Home » Insulation

Reading time 12 min Published 08/17/2019

Every year before the heating season, utility services notify citizens living in high-rise apartments that it is necessary to bleed air from the heating system. The reasons for the formation of air in the heating system are factors such as the release of hydrogen during chemical reactions, as well as repair work, as a result of which water is drained from the system. To remove air, special devices are used - air vents.

Air vents for heating systems are also called air release valves, without which it is impossible to ensure the normal functioning of the heating system.

How does air enter the circuit?

There are two types of contours:

Peculiar automatic air vents in an open-type heating system allow coolant to pass through them, which circulates by gravity. The direction of circulation is determined by the design of the circuit. It always maintains a slope from the highest point, on the supply flow, to the lowest, on the return. There should be no air pockets. Air enters the heating system together with the coolant, which is in contact with it in the expansion tank. Then it is drawn into the flow in the form of small particles, since it is impossible to bleed air from the heating system from a coolant with a temperature of 20 degrees. The hotter the water, the more intense the process of separation of bubbles from the coolant occurs. The liquid pushes the bubbles upward. Accordingly, they reach a peak point where they find a way out.

Since expelling air from heating is one of the key tasks for safe and efficient heating of premises, equipment specially designed for this purpose is installed in the circuit.

Closed systems are sealed and circulation in them occurs thanks to a pump. In such circuits the flow rate is higher. They are designed in such a way that air pockets are formed in them. In this case, the installation of special equipment is required, since it is necessary to bleed air from the heating system while maintaining its tightness. It's called an automatic heating system air bleeder. Since the system is not in contact with the environment and is sealed, oxygen can only enter it with the coolant.

In addition to the transit of oxygen by the coolant into the circuit, airing can occur:

- due to mechanical damage;

- due to repair work;

- in case of leakage;

- after verification work.

Since it is not possible to prevent oxygen from entering the system, it is necessary to ensure that it finds a way out. For this purpose, several types of equipment are used to perform the task. They can work autonomously or in manual mode.

What are the dangers of not having air vents?

Air vents are used not only in heating networks of multi-storey buildings, but also in private ones. Each radiator is equipped with an air vent, which is often presented as a manual type.

The air inside the heating system impedes the circulation of the coolant, which negatively affects the heating of the premises. If you do not bleed air from the system in a timely manner, vibration is created when the coolant heats up. This phenomenon can ultimately lead to physical damage to the heating network circuits. The main places of damage are the connection points of heating radiators, as well as welding or soldering seams.

If there is no air in the metal pipe circuit, then the internal walls of the pipelines do not corrode, unlike in cases where there is oxygen in the system. When the internal walls of pipelines rust, not only does the service life decrease, but also the coolant becomes clogged. Draining or bleeding air is a prerequisite, since residents of houses and apartments who ignore to carry out such a procedure themselves may be left without heat.

Types of equipment and principle of its operation

- open type expansion tank.

How to remove air from a closed heating system with a simple tank? It can perform the function of an air vent only in open circuits. Since it is not possible to ventilate a closed circuit heating system using a tank. Only sealed tanks are installed in them. The open tank is at the peak of the circuit, where oxygen bubbles tend to flow. The problem is that the water is enriched with it in the same tank, so there is a high level of air in the coolant, which is there until the liquid is heated;

Installed at the highest point or in a place where oxygen accumulates. The threaded part of the heating system air bleeder comes in two diameters: ½ or ¾ inch. In shape they can be flat or bent at a right angle, like the letter “g”. The air outlet hole is located either at the end or on the side of the housing. Works offline. Air is released from the heating system when the pressure in the system rises to a critical level. Consists of a valve and a float. The working principle is that when oxygen rises, the float moves down and opens the valve. As soon as a release occurs, the float rises, returning to its original position, and closes the valve;

- air separator for heating.

