When installing a heating system, sooner or later you get to installing a boiler room. Very often in Russia and the CIS countries, wall-mounted gas boilers are installed in private homes and beyond. This is primarily due to good gasification and ease of use of such boilers in comparison with solid fuel ones.

Ideally, when installing a wall-mounted gas boiler, you need to involve a certified specialist. But what to do if a problem arises with such personnel? Let's look into this issue in detail.

Types of gas boilers

Many companies involved in the production of gas equipment offer users various types of heating boilers, the designs of which are designed exclusively for working with blue fuel. They can be used for absolutely any scale and area.

Speaking about installation types, boilers are divided into:

Floor-standing

They are characterized by such indicators as high power, durability and reliability. Their purpose is installation in buildings with an area above the average size and area. However, flagship models also have their drawbacks: the need for a separately installed and equipped room.

Wall mounted

This type of boiler is a great option for small private homes. Consequently, there is no need to build a separate room for them, and they are multifunctional models. They contain a built-in expansion tank, a circulation pump, a safety group, and sophisticated automation. Assembly and installation do not require special elevated conditions.

This type of boiler is installed everywhere and is widely used in modern apartments, dachas, houses and cottages, which is due to the provision of maximum comfortable environmental conditions and minimal effort and expense for assembly and installation. Currently, they are created using design solutions and compact resolutions. We also wrote detailed material on the topic of comparing these types of boilers.

There is also a division according to the type of combustion chambers of boilers.

Open combustion chamber

This model is prone to natural traction. One way or another, air is produced and penetrates from the interior of the room, and the combustion products themselves are discharged exclusively through the chimney. If there is insufficient ventilation, there will be a lack of oxygen. The performance of heating units with an open combustion chamber depends on the draft. It is important to install chimneys correctly and not skimp on their insulation. In this case, there is a high probability of risk of combustion products entering the interior of the room. Based on this, the price categories are much lower than average.

Closed chamber

They are characterized by forced traction. Electric fans (smoke exhausters) are installed in them, with the help of which it becomes possible to remove substances formed during the combustion process through the chimney. Air enters the chamber by sucking it through the outer, external pipe, and exiting through the internal one.

Specifics of equipping gas equipment from Baxi

The range of trade offers from Baxi SpA offered to the buyer includes floor-mounted and wall-mounted units. The first ones are purchased for autonomous heating in spacious country houses, industrial or commercial facilities. The latter are popular with owners of apartments, small dachas and small private houses.

Both wall-mounted and floor-standing models of this brand are produced with one or two heat exchangers. Each heat exchanger is designed to heat the medium of a separate circuit. Single-circuit boilers are designed to prepare coolant, double-circuit boilers serve the heating system and supply hot water to mixers.

The range of boilers from Baksi includes atmospheric and turbine units. Atmospheric models are equipped with an open combustion chamber, while turbine models are equipped with a closed one. The first ones are somewhat cheaper and easier to operate, the second ones are more expensive and more complex, but much safer, and therefore more popular among consumers.

Operation control and protection devices

Gas boilers in demand on the market are equipped with the following systems for regulating the operation of the heat generator and ensuring safety:

Protection against the formation of ice jams in a system filled with coolant or sanitary water is not turned off even when all other electrically dependent systems of the unit are disconnected from the power supply. A two-pole shut-off device allows you to leave it in working condition if the boiler is not used for some time.

In addition, the boilers are equipped with systems that provide post-circulation of the heated medium. Those. after the burner stops, the coolant will circulate around the heating circuit for another three minutes. There is a function that forces the circulation pump to periodically turn on for 10 minutes if the boiler is not used for more than a day, and many other useful innovations.

Source

Difference between closed and open chambers

The answer is quite simple and clear: in their design features, the method of oxygen absorption.

It is worth understanding that in a residential building you need to resort to an option such as a closed one, since only this will be acceptable for use in private buildings. Open spaces require a separate room.

Studying the process diagram, it can be noted that the air, which ensures normal and stable operation, is absorbed through a coaxial chimney from the external space. In the future, the already processed substances also move from the premises to the street. So there is no need for extra costs and expenses for additional ventilation devices.

