The emergence of new heating systems is due to the insufficient quality of the existing ones. One of these new products, the introduction of which is becoming more widespread, is the use of systems such as gas heat generators for air heating. This is a simple and, at the same time, reliable system in which the heating of the room is quite fast (especially in comparison with existing systems). At the same time, the cost of equipment, as well as its installation and further maintenance, is relatively low. Of course, such a system is not able to work without a device that is used to heat the air masses - a gas heat generator.

The room is heated by gas heat generators

Equipment selection rules

As mentioned above, gas heat guns are presented on the market in a wide variety, which makes it possible to fully satisfy consumer demand. However, when choosing these devices, a number of problems arise. It is necessary to determine the exact power of the equipment. The difference in price between heaters of different power can be very noticeable, and therefore it is necessary to accurately determine the technical characteristics. provides you with the services of competent employees who will help you with the selection and further purchase of equipment. Our specialists will calculate the power of the installation based on the conditions of your specific facility. This will allow you to save a lot on your purchase.

Supply of Ermaf heat generators

The heat generators in the Sagrada range are produced by leading Western European suppliers of equipment for the agricultural industry. By purchasing an Ermaf heat gun, you receive evidence of its quality and safety - certificates and declarations of conformity with the CU TR.

TM Sagrada is the first importer of European equipment for the microclimate of poultry farms and livestock complexes, equipping leading farms in Russia, Kazakhstan, Belarus and other CIS countries with modern equipment at low prices.

Types of heat guns

Equipment for air heating is conventionally divided into two classes:

- Mobile;

- Stationary.

But units belonging to the first type do not always have compact dimensions. Some mobile models have quite impressive dimensions. Such devices are usually equipped with special trolleys necessary for moving the equipment.

They received the name mobile only because they are designed to operate from gas cylinders and do not require connection to the central highway. They can be installed anywhere and are designed for heating industrial premises. But cavitation heat generators of heating systems require an effective ventilation system at the site, because the heated air is removed along with the exhaust gases.

Stationary devices are designed for connection to a gas pipeline. They differ in the installation method and, depending on this, the criteria are:

- hanging;

- floor

The first ones have small dimensions, which means they take up little space. They are intended for heating private households. Suspended heat generators are easy to operate and install, quickly warm up the room, and have clear instructions for use.

Floor-standing units are more bulky devices. They are used to heat large areas. Many models of such equipment can be connected to an air duct system, which allows heat to be evenly distributed throughout all rooms.

What you need to know to make the right choice

Efficient gas-air heating can only be ensured by installing equipment that matches the parameters of the room. Important characteristics in the choice are:

- Heater type;

- Power.

In addition, for reliable operation of the device, it is necessary to ensure air flow into the room. A ventilation system is most often used for this. It is capable of not only supplying oxygen to the room, but also removing exhaust gases outside.

Review of popular models

The leader among heat guns, of course, remains the products of foreign companies and in particular US manufacturers. The device under the Master BLP 73 M brand is popular among owners of private homes and industrial facilities. It can be used not only as heating equipment, but also as a construction hair dryer.

Watch a video about the Master BLP 73 model:

An American-made heat gun consumes no more than 4 kg of liquefied gas per hour, generating up to 70 kW of energy. Its power is enough to heat a room of up to 700 m² with a capacity of about 2.3 thousand cubic meters of warm air per hour. The cost of such a device is no more than $650.

But there are also domestic models on the market that meet all regulatory requirements. One of them is the Patriot GS53 heat gun. It is capable of generating up to 50 kW of thermal power at a flow rate of up to 4.5 kg of gas per hour. This is enough to heat a room of no more than 500 m². The cost of the unit does not exceed $400.

Among the models that consume main gas, the heat generator AKOG-3-SP can be noted. This is a small device whose power is enough to heat a room with an area of 30 m², while consuming 0.3 m³ of natural gas.

The thermal convector of this brand is designed for wall mounting and can heat one functional area in a country house. The cost of this device is one of the lowest and is less than $250.

Conclusion

The use of such equipment in heating systems is considered one of the most effective and economical solutions. It is easy to use, safe and therefore can be used not only at production facilities, but also in residential premises

Conclusions and useful video on the topic

The following video will provide additional information on the topic:

Gas heat generators for heating systems are a highly efficient and economically feasible solution. Due to safety, reliability and ease of operation, the equipment can be used in residential buildings and industrial facilities.