Placed on the feed. Unlike an automatic air vent, it does not remove the oxygen that itself separated from the coolant and rose up. The air separator in heating independently separates oxygen particles and gets rid of them. It is designed in such a way that the flow mixes when encountering obstacles. Barriers may include:

Air separator for heating

Since they are installed in the area behind the boiler, where the temperature is highest, their operation becomes more efficient. Oxygen is more readily separated from hot water. Automatic air discharge from the heating system is carried out continuously. Works autonomously without human intervention;

Removing air from the heating system requires human intervention. The tap is located at the end of the heating radiator. This is the white “twist” on the battery with a bolt screwed into it in the middle. There is a hole in the plastic, small as a needle, since this is more than enough to bleed air from the heating radiator. In order to do this, you need to prepare a vessel for water, a half-liter jar will do, unscrew the tap a little and after the hissing stops and a trickle of water starts flowing, close it. That's it, the plug has been removed.

The air vent in the heating system, depending on the type, can be installed not only at the top point of the circuit. They are also installed in problem areas and downstream of the boiler.

What types of air vents are there?

Air vents are divided into two types:

Manual products are designed to deflate air through human intervention. To do this, utility workers either independently go around all the apartments to carry out such manipulations, or inform the residents of the house. Automatic air vents for heating systems do not require human intervention, so they release oxygen on their own. The cost of such devices is several times higher than manual ones, so utility services are not able to provide all high-rise apartments with automatic air vents.

Automatic air vents are installed in places where there is a high probability of air lock formation. The locations for such devices are heating radiators.

How to remove a plug from a circuit

Before removing air from the system, it must be detected. Options:

- before you bleed the air from the heating system yourself, would it be better to call a technician and get it over with?;

- try to find it yourself by knocking on the pipes. The sound in the area where the traffic jam is located will be different;

- check the uniform heating of the radiators. The top should be warm, there may be a slight difference from the bottom. The main thing is that the temperature at the top is higher. If this is not the case, then there is a problem in the batteries.

To remove air from the radiators in a private heating system, it is enough to use a Mayevsky tap. In other cases, you must first check the condition of the equipment responsible for this process. If it is in working condition, you can increase the pressure so that the plug comes out on its own, or refuel the system. If the circuit is filled from scratch, then you need to fill in water in several stages, without rushing. In this case, all taps, except the drain, must be open. We need to provide more options for oxygen to escape. Some craftsmen remove the cork by tapping along the contour. The method works, but this does not mean that you need to take a hammer and hit the pipe harder. No, you need to know how and where to hit, otherwise there will be no use, only harm.

In addition to the familiar Mayevsky taps, modern heating systems commonly use a device such as an automatic air vent. Its task is to remove air from a certain section of the heating network without human intervention. How this important device works, the principle of its operation and its installation location - all these nuances will be discussed in this article.

Features of choosing air vents

Not everyone knows where to start choosing an automatic air vent. In order for the product to serve for a long time and without failure, it is recommended to buy products of European or domestic production, but not cheap Chinese counterfeits. Buying a cheap automatic graduate can cause the following adverse consequences:

- Passing not only air, but also coolant through the valve. In this case, a puddle of water will be detected under the radiators or in the places where the air vents are installed.

- The product is jammed, so it will not work.

- Rapid deterioration.

Although automatic type safety valves have a shorter service life than manual ones, they must serve without fail for at least 10 years. Manual products have a service life of over 15 years, so instead of buying a cheap machine, it is better to give preference to a manual device. This will allow you to win not only in terms of savings, but there will also be no problems with air bleeding.

To choose good quality Mayevsky uranium, you need to pay attention to the following criteria:

- The presence of a handle allows you to conveniently open the valve for bleeding air. The disadvantage of faucets with handles is that they can be accessed by children, who are quite capable of opening them. Installation of such outlets with handles is appropriate only in hard-to-reach places; in other cases, it is recommended to install conventional products with a key or a screwdriver.

- To avoid losing the special bleeder key, it should be placed on the wall next to the radiator. This will prevent you from losing the key, and will also allow you to quickly bleed the air.

- Buy products with anodized coating. This spraying allows you to protect the metal from the occurrence of oxidative processes.

- If your budget allows, you can purchase a product that can trap air bubbles. However, such manual air vents do not differ much in cost from automatic air vents.

