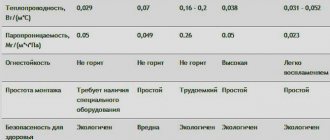

Expanded polystyrene and polystyrene foam are undoubtedly very similar to each other and have a number of similar properties and characteristics. At least, in the manufacture of both building materials, polystyrene is used as a starting material. From this material, depending on the reagents and technologies used in production, polystyrene foam or polystyrene foam is obtained. They are both popular in the market. But what is better - polystyrene foam or penoplex for insulating a house, you need to decide after considering all the characteristics of these materials.

Popular mistakes and misconceptions

Widespread errors and numerous misconceptions in the evaluation of expanded polystyrene foam do not allow us to correctly consider the characteristics of these materials and correctly determine the scope of their application:

- the insusceptibility of both insulation materials to combustion is a common myth. Of course, heavily foamed insulation burns much better, which is due to the presence of a large amount of air in the structure, but so-called self-extinguishing polystyrene foams, well impregnated with fire retardant, are also produced. Such a self-extinguishing material practically does not burn, but smokes heavily, releasing toxic materials;

- It is generally accepted that both materials have a unique, incomparable, very low thermal conductivity. As practice shows, penoplex has better, but not at all unique, thermal conductivity, for example, compared to the fairly popular and “light” mineral wool;

- the statement that they are practically eternal materials is considered practically true. However, it must be remembered that the molecular structure of any polystyrene foam is strongly damaged by many factors, such as heat, air, sunlight and radiation;

- expanded polystyrene practically does not absorb water and tolerates about fifty cycles of freezing and thawing, but even very high-quality polystyrene foam is less breathable, which must be taken into account when choosing the scope of application;

- both types of insulation are often used for the purpose of sound insulation, which is absolutely wrong. Such materials are completely incapable of blocking noise, so sound penetrates unhindered.

Wall insulation elements

As practice shows, high-quality polystyrenes and any products made from such materials are safe if they are manufactured in accordance with technological requirements and do not contain harmful impurities.

Before purchasing one of these insulation materials, you must make sure that the material is not impregnated with toxic fire retardants, which are dangerous to human health and cannot be used in residential premises.

For internal partitions

To insulate internal walls, you can use polystyrene foam or penoplex. Cheap foam blocks are easy to install, so they are mainly used for insulating walls in offices or technical rooms.

The extruder material is stronger and is most often used for thermal insulation of partitions in residential buildings:

- more durable, energy efficient, so the purchase is justified;

- good air and moisture resistance eliminates the need to install additional steam protection between partitions and insulating sheets;

- Good sound insulation is provided by panels with a thickness of at least 3 cm.

Both types of insulation are suitable for insulating a balcony. If the loggia is large, you can use inexpensive foam plastic with a thickness of 5-10 cm. For small balconies, foam plastic with a thickness of 2-3 cm is preferable, which allows you to save the deficit of usable space. Products made from foam granules and extruded ones can be combined, which makes it possible to more effectively insulate a room.

Photo: insulating a balcony with penoplex

Properties of materials

Advantages of penoplex.

Both materials can be easily set on fire. However, lighter polystyrene foam belongs to the category of normally flammable materials (G3), and dense foam plastic belongs to the category of highly flammable building materials (G4). Manufacturers eliminate the inherent disadvantage of plastics by treating polystyrene foam with fire retardants, which makes them more resistant to fire. But the result of treatment with fire retardants was a deterioration in the environmental performance of the materials: they became self-extinguishing and began to release toxic substances into the atmosphere.

Foam plastic and penoplex are considered almost eternal materials. Their manufacturers emphasize this, but the statement about an unlimited resource can only be partly true, since expanded polystyrene foams are sensitive to such factors as environmental influences. They themselves need protection from ultraviolet radiation, temperature changes, air chemistry, etc. Therefore, it should be noted that penoplex or foam plastic can show their effectiveness only after they are covered with other materials. By the way, sufficient insulation from external influences is provided by a layer of plaster applied to polystyrene foam.

Advantages of polystyrene foam.

An important factor that allows the material to be used when insulating surfaces located in an environment with high humidity is the high moisture resistance of penoplex. Mineral wool, which is superior to this polystyrene foam in terms of noise and heat insulation, is completely unsuitable for laying on a plinth or foundation. Due to its properties, penoplex is practically airtight. In contrast, polystyrene foam cannot serve as a reliable barrier to free air circulation.

Having examined the characteristics that foam plastic and penoplex have, we can conclude that the differences between both materials lie in the degree of their strength, moisture resistance and breathability. The main differences between one material and another can be listed in a short list. Penoplex:

- more dense, which worsens the thermal insulation properties;

- moisture resistant;

- more flammable without special treatment;

- less environmentally friendly (as a result of treatment with fire retardants).