It is worth resorting to purchasing an open version only for their installation in boiler rooms. Its operating principle is the absorption of oxygen from the oxygen contained in the room. Therefore, it is important that regular and stable ventilation of the building is ensured.

The main rule is to install a gas boiler completely separately from the house, which ensures safety, since the likelihood of leakage of gas and substances formed during combustion is reduced to a minimum, which is due to the non-use of air from the house. To completely eliminate the possibility of emergency situations, it is worthwhile to first undergo a thorough inspection of the pipeline for the presence of various types of distortions, scratches and damage.

Look at an example of converting a boiler room from an open boiler to a closed one:

The advantage of installing a boiler with a closed chamber

- When getting rid of the products consumed in the isothermal process, a reverse reaction occurs - cooling, which dramatically increases the safety and reliability of such boilers.

- The room equipped for this device does not overheat and is protected from various and numerous air pollutants, since combustion occurs only on the street, that is, not within the house.

- High efficiency

- Air enters the room, the pressure increases, as a result of which its temperature increases. Thus, the closed chamber is environmentally friendly and clean.

There are also disadvantages:

An installed gas boiler with a closed chamber will not be able to operate without electricity. But as soon as electricity appears, all work starts automatically.

Recommendations for reducing operating costs

If all operational settings are made in accordance with the tabular data given by the manufacturer, then the equipment will consume energy very economically, generating the necessary heat in the volume required by the owners.

To do this you should:

- For systems with radiators or thermosiphons, select the temperature of the coolant at the boiler outlet +60ºС. It is worth increasing it only if, during operation of the unit, comfortable heat in the room was not obtained.

- Adjust temperature conditions in accordance with the manufacturer’s instructions and the purpose of the room. To heat bedrooms and other rarely visited rooms, the heating temperature can be set below average.

- Do not exceed the temperature background recommended by the manufacturers of the heating devices included in the circuit.

- Use indoor and outdoor temperature sensors that record temperature increases/decrease. The thermostat connected to them will independently start/stop the boiler as needed.

- Adjust the temperature of the coolant by the hour using a timer. At night, for example, it can be lowered by 3-5 ºС.

It should be remembered that by increasing the temperature in the room being treated by just 1º, we immediately increase costs by approximately 6%.

In order not to constantly change the coolant temperature settings during the difficult autumn-spring period, it is better to install an outdoor temperature sensor. If you don’t find a suitable model or don’t have the funds to buy the original, you can build a homemade device like this:

Image gallery

Photo from

Stage 1: Assembling a homemade street sensor

Stage 2: Drilling the Wall to Externally

Stage 3: Adjusting the coolant according to the outside temperature

Step 4: Attaching the outdoor temperature sensor

In case of prolonged absence, it is better to disconnect the boiler from the power supply, but you should not turn off the frost protection system. It is turned off only for the summer period, during which the heating function is abandoned, completely turning off the single-circuit model and switching to the dual-circuit version for the supply of hot water.

In order to save on heating, you should not cover radiators with screens and heavy curtains. They will disrupt normal air circulation and force the boiler to work at full capacity for no apparent reason.

Also, the equipment manufacturer does not recommend micro-ventilation in rooms, keeping the transoms constantly ajar. It is better to open the window wide and ventilate in one gulp than to artificially lower the readings of the room temperature sensor for a long time. It has been proven in practice that it is more economical.

When using the water preparation function, it is better to initially select a temperature that is comfortable for use, without counting on mixing heated and cold water in the mixer. Believe me, thanks to this solution, the thermal energy generated by the generator will not be wasted. In addition, limescale will not settle on the inner walls.

Requirements for a boiler room with a gas boiler

Much depends on the performance of the boiler: if it reaches more than 30 kilowatts, then there is a need for a separate room. It is on the basis of the provisions of the 'Building Codes and Rules' that specific instructions are built and created for the arrangement of a boiler house specialized in heating for the combustion of products.

- It is possible to place a boiler room in attics, basements, that is, in special rooms of houses. But it is worth considering that a cleared corridor and sufficient illumination are required.