In order not to make a mistake with your choice, you need to pay attention to the manufacturer. Depending on the brand of plumbing and heating equipment, not only the quality, but also the cost will differ. In addition, if a closed heating system is used, then you need to pay attention to the technical parameters of the devices, in particular, operating pressure.

The air in the heating system is one of its main enemies. Therefore, automatic air vents must be provided in the heating system. Since not all heating systems operate on the same principle, the process of air circulation in the circuit also differs. Before you bleed air from the heating system, you should figure out how to do this, or you don’t need to do anything and it will come out on its own, for example, like in an open system.

Design and principle of operation of the air vent

Due to various circumstances, an air lock may appear in water heating systems, preventing the normal circulation of the coolant. As a result, part of the radiator or several batteries located on the same branch or riser cool down. So that the air that appears can leave the system on its own, an air vent operating in automatic mode is installed at certain points.

The device is a sealed metal case with a connecting pipe located at the bottom. Inside the body, in the chamber, there is a float made of polymer material, connected by a rod to a needle valve, the hole of which is made at the very top of the lid. The air vent device is shown in detail in the diagram:

The normal state of the air separator is when the body is filled with coolant, the float is raised to the maximum upper position, and the needle valve is closed. Over time, air from the network enters in small portions into the chamber of the device and displaces water.

The float gradually lowers and at a critical point begins to open the valve communicating with the atmosphere through draft. Thanks to this, all the air accumulated in the chamber under water pressure quickly leaves it through the open hole. This is the operating principle of the automatic air vent, as shown in the figure:

After all the air has gone out, water takes its place in the chamber, raising the float to its original position. The valve closes and the air vent goes into standby mode. The automatic float air vent also plays a very important role when emptying the system or its section. Since when the coolant level in the chamber decreases, the lever will open the valve, this will allow air to enter the system and thereby speed up its emptying.

Features of the functioning of manual descenders

The design of the simplest manual air vent is shown in the diagram below.

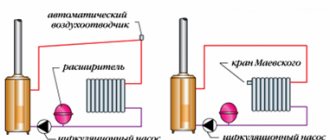

This air vent is called the Mayevsky crane, the operating principle of which is very simple. The device has two holes that are covered by a threaded element. When unscrewing the threaded element, air is released, which is pushed through the 2 mm hole in the diagram above, and exits the system through the second hole.

To bleed air from the system, it is enough to make 2-4 turns of the screw, after which, under the pressure of the coolant, the air will tend to escape through the holes. You can know that all the air has been drained from the system by the appearance of water flowing out of the hole. As soon as a dense stream of water flows from the hole, you need to screw the screw in until it stops. Modern Mayevsky cranes are presented in various types: turnkey, with handles and even with a screwdriver. The photo below shows a list of such types.

A manual air valve in a heating system is an ideal device that functions flawlessly over a long period of time. The reliability of this device is due to the absence of moving parts, which over time are subject to clogging, corrosion and failure. This is typical for automatic air exhaust products.

Often, instead of Mayevsky’s manual taps, apartment owners install drainage taps. They can be installed temporarily, but not permanently, since they are not intended for installation on radiators. If such products fail, it will be very difficult to replace them during the heating season.

Types of Automatic Air Valves

Based on their design, devices can be divided into 3 types:

Note. Despite external differences and different areas of application, the principle of operation of the air vent remains unchanged.

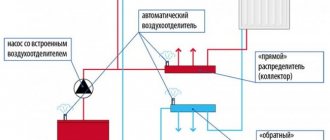

The most common are traditional devices with a direct connection pipe. The scope of their application is very wide. Automatic air separators are primarily designed to release air through the highest points of the pipeline network. To do this, they are placed at the very top of vertical risers, where, according to the laws of physics, all air accumulations that appear in the pipes tend to fall. If it were not for the automatic air vents in the heating system, it would have been very difficult to manually release air from the highest points.

Closed heating systems under pressure are equipped with boiler safety groups, which are located on the supply pipeline leaving the heat generator. Along with the safety valve and pressure gauge, this group also includes an automatic air valve. Its task is to bleed air when the boiler tank is filled with water. If the piping of the unit is done prudently, then, if necessary, it can always be cut off from the rest of the system and emptied using an air vent, and refilled after servicing.