At the same time, polystyrene foam:

- less dense;

- retains heat better due to its friability;

- because of it, it protects less well from moisture;

- does not isolate from noise;

- effective only when covered with denser materials.

In other respects, both are approximately equal. Expanded polystyrene is easy to transport, process, and install. Builders must take all these circumstances into account before finding the most suitable application for materials.

Ease of installation

When choosing polystyrene foam and expanded polystyrene, it is recommended to pay attention to one feature of the appearance of the slab of the second candidate. The side surfaces have L, S-shaped protrusions. This results:

- to the formation of a continuous layer of insulation without the formation of cracks and gaps;

- obtaining a more rigid and time-stable thermal insulation field;

- increasing installation speed.

Polystyrene foam has smooth side surfaces, which leads to the need for additional work on the insulated surface. This is expressed by filling the joints with adhesives or polyurethane foam.

The technologies for installing the slabs and the materials used for fastening are identical.

Penoplex and polystyrene foam: what is the difference?

Production

Both materials are made from polystyrene, but the production process is completely different:

When polystyrene granules are treated with steam, their volume increases almost fifty times and they stick together. The result is an airy material with micropores and voids between the granules.

If they are pressed well, then the density of such foam is high, and accordingly, the quality characteristics increase. Another name for the material is expanded polystyrene.

Manufactured by extrusion. Under conditions of high temperature and high pressure, a material appears that has a very uniform, dense structure with good consistency. The material is otherwise called extruded polystyrene foam.

Penoplex is much denser than polystyrene foam; accordingly, it weighs more, so it can withstand greater loads.

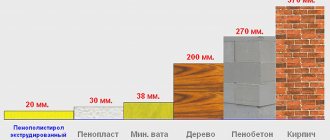

Thermal conductivity

Since the foam granules foamed during the production process do not fit too tightly to each other, its properties as a heat insulator are much lower than those of penoplex.

The latter has much smaller pores, since the material is much more compressed.

For an equal degree of protection from the cold, you will have to purchase 25 percent more polystyrene foam than polystyrene foam.

Moisture permeability and vapor permeability

Penoplex is more moisture resistant. Its degree of water absorption is approximately 0.35 percent, versus two percent for polystyrene foam. Although foam granules do not absorb water, it is quite capable of penetrating into the spaces between them. As a result, the foam may become slightly saturated with a small amount of moisture. Polystyrene foam is more vapor permeable than penoplex insulation, in which this indicator is reduced to almost zero. In principle, both materials have an extremely low degree of vapor permeability.

Strength

Polystyrene foam is more fragile because it consists of small particles that are connected to each other; it crumbles easily due to a small force.

Penoplex is almost six times stronger and is extremely difficult to break. In addition, polystyrene foam is afraid of kinks, it breaks, its analogue bends much better. If we compare the indicators of materials in terms of compressive strength, then they are incomparably higher for foam plastic.

Service life and processing capability

Both of these thermal insulators are durable, however, penoplex has a longer service life. Over time, the foam begins to crumble. But in order for both materials to serve for a long time, they must be protected from direct sunlight, as well as from other atmospheric influences.

Both polystyrene foam and polystyrene foam can be cut with a regular knife, although polystyrene foam must be cut much more carefully, it can break because it is fragile. This is especially true for three-centimeter sheets.

Polystyrene foam is much cheaper than polystyrene foam, this must be taken into account if the cost part of your project is of great importance. For example, one cubic meter of polystyrene foam is more than one and a half times cheaper than its competitor, for this reason, when constructing buildings, the first option is often chosen: the cost of housing is significantly reduced

For example, one cubic meter of polystyrene foam is more than one and a half times cheaper than its competitor, for this reason, when constructing buildings, the first option is often chosen: the cost of housing is significantly reduced.

Advantages and disadvantages

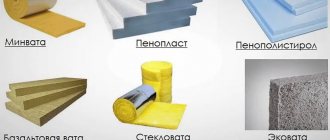

Now it’s worth considering what the advantages of one and the other materials are. After all, each of them was invented for a reason and is in demand among consumers.

Styrofoam

The main positive qualities of polystyrene foam include:

- Using it as wall insulation both inside and outside the building.

- Its relatively low price is why it is in demand among consumers.

- The material is quite moisture resistant.

- Has little weight.

- Easy to use and install. In addition, it is easy to cut using a knife or other cutting object.

- Good insulation for foundations.

