Plumbing has become an integral part of a modern country house, along with heating and sewerage.

At the same time, metal products are gradually disappearing calmly and with dignity, giving way to plastic. Thanks to the simplicity and manufacturability of execution, do-it-yourself installation of polypropylene pipes for water supply is becoming the norm today.

The decision to use plastic products is dictated by time; such networks are more durable, they are environmentally friendly, and also have a number of other advantages. But which products are better to choose for water supply - polypropylene or metal-plastic, we will analyze in this article.

Classification and design parameters

Existing GOST standards (ISO10508) establish a classification of polypropylene hoses, based on which this material can be used under certain operating conditions.

Marking of PP pipes clearly indicates operational parameters

Taking this designation into account, it is easy and simple to select a material for a specific heating system configuration. Long polypropylene products are divided into 4 classes (1.2, 4.5) according to typical areas of application and operating pressure values (4,6,8,10 ATI):

Long polypropylene products are divided into 4 classes (1.2, 4.5) according to typical areas of application and operating pressure values (4,6,8,10 ATI):

- class 1 (hot water systems up to 60°);

- class 2 (hot water systems up to 70°C);

- class 4 (underfloor heating and radiator systems up to 70°C);

- class 5 (radiator systems up to 90°C).

For example, polypropylene pipes are required to make a low-temperature heating system. Then, by the designation on the outer surface of the pipes, you can determine the appropriate material.

For this case, hoses with the designation Class 4/10 are quite suitable, which corresponds to the limiting temperature parameter of 70ºС and the permissible operating pressure limit of 10 ATI.

Industry, as a rule, produces products for universal use. The manufactured products support an extensive classification. In the documentation for such material, the marking of PP pipes is indicated by a standard listing of acceptable parameters (Class 1/10, 2/10, 4/10, 5/8 bar).

Each branded product has an application class designation on its external surface, which actually determines the operational parameters of the future home heating design

Thus, when planning to make heating in a polypropylene house with your own hands, the main material is usually chosen by the master in direct proportion to:

- from planned operating parameters;

- on methods of heating the coolant;

- on the applied regulatory system.

It is also advisable to calculate the service life of the future heating system using the following parameters:

- upper values Trab and Prab;

- pipe wall thickness;

- outside diameter;

- safety factor;

- duration of the heating season.

On average, the service life of polypropylene should be at least 40 years.

Wiring

How is polypropylene water supply pipes installed?

In the vast majority of cases, it is a tee, with serial connection of plumbing fixtures. Tees are mounted on the connections, to which bends with thread adapter fittings are welded.

Tee water supply made from polypropylene

Collector distribution of water with polypropylene is not that impossible, but rather impractical, since it involves the installation of a large number of fittings. In such cases, pipes supplied in coils - PEX and PERT polyethylene - are more preferable.

Installation of heating from polypropylene pipes

Creating heating from polypropylene pipes with your own hands begins with installing a boiler. Only professionals can perform error-free installation.

Boiler room, fragment of heating system with pp pipes

They will issue a document confirming proper installation. It will not allow you to lose the warranty of the equipment manufacturer.

Strapping sequence

First, preparatory work is carried out. The installation locations of radiators are determined. This allows you to perform a hydraulic calculation if necessary. Then the process is carried out in the following order:

- A riser from the boiler, an expansion tank and a starting line are installed.

- Heating devices are installed in each room.

- The installation points for fittings and shut-off valves are outlined.

- The circulation pump is being connected.

- PP pipes are installed. When laying in building structures, insulating material is used.

- Radiators are connected to the created thermal circuit of the house.

Finally, system checks are performed. The pipeline network is filled under pressure with water or air to check the tightness of the joints. After successfully completed tests, the heating system is fully launched.

Solder connection

To join polypropylene elements, socket soldering is used if the PP pipes have different diameters. Straight parts are inserted into each other. A special soldering iron is used to heat the elements. The same equipment is used when joining using fittings.

Elements with a large identical diameter are connected by end soldering without the use of couplings. Another type of equipment is used to heat the parts. Its kit often includes a trimmer.

Soldering equipment

The tool, in the form of a soldering iron, is equipped with nozzles of different diameters. Its cost is approximately from 20 to 100 dollars.

Soldering is carried out as follows:

- Straight sections are cut to the required length using a pipe cutter.

- If necessary, the ends are cleaned to remove burrs and debris.

- Nozzles of the required diameter are attached to the soldering iron.