- The installed volume is at least 14 square meters, taking into account a power of 30-60 kilowatts and above 15 square meters intended for boilers of higher productivity.

- Comfortable and unhindered access to the device.

- Covering the walls with non-flammable material.

- Providing a ventilation process with three times the amount of air exchange.

What to do if there is a sudden power cut?

UPS for gas boiler Baxi

Many people install generators to protect themselves and their expensive equipment. Of course, this is a good solution. But there is a much simpler and less expensive solution to the issue.

All that is required is to install a five percent Stihl thyristor stabilizer with a power of 1.2 kW and SmartUps 1000. Next, we replace the 24-volt internal battery installed in the uninterruptible power supply with two 12V car batteries, each of which has a capacity of 75 A/ h. We connect the batteries to each other in series. As a result, we get an additional energy reserve of 150A/h.

Note that when the fan, circulation pump and boiler are operating at full power, the battery charge will be enough for approximately 11–12 hours of operation, which is quite enough for the emergency situation to be resolved.

Three options for installing a gas boiler

When installing a wall-mounted gas boiler in a private home, you have three options:

1. You contact the company yourself and order the service of installing a gas boiler at home. The company’s employees not only install the boiler, but also provide post-warranty service, and also place the boiler for servicing. 2. If you do not have the opportunity to order boiler service and installation directly from the company, you will order a specialist to install the boiler. Then the company that sold you the boiler itself sends a service department. It carries out commissioning work and also supplies equipment for service. 3. If you live in a rural area and there are no service centers nearby, then you can do the installation yourself, following the instructions. Moreover, instructions for installing a wall-mounted gas boiler in a private house should be exclusively from the manufacturer. You also need to consider your heating system when installing.

How to properly install a wall-mounted boiler

Before installation, unpack the heat generator and check the completeness of the device. Make sure the stock fasteners will fit your walls. For example, special fastenings are required for aerated concrete; ordinary dowels are not suitable.

We follow the following order of work:

Important point. When installing a wall-mounted boiler in a wooden house, the wall should be protected from fire, these are the requirements of the standards. Between the rear panel of the unit and the combustible structure, a sheet of roofing steel is attached, protruding 100 mm beyond the body, as shown in the photo.

When marking holes in a wooden log wall, make sure that the fastening is on the crest of the log. Screw the hooks directly into the wood, without plastic plugs.

Possibility of installing a gas boiler with your own hands

In short, installation of a gas boiler in a private house is possible for everyone. Follow the installation diagram and installation rules and everything will work properly. But the exception is the input, which must be carried out by gas service specialists. Also, boiler testing is carried out only by a specialized company, since they have certificates and licenses for this.

However, it would be safer to rely on the qualified employees of a professional company. After all, only they will be able to carry out the necessary work with excellent accuracy and competence and provide the necessary safety during operation of the equipment.

Connecting the boiler to communications

The Baksi boiler unit is placed in a non-residential area, for example, in the kitchen, subject to reliable supply ventilation providing 3-hour air exchange.

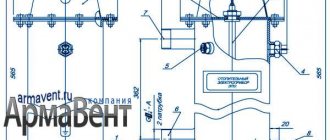

The heating circuit is connected to the supply/return pipes located on the rear panel of the device according to the accepted wiring diagram.

Next, the boiler chimney system is connected:

Next, connect the internal elements to the Baxi boiler control module:

Gas boiler installation steps

Chimney hole

Before installing the pipe under the chimney, it is necessary to create a hole with the exact size (usually 120 mm) and place a specific protective and sealing apron, onto which the chimney is connected.

Boiler installation

The boiler package usually includes, first of all, the boiler itself and the operating instructions, a warranty service coupon, a mounting strip, and an installation diagram.

First of all, you need to decide on the installation location of the boiler. In European countries, boilers are usually installed in the kitchen. They do not violate harmony and fit into almost every kitchen interior. The equipment operates quietly.