- Polystyrene foam can be cut at various angles, and any shapes can be cut out of it.

- The material can be painted and plastered.

Polystyrene foam is a good insulation material for foundations.

The disadvantages of the material include:

- The thickness of the material used should not exceed 3 cm.

- To better attach the material to the wall, it must be perforated, for example, with a needle roller.

- It is necessary to take care of the fireproof coating for the material.

- When installing foam sheets, it must be completely coated with glue.

- When leveling the sheet, it is necessary to use a moisture-proof putty.

It can be seen that the material has both positive and negative sides. Therefore, before purchasing, you need to weigh the pros and cons so as not to get into trouble.

Expanded polystyrene

Its main advantages are:

- It does not transmit heat well, meaning it remains indoors.

- It does not allow moisture to pass through well, which means that even if the material is exposed to rain for several hours, it will remain dry.

- Despite its artificial origin, it allows the house or any other structure to breathe.

- Not subject to rotting.

- Not affected by fungus.

- Durable. Can last about 50 years.

- The material is good to use as a sound insulator. Because it has a homogeneous structure that muffles and absorbs sounds.

The disadvantages of this material include:

- Price. This material is not the cheapest. This is why many consumers buy polystyrene foam.

- This material is destroyed under the influence of certain solvents.

- Expanded polystyrene is susceptible to destruction by rodents. It is quite easy for them to build passages and houses in the material.

- Just like polystyrene foam, polystyrene foam is a flammable material. Therefore, it is necessary to take care of safety. Cover it with a special solution.

It can be seen that the positive aspects of expanded polystyrene are quite attractive, in some cases even better than those of polystyrene foam. However, the main and sometimes decisive disadvantage is the high price of the material.

Properties of expanded polystyrene

This thermal insulation material has been known in Europe for more than 50 years. Its popularity is explained by the presence of closed pores, where the use of freon is not expected, as well as low cost of production. You can purchase extruded polystyrene foam at any building materials store. Despite its low cost, it has high thermal insulation efficiency.

Polystyrene foam consists of air bubbles, frozen foam. This is where the name Expanded Polystyrene comes from.

The differences lie in a completely new production method and a more modern material base.

The original foam is not permeable to steam, but it can absorb moisture up to 4%. Expanded polystyrene practically does not absorb water due to its density. But the improved waterproofing properties do not prevent this material from breathing. This happens due to the molding method; extruded polystyrene foam Penoplex is molded by cutting. The strength of this insulation is much higher due to the production method using extruders. The molecular bonds in this material are several times higher than in simple foam.

The fire safety of Penoplex is due to the addition of fire retardants to it. These are special substances that prevent the material from catching fire. Like any polymer, foam will burn if it can be set on fire. This is prevented by high resistance to sunburn. Its biological stability is also high. Molds cannot live on polymers.

It is necessary to take into account a number of properties that polystyrene foam cannot provide:

- Low noise absorption ability. The rigid cells of insulated air act as resonators rather than sound dampers.

- Expanded polystyrene is not resistant to aggressive environments. He is afraid of acetone, varnishes, drying oil and turpentine. But it does not react with bitumen, soap and mineral fertilizers.

- In the heat, the foam oxidizes. While it is impossible to carry out complete polymerization of the components in production, harmful substances will be released when exposed to high temperatures.

No moisture needed

When choosing between expanded polystyrene foam and extruded polystyrene foam, one cannot ignore such a characteristic as water absorption. It is important when using them as a thermal insulator for buried foundations, linear road construction facilities, and runways.

EPS absorbs 10 times less moisture than polystyrene foam.

The presence of water in the pores of the material negatively affects its heat-holding capacity.

Expanded polystyrene can be used as a watercraft - it is so waterproof

The difference in the internal structure of the candidates under consideration affects the numerical indicators. Expanded polystyrene differs from ordinary polystyrene foam in the minimal distances between styrene granules. Quantitative superiority belongs undividedly to polystyrene foam made by extrusion. It absorbs 10 times less moisture than polystyrene foam.

What is insulated with foam plastic

EPS is the warmest.

The internal structure of the foam does not allow steam to pass through well, so condensation forms inside the room

Polystyrene foam is not suitable for internal insulation because it is not capable of convecting air and has low vapor permeability. This can lead to the fact that heat stops flowing to the desired surface, and the dew point moves inside the structure. This is the best and most cost-effective option for external insulation. Scope of application:

- roofing and attic structures;

- foundations, especially strip type;

- loggias and balconies;

- industrial and agricultural premises;

- cooling units.

