According to some beekeepers, insulating hives for the winter does not make any sense. For this reason, their charges spend the winter outside. In reality, there is nothing to worry about here, since the bees, being left to their own devices, will be able to make the final flight before frost and the first one in the spring, when they feel that it has noticeably warmed up. However, most owners still insulate their hives for the winter. How to do this and how to avoid common mistakes during work will be discussed in today’s article.

- 1 Selection of material for insulating hives 1.1 Option No. 1. Plastic or foam

- 1.2 Option No. 2. Mineral wool, other fibrous materials

- 1.3 Option No. 3. Use of improvised means

- 2.1 Ventilation is an important point when insulating for the winter

Why is it necessary to insulate the hive?

Bees are able to tolerate temperatures in the range of –40…+40°C. However, for normal life (feeding, reproduction) they need a temperature from +10 to +30°C. If there is any change in the indicators, they try to regulate them. By nature, bees are designed in such a way that they can independently warm or cool themselves. Because of this, for many, the question of insulating the hive becomes unclear.

Yes, if the family is not weak, then it is capable of heating itself on its own, but in order to produce the required amount of heat, insects spend their vital energy, the reserves of which are replenished through food. It turns out that the more heat they need to generate, the more they must absorb food - honey, the reserves of which are limited, and it is impossible to replenish them before spring.

If food supplies are used up before spring, the bee colony may die, so it is necessary to insulate the hive so that the little workers spend less energy maintaining a comfortable temperature.

In addition, if a hive without insulation is located outdoors in an area with strong winds, then the colony will develop more slowly, since it is more difficult for the bees to maintain the required temperature. This leads to a decrease in the fertility of the uterus, which means that the family will grow slowly.

Top dressing

For one family in winter it is required to leave 20-25 kg of honey. The amount of honey for wintering depends on the air temperature inside the hive. If it remains normal without fluctuations, then the sweet mass is consumed optimally. When the temperature rises or falls, bees eat food faster.

You should not give honey and honeydew to insects. If they consume such food, substances that cannot be digested will form in the stomach. The insects will die.

Check the quality of honey. Pour a liter of quicklime into a 2-liter jar, fill the rest with water. Let the solution settle. In another container, mix the treat with water, and then pour the mixture with lime into it. If flakes appear, then such honey should not be given to bees.

In addition to honey, insects are given sugar syrup, kandi and potato mixture in winter. To prepare the syrup, boil a liter of water and add 2 kg of sugar. Stir until a viscous mass forms.

We prepare honey kandi from powdered sugar, honey, water and acetic acid. At home, boil 2.5 kg of honey to a temperature of 55 degrees to kill the microbes in it. Cool and mix the bee treat with powdered sugar. Add sugar gradually. In total you need to add 7.5 kg. Pour 200 ml of water and 20 ml of vinegar into the dough.

To make food with potato juice, you first need to prepare sugar syrup. Pass the peeled potatoes through a meat grinder, blender or grater and extract the juice from them. For one liter of sugar syrup, add 60 ml of juice.

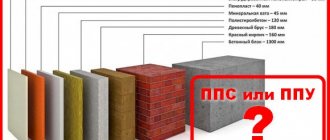

Possible materials for insulation

There are many options for insulation, each of them has its own advantages and disadvantages. Let's look at them in more detail.

Important! Folgoizolon can be used all year round. In winter, turned with foil towards the hive, it will retain heat, and in summer, turned with foil outward, it will reflect the sun's rays.

Plastic, foil insulation or polystyrene foam

Isolon (elastic polyethylene foam with a closed cell structure) or polystyrene foam (expanded polystyrene) are often used for insulation. The plastic acts as a holder, between the sheets of which one of the listed materials is placed. Sometimes folgoizol is used, which is a foil-coated isolon. Both polystyrene foam and isolon have similar characteristics, so they have the same positive and negative qualities.

Advantages

The main advantage of these materials is their lightness and high density. When using them, the hive structure does not become much heavier. In addition, the materials are good thermal insulators, thanks to which they retain heat in the hive; they are easy to install. When using these materials, there is no need to use additional insulating sides for the sidewalls and nest insulation.