You can mount a wall-mounted gas boiler in a basement or basement. In this case, certain standards must be observed. The boiler must be installed by at least two people, even if it is not too heavy. A distance of at least 30 cm must be provided on all sides of the boiler. Regarding the height of the boiler: it is important that the control panel is located depending on the height of the owner.

Important! Keep the control panel out of reach of children. You should not place the boiler obviously high above the floor, because in case of repair or service work it will be inconvenient for specialists and they will have to use a stepladder or stool .

Next, we take the installation template (it is attached to the boiler), which is developed for several types of boilers. Using the template, you can mark the pipe outlets, chimney and fastenings and then install a wall-mounted gas boiler without any problems. In Europe, during the construction of a house, pipes are laid in accordance with a pre-selected gas boiler.

Chimney installation

The coaxial chimney has a diameter of about 100 mm, but the hole is made with a diameter of 120 mm or more. The play is necessary so that the chimney is directed towards the street at an angle of approximately 5 degrees. Condensation that forms during operation must be drained outside. After installing the chimney, the hole can be foamed with foam. A coaxial pipe consists of two pipes. A pipe with a diameter of 60 mm removes combustion products, and air from the atmosphere is sucked into the space between 60 and 100 mm. This is why the walls of the pipe are slightly warm.

The mounting bolts have plastic dowels. They can be used for various walls.

Connecting pipes to the boiler

There are two options for connecting hot and cold water supply pipes, as well as the heating system. The first is that the pipes are supplied during the construction or renovation phase, taking into account the boiler you choose. However, it may be necessary to install a wall-mounted gas boiler if a heating system already exists.

The supply pipeline is connected to the boiler supply, return to return. When installing a double-circuit boiler, it is necessary to connect a cold water supply circuit to the boiler. Connect the hot pipeline to the remaining connection and install it in the hot water supply riser.

Do not forget to install a dirt filter on the return, a check valve on the supply, as well as ball valves on each connection.

A dirt filter is necessary to prevent large debris from entering the boiler. A check valve is needed to protect against sudden pressure of coolant into the supply. The taps will be useful when servicing the boiler.

As you understand, there is nothing complicated in installing a wall-mounted gas boiler and you can do the installation yourself.

Gas connection

This action can only be performed by a gas service employee. He will install a pipe for you in accordance with the design, and the gas hose from the pipe to the boiler is installed independently.

It is advisable to use cardboard spacers. Rubber gaskets can tear when clamped, which is very unsafe. Today, paronite cardboard gaskets are in high demand.

Electrical installation

Produced for boilers with modern automation and for models with a closed combustion chamber, as they are equipped with electronic devices. Usually limited to supplying electricity closer to the boiler and installing a plug to the boiler wire. Don't forget about phase dependence. If suddenly the boiler does not turn on, try simply turning the plug over and plugging it in again.

Sockets and other connections must be located at a distance from the boiler so that in the event of an emergency, splashes do not get on the electrical wiring. The gas hose must have a yellow metal braid. It is necessary to prevent a breakdown of the hose in the event of lightning or overvoltage.

In order to ensure the safe operation of a gas boiler, it is better to install a network voltage stabilizer.

Starting a gas boiler

After the wall-mounted gas boiler is installed, it must be filled with coolant. If the system is new, the pressure should be approximately 1.8 bar. When you first start, set the temperature at 45-50 degrees. Modern boilers quickly accelerate the system. Try to increase the temperature gradually to avoid temperature shock. If the boiler power is 24 kilowatts, then this is enough to heat a house of 300 square meters. meters if the house is well insulated. Try not to buy boilers of lower power, because even if the area of the house is approximately 160 square meters. meters, but it is poorly insulated, then even 24 kilowatts may not be enough. It should also be taken into account that gas has different calorie content.

Nuances of operation

The boiler is very functional; after the temperature mode is set on the operating display, the device will work automatically, with virtually no human intervention.

During operation, you need to pay attention to the absence of noise and vibration, the sufficient temperature in the supply line, the absence of gas contamination in the room and the operation of the heating radiators.

Baksi boilers have an excellent diagnostic system, which will automatically determine the reasons for the unsatisfactory operation of the boiler and, if necessary, stop it. An error code will be displayed on the display for the user so that he can troubleshoot the problem.