Note. Safety groups for heating must be installed on boilers that burn solid fuel.

Air vent devices are also used in some models of circulation pumps. The goal is to ensure uninterrupted operation of the pumping unit. The fact is that the pump can only move an incompressible medium - water or other liquid. The entry of air into the area of the unit's impeller threatens to completely stop the circulation of the coolant, which is what the air vent of the circulation pump is designed to prevent. Any air or steam from the boiler that enters this area will be immediately released and the pump will continue to operate.

How does an automatic air vent work?

Let's figure out how an automatic air vent works, the cost of which is 2-3 times higher than manual devices. Such products are equipped with air release valves that function without outside intervention. The design of the product is a vertical barrel with a ½-inch threaded connection method. The body of the product is made of brass, and inside the device there is a plastic float. This float is connected to the spring-loaded air release valve and the cap.

Automatic air vents have ½ and 3/8 inch threads. The last option comes up rarely.

The operating principle of the automatic air valve is to perform the following tasks:

- If there is no air in the system, the chamber of the device is filled with water, which presses the float to the top. In this case, the spring-loaded valve is in the closed position.

- When air enters the system, the pressure decreases, so the float drops.

- When the pressure decreases to a certain value, the mass of the float device will overcome the spring, which will lead to the opening of the valve.

- The excess pressure will force air out of the circuit, after which the valve will close again.

The diagram shows in detail how the automatic air vent functions. The advantage of such a product is the complete absence of water leakage, since the device leaves some of the air mixture inside, which does not negatively affect the operation of the heating network.

Depending on the type of connection, automatic air vents can be straight or angular. The photo above shows a corner air vent with a jet in the upper part. On direct devices, such a jet is located on the side. The products differ from each other not only structurally, but also technologically. A valve with a side outlet is more reliable, but it does not retain air as well as a device with a vertical outlet.

Automatic air vent valves from the heating system are constantly being modernized, as manufacturers strive to make them more advanced. At the same time, they are complemented by various functions:

- Elimination of water hammer, which is facilitated by a special plate inside the product.

Corner and radiator air vents

In different heating systems, many situations may arise when it is necessary to remove air pockets in the most inaccessible or remote places. It is impossible to list them all, as there are too many options. Where it is not possible to install a simple valve because the threaded pipe at the end is in a horizontal position, an angled air vent will do. Its pipe, coming out from the bottom, turns at an angle of 90º and can be connected to a horizontal section.

It should be noted that an angular air vent with an external threaded connection is no different from a conventional straight valve except for a rotated pipe and can be used instead of it if necessary.

Often, to automatically bleed air from batteries, instead of the traditional Mayevsky tap, some users install an angle valve. This can be relevant in an unpleasant set of circumstances, when gases are constantly formed in the network and this happens precisely in radiators. The reason is a chemical reaction of substances sometimes present in water with the aluminum alloy of batteries at elevated temperatures. There is no point in installing a valve with an angle pipe, because there is a special automatic air vent for radiators, shown in the photo:

These devices are designed for batteries only and have a suitable threaded connection. Instead of manual taps, it is preferable to place them on heaters made of aluminum or partially bimetallic, where there is also contact between the alloy and water. In other situations, the radiator air vent is mounted at will, but there is no doubt that it will bring ease of use.

Note. It is still better to equip traditional cast-iron batteries included in the centralized heating network with a Mayevsky manual tap and drain pipe.

For ease of maintenance and cleaning, complete devices are available for sale - automatic air vents with a valve. The latter is a small threaded adapter with a spring-loaded petal valve inside. The adapter is screwed onto the thread directly in front of the air vent and serves so that when the system is in operation, it can be removed and cleaned or replaced. Air vents from DANFOSS, VALTEK and many other well-known brands are equipped with similar adapters.