Mineral wool slabs retain sound waves, but the denser the material, the greater the sound permeability

It is advisable to use mineral wool in cases where polystyrene foam cannot be used. It is chosen for insulating houses and structures made of wood, since foam plastic cannot allow air and moisture to pass through, causing damage to the structure. Mineral wool works most effectively in rooms exposed to high temperatures.

When it is necessary to insulate warehouses or structures for storing flammable or combustible substances, mineral wool insulation is an excellent choice. The material is also suitable for those who want to create good sound insulation in the room in addition to thermal insulation. It practically does not allow sounds to pass through due to its composition and dense texture.

We invite you to familiarize yourself with: Do-it-yourself stone stove for a bathhouse

Quite often, polystyrene foam is used where there is high humidity. Polystyrene foam is used for many tasks:

- Even when in contact with wet soil, the foam will not lose its characteristics. This allows the material to be used for insulating foundations. After many decades, the insulation will have the same characteristics as during installation. The foundation with such insulation is reliable and durable.

- If the house is being built on a monolithic foundation, using polystyrene foam is quite beneficial. The insulation boards are laid on a flat area. They are filled with concrete on top.

- To prevent freezing of the foundation, it is better to lay the insulation both horizontally and vertically. Lay the slabs along the base. Afterwards, they need to be covered with a layer of waterproofing. This method of insulation allows you to reliably protect the foundation of the house from frost.

- If the walls of the house are made of foam blocks or bricks, insulating them with foam plastic is the optimal solution.

- Expanded polystyrene is often used when it is necessary to insulate non-ventilated roofs. Waterproofing is laid on top. Cold ventilated roofs use a different thermal insulation method. In this case, space for ventilation must be left. This allows you to get rid of condensation.

- Floors are often insulated with polystyrene foam. It is necessary to lay insulating material under the slabs. The insulation slabs are poured with concrete on top.

Such areas of application of polystyrene foam indicate its reliability and efficiency. The material has gained popularity not only in the construction industry, but also among craft lovers.

Produced from the same thing, but in different ways

Let's start comparing insulation with production technology. Made from the same source material, they are produced using different technologies. What is the difference?

When producing polystyrene foam, polystyrene foam is fired with steam, which causes an increase in the volume of gases in the styrene granules. Subsequently, the use of an adhesive composition and high temperature leads to the formation of a finished insulation board.

The extrusion material is passed in a heated melt under pressure through a small hole into a pre-prepared mold. After the mass has cooled, the finished product is removed from the mold. Extrusion allows you to obtain a heat insulator that is more dense in its structure.

Selection of material by area of use

Quite often, modern developers wonder what is better - penoplex or polystyrene foam for insulation. To solve this problem, it is necessary to decide on which part of the building the material will be installed. For example, for a façade it is best to choose polystyrene foam, since it is cheaper and can allow air to pass through. This choice will reduce the cost of vapor barrier, because the wall will not lose its ability to breathe. For internal insulation of a house, it is best not to use such materials, although they themselves are environmentally friendly, they can be impregnated with special solutions. The latter emit toxic substances during operation.

If you are thinking about what is the best way to insulate a house - polystyrene foam/penoplex - then the latter option is better to choose for loggias or balconies. It has lower thermal conductivity and does not reduce the internal space as much. But if you have a flat roof and need to insulate it, both options are suitable. The ceiling can also be thermally insulated with any material of your choice. However, this decision is justified if you do not plan to walk through the attic afterwards. Otherwise, it is best to choose penoplex. Both materials are suitable for floor insulation, but it is better to make the rough surface using joists.

It can be more expensive, or it can be cheaper

An important indicator is the cost per square meter of insulation. The higher the price, the longer the payback period for the costs incurred with the same result.

More complex technology for the production of expanded polystyrene inevitably leads to a significant increase in the cost of the final product.

A differentiated approach to choosing a heat insulator will help you avoid unnecessary expenses. To insulate horizontal surfaces and buried foundations loaded with screeds, use polystyrene foam. For walls and other surfaces, purchase polystyrene foam. Use it when insulating a house with installation under siding. This approach will give an economic effect if the necessary heat saving parameters are observed.

Properties of materials

Advantages of penoplex.

Both materials can be easily set on fire. However, lighter polystyrene foam belongs to the category of normally flammable materials (G3), and dense foam plastic belongs to the category of highly flammable building materials (G4). Manufacturers eliminate the inherent disadvantage of plastics by treating polystyrene foam with fire retardants, which makes them more resistant to fire. But the result of treatment with fire retardants was a deterioration in the environmental performance of the materials: they became self-extinguishing and began to release toxic substances into the atmosphere.