If a gas heat generator is installed in your home, you have additional information about the advantages and disadvantages of the equipment, or you know which generator is best to purchase for heating a private home, share your experience and knowledge with readers in the comments.

Design of gas heat generators

Air heating is most effective in exhibition halls, production facilities, film studios, car washes, poultry farms, workshops, large private homes, etc.

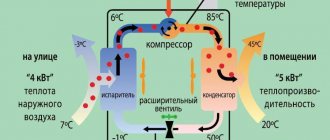

A standard gas heat generator for air heating consists of several parts that interact with each other:

- Frame. All components of the generator are hidden in it. In its lower part there is an inlet opening, and at the top there is a nozzle for already heated air.

- The combustion chamber. This is where fuel is burned, causing the coolant to heat up. It is located above the supply fan.

- Burner. The device supplies compressed oxygen to the combustion chamber. Thanks to this, the combustion process is supported.

- Fan. It distributes heated air throughout the room. It is located behind the inlet grille in the lower part of the housing.

- Metal heat exchanger. A compartment from which heated air is supplied to the outside. It is located above the combustion chamber.

- Hoods and filters. Limit the entry of flammable gases into the room.

Air is supplied to the housing via a fan. Vacuum is generated in the area of the supply grille.

An air heating device costs 3-4 times less than a “water” circuit. In addition, air options are not at risk of loss of thermal energy during transportation due to hydraulic resistance

The pressure is concentrated opposite the combustion chamber. By oxidizing liquefied or natural gas, the burner generates heat.

The energy from the combustion gas is absorbed by a metal heat exchanger. As a result, air circulation in the case becomes more difficult, its speed is lost, but the temperature rises.

Knowing the power of the heating element, you can calculate the size of the hole that will provide the necessary air flow

Without a heat exchanger, most of the energy from the combustion gas would be wasted and the burner efficiency would be lower.

Such heat exchange heats the air to 40-60°C, after which it is supplied to the room through a nozzle or socket, which is provided in the upper part of the housing.

Fuel is supplied to the combustion chamber, where during the combustion process the heat exchanger is heated, transferring thermal energy to the coolant

The environmental friendliness of the equipment, as well as its safety, make it possible to use heat generators in everyday life. Another advantage is the absence of liquid moving through pipes to convectors (batteries). The heat generated warms the air, not the water. Thanks to this, the efficiency of the device reaches 95%.

Calculation of SVO

Q = Gc (t(hor) – t(oh))

Q (h.o.) – Heating power (amount of heat in kJ/h);

G – amount of air (kg/h);

c – specific heat capacity of air in the room (varies depending on temperature);

t (hot) – hot air temperature;

t (oh) – temperature of cooled air.

Dependence of the required power of the air heater on the volume of the heated building

Nuances t (oh) - if air is taken from a heated room at a height of more than three meters, then t (oh) is considered 3-4 degrees higher than in the working area of the room.

To increase the heating power, t(hot) should be as high as possible. But there are limitations:

If air from the heating system is supplied directly to the area where a person is located, it should not be higher than 25 degrees C;

at a distance of 2 m – 45 C;

more than 3.5 m. – 70 C.

If the installation of air heating can be done independently, then it is still better to entrust the calculations to specialists.

Advantages and disadvantages of using heat generators

Air heat generators have the following advantages:

Heating systems that use air as a coolant are considered the most economical and safe. The equipment does not leak or freeze while operating at sub-zero temperatures

These advantages are provided by the absence of coolant liquid. Another important advantage is the absence of an intermediate heat carrier. Insignificant costs for purchasing fuel, maintaining the device and generating thermal energy. Several functions can be combined in one unit, for example, ventilation, heating and air conditioning. Since the efficiency of the device is very high, even a large room can be heated in 1-2 hours. The warm air leaving the unit can heat the entire room or its individual parts. Heating zones are not located around radiators or stoves. Additional advantages are the mobility of the device, quick and easy installation and dismantling. Supply grilles can be installed on walls, floors, ceilings or convenient open areas. The affordable price of heat generators is ensured by the fact that such equipment uses few metal elements. Heat generators are suitable for heating large premises, including production workshops. Simple coolant circulation. The system elements are reliably protected from corrosion and other damage.

The main disadvantages are related to the energy dependence of the system. In other words, the equipment will only work if there is a power supply. In regions where there are frequent power outages, these devices are not recommended. Another disadvantage is that the cost of air heating increases in proportion to the requirements placed on it.

