The most popular building materials for insulating buildings are polystyrene foam and penoplex. They have many identical characteristics: light weight, ease of processing. But, nevertheless, they have certain differences. Therefore, it is necessary to figure out what is better for insulation: polystyrene foam or penoplex?

Foam plastic or penoplex - which is better?

Until recently, rooms were insulated with polystyrene foam. But over time, a new, more modern penoplex appeared, which has different properties than its predecessor, although the same raw materials are used for their manufacture. This article is aimed at determining the capabilities of these materials, their fundamental differences from each other, and helping to make the right choice.

Production of foam plastic and penoplex

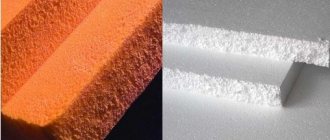

Polystyrene is used to make these insulation materials, but their production itself is different. Thus, during the production of polystyrene foam, polystyrene granules are treated with steam, and therefore their volume increases 50 times. When gluing together, the output is a rather airy raw material, in which there are micropores and voids between the granules. To achieve high density, the granules must be well compressed to improve the quality of the material. Polystyrene foam is often called expanded polystyrene.

Foam production

To create penoplex, the extrusion method is used. Due to the significant temperature conditions and high pressure, a material with a uniform dense structure and excellent consistency is obtained. This product is also commonly called extruded polystyrene foam.

Penoplex production

Differences in laying technology

*

It is better to install the sheets outside the building. The production technology of extruded polystyrene foam involves the transfer of the “dew point”. External thermal insulation can reduce heat loss by half. The slabs are covered with plaster or siding.

Important! To make effective thermal insulation and improve the quality of sound insulation, the slabs must be placed tightly. Laying work begins from the bottom, otherwise the material on uncured glue will slide down.

Penoplex is attached in 2 ways:

- On glue. For reliability, the fastening of the slabs is reinforced with umbrella dowels;

- Ventilated facade. A sheathing is made from wooden slats or a metal profile, insulation is placed in the cells, and everything is covered with cladding.

When thermally insulating the facade of a house with polystyrene foam, unusual decor is often used. Penoplex is covered with various plaster and mosaics, and other materials are used that distinguish them from other buildings.

Cleaning the wall from old layers of paint

It is better to use slabs with a tongue-and-groove edge. This makes it possible to prevent the appearance of cracks and cold bridges. Penoplex brand PPS 25-RG-B is often used.

Characteristics of penoplex and polystyrene foam

Penoplex is denser than polystyrene foam, which is why it weighs more and, therefore, can withstand a greater load. The tightness of the granules in the production of polystyrene foam is not strong, so in terms of its thermal insulation properties it is inferior to penoplex, which is highly compressed.

Penoplex slabs

In order for the protection against cold to be the same, you need to buy 25% less penoplex than polystyrene foam.

Penoplex belongs to the category of moisture-resistant materials. It has a water absorption rate of 0.35%, while for foam plastic this figure reaches 2.0%. Foam plastic has a greater degree of vapor permeability than penoplex, for which this value is almost zero. But it is worth noting that these two insulation materials have a very low degree of vapor permeability.

Foam boards

As for fragility, foam loses here. It is more fragile, easily crumbles and breaks, and is afraid of bends. The strength of penoplex is 6 times greater, and it cannot be broken without much effort. It also bends well, which compares favorably with polystyrene foam.

In terms of operating time, both of these materials will last quite a long time, but penoplex will retain its qualities longer. Over time, the foam will begin to crumble.

Polystyrene foam is more fragile than polystyrene foam

You need to know that both of these insulation materials are afraid of bright sun and negative atmospheric influences.

Polystyrene foam and polystyrene foam can be cut with an ordinary knife, but when working with the first material, great care must be taken, as it may break. Especially when it comes to three-centimeter sheets.

If we take into account the pricing policy, the cost of polystyrene foam is much less, so in the construction of high-rise buildings this insulation is used so that the cost of the project does not increase. It is also chosen by those who have limited financial capabilities.

How to insulate a balcony with extruded polystyrene foam

Installation is carried out on leveled walls; after sealing the cracks, it is advisable to cover them with a layer of putty.

Balcony insulation with penoplex (expanded polystyrene) is carried out in the following sequence:

- Cut polystyrene foam with a construction knife to the size of the floor, ceiling and walls.

- A foil vapor barrier is attached to the wall. The foil should be on the polystyrene side.