Flaws

Another feature of the listed materials is waterproofing, that is, they do not absorb moisture. When insulating hives for wintering, this feature is a negative factor, since the moisture generated as a result of the vital activity of bees will flow down the walls. This will lead to increased insect activity, which means more food will be consumed.

Did you know? The ancestors of bees were predatory wasps, part of the sand wasp family. The transformation of predators into nectar lovers most likely occurred because they fed on pollinating insects, on which pollen was constantly present.

Mineral wool or other fibrous materials

These materials are considered the most popular insulation for bee nests. Mineral wool or tow (flax, potato, hemp) is stuffed into fabric bags and spread evenly. Sometimes, to give strength, the finished pillow is fixed in a wooden frame. Fibrous materials absorb moisture, but are destroyed very slowly under its influence, which is their main advantage over polystyrene foam and isolon.

Other improvised means

Leaves, hay, straw, and moss are used as available materials. They stuff the burlap, straighten it evenly and stitch it well so that the material does not bunch up. These cushions are attached to the walls and roof of the hive. If there is no burlap, then you can put together a wooden frame, cover it with thick fabric, and fill the space with any of the available means. This insulation option is the most budget-friendly, but, unfortunately, this insulation will not last long - over time it cakes and begins to transmit heat.

Important! When making holes in the roof, you need to

not to overdo it so that there is no draft.

And if straw is used, mice may want to eat it. In addition, all these materials are of plant origin, so they can easily become moldy. Some people use film as a means of improvisation, but this insulation option is ineffective in winter. It is best to use it in the spring, when you need to maintain a certain temperature regime in the hive.

The potential of bee venom against coronavirus

The development of adjuvant therapies (using APi M and PLA2) for use against SARS-CoV-2 infections offers a unique approach to viral therapy. The development of a DC-based bee venom vaccine using APi M and bvPLA2 opens new opportunities for additional medical interventions against SARS-CoV-2 infections. Research examining cellular signaling between the bee venom proteins Janus kinase (JAK) and activator of transcription (JAK-STAT) will help strengthen its use in complementary medicine against SARS-CoV-2. JAK inhibitors are associated with improved prognosis in patients with COVID-19, but studies are needed to elucidate the cellular mechanisms. Synergistic activity through combinations in alternative and complementary medicine will help combat side effects associated with current monotherapies for treating SARS-CoV-2 infections. SARS-CoV-2 is a new virus, and new treatments may be needed to support treatment over time, which may be important for supporting the immune response in patients suffering from so-called long COVID.

Read more

Ventilation in winter

Ventilation is not only the flow of fresh air, but also the maintenance of a certain microclimate. It is very important if the winter keeping of bees involves placing their house in an omshanik (an insulated room for wintering bees). The humidity in the air quickly increases, which negatively affects the condition of the bees. Typically, ventilation in the hive is carried out through the flyer.

If the hive is located outside, where the temperature has dropped below –15°C, then the hive will quickly become covered with frost, which is formed due to the warm air coming out of it. Gradually, the air gap will decrease, which causes a decrease in air flow. To avoid such a situation, it is recommended to make several holes in the roof (d=5 mm), if the insulation allows it, or to make the roof deck wider.

What is wintering?

Many insects, having grown fat over the summer and autumn, have adapted to wait out an unfavorable period with low temperatures and a lack of food in a state of hibernation. Bees are not able to accumulate fat for the winter and can survive only if their body temperature does not fall below +14…15 ℃.

One of the features of a bee is that its body temperature can fluctuate from +13 to +44 ℃. At temperatures below +13 degrees the insect stops flying, at +8 it falls into torpor, and when it drops to +2 ℃ (and below) it dies.

To survive the winter, bees have developed their own unique method - gathering in a club. This usually happens when it gets cold outside and the ambient temperature does not rise above +8 ℃.