Buy gas air heaters in Moscow

In the city of Moscow there are many companies that operate in the field of sales of air heating systems, providing a variety of products that vary in functionality and cost. We offer consumers interested in high-quality and economical heating of their production area to purchase modern air heaters, the price of which most closely matches their operational potential.

Sonniger is an experienced company with offices in many countries in Eastern and Central Europe. We provide premises that can provide comfortable conditions for any production workshop, warehouse, industrial facility, various sports and entertainment centers, etc.

How to choose a heat generator?

When choosing heating equipment you need to take into account a lot of details

First of all, it is important to assess the area of the heated room. The larger the building, the more powerful the heat generator should be

The heat capacity of a building is calculated using the formula:

р=V·ΔT·k/860

p is the desired heat capacity;

V - heated area (the height, length and width of the room are multiplied);

ΔT is the difference in temperature in the building and outside it;

K - thermal insulation (indicators of the material with which the building is insulated).

Indicators of the most commonly used materials:

- double layer of brick - 1-1.9 W/m°C;

- single layer of brick - 2-2.9 W/m°C;

- wooden panels or corrugated sheets - 3-4 W/m°C;

- modern heat and waterproofing - 0.6-0.9 W/m°C.

The indicator for the number of kilocalories in kilowatts is 860. Generally accepted standards - for 1 kW of heat generator power, 30 cubic meters of forced air are required.

The power of the air heater must exceed the power of the burner by at least 15%. Such equipment is reliable and effective in any situation. Its use reduces energy costs

Knowing the value of heat capacity, you can select equipment that can heat the entire area of the room.

Nuances when choosing a heat generator

Before purchasing heating equipment, you must:

- arrange a chimney to release toxic gases;

- think over a system of ventilation ducts for circulating heated air;

- Using the formula, calculate the power of the device.

Having completed all these steps, you can safely go shopping.

If there are problems with ventilation in the room, it is recommended to install a powerful floor-standing generator and synchronize its operation with ventilation that takes air directly from the street

To select a high-quality gas heat generator model, you need to pay attention to the following nuances:

- type and design of the burner - relevant if a fuel change may be required;

- warranty card and technical passport - a guarantee of the purchase of original (not defective) equipment;

- high-quality components - such equipment is more expensive, but its service life is much longer.

Taking these factors into account, the selected heat generator will last for many years.

Tips for choosing reliable equipment

By following simple recommendations you can avoid purchasing low-quality goods:

- It is better to make purchases at certified points of sale. Often, at wholesale stores and on the Internet, defective products are sold under the guise of high-quality equipment. The trap is the price halved.

- If it is not possible or you did not have time to calculate the required power of the device, then the consultants in the store will do this for you. To do this, you only need to know the area of the house, the height of the ceilings and the thickness of the walls. After making calculations, specialists will offer the optimal model for your home.

- It is recommended to purchase brands that have positive reviews on the Internet. You can also find out in advance how the equipment behaves during operation and other features.

For home use, the ideal option would be models such as Airmax D 28, Titan 25 (30, 35), Fuela, TG-7.5, Dragon 12.

Rating-review of the best models with power up to 5 kW

Low-power gas generators are characterized by low cost, compactness, mobility and ease of use.

Rating of the best models of gas generators up to 5 kW for the home based on customer reviews and ratings.

Greengear GE-5000 (5000 W)

The Greengear GE-5000 compact gas generator is an easy-to-use and reliable mobile equipment that can be used as a backup power source in a country house or in a private home.

The generator is equipped with a high-performance four-stroke GG4GN engine, which is characterized by silent and smooth operation.

Special socket covers protect contacts from dirt and moisture.

For ease of transportation there are ergonomic case handles.

Additionally, the station is equipped with a voltmeter and an hour meter to monitor the current condition of the equipment.

Specifications:

- start - electric, manual;

- number of phases - 1 (220 V);

- engine capacity - 390 cubic meters. cm;

- nominal/maximum power - 5.0/5.5 kW;

- features - muffler, overload protection, wheels, voltmeter, hour meter;

- overall dimensions - 700×500×530 mm;

- generator weight - 83 kg.

Advantages

- affordable price;

- increased engine life;

- high quality of assembly and materials;

- Ease of use.

Flaws

- high noise level;

- difficult manual start.