Foam plastic and penoplex are considered almost eternal materials. Their manufacturers emphasize this, but the statement about an unlimited resource can only be partly true, since expanded polystyrene foams are sensitive to such factors as environmental influences. They themselves need protection from ultraviolet radiation, temperature changes, air chemistry, etc. Therefore, it should be noted that penoplex or foam plastic can show their effectiveness only after they are covered with other materials. By the way, sufficient insulation from external influences is provided by a layer of plaster applied to polystyrene foam.

Advantages of polystyrene foam.

An important factor that allows the material to be used when insulating surfaces located in an environment with high humidity is the high moisture resistance of penoplex. Mineral wool, which is superior to this polystyrene foam in terms of noise and heat insulation, is completely unsuitable for laying on a plinth or foundation. Due to its properties, penoplex is practically airtight. In contrast, polystyrene foam cannot serve as a reliable barrier to free air circulation.

Having examined the characteristics that foam plastic and penoplex have, we can conclude that the differences between both materials lie in the degree of their strength, moisture resistance and breathability. The main differences between one material and another can be listed in a short list. Penoplex:

- more dense, which worsens the thermal insulation properties,

- moisture resistant,

- more flammable without special treatment,

- less environmentally friendly (as a result of treatment with fire retardants).

At the same time, polystyrene foam:

- less dense

- retains heat better due to its friability,

- because of it, it protects against moisture worse,

- does not isolate from noise,

- effective only when covered with denser materials.

In other respects, both are approximately equal. Expanded polystyrene is easy to transport, process, and install. Builders must take all these circumstances into account before finding the most suitable application for materials.

Useful and harmful properties

Those who use penoplex or expanded polystyrene for thermal insulation are interested in the question of possible harm to human health. If the production technology is followed, the materials become safe. There is no need to use personal protective equipment during installation. If the service life of expanded polystyrene is exceeded, the foam may begin to decompose with the release of harmful substances, such as styrene, ammonia, benzene, which can negatively affect others. The real threat is the use of low-quality material. In Moscow and other large cities there are a large number of offers of insulation materials. To avoid mistakes, you should carefully study the accompanying documentation, consumer reviews, and price compliance.

Working with polystyrene foam is convenient and easy. Processing of materials is simple; even an inexperienced person can cope with insulation.

It is important to note that polystyrene foam and penoplex are susceptible to fire. As a result of smoldering, insulation materials release harmful substances that are dangerous to humans. Manufacturers are working to reduce the level of flammability through additional processing and adding antiprenes to the composition of materials.

The beneficial properties of insulation are obvious - a warm house with a comfortable atmosphere inside. Penoplex and polystyrene retain heat well and provide sound insulation. At the same time, working with them is convenient and simple. Processing of materials is simple; even an inexperienced person can cope with insulation.

What to look for when choosing

Extruded polystyrene foam Penoplex is produced in the form of slabs of various markings - Penoplex 35, 31, 31С, 45С, 45, 75. Moreover, recently the marking of slabs 35, 31, 31С has been replaced by new types:

- 35 (without fire retardants) - Penoplex-Foundation;

- 35 — Penoplex-Roof;

- 31 - Penoplex-Wall;

- 31C - Penoplex-Comfort.

The average consumer is unlikely to be interested in super-dense slabs marked 45C, 45, 75 to solve pressing insulation problems.

Plates with increased strength are used for thermal insulation of load-bearing structures of buildings and structures, road surfaces, for loaded structures and airfield runways. The thickness of the slabs is 40, 50, 60, 80 and 100 mm, and the size is 600 by 2400 mm.

Therefore, the question of choosing between the materials expanded polystyrene and penoplex 45 or 75 is raised only on an industrial scale.

An ordinary buyer, as a rule, needs to choose one of two options - expanded polystyrene or penoplex 35? Or, in light of the latest innovations from the penoplex manufacturer - Penoplex-Foundation, Penoplex-Roof, Penoplex-Wall and Penoplex-Comfort.

The new labeling of thermal insulation boards speaks for itself here. Extruded polystyrene foam or Penoplex 35 is divided by the manufacturer into two types - without the use of special treatment to reduce flammability for Penoplex-Foundation and with impregnation with fire retardants for Penoplex-Roofing.

Expanded polystyrene Penoplex-Comfort is the most versatile brand of material. The slabs are used for thermal insulation of balconies and loggias, roofs, walls, plinths, foundations and floors, as well as insulation of garages and outbuildings.

The almost complete waterproofness of the slabs makes it possible to use them for thermal insulation of bathhouses, saunas and swimming pools with high levels of humidity. The thickness of the slabs is 20, 30, 40, 50, 60, 80 and 100 mm, and the size is 600 by 1200 mm.