Replacing the air vent on the Main-5 24f boiler

Replacing the air vent on the Main-5 24f boiler

Post by Aclii » Sep 28, 2015, 02:28 pm

Boiler: Baxi Main 5 24F Pump: WILO INTBXSL 15/5-1

Today water started dripping from the boiler - I removed the front cover and discovered a leak from the pump air vent, I never raised the pressure above 1 kg/cm2, before leaving for work I closed the red cover of the air vent valve, in the evening I’ll see if it’s dry there or not.

Tell me, please, what to do?

I read the Internet, they write that cleaning the air vent valve can help, is this true?

Main 5 24f – water from the air vent

Post by Bahus » Sep 28, 2015 4:38 pm

Main 5 24f – water from the air vent

Post by Aclii » Sep 28, 2015, 04:42 pm

Main 5 24f – water from the air vent

Post by Bahus » Sep 28, 2015, 05:01 pm

Main 5 24f – water from the air vent

Post by garry » Sep 28, 2015 5:49 pm

Main 5 24f – water from the air vent

Post by Guest » Sep 28, 2015, 11:54 pm

Thank you all so much for the tips!

I decided to fix/clean it myself and now it doesn’t drip.

Inside there is nothing special to break, except for the metal spring (I think it is made of stainless material, since there was no rust), the rest of the parts are plastic/rubber. There was a black oily coating, I took everything apart, cleaned it, assembled it and put it back in place.

Main 5 24f – water from the air vent

Post by electric » Sep 29, 2015, 00:03

Main 5 24f – water from the air vent

Post by Aclii » Sep 29, 2015, 00:35

Main 5 24f – water from the air vent

Post by Aclii » Sep 29, 2015, 05:12 pm

I made a short photo report, in case it will be useful to someone.

The photo does not show the removal and installation process, here is a brief description:

- Before carrying out work, remove excess pressure from the heating circuit and disconnect the boiler from the network;

- Before you begin to remove the valve, you need to remove the fixing U-shaped clip; to do this, you need to push it out of the mounting holes towards the rear wall;

- To remove the valve from the pump body (the pump was not removed, only the front panel of the boiler was removed), you will need a regular adjustable wrench - adjust the size of the wrench to the size of the valve, insert it between the pump body and the “ears” of the valve, then swing the wrench lightly up/down valve and gradually remove it from the pump housing. During this operation, air will begin to enter the system and a characteristic “gurgling” will be heard;

- To install the valve in place, it is necessary to lubricate the rubber sealing ring with a thin layer of silicone grease (petroleum-based lubricants destroy rubber), in this case it is quite easy to install, otherwise the sealing ring or the nervous system can be damaged;

- Place the fixing clip in place;

- Fill the heating circuit until the required pressure is reached, then turn on the boiler - if everything is done correctly, you will hear a short hissing from the valve, this is removing excess air.

How does air affect heating performance?

Air in the heating system is one of the reasons for heat transfer disturbances

reduction (sometimes partial) of circulation. When the heating system becomes airy, it causes a decrease in the efficiency of its operation and excessive fuel consumption;

Air in the heating system can lead to pipe leaks

Safety group for heating system boilers. What is it?

Due to the gradual abandonment of centralized heating and the transition to an autonomous option for heating one’s own home (using all types of fuel), the requirements for safety, ergonomics (space saving) and a general increase in the efficiency of heating equipment have increased. It was also influenced by the fact that every day more and more people prefer a closed type of heating system instead of an open one. And lastly, you cannot do without safety elements for the heating system, despite the fact that most boilers already have an expansion tank and other safety elements built into them.

Where does the air come from in the system?

It would seem that everything is being made airtight, and the question would be quite reasonable: where does the air in the heating system come from? It is quite difficult to answer unequivocally, there are many such reasons, of which it is worth noting:

- Failure to comply with the requirements regarding compliance with pipe slopes during the installation process;

- Incorrect filling of water, as a result of which the heating system becomes airy;

- Loose connections of various components and parts can be a source of air entry, which will air the heating system;

The absence of special automatic devices (air vents) that automatically remove air from the system, or their incorrect operation;

The reasons for airing in the heating system outlined above do not cover all possible situations when and how this can happen. But they make it possible to understand why the heating system is becoming airy, and to take timely measures to eliminate this phenomenon.