Gazvolt Standard 6250 Neva (5000 W)

The single-phase Gazvolt Standard 6250 Neva model is designed for outdoor use in any weather; this provides a high IP65 protection class, reliability of components and assembly.

The Neva line generator is recommended for backup power supply. The device is equipped with a G420FD engine.

Technical stops and engine maintenance are performed every 50-100 operating hours. The unit is equipped with a noise-vibration casing and a muffler.

The noise level of a running generator is 65 dB.

The station can optionally be equipped with a multifunctional automatic transfer switch (ATS), a charger for a generator without an ATS.

Specifications:

- start - electric;

- number of phases - 1 (220 V);

- engine capacity - 420 cubic meters. cm;

- nominal/maximum power - 5.0/6.0 kW;

- features - soundproof casing, muffler, overload protection;

- overall dimensions - 805x600x600 mm;

- generator weight - 120 kg.

Advantages

- low cost of fuel used;

- ease of operation and maintenance;

- high power;

- quick start.

Flaws

- noisy model;

- heavy weight;

- limited equipment.

Generac 6520 (5000 W)

The Generac 6520 household station is an ideal backup power supply option for a country house equipped with a gas heating boiler or water heater.

The equipment is equipped with a rigid stainless steel noise-insulating casing, a digital LED controller, a convenient control panel, a flexible fuel line connector and composite mounting pads.

The unit runs on natural gas or liquid propane vapor. Removable housing panels allow easy access for maintenance.

The reliable and durable Generac OHV powertrain is complemented by a protective shutdown system for low oil level and overheating.

Specifications:

- start - electric, automatic;

- number of phases - 1 (220 V);

- engine capacity - 420 cubic meters. cm;

- nominal/maximum power - 5.0/5.6 kW;

- features - soundproof casing, muffler;

- overall dimensions - 957x643x680 mm;

- generator weight - 115 kg.

Advantages

- price-quality ratio;

- excellent performance;

- the presence of a noise-absorbing casing;

- no strong vibrations.

Flaws

- poor equipment;

- heavy weight;

- impressive dimensions.

Gazvolt Standard 6250 TA SE 01 (5000 W)

The compact gas generator Gazvolt Standard 6250 TA SE 01 in an economical configuration allows you to optionally use a special kit for automatically turning off or turning on equipment at subzero temperatures.

The single-phase station has an open design on a steel frame. The noise level of a running generator does not exceed 75 dB.

420 cc engine cm develops a power of 10.9 liters. With. To connect consumers, the unit is equipped with three 220 V sockets.

The station is equipped with a digital display panel, a muffler, an overload protection system, and forced air cooling.

Specifications:

- start - electric, manual;

- number of phases - 3 (220/380 V);

- engine capacity - 420 cubic meters. cm;

- nominal/maximum power - 5.0/6.0 kW;

- Features: muffler, overload protection;

- overall dimensions - 700×530×570 mm;

- generator weight - 78 kg.

Advantages

- three-phase output;

- high power;

- high-quality assembly and materials;

- compact dimensions;

- light weight;

- economical fuel consumption.

Flaws

- noisy model;

- economy package.

What does a gas heat generator for air heating consist of?

Each of these parts of the system plays a specific and important role, namely:

- the function of a gas burner is to ignite the fuel and ensure its further combustion;

- the purpose of the air fan is to continuously supply fresh air, as well as to eject exhaust air upward from the system;

- Complete combustion of the heat source occurs in the combustion chamber. Provided that the fuel burns completely, the amount of carbon dioxide released by the system is not large;

- a heat exchanger is necessary to ensure that normal heat exchange occurs between the heat generator and the room itself, that is, it prevents overheating of the heating equipment;

- Air ducts are special channels that are necessary to remove hot air to the desired areas of the room.

Types of air heating systems

Among the heating systems known to science, three types can be distinguished:

- direct flow;

- recirculation (aka gravity);

- recirculation with partial intake of outside air.

Direct-flow systems are the most ancient and simplest in design. They were used back in Ancient Rome and were widespread in London before the start of the industrial and technological revolution.

This diagram shows the design of a direct-air heating system, which is characterized by low efficiency. Modern systems are more complex, but have significantly higher efficiencyWith a direct-flow system, the heating device, i.e., a wood-burning stove or fireplace, was located in the lower part of the house, optimally in the basement. The heat from the air heated by the stove rose upward and was transferred to the walls and ceilings.

To improve the circulation of hot air and heating efficiency, special holes were made in the floor.