Looking into the hive in winter, you can see a club that looks like a flattened ball

The active life of insects continues in the club: they consume food and, thanks to the use of muscular energy (due to micromovements of the pectoral muscles), maintain a constant temperature - about 25 degrees inside and 12 along the outer edges of the club. The insects located in the outer layer form a shell 3-5 cm thick. When the honey in the crops of these bees runs out, they move inside, giving way to insects from the central part. With increasing cold weather, the club contracts, increasing the thickness and density of the shell; with warming, it expands. The club does not remain in one place, but gradually moves from the brood frames towards the top of the hive.

How to properly insulate a hive for the winter?

Warming a hive is a simple procedure, but the process itself requires certain knowledge and skills, so a beginner cannot cope without tips.

Preparatory work

If you plan to winter the bees in the wild (on the street), then you need to line up all the hives in a row so that their side walls touch: this will reduce the number of blown sides, which means the bees will be warmer. When insulating a structure, you should not forget about its bottom, so the hives should be placed on felt mats or boxes filled with straw. After this, you should take measurements of each bee house.

Did you know? Frame hives, the prototypes of which are most often used today for keeping bees, were invented in 1814 by the Russian beekeeper P. I. Prokopovich.

Material selection

Now you can start choosing the material. When giving preference to one option or another, you need to consider the following points:

- Availability. The material should be such that it can be easily obtained and convenient to work with.

- Thermal conductivity. Each of the described material options has its own ability to retain heat. You need to study the characteristics of each to choose the optimal one for your climate zone.

- Hygroscopicity. This indicator should be minimal so that wintering bees do not increase their activity due to moisture and do not consume honey reserves. The best option is hemp tow.

- Structure. It’s good if the insulation is elastic and does not cake over time. Tow and dry moss have these properties.

- Rodent resistance. It is very important for bees to feel protected in their shelter, so the material of their house should not be attractive to rodents who may want to feast on insects or honey. Firewood, cotton wool and felt are not interesting to rodents. You can also use straw and hay, but only mixed with pine needles.

Assembly technology

Now we will describe step by step the process of assembling some insulating structures.

From foam plastic or isolon:

- Cut out the necessary parts from wooden blocks - the size of the sides of the house.

- Assemble the wooden frame by connecting the parts with nails or self-tapping screws.

- Measure the internal dimensions of the resulting frames.

- Under each of them, cut out a piece of polystyrene foam or isolon.

- Insert insulation into frames.

- Treat the joints with sealant or foil tape.

- Hang the resulting frames on the bee houses.

Video: insulating a hive for the winter with polystyrene foam

Fibrous materials:

- Select fabric bags of suitable sizes or sew them.

- Fill the bags with insulation.

- For the roof, create a frame structure by securing the bag between two sheets of plywood.

- Secure the resulting pillows to the house.

From available means:

- The first two actions are similar to the previous case.

- In bags, the insulation must be well leveled and stitched so that it does not bunch up.

- To prevent heat from escaping through the voids, you need to build a plywood box for the pillows.

You will be interested to know where wasps and hornets spend the winter.

Bee venom in the treatment of cancer

Bee venom has been studied for cancer; melittin is considered cytolytic but nonspecific. Melittin can disrupt the lipid bilayer of the membrane and exhibits toxicity when administered intravenously. APi M has the ability to suppress tumor growth in breast, liver, prostate and lung cancer cells. In vitro and in vivo studies indicate that melittin can suppress cancer cell growth by inhibiting NF-κB signaling and activating caspase 3 and 9 pathways. Inhibition of hepatocellular carcinoma cell motility has been observed in vitro and in vivo through inhibition of Rac1-dependent pathways.

Recommendations from experienced beekeepers

Often, due to inexperience, novice beekeepers make many mistakes. To avoid them, you need to follow the recommendations:

- You should not over-insulate the bee house, as high temperatures cause insects to awaken from hibernation and go about their daily business.

- You cannot do strong ventilation, as this will negate all the insulation.

- It is better to avoid using raw materials that attract rodents.

- If you did not have time to build a utility room before November, then in this case you cannot do without insulation.

- In order for moisture to escape better from the house, you need to drill 2 holes in the roof and floor.

- If ventilation is carried out through several summer houses, then it is better to build valves on them and open them one by one.