Recommended reading:

Installation locations for air vents

DIY security group

You can make a security group yourself, but it will most likely cost more than a security group purchased pre-assembled. You need to buy a pressure gauge, an air vent and a safety valve, and then connect them using tees, bends and adapters in the manner of ready-made safety groups.

Homemade safety group for heating. Photo: mlhouse.ru

Source

How to prevent air from entering the system?

Here it is necessary to consider several situations - when filling the system with coolant and during its operation. Its design must include air vents and Mayevsky taps, allowing for de-airing of the heating system. The recommendations given apply to a closed system with forced circulation.

Installation of air vents

They are placed in critical places, such as pipeline bends or their highest points. In many cases, when the heating system is constantly airing, they help cope with this problem. There are manual and automatic.

- Manual air vents. These include, first of all, the Mayevsky crane, named after the inventor. Installed at the end of the battery, thanks to it you don’t have to think about what to do if the heating system is airy. With its help, you can independently release the accumulated air.

- Automatic air vents. They allow you to solve the problem of how to ventilate the heating system without additional participation and expense.

Filling the system with water

It is carried out from the bottom up with cold water. In this case, all taps must be open, except those that drain water. Thanks to this filling, the heating system will not be aired; as the water rises, it will squeeze the air out of it. Filling is carried out smoothly; with a sharp rise in water, the formation of closed volumes and the formation of air bubbles is possible.

Filling the heating system with water

As soon as water flows through the open tap, it is closed, and so they gradually rise higher until the entire system is filled. After this, it is quite possible to start the pump; if everything is done correctly, then circulation will occur, and there is no need to rack your brains about how to bleed the heating system.

Where to install the security group

The safety group is installed on the supply pipeline, near the heating boiler so that the pressure gauge readings are visible at a distance of a meter from the device. Valves cannot be installed between the safety group and the boiler (except for shut-off valves, but even those are undesirable).

You must train yourself to pay attention to the safety team every time you visit the boiler room in order to take timely measures if problems arise in the operation of the equipment.

The pressure gauge should be positioned so that its readings can be seen without straining during any visit to the boiler room. The coolant flowing out through the safety valve should also be easily noticeable, because it is imperative to be aware of such a phenomenon!

Removing air from the system during operation

However, with all the measures taken, the formation of traffic jams is possible during operation. The reasons why the heating system will air are discussed above, and we will not return to them again. However, it is necessary to consider how to properly ventilate the heating system during its operation.

When faced with such a task, you need to act as follows:

- Determine the place where the air has collected. This can be done by noise or pipes and radiators, they are colder in such places.

We are looking for a point located higher in the direction of movement of the coolant, at which there is a Mayevsky valve through which air can be released.

This is a universal, standard algorithm of actions that allows you not to think about how to eliminate air from the heating system.

The operation of heating any home largely depends on its correct installation and provision of the necessary conditions during operation. One of them is the lack of air in the heating system. The use of the necessary equipment and proper operation will create the prerequisites for its long-term and trouble-free operation.

Installation and maintenance rules

According to modern safety requirements, each radiator must have a shut-off valve in front of it in case it fails and repair work is carried out without stopping the entire system. Which is especially important in the cold season. The safety group for the heating system should be installed similarly - the tap that shuts off the coolant MUST BE AFTER the safety system.

A common mistake is to install a shut-off valve between the boiler and the security system itself. In this case, if you need to stop the boiler as quickly as possible (especially a solid fuel boiler, for example, if pipes rupture or a radiator leaks), then it will be impossible to do this without consequences. After all, the coolant will continue to heat up for some time and will not find a way out. As a result, pressure increases and either pipes burst in another place or the boiler collapses. Both lead to significant losses.

After the device is installed according to the instructions, it is put into operation by opening a special cap on the automatic air vent. Please pay special attention - it is forbidden to remove it completely

Also, depending on the quality of the coolant and the degree of operation of the entire system, it is necessary to periodically (on average, once a month) inspect the valve for contamination between the seat and the plate. Because if dirt is not removed for a long time, this can lead to further leaks - just turn the device in the direction of the arrow and it will clean itself.