- The two elements being connected heat up.

- One part is inserted into another until it stops without turning around its axis.

The created joint is held motionless for several seconds until the polypropylene cools. The result is a tight and durable connection.

Gasket in walls

Due to the expansion of polypropylene when heated, the laying of PP pipes in house structures is carried out with heat-insulating material. This is glass wool, mineral wool or other heat insulator.

With hidden installation, a minimum of joints are made. It is better to install hatches at the junction points.

The grooves in the walls are created using a grinder and a hammer drill. After laying the pipelines, the tightness of all joints must be checked. Only upon completion of the tests are the grooves sealed with cement or gypsum mortar.

Mounting methods

There are two options for installing pipelines - hidden, external. The second option is simple, but the pipes do not always look beautiful. The first option is more labor-intensive, but the pipeline will be hidden from view.

External mount

To perform external installation of a pipeline, you need to prepare a minimum set of tools. Regardless of fastener type, the workflow remains the same. Dowels are used to secure clips or clamps.

External pipe fastening to the wall

Hidden mount

To hide pipes in the walls, you need to use high-quality materials and follow all technologies. Polypropylene can withstand high loads and exposure to chemicals. Thanks to this, the material will last a long time without deformation. To complete the installation, you will need more tools than with an open pipeline.

Stage one. Drafting

Installation work should begin with drawing up a project for the future highway. An important criterion in this case is ergonomics, as a result of which the number of turns and connecting elements should be minimal.

Heating wiring

Heating wiring

When arranging a heating system, a well-designed project is especially important, in which you should indicate the location of such elements as:

- couplings;

- adapters;

- fasteners;

- corners;

- heating equipment.

The line is connected to the radiators in a one- or two-pipe way, from the side or from the bottom.

Heating system diagram

Plumbing

Laying water pipes in the bathroom

Here the main line is connected to a centralized system for the purpose of water supply to the necessary plumbing fixtures - toilet, sinks, boiler, etc. There are two ways to do the wiring.

Method number 1. Open option. Horizontal pipes are installed slightly above floor level, and vertical pipes are installed exclusively in the corners. All this allows you to make the pipeline less noticeable.

Method number 2. Closed option. It is extremely difficult to implement, since it involves preliminary carrying out the most accurate calculations. Pipes (necessarily solid) are walled up in the walls, and there must be free access to each joint.

Laying water pipes in the bathroom

In addition, the water supply layout can be:

- sequential type (the most cost-effective and easiest to implement option);

- collector type (a collector is used when supplying water);

- with pass-through sockets (not very popular).

System planning

When developing a design for a heating system for a cottage or house, the area of living quarters and the degree of wall insulation are taken into account. The standard heat rate per square meter is 41 kcal. The technical characteristics of the battery indicate the thermal power of one section. Based on these data, the number of radiator sections is calculated.

Additional calculations include:

- Length of polypropylene pipe routing;

- Number of turns and adapters;

- Availability of thermostats and bypasses;

- Installation of vertical and horizontal structures;

- Connection diagram to the boiler room (bottom, side, two-pipe or single-pipe version.

Preparation for installation of PP pipes

To install PP pipes, it is important to carefully study the diagram of the water supply and heating system, prepare a number of tools and read the step-by-step instructions. All work is carried out in several stages

All work is carried out in several stages.

Stage 1 drafting

Before purchasing materials for installing pipes with your own hands, you need to draw up a diagram of their connection. To connect batteries to the heating circuit, the following methods are used:

- Flow-through.

- Installation with unregulated bypass.

- Installation with valves.

- With three way valve.

Home plumbing may also differ in wiring diagram. Today, two technologies for installing polypropylene pipes are used:

- Parallel. It is carried out according to this principle: a collector resembling a flute is installed at the entrance of the water supply system. With its help, you can create a series of bends in any convenient direction.

- Tee (considered a traditional solution).

A separate pipe is pulled from each branch. The advantage of this system is the same level of pressure at all points of liquid collection, but the disadvantage is the need to use a large number of pipes. Moreover, if one element is damaged, the remaining parts will work without failure.

The last scheme is called sequential and consists of laying a single pipe for all plumbing. Further branches are made from it using a tee.

Stage 2 preparation of instruments

Working with polypropylene pipes requires the use of special tools. The cost of all devices will vary from 5 to 10 thousand rubles. The basic set consists of:

- Welding equipment or soldering iron for working with polypropylene.

- Scissors for cutting pipes.