Prices

The production of both expanded polystyrene and penoplex is quite cheap. What is their retail price?

The price of extruded polystyrene foam and penoplex with the most minimal parameters (density, thickness, quantity per package) starts from 1000 rubles, respectively. and 1200 rub. per package. Conclusion - the brand name of various manufacturers also matters when choosing and purchasing insulation.

Penoplex turned out to be the most expensive insulation among all brands of extruded polystyrene foam. And with an increase in the characteristics of heat-insulating boards of different brands, the price correspondingly increases further - up to 3,000 rubles. and 4200 rub.

The cost of expanded polystyrene (foam) also depends on the physical characteristics and manufacturer and is in the range of 1000 - 3000 rubles. per package. The price of penoplex and expanded polystyrene on the building materials market is slightly different in favor of the latter.

The small price difference between expanded polystyrene and penoplex is most likely due to the more complex manufacturing technology of penoplex. or maybe the seller’s trade markup is too high.

Features of foam insulation

Important parameters:

- Thermal conductivity of the material: 0.04 W/m;

- Operating temperatures: -40/+700С;

- Compression density of polystyrene foam: 7-9 t/m2;

- Moisture absorption: 2.1%;

- Service life: up to 30 years;

- Flammability: G4;

- Practical slab thickness during operation: ≥ 10 cm.

Other characteristics are indicated in the tables above.

Characteristics of foam plastic

Your choice of good insulation

When the question arises about choosing insulation for a home, an ignorant person, when searching for options, comes across many discrepancies. Commercial offers on the Internet are replete with different terms. Polystyrene foam, as the general name for many insulation materials, is widely used in advertising by many suppliers. Let's take a closer look - Penoplex or expanded polystyrene?

The technology of combining the mixing of molten polymer components with the injection of a steam generator into it, called direct carbonation extrusion, was developed in the United States half a century ago. The development of technology, the development of new, more modern extruders, and the use of improved materials and components have led to the fact that extruded polystyrene foam is produced in several countries. Penoplex is produced in Russia from general-purpose polystyrene using a foaming agent based on light freons with an admixture of carbon dioxide. These freons are ozone-safe, non-flammable and non-toxic.

Penoplex is the most popular type of extruded polystyrene. Penoplex is available in the form of special mats. It has many advantages, of which it is worth highlighting moisture resistance and the ability to retain its original properties even under adverse external influences. This material is widely used as a good thermal insulator for foundations and roofs, as well as for finishing wall surfaces.

The brands of Penoplex produced differ in their intended purpose. The characteristics of each brand correspond to certain production standards and meet a specific purpose of use. Below is a comparison of the properties of the two most popular brands of Penoplex.

| № p/p | Characteristics of properties | Unit | Penoplex brand | |

| 35 | 50 | |||

| 1. | Density | Kg/m3 | 29,5 – 38,5 | 38,6 — 50 |

| 2. | Compressive strength | MPa | 0,25 | 0,5 |

| 3. | Static bending strength | MPa | 0,4-0,9 | 0,4-0,7 |

| 4. | Thermal conductivity coefficient (at 25 C°) | 0,028 | 0,03 | |

| 5. | Operating temperature range | С° | — 50 +75 |

Briefly, these brands can be characterized by their purpose.

Penoplex 35

Penoplex 35 is produced for use in construction, including housing. The main goal is thermal insulation of buildings and structures. During production, a fire retardant is introduced into it to increase resistance to fire.

The uniqueness of these additives is that when burning Penoplex 35 emits only CO2 and CO gases, similar to burning wood, which shows its high environmental safety. The size of the produced slabs is also dictated by ease of use in construction. Width 600 mm, length 1200 mm. The thickness of the slabs varies from 23 mm to 100 mm with a gradation of 20 mm. For insulation of foundations, this brand can be produced without fire retardant additives in order to reduce the cost.

Penoplex 50

Penoplex 50 is characterized by increased compressive and bending strength. This brand is used for thermal insulation of road surfaces, runways, and railways. Can be used for insulation of building foundations and basement floors, as well as existing roofs. It is in this brand that qualities such as resistance to wetting and operational durability are most in demand. Environmental requirements are lower; the requirements for density and strength of the material come to the fore. This brand is more often advertised under its production name expanded polystyrene Penoplex 45, which can withstand loads of up to 50 tons per 1 m2.