During installation, you must adhere to certain rules that will ensure the safe operation of the entire heating system. Firstly, there should be no foreign objects or pipes in front of the group so that they do not obscure the view of the pressure gauge. The best location is considered to be one in which, upon entering the boiler room, the readings of the measuring device are immediately visible. Secondly, it is prohibited to install other elements on the pipe between the group and the heat exchanger. Ideally, this pipe should be as short as possible in length and located as close to the boiler as possible. The manifold has threads on all outlets. Actually, installing a boiler safety group means screwing all the parts onto the crosspiece and installing it on the pipe. To prevent leaks, FUM tape, sealing paste or flax are applied to the threads before installation. Compliance with these simple rules during installation will allow the boiler equipment to operate without leaks and dangerous situations.

Radiator air vent

Radiator air vent

An automatic radiator air vent is mounted on radiators instead of Mayevsky taps. It is slightly different from the traditional model in size and more expensive. Insertion of the element is necessary in aluminum and bimetallic batteries, where air pockets are constantly formed during the chemical reaction of the metal alloy with the carrier.

Basic error codes

In the event of malfunctions, the automatic monitoring system displays an error code on the display, allowing you to determine the malfunction. In some cases, this is simply a system failure and the boiler can be restored to operation by resetting the error.

The most common malfunctions of the Navien gas boiler include the following:

- error 02 indicates insufficient water filling of the boiler and heating pipes or an open circuit of the flow sensor. Why does the pressure drop - the system may become airy, bleed the air, there may be a leak in the batteries, determine the location and fix it.

If the circulation pump is damaged, repair it if possible, otherwise replacement is required. The flow sensor is broken, check the resistance at its contacts with a multimeter, if it does not match, replace the sensor.

Flow sensor

If there is not enough water, add water to the system until the pressure reaches 1.2 - 1.5 Bar by opening the valve. There is no voltage on the circulation pump - check the control board, if it is faulty, replace it. Code 02 appears if antifreeze is used in the coolant - it is prohibited in Navien boilers, drain the antifreeze and fill with water; error 03 in Navien Ice and Navien Deluxe boilers appears when the boiler does not start, there is no signal about the presence of a flame, or there is an open circuit in the sensor.

Mayevsky crane

Of course, Mayevsky’s faucet does not belong to the category of automatic air vents, so it seems to be off topic of the article. But there’s not much to write about it, and since it’s still an air vent, a few words about it here.

Mayevsky taps are installed on radiators:

To bleed air, you just need to slightly open the screw on the tap with a screwdriver:

The blue arrow shows where the air will come out from.

If initially (when installing heating) we plan to install a Mayevsky tap, then we need to install the radiator so that the part where the tap is “looks” upward (1...2 cm higher).

The heated towel rail is airy: solutions

Everyone is familiar with the heated towel rail, a faithful friend of the bathroom. It has different configurations: in the form of a ladder, the letter “U” or “M”. Have you noticed that the heating pipe has become airy and has stopped heating? Then you need to take urgent action to prevent negative consequences in the form of mold formation. That is why it is extremely important to know how to bleed the air from the coil yourself. Read more about how to eliminate the causes of poor device performance below.

Causes and symptoms of the problem

When air forms in the heated towel rail, the following sign occurs: the coil stops working, but hot water is still available in the house. The equipment can also be either warm or cold.

First, you should refer to the diagram of how the device is connected to identify differences from a conventional heating system. The main thing that may catch your eye is that the coil is included in the DHW circuit, but not in the heating circuit. In most cases, this is done because the heating system is turned off during the summer, and the coil must work all year round. The task of its work is to maintain a regular dry climate in the bathroom.

Connecting a heated towel rail

Important!

The main mission of a heated towel rail is not only to dry laundry, but also to maintain a low level of humidity in the room.

Has your heated towel rail stopped working? The walls in the room begin to become covered with mold and mildew. In particularly severe situations, a faulty coil can damage the finish of the bathroom. It is worth noting the appearance of a feeling of discomfort when being in the bathroom. Steel types of coil with a long absence of coolant leads to a corrosion process due to oxidation of the steel material in air. Over time, this can lead to pipes depressurizing and possible flooding of the house.