For Baxi boilers that are under warranty, independent repairs are carried out only in the case of visible and easily removable causes.

Possible malfunctions of Baksi boilers:

System clogging and cleaning

The most common malfunction of a Baksi boiler is a sharp jump in the temperature of the water in the heating circuit at the outlet of the device.

The cause of such a failure is a violation of water circulation in the boiler for the following reasons:

In the latter case, you will need to clean the heat exchanger. To do this, drain the water from the boiler by opening the drain valve on the unit on the right. If possible, drain the water from the heating circuit.

To clean the internal heat exchanger, use the “Jel” device. First, connect the pipes of this device to the Baksi pipes. Remove the cover on the device and pour cleaning liquid into it. Usually its composition is indicated by the manufacturer in the factory instructions.

Turn on the “Zhel” in the power supply for a couple of hours, switching from time to time the direction of movement of the flushing liquid “forward - backward”. Next, disconnect the device and restore the heat supply circuit.

This cleaning of the boiler unit removes all deposits from the internal heating surface of the Baxi Main boiler, thereby preventing the system from breaking down.

Installation cost

When contacting gas boiler installation specialists, many clients are interested in the cost of the work. It is important to understand that pricing policies may differ in different regions.

A comprehensive boiler connection with a hole and start-up starts from 5,000 rubles. This amount will be asked from you provided that there is no additional work. If the heating system is made of metal pipes, then the cost of installing wall-mounted gas boilers will be higher. Around 6000-8000 rubles.

Also budget 3000-4000 rubles for the purchase of materials (hose, pipes, taps, fittings, etc.)

Only competent people who have access to this type of work can install a gas boiler. Even if the boiler is installed by company specialists, you need to know its operating system. The boiler itself is as safe as possible in operation as it has many degrees of protection.

Baxi heating system wiring diagrams

Despite the fact that the manufacturer has taken care to provide the user with all the necessary documentation for connecting the boiler to the heating system, in order to maintain warranty obligations, it is not recommended to do this yourself; you need to invite a service department, which will be recommended in the store when purchasing the unit.

This will allow not only to maintain the warranty on the equipment, but also to resolve future issues with the city gas inspection, which will have to give permission to operate gas equipment.

Thus, the user’s task will be to select the desired strapping pattern. It will depend on the installed heating circuit. According to existing heat supply schemes, it can be:

How to hide communications

The design of a kitchen with a gas boiler involves not only masking the heater itself, but also the pipe, hose and chimney. During repair work, under no circumstances should they be walled up in the walls. All parts of the gas boiler must be easily accessible and at hand. Communications just need to be decorated in the right colors. They are hidden in special boxes and profiles with doors that can be easily opened if desired. If the kitchen interior is done in high-tech style, then all communications can be left open and visible. It is enough just to tint some in the desired colors.

Pipes and gas meter inside the kitchen module

The pipes in this kitchen fit well into the loft interior, and the column is simply covered with a decorative panel

Features of choosing and installing doors

If the boiler is installed in an extension or one of the rooms of the house (including the basement), then the door to the boiler room from the house must be fireproof. That is, the structure must withstand at least 15 minutes of exposure to open fire - this will allow people to evacuate in the event of a fire. Fireproof doors must be made of metal and open towards the living space.

External doors in the boiler room of a private house (free-standing or in an extension) must be unreinforced (weakly reinforced). This will allow the blast wave to blow the door outside - the energy of the explosion will be directed to the street, and not to the internal walls of the house. In addition, gas will escape through the torn doors.

The door for the boiler room also serves as one of the ventilation elements - the leaf with a grille in the lower part ensures air flow into the room. The use of such a design may be a mandatory requirement of the boiler room installation project.

Installation of hood and ventilation

Safety precautions require that supply ventilation be provided to the room where the boiler is installed.

Everything is quite easy if we are talking about a device with a closed combustion chamber (and the majority of them are now). By installing a coaxial chimney pipe, the owner receives two in one: both the flow of fresh air directly into the boiler and the removal of exhaust gases.