General information

It is possible to compare which of these products works better for insulation only after their performance characteristics have been studied. What does the marking of PSB or PSB-S material mean:

- PS – foamed polystyrene;

- B – non-pressed production;

- C – self-extinguishing non-combustible material;

- The numbers in the marking indicate density and resistance to mechanical loads.

| Characteristics | PSB-S-15 | PSB-S-25 | PSB-S-35 | PSB-S-50 |

| Density, kg/m3 | ≤ 15 | 15,1-25 | 25,1-35 | ≥ 35,1 |

| Compressive strength at 10% deformation, ≥ MPa | 0,041 | 0,032 | 0,15 | 0,15 |

| Bending strength, MPa | 0,065 | 0,17 | 0,21 | 0,32 |

| Thermal conductivity at 250C +/- 50C, ≤ W (m•K) | 0,042 | 0,042 | 0,032 | 0,032 |

| Burning time, ≤ seconds | 4,01 | 4,01 | 4,01 | 4,01 |

| Humidity, ≤ | 12,15% | 12,15% | 12,15% | 12,15% |

| Moisture absorption per day, ≤ | 4,15% | 3,1% | 2,2% | 2,3% |

Brief characteristics of foam in slabs Foam is made from artificial substances, causing them to react to the addition of gaseous fillers and foaming agents.

The gas bubbles formed as a result of this reaction expand during the production process, turning into foam balls of light weight and high thermal insulation. These balls are then pressed or fused into slabs of varying densities and used in construction and renovation. Thus, insulating a frame house with penoplex is considered one of the most effective and cheapest insulation methods. Penoplex is a variant of polystyrene foam with much better characteristics. Penoplex is also called extruded polystyrene foam, since it is produced by melting or extrusion in special equipment - an extruder (high-pressure thermal oven). In the extruder, the balls are fused into a molded blank, which is a cooled and hard foam, similar to construction foam after hardening.

How to attach foam boards to external or internal walls

Many people are still arguing which foam plastic is better for insulating a house from the outside - penoplex or regular foam, since each of these materials has its own advantages and disadvantages inherent only to them. Penoplex is a fairly durable material that is resistant to mechanical damage. It is better to use polystyrene foam for intermediate insulation, since this rather soft insulation must be additionally protected from shock and mechanical pressure.

Types, characteristics, properties

Penoplex is available in several categories:

- Comfort. For insulation of walls, balconies, loggias.

- Foundation.

- Pitched roof.

- Wall.

Types and purpose of Penoplex insulation

As you can see, the manufacturer clearly delineates the areas of application of the material. With the general technology, they differ in density. The densest ones are for the foundation and floor, since they must withstand considerable loads for a long time. The manufacturer claims that the service life of Penoplex Foundation is up to 50 years.

Design differences

Some of the types of Penoplex have structural differences:

- Penoplex Wall slabs have a rough surface; stripes are applied to the surface of the slab using a router. All this improves adhesion to the wall and/or finishing materials.

- Penoplex Comfort is distinguished by an L-shaped edge, which during installation guarantees the absence of through seams.

- Penoplex Roofing has a U-shaped edge, which increases the reliability of the connection.

Can be distinguished by external signs

This is what concerns external differences. Next, consider the technical characteristics

First, let's pay attention to what is common to all types, then to what distinguishes them

General characteristics

Since the production technology of all types of Penoplex is similar, they have many of the same characteristics:

- Water absorption is very low: when immersed in water for a day, no more than 0.4% of the volume;

- when immersed for 28 days, 0.5% of the volume.

As you can see, according to temperature indicators, any type of Penoplex can be used in any part of the country - from the south to the north. Moreover, if you leave it to “winter” unprotected, nothing will happen to the material. This is not the merit of Penoplex, but a general property of extruded polystyrene foam.

What distinguishes different types

The manufacturer divided the types of Penoplex into areas of use. Their properties are optimal for a specific application. For example, the increased density of EPS required for a screed will not be needed when installing it on a plinth. Taking into account the fact that the price differs significantly, it makes no sense to use the “Foundation” brand for other purposes. But the difference in locks, with other characteristics being equal, can be neglected. This is about ease of installation.

Although this is also important

| Parameter | Comfort | Foundation | Roof | Wall |

| Density | from 20 kg/m3 | 27-35 kg/m3 | 26-34 kg/m3 | from 20 kg/m3 |

| Elastic modulus | 15 MPa | 17 MPa | 17 MPa | 15 MPa |

| Thickness | 20, 30, 40, 50, 100 mm | 50, 100 mm | 100 mm | 50 mm |

| Static bending strength | 0.25 MPa | 0.4 MPa | 0.4 MPa | 0.25 MPa |

As can be seen from the table, Penoplex for foundations and roofs is denser, stronger, and better able to withstand bending loads. Designed for walls and the “Comfort” brand are less durable, since their area of application does not require resistance to mechanical stress.