- Glue is applied to the cut parts pointwise, retreating 5 millimeters from the edges. The thickness of the adhesive layer must be at least 2 mm.

- To improve fixation, plastic dowels are additionally attached for thermal insulation. It is recommended to install at least six dowels per square meter.

- Next, install the second layer of vapor barrier.

- After installation, a reinforcing mesh is installed on top of the glue. The cell size should be 5 millimeters. The mesh should not be pressed too hard and should not be buried in the glue.

When the insulation of the balcony with extruded polystyrene foam is completed, plaster can be used as finishing for the walls (for more details, see the article “finishing the balcony with decorative plaster”) or plasterboard. Installation on the floor is carried out only after leveling the slab. After installation, a concrete screed is poured over the reinforcing mesh. The next layer is to apply floor leveler.

Properties of foam plastic

Polystyrene foam belongs to the category of artificial materials; it is not afraid of corrosion, excessive humidity, and is not afraid of the harmful effects of external factors. In its basic properties it is similar to mineral wool and is practically in no way inferior to it. Its density is slightly lower, and its thermal conductivity is slightly lower.

Walls insulated with foam plastic almost stop breathing. To prevent condensation from forming between the wall and the foam, it is necessary to correctly calculate its thickness so that the dew point is in the insulation itself.

The average thermal conductivity of polystyrene foam is 0.037-0.047 W/m °C. It can be used at temperatures from -40 degrees to +70 degrees. According to the flammability class, it is classified as a fire hazardous material. Such insulation can be safely used for about 30 years.

Insulation of the floor on the balcony with expanded clay

First you need to clean the surface, seal cracks and irregularities with cement-sand mortar.

Now you need to set the beacons so that the floor remains level after insulation:

- Screw one screw into two corners of the loggia; it is important that it rises to the height of the expanded clay layer. Typically its thickness is 10 centimeters. A laser level is placed in the center of the room.

- One long strip is placed vertically on each self-tapping screw.

- At the point where the beam intersects with the staff, you must mark a point with a marker. One point is placed in both corners.

- If the mark does not coincide with the beam, you need to screw in or unscrew the screw harder. Thus, markings are made in the remaining corners.

Cement mortar must be poured onto each self-tapping screw. Next, the guides are secured, the beacon is placed on top of the solution and pressed. When it hardens, you can move on to the next stage.

Next, thin layers of expanded clay are poured and each layer is leveled with a rule. This is necessary so that there are no voids left, otherwise in some places the level of thermal insulation will be lower. After backfilling and leveling, a concrete screed is made. Before doing this, it is advisable to spill the expanded clay with cement laitance. If expanded clay is poured inside a wooden sheathing, a screed is not needed. The top is covered with plywood.

Properties of penoplex

It is widely used for floor insulation, and there is no need for a full-fledged frame. Its thermal conductivity indicators are significant, which makes it possible to use it in small quantities.

If floor insulation with polystyrene foam requires a thickness of 8-11 cm, then with penoplex this figure decreases to 3-4 cm. Moreover, the floor will be warmer than with polystyrene foam. This makes it possible to widely use penoplex in the Far North with its critical sub-zero temperatures.

Floor insulation with penoplex

Penoplex has absorbed the best properties of polystyrene foam, only improving them significantly. This means good strength and low breakability. As for flammability, it is lower compared to polystyrene foam. In terms of cost, it is superior to polystyrene foam, but the price-quality ratio is excellent.

Balcony insulation with penoplex

This material tolerates operating temperatures from -50 degrees to +75 degrees and will last for half a century without losing its capabilities.

Installation

The sequence of actions is slightly different for different insulation materials.

Typically the following steps are followed:

- Laying waterproofing – protects against moisture penetration. It is important to remember that dampness can penetrate micropores in a concrete slab. To avoid this, it is recommended to first coat the walls with a primer. If mineral wool is used, it should be covered on both sides with a waterproofing film.

- If the frame method is chosen, the racks and crossbars are screwed on.

- Next, the insulation is installed. With the frameless method, it is glued without first performing waterproofing.

- A membrane, film or penofol is laid on top. The insulation of the PPU loggia is carried out by professionals using specialized equipment.

- The floor on the balcony is being insulated.

- The final stage is finishing the balcony with plasterboard or clapboard (for more details, see the article “how to cover a balcony with clapboard with your own hands, step-by-step instructions”).

