same way as the blower.

Installation of the combustion door

Note. The wire securing the combustion door quickly burns out from close contact with the flame. In order not to resort to repairing this element too often, use a steel or tin strip instead of wire.

Rows No. 5 and 6 do not need comments - you just need to lay out the bricks according to the order. Just pay attention to the fact that in the 5th row the blocks are placed on the bed (flat), and in the 6th row, as in the 4th row, on a spoon.

Row six

Row No. 7 is mostly laid out on the bed, but the back wall is laid out on the spoon. In subsequent rows, bricks are laid only on the bed.

Row seven

The front bricks of row No. 8 need to block the fire door. Blocks hanging over the firebox must be cut at an angle, as shown in the diagram. Due to the presence of an inclined surface, the fire will lean back when the fire door is open. This will allow the user to admire the flames while using the Dutch oven as a fireplace.

Row No. 9 needs to be moved back slightly. This creates sufficient counterweight for the heavy cast iron firebox door when it is open.

On top of the 9th row you need to lay a mineral lining under the hob. You can use strips of asbestos, basalt or kaolin cardboard. A hob is installed on top of the lining. Installing it on a mortar is unacceptable - due to the significant difference in the coefficients of thermal expansion of cast iron and clay. An asbestos cord should be placed in the gap between the slab and the brick.

Asbestos cord

Note! Some models of cookers have stiffening ribs on the underside. In this case, grooves should be cut in the bricks into which these ribs will be recessed. If such a slab is laid without grooves, it may crack along a line running between the ribs and parallel to them.

Row No. 10 represents the source of the chimney. But we will not build the pipe itself from brick, otherwise the Dutch oven will not be able to be made light. We will install a stainless steel chimney, especially since a brick chimney under a Dutch oven, which is characterized by abundant condensation, would still have to be lined.

A valve should be installed on top of the bricks of the 11th row. Just like the doors, it should be wrapped with asbestos cord.

Gate valve installation

On the 12th row, it is necessary to make a transition from the rectangular section of the brickwork to the round section of the steel chimney. The chimney should be carefully insulated - this is a prerequisite for good draft.

Advice. If you have available funds, you can purchase a prefabricated smoke removal system - the so-called sandwich chimney. The kit contains all the necessary parts - from a tee to an umbrella, which are ideally sized and equipped with effective insulation.

The chimney is vented to the street through the ceiling and roof.

The height of its head relative to the grate must be at least 5 m. At the intersection of the ceiling and the roof, it is necessary to arrange fireproof cuts - fireproof heat-insulating gaskets are installed between the pipe and the wooden elements. The gap between the chimney and the roofing must be carefully sealed.

Note. Factory-made sandwich chimney kits include both cutting and a special apron to bridge the gap between the pipe and the roofing. Installation of the elements is not difficult, as the kit comes with detailed instructions.

If the floor in the room where the Dutch oven is built is made of wood, it must be protected with a fireproof coating near the firebox. Typically, a steel sheet with a thickness of 1.5 mm is placed on top of the asbestos lining. The dimensions of the covering must be such that it protects the floor within a radius of 1.2 m from the center of the fire door.

A steel sheet is strengthened in front of the firebox

After laying

Drying

Drying a brick heating device is one of the mandatory measures that is carried out before the active operation of the device begins. Dry the oven in two stages:

- in natural conditions. The period for this type of oven drying after completion of masonry work is approximately 6 - 8 days. At this time, all doors and valves must be open to ensure natural circulation of air flow, which, passing through the channels of the device, removes moist vapor through the chimney to the street. This ensures only drying of the surface of the masonry layers;

- forced drying. It is carried out using dry small firewood every day for a week during the warm season. In the autumn-winter season, the time for forced drying should be extended by 1 - 2 weeks.

The end of drying can be signaled by the absence of condensation products on the doors and valves of a closed device.

Finishing and cladding

The finishing of a Dutch oven can be done in different ways: covered with a layer of decorative plaster and whitewashed, faced with tiles, tiles or flat stones.

Expert opinion

Pavel Kruglov

Stove maker with 25 years of experience

In order to increase fire safety, heat-insulating material must be placed on the floor covering in front of the blower door and covered on top with sheet steel, the width of which must be at least 0.6 m.

First test firebox

When all parts of the stove and the chimney are completely dry, you need to test fire the stove.

Basic moments:

- It is better to carry out short-term ignition in the late evening, when the temperature outside is lower than inside the room. The fuel load during the first fire should be minimal. If the ignition was successful, you need to add some damp wood, which smokes more.

- If the chimney is of sufficient height and well insulated, then smoke will not penetrate into the room. If the opposite situation occurs, then you need to check the channels for inaccurate installation and damage.

- The last stage of the first combustion is the maximum heating of the unit for several hours. During this period, check whether cracks have appeared in the seams on the front surface of the device.

Large Dutch oven - how to build

All elements - valve, doors, grate - are mounted in the same way as in the version just described. But the design, of course, will be somewhat different: there is already a smoke circulation (channel labyrinth) in which the flue gases give off their heat. The order of a large Dutch oven, as well as its diagram, are shown in the figure.

Arranging a large Dutch oven

Let's dance to the stove

Materials and technology

The Dutch woman, as already mentioned, is undemanding when it comes to the quality of materials. For its laying, solid ceramic fired bricks of average quality (slightly cracked) or even used ones will be used. The solution is a medium-fat clay solution with the consistency of sour cream; Commercially available ready-made dry mixes will do. You can fold a Dutch oven if you know how to lay out a straight wall and bandage the seams. Even if it turns out unsightly, it will still heat.

Decorating a Dutch oven

It has long been customary to decorate a Dutch oven with tiles.

Examples of decorating a stove with tiles

If this method of decoration is not available, a more familiar one will do - the stove can be plastered and whitewashed.

One way or another, if the interior of the room is at all important to the owner of the stove, the Dutch oven definitely needs to be refined.

Round Dutchman's finishing

In a purely brick design, it looks stingy and uninteresting.

Features of operation

A characteristic feature of Dutch stoves is that due to the considerable length of the flue, during reheating, flue gases are not completely removed through the chimney and some of them, including poisonous carbon monoxide, can enter the room. To avoid such phenomena, during operation it is necessary to monitor the temperature in the middle of the front surface (forehead) - it should not exceed 60 degrees. This is a temperature that is tolerable for the palm, but not for the back of the hand.