- If fiberboard is used to insulate hives in winter huts or outdoors, then it must be oiled.

Insulating a bee house is an extremely important point in beekeeping: without creating comfortable conditions, it is impossible to raise a productive swarm. If the bees die, then the costs of restoring their numbers will be more significant than the costs of insulating their homes.

Anti-inflammatory potential of bee venom

Low doses of bee venom produce a range of anti-inflammatory responses that have been studied in diabetes, rheumatoid arthritis (RA), heart disease, obesity, asthma, skin diseases and diseases associated with the central nervous system (Alzheimer's disease, Parkinson's disease, etc.) sclerosis). Bee venom suppresses inflammatory cytokines, including interleukin-6 (IL-6), IL-8, interferon-γ (IFN-γ), and tumor necrosis factor-α (TNF-α). Reductions in signaling pathways responsible for the activation of inflammatory cytokines, nuclear factor-kappa B (NF-κB), extracellular signal-regulated kinases (ERK1/2), protein kinase Akt, and human Porphyromonas gingivalis lipopolysaccharide (PgLPS) keratinocytes are associated with melittin treatment (65 ) (Fig. 2).

Beekeepers' opinion

Beekeepers note the disadvantages and advantages of a hive made of polyurethane foam.

The benefits include:

- rapid increase in bee colony. Thanks to the comfortable microclimate, the queen begins to lay eggs in early spring;

- in extreme heat the hive does not overheat. This avoids swarming;

- In winter, houses made of polyurethane foam are warm. Insects do not form a ball, but will continue to actively move around the hive;

- there are no voids inside;

- The smooth surface of the structure simplifies maintenance and disinfection.

This design also has disadvantages:

- difficulties with collecting propolis with a chisel;

- if the fitting of parts is done carelessly, insects gnaw at the joints of the hive;

- low strength of the material, which is why birds often damage the hive.

As mentioned above, the low weight of the bee house increases the risk of it tipping over.

Beekeepers do not have a clear opinion regarding the use of polyurethane foam for making hives. Someone is against such structures. Others, on the contrary, introduce innovations and get good results.

At this time, most beekeepers have very mixed opinions about polystyrene foam hives.

Many people think that it is very difficult to make, since the foam tends to crumble. When cleaning the housings, polystyrene foam is subjected to destruction, crumbling into grains. At the same time, the products begin to lose their healing qualities.

Also, hives made of such material can be worn out quickly. Then the gaps must be closed with propolis. In addition, polystyrene foam is attractive to various small rodents, who chew it with pleasure and easily seep into the bee house. You can convince yourself whether bees gnaw such hives by watching the video.

You can’t do without a net on the bottom, otherwise the sunbed will become damp and covered with mold. Food in such a hive quickly deteriorates, which is destructive for the bees.

Positive feedback includes the fact that the polystyrene foam hive holds the temperature well and is stable.

Evidence made from such material is fragile and must be constantly monitored in case of shock.

Beekeepers who prefer everything natural believe that a wooden hive is best suited for keeping bees. After all, they are accustomed to living and developing in tree hollows. This material is quite durable and is better suited for collecting honey.

There have also been complaints about light leaking into the polystyrene foam hive. It cannot be painted, as the material is hypersensitive to solvents. It was also discovered that the small moth manages to make a move, but there is no way to disinfect it with a burner.

Many beekeepers insist that evidence made from polystyrene foam is warm and moisture-resistant. Others, on the contrary, insist on excessive dampness and mold.

Judging by the reviews, the conclusion suggests itself that making beehives from polystyrene foam should be done very carefully, strictly follow the drawings and take into account any nuances. If you do not adhere to them, unpleasant consequences will appear in the near future. The location of the apiary of such hives and climatic conditions also matter.

For example, in Europe hives made of polystyrene foam are highly valued. Beekeepers insist on their strength, since the material is quite dense in nature. There they completely abandoned wooden hives, and for a long time. Europeans believe that they have a lot of shortcomings.

To draw a conclusion, you should read reviews and watch videos of those beekeepers who have already tried polystyrene foam hives in their apiary.