Insulation materials produced in rolls are attached directly to the wall. Tile materials, for example, polystyrene foam or polystyrene foam, are installed in several ways. The sheet can be glued with glue or attached with dowels. In this case, space is saved, since there are no gaps between the heat-insulating building material and the wall.

The second method, which is used most often, is fastening to a wooden or metal sheathing.

The insulation is cut according to the cell size, usually it is 60x60 centimeters. The resulting parts are placed inside the cells. When using this method, condensation does not form on the walls; due to the air gap, the level of thermal insulation is higher. You can screw the trim to the sheathing - plasterboard, hardboard or clapboard.

Two ways to install sheet or roll insulation

If you use the frame method, you will first have to secure wooden posts or a galvanized profile. Most often, wooden racks are used, since they can be selected according to thickness, and they are cheaper. The vertical elements are connected by crossbars. To make the structure, a 50x50 cm beam is suitable. Then you need to lay thermal insulation material inside the frame.

Do-it-yourself insulation of a balcony with polystyrene foam can also be done using a frameless method. It is easier to secure the sheets with glue; there is no need to install racks. Due to the absence of a frame, there are no cold bridges formed in places where the wood is not covered with insulation.

Only rigid material can be attached directly to the wall. In this case, the mineral wool will not hold. It is important to remember that the absence of a frame leads to increased loads on the thermal insulation. Over time, the sheets will begin to deform and their properties will deteriorate.

Pros and cons of penoplex

Like any other insulation, penoplex has its own positive and negative properties.

| Advantages | Flaws |

| Low vapor permeability, preventing the absorption of moisture, water and condensation | Excessive fire hazard |

| Low thermal conductivity | May be damaged by rodents |

| Excellent durability | Capable of melting and flaming |

| Ability to withstand significant loads | Requires special handling to minimize the possibility of fire |

| Significant service life of the material | |

| Simplicity and speed during installation work | |

| Light weight | |

| Good combination of "Price - Quality" |

Concept of polystyrene thermal insulators

Polystyrene foam, like expanded polystyrene, is made from the same material, but using different technologies, and therefore has a number of differences.

Polystyrene foam is formed as follows: styrene granules are heated with steam for a long time, it expands and takes the shape of a slab. With prolonged exposure to heat, the material hardens, becomes hard, and pores form on the surface, due to which the foam breaks down into individual granules over time.

Expanded polystyrene or, as they also say, extruded polystyrene foam. Its manufacturing technology is slightly different - styrene granules are initially filled with a certain gas, then the whole mass is heated so that it begins to expand. After which it is extruded using an extruder into a special shape, this is necessary in order to obtain a more uniform structure of the material and strengthen the bonds between molecules. When the material fills the entire workpiece (block), it is pressed - this increases the quality characteristics of polystyrene foam. After the material hardens, a block of penoplex is obtained, which is sold in stores.

Pros and cons of foam plastic

When choosing insulation, you must first become familiar with its strengths and weaknesses. So, the main positive and negative aspects of polystyrene foam are the following:

| Advantages | Flaws |

| Affordable price | During the combustion process, toxic substances are released that have a negative impact on the human body. |

| Excellent thermal insulation properties | Possibility of releasing harmful substances even with a slight increase in temperature |

| Light weight | Able to create a vapor barrier |

| Wide range of applications and versatility | Hygroscopic |

| Long service life | Does not tolerate direct sunlight |

| Resistant to fungal growths and various microorganisms | Can be destroyed by rodents |

| Easy to install | Instability to various types of solvents has been revealed |

| Environmentally friendly product | Does not tolerate mechanical damage well |

| Noise insulation is minimal |

Price

Expanded polystyrene can be bought from 1300 rubles per 1m3. The cost may vary depending on the raw materials used in production. This also affects the brand of material, which is the difference between Penoplex in terms of density and operating temperature range.

The cost of 1 m3 of Penoplex is 3.5–4.5 thousand rubles. It may vary depending on your region and the season of purchase of the material. Often, when purchasing in bulk, material can be purchased cheaper; often the size of the discount is affected by the total purchase volume.

When purchasing, you need to take into account the need to cut the material and adjust individual elements; for this reason, it is necessary to increase the volume of the purchased batch of insulation by 10% of the calculated one.

Foam plastic or penoplex: which is better for external insulation

If we take into account the fact that penoplex is superior in density to polystyrene foam, nevertheless, residential buildings are insulated from the outside with the latter.