The cooled air left the room through holes in the roof, and the stove (fireplace) warmed up new air masses coming from outside, since serious thermal insulation of buildings in those days was not yet developed.

The low efficiency of direct-flow systems is obvious. It requires the combustion of a large amount of fuel, but a significant part of the heat is absorbed by the material of the walls, floors and ceilings.

At the same time, the rooms are heated unevenly: it is too hot below, and the upper rooms no longer have time to warm up. Some of the heat generally left the house through the roof along with the air.

A more modern recirculation system appeared thanks to the development of gas heating. Heating equipment of this type allows you to warm up not the entire house, but only specific air masses. They form air flows that are directed from bottom to top to specific rooms.

At the same time, hot air masses displace cold air, which escapes through grates located in the floor of the room. Cold air flows through the ducts to the heater and returns to the system in the form of a hot stream. The recycling cycle repeats over and over again.

Thermal energy consumption with a recirculation heating system is several times less than when using a direct-flow scheme. But there are also disadvantages to this option. A closed system prevents air renewal, which worsens the quality of life in the house.

In a closed recirculation air heating system, air flows constantly circulate between the rooms and the heating device, giving and taking away heat

The problem can be partially solved by using tools such as filters, ionizers, humidifiers, etc. But good devices of this type are quite expensive, and their maintenance will require additional effort, as well as automation.

The problem of restoring air flows can be solved more effectively using a recirculation heating system with partial air intake from outside.

When arranging such a scheme, they provide for the partial removal of a small amount of air to the outside and the intake of the corresponding volume of air masses from the street. As a result, the composition of the air inside the building is regularly updated.

Recirculation systems operate on the gravitational principle: hot flows rise upward, and cold flows fall down. Unfortunately, not every building has such circulation efficiently enough. In this case, a fan is turned on in the system to force the recirculation process.

Advantages of air gas heating at home

Among the undeniable advantages of air heating, the most correct ones would be to highlight the following:

- This heating option is characterized by high performance and efficiency due to the fact that the air is heated not in the boiler room, but directly in the living room;

- this heating method makes it possible to completely warm up the house in just 1 - 2 hours, which is a very fast time for any heating system;

- a small amount of financial resources spent on servicing the heat generator, since the installation of these devices is not difficult, and during operation they do not require increased attention from the owners due to the fact that they are fully automated. In addition, in the case of heating at a low temperature, you can also save money on the low volume of gas consumed;

- the functionality of a gas stove is very high, since in addition to the standard heating function, it is also capable of ventilating the room and playing the role of an air conditioner;

- the probability of such a system leaking is very low due to the lack of coolant as such, as well as the pipe system;

- There will be no need for central heating, which will also reduce operating costs.

Air heating using gas is an excellent heating option in terms of economy, safety, and environmental friendliness, since all harmful substances, as already mentioned, do not accumulate at the bottom of the room, but go up.

Air heating options

An air heating system (AHS) is a heating system that does not have radiators. The heat generator heats the air directly, not the liquid. SVO in a private house are conventionally divided into:

- Gravitational.

- Forced.

Gravitational principle

Warm air from the stove rises, spreads across the ceiling and cools down at the far walls. An air circulation is created without any additional devices. This is a classic system, the predecessor of water and steam heating.

Gravity hot air distribution system

Today it is also used, only the boilers that heat the air have changed. The “Russian stove” was replaced by Buleryan, Butakov’s stove and others.

The system is good in its simplicity. It does not create noise, drafts, is economical, and reliable.

The downside is that the heat is concentrated in the room where the stove is located.

Coercive principle

The air is pumped using a fan. This could be an air cannon that mixes large volumes of air in large rooms.

Another option is that warm air is supplied to adjacent rooms through an air duct system.

After which, part of the air is returned to the system for reheating, and part is discharged outside.

With the help of a recuperator installed at the outlet, warm air heats the incoming cold stream before leaving the house. Fresh air enters 15 - 20%. A recuperator is a useful thing, but not necessary. Given the low price of fuel, it can pay for itself only after 7–10 years (The approximate cost of a recuperator in Russia is 17–27 thousand rubles)

To prevent specific odors from spreading throughout the house, air outlets to the street can be installed in the kitchen and toilet.

Comparison of natural heating systems and forced heating with recuperation

An important component of the system is the air ducts. They are made from galvanized sheets, special corrugation, etc. The insulation is a self-adhesive heat insulator. They are connected to each other with clamps or special reinforced tape. Air ducts can be:

- flexible (corrugated), or rigid;

- round or square.