If the hood is mounted on the roof, it is usually made in the same block with the flue, but the latter must be a meter higher.

Gas workers will periodically check the pipeline for cleanliness and draft. Cleaning hatches and condensate receivers must be provided.

Normative documents

Gas equipment

Before making a final decision to install rather expensive equipment, you need to carefully study the official documents. These are standards that regulate the use of gas boilers by the population.

They have the general name “Building Norms and Rules” (SNiP) and contain general rules and specific, clear requirements for those wishing to equip home boiler rooms.

The main specialized SNiPs, where you can find all the information of interest, are collected in the table:

| SNiP number | Name | Regulate |

| 31-02-2001 | Single-apartment residential houses | Operating and safety requirements |

| 41-01-2003 | Heating, ventilation and air conditioning | Installation and use of heating systems |

| 21-01-97* | Fire safety of buildings and structures | Fire protection rules for premises |

| 42-01-2002 | Gas distribution systems | Design of gas distribution networks |

Infrared ceiling heater with thermostat - modern technologies in your home (Prices) + Reviews

Is a window needed in the boiler room of a private house according to the standards of the Republic of Belarus?

The need and size of a window in the boiler room of a private house are regulated by clause 21.12 of Amendment No. 7 to the above sanitary norms and rules (SNiP) of the Republic of Belarus.

In a room with installed gas boilers, for ventilation it is imperative to provide an opening window facing the outside (to the street) with a minimum area of 0.25 m2.

Important! For heating boilers with a coaxial chimney and a closed combustion chamber, the presence of a window in the combustion room is not necessary. The coaxial chimney pipe for a gas boiler is made according to the “pipe-in-pipe” principle

The double-circuit design allows you to forcibly remove combustion products and suck the required amount of atmospheric air into the closed combustion chamber of the heating apparatus from the street

The coaxial chimney pipe for a gas boiler is made according to the “pipe-in-pipe” principle. The double-circuit design allows you to forcefully remove combustion products and suck the required amount of atmospheric air into the closed combustion chamber of the heating apparatus from the street.

You will learn further about how to correctly design the entrances to a private boiler room.

Chimney installation standards ↑

The material for the chimney is selected depending on the fuel being burned and the type of boiler. For a gas boiler, the pipes must be cylindrical and made of metal, preferably stainless steel. Such chimneys are the safest, most durable and reliable.

The chimney is installed above the ridge of the house. A hatch for cleaning the chimney must be installed. In order to ensure convenient collection of soot during cleaning, collection and removal of condensate, an empty space under the chimney inlet is necessary.

Gas boiler chimney diagram

When installing a chimney, there should be no more than three elbows and turns. The pipe connecting the boiler and the chimney should be as short as possible, no more than 25 cm.

The vertical section at the boiler outlet must be equal to at least two diameters. Beyond this vertical section, the pipe of the connecting section must necessarily rise upward with a slope towards the boiler.

Smoke removal in this case is carried out due to natural draft through the chimney.

Following all the requirements and rules for installing gas boilers will ensure their efficient operation, durability and fire safety.

Boiler power calculation

When the type of heating unit is selected, you should decide on its power. If desired, you can order a thermal engineering calculation that allows you to determine heat loss in the premises. Based on this figure, they begin to select the boiler power.

You don’t have to make calculations, but use the standards obtained experimentally, according to which 1 kW of boiler power is required for 10 “squares” of area. To this result should be added a reserve of productivity for various losses.

For example, to supply heat to an apartment with an area of 60 square meters, you need a 6 kW device. If you plan to heat the water, add 50% and get 9 kW of power, and in case of abnormally cold weather another 20-30%. The final result is 12 kW.

But this is a calculation for central Russia. If the settlement is located to the north, the productivity of the unit should be further increased. The specific value depends on the degree of insulation of the house. For a panel or brick high-rise building this will be 50% or more.

The process of obtaining permission related to whether it is possible to install a gas boiler in an apartment is quite complex, costly and time-consuming. But all the effort is worth it, since it is much better to live at a comfortable indoor temperature. At the same time, you will have to pay less for individual heating than for centralized heating.