Here are the vapor permeability coefficients of some materials, including polystyrene foam:

| Material | Vapor permeability, mg/(m*h*Pa) |

| Brick | 0,11 |

| Concrete | 0,03 |

| Drywall | 0,075 |

| Pine, spruce | 0,06-0,032 |

| Mineral wool, stone | 0,3-0,37 |

| Mineral wool, glass | 0,5-0,54 |

| Styrofoam | 0,05 |

As we can see, the values of foam plastic are more or less comparable to the vapor permeability of brick, concrete and pine. Although polystyrene foam boards can “breathe,” they nevertheless transmit steam rather poorly. Thus, it is necessary to keep in mind that condensation does not appear in the structure of a building with insulation. Although foam plastic does not get wet, there is nothing good about walls wet from condensation. In other words, before installing insulation (any kind, not just foam plastic), it is necessary to accurately calculate its thickness, taking into account the temperature inside the house, the temperature outside, the level of air humidity, the thickness and material of the walls, etc.

Insulating the outside of the house with polystyrene foam

Penoplex is also used to insulate the external walls of buildings, but a vapor-permeable membrane must be laid between it and the building, which will automatically lead to an increase in the cost of the facility and an extension of construction time. As for non-residential buildings, insulation is carried out with both one and another material.

Insulation of external walls with penoplex

Expanded polystyrene is used, among other things, for insulating ceilings. But it is preferable to use penoplex compared to its competitor. There is one advantage that needs to be taken into account: foam plastic does not need to be covered after it is installed, as it is strong enough to support human weight. With polystyrene foam it is more difficult in this regard. It requires a hard covering, such as covering with boards.

Roof insulation with penoplex

Expanded polystyrene foam can be used to fill frame structures. This makes it possible to build such structures at high speed, but the soundproofing properties there will be minimal. But there are buildings that do not need sound insulation at all.

Selection of material by area of use

Quite often, modern developers wonder what is better - penoplex or polystyrene foam for insulation. To solve this problem, it is necessary to decide on which part of the building the material will be installed. For example, for a façade it is best to choose polystyrene foam, since it is cheaper and can allow air to pass through. This choice will reduce the cost of vapor barrier, because the wall will not lose its ability to breathe. For internal insulation of a house, it is best not to use such materials, although they themselves are environmentally friendly, they can be impregnated with special solutions. The latter emit toxic substances during operation.

If you are thinking about what is the best way to insulate a house - polystyrene foam/penoplex - then the latter option is better to choose for loggias or balconies. It has lower thermal conductivity and does not reduce the internal space as much. But if you have a flat roof and need to insulate it, both options are suitable. The ceiling can also be thermally insulated with any material of your choice. However, this decision is justified if you do not plan to walk through the attic afterwards. Otherwise, it is best to choose penoplex. Both materials are suitable for floor insulation, but it is better to make the rough surface using joists.

Foam plastic or penoplex: which is better for internal insulation

It is preferable to carry out such work using penoplex. If its properties are inferior to foam plastic for external work, then for internal insulation it is several times superior to it. Its positive properties, such as moisture resistance and airtightness, make it possible not to create an additional vapor barrier between the insulating materials and the wall of the building itself.

But insulating premises from the inside is a necessary measure, and from the outside the object remains unprotected from temperature changes and negative atmospheric phenomena. It is also worth remembering the possible release of harmful substances from such building materials into the room.

Floors are insulated with penoplex and foam plastic. In this process, they are almost equal in their characteristics, given their fire resistance and environmental friendliness. These materials are currently widely used when laying heated floors.

Floor insulation with foam plastic

It is worth noting that after installing polystyrene foam boards, they are hidden under various other coatings, so most of their negative qualities are negated.

Features of insulation work

- All wooden parts must be treated with antiseptics and compounds with waterproofing properties.

- The best option for thermal insulation (in regions with harsh climates) is a “pie” with an air layer.

- Penoplex and penofol are suitable as layers.

- Foil-coated polyethylene is considered a good substrate for lathing on the ceiling. It can be attached with double-sided construction tape.

- The outer layer of polyurethane foam must be treated with putty, paint or sealant, otherwise it will quickly darken under the influence of ultraviolet radiation.

- Do not use gypsum putty to seal seams - it is afraid of moisture.

- Suitable heaters are electric, oil and infrared.

If the renovation was carried out correctly and in compliance with all technologies, the balcony and loggia will become a full-fledged extension of the apartment. There you can place an office on the balcony, a dressing room or a mini-gym. Insulation increases the usable area of the apartment, which can be very important when expanding the family.