Round ones have a minimum of aerodynamic drag. Diameter 10 – 20 cm.

Square ones are made in the form of boxes.

If you plan to install an air conditioner, the air ducts must be well insulated to prevent condensation from accumulating.

The principle of operation of the recuperator

Air that circulates around your home over and over again requires filtration. You can install a replaceable filter, or you can install an electronic one, which does not need replacement, but only maintenance. This pleasure will cost about 20 thousand rubles.

The efficiency of forced air heating is high - about 90 - 96%. True, most modern heating boilers have an efficiency level of 85 to 95%.

The price of this air heating system for a private house is also not an advantage, since with all the additions, the system costs almost the same as conventional water heating.

If the air intake is installed at the top of the room, the air will be cleaner (it is more polluted there); if at the bottom - fuel economy (air near the floor has cooled down).

pros

- Possibility to combine ventilation and heating (good where air conditioning is needed);

- No water - no defrosting of the system and no leaks;

- Fast heating and cooling (It’s good, for example, when there is a large difference between day and night t, but this is also a disadvantage. The door was opened and the heat evaporated).

Cons of the system

Difficulties in installation. If a house was not designed for air heating, it is often difficult to reconstruct it.

Installation of a network of corrugations and filters is required.

All this needs to be decorated decoratively, or hidden in a false ceiling, which hides the height of the rooms.

Influent reservoirs can become excellent habitats for micro-life. Dust, condensation and microorganisms accumulate there, although not very quickly, but still. Once every 5-7 years, the air ducts will need to be thoroughly cleaned and treated for mites, but this is not easy, inexpensive and unpleasant.

And don’t forget that you also need to pay for the electricity that is needed to operate the fan, and if the lights are turned off, you need a backup power source.

Air duct before and after cleaning

In addition, if you make a mistake in the calculations, you may encounter the following troubles:

- Noise;

- Drafts;

- Accumulation of hair and dust in unventilated corners;

- Variation t (head – hot, legs – cold);

- Even a well-regulated flow pattern can be disrupted by simply opening the door.

Rating-review of the best models with a power of 5-10 kW

These relatively compact gas generators are suitable for organizing backup and permanent autonomous power supply systems.

Generac 7144 (8000 W)

Equipped with a highly efficient air-cooling system, the Generac 7144 is the best choice for power backup in residential, industrial or commercial applications.

The station is equipped with a noise-proof all-weather casing and an improved two-cylinder gas engine.

The noise level during operation of the device is 60 dB. Bottled or main gas is used as fuel.

It can be started in automatic mode; this requires installing an additional automation unit.

The ergonomic arrangement of components ensures easy installation and maintenance of the generator.

Specifications:

- start - electric, automatic;

- number of phases - 1 (220 V);

- engine capacity - 530 cubic meters. cm;

- nominal/maximum power - 8.0/8.5 kW;

- features - soundproof casing, muffler, overload protection, wheels, voltmeter, hour meter;

- overall dimensions - 1228x733x635 mm;

- generator weight - 155 kg.

Advantages

- high reliability;

- decent workmanship;

- factory kit for heating the battery and oil;

- relatively quiet model;

- low fuel cost.

Flaws

- not an affordable price tag;

- heating during operation;

- non-critical vibrations.

Greengear GE-7000 (7000 W)

The gas generator for home and garden Greengear GE-7000 is equipped with an innovative Enerkit Basic carburetor with built-in first and second stage regulator, throttle valve, safety switch and power valve.

The mobile equipment is equipped with a convenient control panel. Wheels and ergonomic handles make the device easy to transport.

For the operation of the unit, special bottled gas fuel is required.

On average, one cylinder is enough for a day of continuous operation. The noise level of the existing installation is close to 78 dB.

The station is equipped with a muffler, an overload protection system, and devices for monitoring output voltage and engine hours.

Specifications:

- start - electric, manual;

- number of phases - 1 (220 V);

- engine capacity - 445 cubic meters. cm;

- nominal/maximum power - 7.0/7.5 kW;

- features - muffler, overload protection, wheels, voltmeter, hour meter;

- overall dimensions - 700×530×500 mm;

- generator weight - 89 kg.

Advantages

- stable operation at low temperatures;

- ease of operation;

- environmental Safety;

- economical fuel consumption.