Sources

- https://MyPchel.ru/pchelovodstvo/uley/uli-ppu-i-pps

- https://UlejPchel.ru/paseka/uli-iz-penopolisterola

- https://alt-zem.org/drugoe/izgotovlenie-ul-ev-iz-penopolistirol-nyh-plit.html

- https://upchel.ru/pchelovodstvo/uli/iz-ppu-i-pps

- https://DomaFerma.com/pchyoly/obustroystvo-ulya/uli-iz-penopolistirola.html

- https://DomPchel.ru/pchelovodstvo/ulej/penopolistirol/

- https://PchelGid.ru/ulej-iz-penopolistirola-svoimi-rukami

- https://stroimpilim.ru/%D0%B1%D0%B5%D0%B7-%D1%80%D1%83%D0%B1%D1%80%D0%B8%D0%BA%D0%B8/ uli-iz-penopolistirola.html

- https://MirPchely.ru/pchelovodstvo/uli/iz-penopolistirola

[collapse]

Some nuances when using

Due to the fact that the inner walls of the polystyrene foam hive do not absorb moisture, the process of thermoregulation occurs differently than in wooden structures. Therefore, instead of the usual canvas for beekeeping, plastic film is used here.

To ensure a comfortable air-temperature regime for bees, the hole in the bottom is closed in the spring, and the entrance is open 4-5 cm. In the cold season, on the contrary, the lower ventilation hole is open and the entrance is completely closed.

In this case, wet condensation from the bees’ breath settles on the walls and flows down to the open hole. In warm summer weather, the internal space is ventilated through the entrance and the lower mesh, and the upper hole is closed until honey collection begins.

To stabilize a light hive in an apiary in windy weather, bricks or other sufficient weight should be placed on top of the lid. In this case, the wind will not be able to disturb the established position.

Characteristics of hives

Both PPS and PUF are synthetic materials, which are a fairly dense structure extruded from penoplex, styrodur, and polyurethane. Their advantage from the point of view of design is lightness, ease of processing and maintainability.

How bee hives made of polyurethane foam and polystyrene foam function needs to be precisely understood in order for beekeeping to bring extremely positive results.

Beehive made of polystyrene foam PPS

A polystyrene foam hive weighs about 4 kg when empty (body weight). If compared with a wooden structure, it weighs on average 30 kg, which is significantly different in value. Such a bee house can be purchased at a specialized store or made independently. At the same time, the use of polystyrene foam allows the use of simple production technology that does not require complex tools or special skills.

It is necessary to take into account the negative impact of natural and weather conditions. Therefore, polystyrene foam hives are painted on the outer surface to prevent exposure to ultraviolet radiation, thermal changes, and moisture.

Beehive made of PPU polyurethane foam

Polyurethane hives are houses for insects, which are made from modern material that has a number of advantages. It is precisely because of their positive qualities that they are quite widespread in European countries. This synthetic material is safe for both insects and humans.

But, most often, for protection, the structure is covered with aluminum foil, which can significantly extend the period of operation of the houses.

High-quality assembly of the hive and the presence of ventilation are the key to the survival of bees

Bottom ventilation diagram

When preparing hives for the winter, you should remember such an important point as ventilation. It is necessary so that carbon dioxide and excess moisture leave the hive, and in turn oxygen enters.

Note! In order for the hive to be well ventilated, it is equipped with two entrances - one from below, the other from above.

Preparing the hive for assembly

One of the bees' winter feeding sessions

Let's start with the fact that preparing hives for winter directly depends on where the bees winter. They can be located outside, in a special winter hut, a damp cellar or basement. When wintering outside, do not forget to insulate the hive well so that your bees simply do not freeze.

As for assembly, this also has its own nuances: pay attention to the fact that insulation depends on the type of hive structure and the material from which it is made (do not forget about honey, which will also require a considerable amount).

Now let's look at several types of schemes that are most often used among beekeepers:

- Single-sided assembly;

- Double-sided assembly;

- Assembly "Beard".

Attention! Insulation of the loggia is not required if you store beehives on it. It will be sufficient if it is simply glazed.

Assembly "Beard"

Beehives insulated with foam plastic