Difference in functional properties based on thermal conductivity

What is better to use for insulation - polystyrene foam or polystyrene foam?

Analyzing the capabilities of the materials under consideration, one can note their differences.

The main characteristic of insulation is thermal conductivity.

As it decreases, the efficiency of the material increases and it becomes thinner.

- thermal conductivity figure for polystyrene foam – 0.028 W/μ;

- foam plastic - 0.039 W/μ.

Considering these indicators, it is clear that polystyrene foam exceeds the characteristics of polystyrene foam, and not only it, but in general other existing insulation materials.

The following facts can confirm this:

By mechanical strength

We must not forget that polystyrene foam is a good monolith, and in polystyrene foam the particles are soldered together. This significantly affects the strength of materials.

Expanded polystyrene is resistant to fractures from 0.4 to 1 MPa, its compressive strength is 0.25-0.5 MPa, and polystyrene foam has a standard within the limits of 0.07-0.2 MPa and 0.05-0.2 MPa, respectively .

It is well known that polystyrene foam, when subjected to serious mechanical stress, begins to fragment into small balls and breaks. Expanded polystyrene can withstand heavy loads and temperature changes.

The density of extruded polystyrene foam varies from 30 to 45 kg/m3, and that of polystyrene foam varies between 15-35 kg.

According to the ability to absorb water

This is one of the significant characteristics of thermal insulation materials, and this property should be minimized. As it picks up moisture, the insulation will lose its most important features, swell and, on top of everything else, begin to rot and collapse.

Expanded polystyrene, which has a cellular composition, has zero moisture absorption. By immersing it completely and for a long time in water, you will notice that the absorption of liquid can be up to 0.2% of its volume.

For polystyrene foam, which has a different composition, this characteristic is significantly lower. By immersing it in water for 24 hours, you will notice that the material has absorbed 2% of the volume; in 30 days it will absorb 4%.

So which is better: polystyrene foam or polystyrene foam? All of the above once again proves the advantages of the second material in terms of hydrophobicity, especially if it is used to insulate such parts of the building as the ground floor, foundation and facade.

According to fire resistance

Flammability is an important component when it is necessary to insulate objects with wooden structures - attics, roofs. It should be noted that both materials are classified as groups with increased combustion ability. For more information about the differences between materials, watch this video:

The manufacturer began to add fire retardant to the composition of polystyrene foam and expanded polystyrene - with its help, insulation materials self-extinguish. If there is no direct contact with fire, the materials will go out in a matter of seconds.

By susceptibility to shrinkage

The main disadvantage of any insulation is shrinkage. With this phenomenon, cracks occur that reduce the effectiveness of the process.

When heated, polystyrene foam tends to shrink, so it is not recommended to use it in a “warm floor” system.

If polystyrene foam is used to insulate the facade, it must be covered with white plaster, which protects against ultraviolet rays.

Expanded polystyrene almost does not shrink during use.

According to temperature range

The temperature balance acceptable for working with both materials is from – 50 to + 75 degrees.

If you exceed these values, the material begins to deform.

Polystyrene foam ignites at a temperature of 310 degrees, polystyrene foam - at 450 degrees.

Environmentally friendly

These materials contain absolutely no harmful components, such as freon and phenol. After time, insulation materials do not begin to emit harmful substances; they can be confidently used to insulate public buildings and residential buildings.

By service life

Studies have shown that penoplex, which is installed correctly, can last up to 50 years, maintaining its shape perfectly.

If the financial capabilities of the consumer do not reach its purchase, polystyrene foam can be used. It is, of course, inferior to polystyrene foam in technical characteristics, but will be the best material among cheap insulation materials. For more information about the properties of polystyrene foam, watch this video:

If we take into account all of the above, then the answer to the question: polystyrene foam or polystyrene foam, which is better, is a completely justified answer: of course, extruded polystyrene foam is a step higher than polystyrene foam in all respects.

How to untangle small knots

- This method is suitable in cases where the hair is not severely damaged and there are no complex (large) knots on the hair.

- To begin manipulation, choose a comfortable place with good lighting. The treatment is performed on dry hair, so there is no need to wet the curls.

- Take the tangle in your hand so that it is clearly visible. Start taking out one hair at a time, gradually stretching each of them to its full length. Your movements should be carried out from the tips to the roots, that is, from bottom to top.

- If you don’t have the time or patience for such activities, use a wide-tooth comb. Do not process the knot itself, carry out normal combing from the tips to the root area.

- In this case, with a comb you risk tearing the hairs. To prevent this, use special sprays or gels that make combing easier. They are marked accordingly; the products do not require rinsing.

Date: September 25, 2022