Flaws

- high noise level;

- difficult manual start.

Russian Engineering Group GG6-230SV (5500 W)

The gas station Russian Engineering Group GG6-230SV, equipped with a noise-vibration casing and an effective muffler, will ensure a low level of noise produced during operation, ensuring comfortable operation of the unit in close proximity to residential buildings.

The generator is equipped with an air flow circulation system for effective engine cooling.

The basis of the power unit was the REG 432 engine with a vertical layout. The synchronous generator unit provides a stabilized voltage of 220 V.

An automatic mode is provided (optional). The oil level sensor is equipped with an automatic engine stop system.

The sound pressure level of the operating station does not exceed 66 dB.

Specifications:

- start - electric;

- number of phases - 1 (220 V);

- engine capacity - 432 cubic meters. cm;

- nominal/maximum power - 5.5/6.0 kW;

- features - muffler, overload protection, soundproof casing, brushless motor;

- overall dimensions - 660×790×560 mm;

- generator weight - 130 kg.

Advantages

- runs on methane, propane-butane, biogas;

- reliable starting at low line pressure;

- modern brushless motor;

- relatively low price.

Flaws

- high noise level;

- not the most efficient cooling;

- small guarantee.

Russian Engineering Group GG8000-A (6000 W)

The inexpensive gas electric generator Russian Engineering Group GG8000-A is a productive power station for use in country houses, construction sites and other facilities as a backup power source.

The presented model is characterized by a large reserve of engine life, a long service life, low cost of fuel and environmental friendliness.

The generator operates on both main and bottled gas.

The unit is equipped with a three-position hour meter (frequency-hours-voltage), a starting battery, a transport set of wheels and an ergonomic handle.

The brush generator is started by a manual or electric starter. The noise level of the operating device is 75 dB.

Specifications:

- start - electric, manual;

- number of phases - 1 (220 V);

- engine capacity - 440 cubic meters. cm;

- nominal/maximum power - 6.0/6.5 kW;

- features - muffler, overload protection, wheels, voltmeter, hour meter;

- overall dimensions - 740x620x550 mm;

- generator weight - 91 kg.

Advantages

- compact dimensions;

- ease of movement;

- two 220 V sockets;

- a complete set of control devices.

Flaws

- ineffective air cooling;

- not very capacious starting battery;

- wheels without turning mechanism.

How to warm up a house with air?

Air is a very effective coolant, much more convenient than water. The simplest option for such heating is a conventional fan heater. This device, consisting of a fan and a heating coil, can warm up a small room in literally a matter of minutes. Of course, for a private home you will need more serious equipment.

A gas or solid fuel boiler can be used as a heat source. An electric heater is also suitable, but this option is not considered very profitable, since electricity costs increase significantly.

An interesting and environmentally friendly heating option is the use of solar panels or a solar collector. Such systems are placed on the roof. They either directly transfer thermal energy from the sun to a heat exchanger or convert it into inexpensive electrical energy. In the latter case, the fan can also be powered from the battery.

The air is heated in a heat exchanger and supplied to individual rooms through air ducts. These are rather bulky structures made of durable metal. The cross-section of the air ducts is significantly larger than the diameter of the water heating pipe.

Gas boilers and other types of heating equipment are also suitable for air heating. The efficiency of such systems reaches 90%; they are used not only in residential premises, but also in workshops and warehousesBut radiators for air heating are not needed. Warm air simply fills the rooms through special grilles. As you know, hot gas tends to rise. Cold air will be forced downwards.

From here, cold air flows move back to the heat exchanger, heat up, enter the rooms, etc.

This diagram clearly demonstrates a recirculation-type air heating device with partial intake of outside air, as well as an air conditioner, ionizer and ultraviolet purifier

Almost all air heating systems include the installation of a fan, which blows hot air and forces it to move through the heating system. The presence of such a device makes the system dependent on electrical energy.

You can also make a system in which hot air moves naturally, without any fan. However, the efficiency of such systems usually leaves much to be desired, since the rooms in this case warm up too slowly.

A convincing argument in favor of organizing an air heating system is to eliminate emergency leaks and flooding with resulting property damage. In addition, if the air ducts are damaged, the automation will stop the system.

Ermaf heat guns with new automatic burner control ACU

SAGRADA supplies Ermaf heat generators of a new type - ACU.