Ideal heated towel rail

The coil ideally has a large diameter pipe, as well as a simple M-shape, which will not limit the movement of water flow in the riser.

Types of air jams

There may be several reasons for the formation of air pockets in the device. The most common are:

- Turning off hot water in the summer with a further restart. Thus, air that gets into the system can accumulate directly in the coil.

- Incorrectly connected device. For maximum performance during the installation process, you need to follow some rules. To avoid narrowing of the pipes, it is important to observe the connection diagram, as well as the slope.

- Illiterate form of the device. Manufacturers from China often make such mistakes without understanding the nuances of engineering. As a result, it turns out that a coil with thin pipes and sharp transitions can easily become a place for the formation of air jams. Such models should be avoided. After all, water will circulate poorly in thin pipes, and the small diameter will become a problem for connection.

There are a large variety of connection schemes. When the coil was connected incorrectly, then this is precisely the reason for airing.

Acceptable and non-recommended connection schemes

How to deflate yourself

Based on the water supply system, the process of bleeding air will be different. Those living in a private house with their own water supply system need to know its diagram and understand where it is possible to open the tap to release the air lock.

Important!

In an apartment building, everything is not so simple. Most likely you will need to bleed the air from the riser when the problem lies there. However, it is important to first try to start the release from the coil in the apartment. The following is an option that is intended for older types of houses with coils that do not have an air vent (Maevsky tap).

- Using an adjustable wrench, you need to remove the nut connecting the coil and the hot water pipe.

- You need to unscrew it slowly and very carefully - you can break the thread, especially on old coils.

- You should first prepare a container for collecting water. When loosening the nut, you need to wait until the hissing stops and water comes out, but without air.

- After this, you need to tighten the nut in place.

Did the presented method not help? Then you need to bleed the air from the entire riser. However, it all depends on the house. Because the riser can be of different designs:

- Old 5-story houses from the Soviet era. In them, the hot water riser is installed up to the 5th floor, after which it goes down in a loop to recirculate hot water. The air accumulates at the peak point, so you will need to go to those living on the upper floors and start deflating the air there. Often there is a prepared hose there. It should be put on a special riser valve and lowered into the sewer. After this, you need to open the tap and drain the water until the air comes out.

- Panel 9-storey buildings. In these houses, it is only possible to bleed air from the attic - communications terminate there. It is important to clarify whether there is access to the attic. As a rule, only plumbers from the DEZ are allowed there. In this case, you need to call them. Is the attic open? Then you can drain the water yourself. First you need to find a hot water pipe, find its outlet, open the tap and drain everything into the sewer.

- Other houses. In such a case, there is only one option - to call the maintenance service, because the technical floors are always closed. The entire process of “restarting the riser” involves a procedure in which the DHW riser is drained in the basement, after which it must be refilled with water.

Reasons for heating heating

There are several reasons for the appearance of air in the heating system:

- the content of dissolved oxygen in water heating pipes, which, when heated, is released in the form of microbubbles, which subsequently form an air plug;

- supply of media too quickly when filling the system, as a result, the air does not have time to bleed;

- air entering the pipes as a result of media leakage (for example, loose connections);

- use of pipes with oxygen-permeable walls in heating;

- the appearance of air jams as a result of improper installation of the heating system and after repairs.

What to do if the heating system is affected by one of the listed troubles? Of course, bleed the air. To do this, an air vent is cut into the system. Let us further understand what an automatic type device is.

Design

Air vents can have different designs, primarily in shape - straight, angular, horizontal, vertical, etc. According to the principle of action, they can also differ - ball or needle.

In general, instead of an air vent, a regular tap can be used, which allows stagnant water to be drained along with the air.

But these are, let’s say, echoes of the past, when there were no such reliable devices. And now the norm should be the widespread use of air vents, together with safety devices.

Air vents must be recognized as an integral element of the heating system, like a radiator or boiler. They allow you to maintain it constantly in working condition, as well as timely and without additional costs to restore functionality in the event of air locks.