External insulation of the walls of the loggia with foil increases the usable area of the apartment, which can be very important when expanding the family. The work (if done independently) usually takes from three days to a week.

Areas of application of foam plastic

In addition to the already given examples of insulation of walls, floors and roofs, polystyrene foam is also used in the following cases:

- For insulating the foundation. It is recommended to insulate it to the depth of soil freezing - that is, on average 1 meter. But it is best to completely insulate the surface of the foundation, and then backfill the pit. It is very important that a continuous thermal insulation contour is maintained between the walls of the foundation or basement and the walls of the first floor of the building. This leads to the absence of cold bridges. If it is planned to build a three-layer wall, which consists of a base, insulation and a decorative wall, then the same structural elements must be in the basement so that the thermal insulation layers can be connected. The same principle of insulation is used in relation to the two-layer wall of the foundation and basement. The only drawback is that the rigidity of the slab does not allow it to adhere tightly to an uneven surface. Therefore, dowels with wide heads are used.

- For insulating the attic. To insulate the slopes of a residential attic, foam plastic is placed as follows: on top of the rafters, while they remain open, decorating the room, or between the rafters, then the foam plastic is carefully cut and additionally fastened, which significantly increases the duration of construction and the cost of specialized teams. Polystyrene foam can also be attached to the supporting frame or under the rafters, but this will significantly reduce the overall volume of the room.

- To insulate flat roofs, polystyrene foam with special rigidity is used. The base is mainly concrete, rarely corrugated board or wood. Moisture insulation in the form of roofing material or film is spread on top, and then foam plastic is tightly laid.

Preparation

Before carrying out work, it is necessary to prepare the balcony. The number of preparation stages is determined by the state of the building, the building materials used and the selected installation technology.

Preparatory work includes the following steps:

- Cleaning things and furniture from the balcony.

- Removing or installing new fencing is usually required in older buildings.

- Construction of a parapet or its strengthening. It is convenient to use foam blocks for construction.

- Sealing cracks. In most high-rise buildings, the loggias are not initially glazed, but even after glazing there are many gaps left. They can be located at the junction of the slabs, between the floor and the wall. They should be sealed with foam.

- Strengthening and leveling the concrete slab.

After completing the above operations, installation begins. This may require preliminary installation of waterproofing.

Areas of application of penoplex

This thermal insulation material is used in various fields of construction:

- To protect the foundation. This material has a number of positive qualities. If you use such insulation, the depth of soil freezing decreases, therefore there is no need to lay a deep foundation. This makes it possible to reduce the work of digging a pit and arranging a deep concrete foundation, which could lead to additional financial and labor costs. At the same time, moisture will not penetrate into the foundation, which will have a positive effect on the human body due to the provision of a favorable microclimate. Moreover, the presence of penoplex helps to save on heating costs.

- For insulation of basements. Due to the fact that penoplex is a moisture-resistant material, it can be laid on top of gravel, which is used as a rough floor covering. If there is a foam concrete base, it is first covered with waterproofing, and then penoplex is laid. If the floor on the ground floor is supposed to be warm, then the waterproofing layer is increased.

- In order to insulate balconies and roofs. Penoplex is light enough, so it will not unnecessarily load the floor slabs on the balcony. You can install this material yourself, thereby reducing the cost of paying for thermal insulation work. As for the roof, it helps reduce heat loss and the service life of the roof is significantly increased. In this case, penoplex is laid on the outside of the roof in such a way that there remains a cavity for ventilation, which can minimize the evaporation process. Before thermal insulation work is carried out, the roof is cleaned, waterproofing work is carried out, then foam boards are installed.

Common Mistakes

It is important to know not only how to properly insulate a loggia, but also what not to do. No one is immune from mistakes, but recommendations will help prevent them.

Placing central heating radiators on a balcony or loggia

Such actions will be detected sooner or later and the system will have to be removed. In addition, this is unsafe - the radiators are included in a common network, redevelopment of which can cause serious disruption. Plus there is a fine for this.

Removing a door or window block from an apartment to a balcony

From a legal point of view, this is a redevelopment that requires permission. It follows that in some cases this permission can be legally obtained.

Blind repetition of stories from television programs about repairs

In such programs, a balcony and a room are often combined. Regulatory authorities may recognize this as a violation: for example, for deteriorating heat supply to neighboring apartments. Then dismantling and payment of a large fine will be required.

Frameless glazing

Visually it looks very interesting. But for insulation you need double and triple PVC windows.