The automatic burner control ACU performs the following functions:

- automatic restart after a drop in gas pressure or a drop in electricity,

- adjustable start delay,

- displaying a detailed description of the error on the control unit,

- flame current reading (ionization),

- and also provides the ability to connect additional devices (fans, external alarms, etc.).

Types of gas heat generators

Gas heaters for heating are divided into mobile and stationary. The latter, in turn, are divided into suspended and floor-mounted. At the same time, mobile units are less common because they use gas cylinders for their operation, which is not always convenient and possible to provide. That is why such devices are used only in extreme cases, for example, when the main heating in the room is turned off, and you urgently need to heat it when the temperature outside sharply drops. Also, such units are used as the main heating in regions with a short winter season.

The stationary type of heaters is used in various fields. Wall-mounted heat generators are hung on walls indoors and outdoors. Floor-standing devices, depending on the assembly features, can be horizontal or vertical. The former are more often used in low rooms, while the latter are suitable for installation in a private home or on the street. Floor-standing units are convenient to use for heating small rooms, installing them at the entrance and exit to the heated zone.

Construction of gas heat generators

A gas heat generator is a heater that heats the coolant (air) to the required temperature.

Its structure is as follows:

- The air fan is designed for uninterrupted supply of air masses and removal of exhaust air from the system. Exhaust air is exhausted upward.

- A gas burner burns fuel and heats the coolant.

- Complete combustion of the heat source occurs in the combustion chamber. If the fuel burns completely without any residue, then the volume of carbon dioxide that the system emits is small.

- The purpose of the heat exchanger is to ensure normal heat exchange between the room and the heat generator. In addition, the heat exchanger protects heating equipment from overheating.

- Air ducts are used to remove heated air into the room.

The operating principle of such heating equipment is as follows: a fan draws cold air into the device, it is heated during fuel combustion to the required temperature and discharged through air ducts into the room.

The operating process of a gas heater can be divided into the following stages:

- cold air from the street or room is drawn into the device by a fan and hits the heating element;

- since gas is constantly burned in the combustion chamber, thermal energy is released, which heats the air;

- after this, the fan supplies heated air to the heat exchanger;

- air ceilings are distributed through the air duct system through the use of air valves;

- Through the grilles, heated air is supplied to the room and gradually heats it up.

Calculation and selection of a gas generator

In order for the system to operate efficiently, the gas heater for air heating must be correctly selected

To do this, first of all you need to pay attention to the size of the heat exchanger. The dimensions of the heat holder should be 1/5 larger than the dimensions of the burner

To choose the right gas generator, you need to calculate its power. To do this, use the formula – Р=VхΔTхk/860, where:

- V in m3 indicates the heated area of the building;

- ΔT in °C is the difference in air temperature inside and outside the house;

- K is an indicator of the thermal insulation of a house (the number can be selected from a reference book);

- 860 - this number is a coefficient that allows you to convert kilocalories to kW.

The power of the device is selected in accordance with the obtained value. As a rule, the operating power of the equipment is indicated in its technical characteristics.

For uninterrupted operation of heating equipment for air heating, it is necessary to ensure a continuous supply of air to the device.

For this purpose, the ventilation system of the structure must be properly equipped. If there are problems with ventilation, then it is better to use a hanging-type device that takes air from the street. Date: September 25, 2022

Types of gas heat generators

Compared to diesel, solid fuel and universal heat generators, gas equipment for air heating is the most popular.

Devices are differentiated by size and weight:

- mobile - easy to transport;

- stationary - installed in one place.

Mobile models of gas heat generators are less popular, since their operation requires gas cylinders filled with liquefied mixtures of propane and butane. The most striking representative of portable heating equipment is a heat gun.

Most often, heat guns are used for a one-time increase in temperature at construction sites and in shopping malls. In everyday life it is used in extreme cases (turning off the heating in the house).

Stationary models of gas heat generators can be:

- wall-hung - hung on brackets built into the walls;

- floor - installed on the floor.

Wall-mounted models are used for heating small objects; their power usually does not exceed 35 kW. Floor-standing equipment is recommended for heating small areas. A number of floor-standing units include models that can be installed outside the building, i.e. on the street.

In order for atmospheric gas processing equipment to operate continuously, it is necessary to ensure a constant supply of air to the combustion chamber

Depending on the distribution of heated oxygen and the method of gas combustion, the equipment is divided into:

- horizontal;

- vertical.

For rooms with high ceilings, vertical devices are used, and for rooms with low ceilings, horizontal devices are used.