- Shaver for removing aluminum coating.

- A calibrator with which you can monitor the diameter of all components.

- Parts for heating the soldering elements.

| Photo of the instrument | Name |

| welding machine, for work at home it is recommended to use units designed for welding PP pipes of small and medium diameter - up to 63 mm. | |

| The pipe cutter is an ideal device for cutting polypropylene. | |

| Shaver - designed to remove a layer of reinforcement. | |

| A trimmer is needed for high-quality pipe joining | |

| Marker for marking pipes. | |

| Using a building level and a pencil, draw the direction of the pipes on the wall | |

| A tape measure is one of the main tools in construction. | |

| A degreaser is needed to remove impurities from the surfaces of welding joints. |

In addition, you need to find an adjustable wrench, a tape measure and a marker. If PPR structures and pipeline installation are implemented once, it is better to ask friends for tools or rent them.

Stage 3 selection of polypropylene fittings

To install a water supply system from polypropylene pipes with your own hands and combine them with home plumbing, you should purchase special PP fittings. Among them:

- Adapters.

- Nipple type bends.

- Connecting couplings.

- Tees.

- Plugs.

- Crosses.

- Ball Valves.

- Clamps.

Since the quality of fittings may vary, it is necessary to select them taking into account the characteristics of the pipe.

Stage 4 selection of connection diagram

To install water pipes in an apartment using polypropylene, you should find a connection diagram. The specifics of soldering may differ for pipes of different diameters. Pipes of the same thickness are connected end-to-end, and pipes of different thickness are connected using the socket method. It involves joining one part of a pipe into an extended fitting.

1. Upper ball valve for heated towel rail. 2. Ball valve on the jumper. 3. Bottom ball valve for heated towel rail. 4. Main tap for hot water. 5. Filter – “Mud trap” 6. Counter. 7. Fine filter. 8. Pressure reducer. 9. Collector. 10. Main tap for cold water.

The connection of PP products can be detachable or permanent. In the first case, threaded fittings are soldered to the ends of the parts. With one-piece installation, two polypropylene structures merge.

Large linear extension

If you are planning to use polypropylene pipes for heating, then immediately plan to use them only in hidden installation. You will need to hide all pipes in the walls and screed, and preferably in insulation.

The main problem with polypropylene is its linear expansion. It is approximately 2.5 mm per linear meter. If you have installed straight pipes, then during operation they will definitely “float” somewhere. Even if you fasten them often. If these pipes are located outside, then you are unlikely to appreciate such a picture.

How to connect plastic and metal pipes for water supply

When choosing a method for connecting plastic pipes, take into account the following features:

- Product material. Couplings are used for gluing polyethylene products; for polypropylene, a welding machine is required.

- Purpose of the pipeline. If pipes for sewerage are connected, sockets are used, for water supply pipes welding is used, heating is held together using couplings.

- Workload. If you are doing a small amount of work, you can do the installation yourself; if you need to do large-scale work, you should use the services of specialists.

Polypropylene

Recently, the most popular are polypropylene products, which are distinguished by their high strength, reasonable price and availability. Installation of such a structure is carried out by welding; it will be impossible to join the pipe without soldering. To carry out the work, use products from the same manufacturer. Before you begin, get the following tools:

- A welding machine, colloquially a “soldering iron.” To get the job done efficiently, choose tools that come with different attachments.

- Pipe cutter Using the device, you can easily cut products and adjust them to the desired size.

- Sandpaper and a file are useful for removing the reinforced layer at the end of the product (use only when working with multi-layer products)

- A tape measure and a simple pencil will help you take accurate measurements.

Metal-plastic

Methods for connecting metal-plastic structures are extremely simple:

- Compression fittings.

- Push fittings.

- Compression fittings.

The most common and simplest is the first assembly option. To complete the work you will need a calibrator and a pipe cutter. If these tools are not available, use a mounting knife and a cylindrical object of suitable size. The welding method will be ineffective, so do the work without using additional equipment.

Polyethylene

Polyethylene pipes are assembled in several ways. The most popular are two installation methods:

- Welding using an electric coupling.

- Use of compression fittings.

When using the second option, the following sequence of work is performed:

- Products are sawn to the required size.

- The chamfer is removed.

- The following are put on the pipe: a nut, a collet, a thrust ring, and an O-ring.

- The end of the product is placed in the housing, screwed with the necessary parts and a nut.

Most often, this method is used to install water pipes in summer cottages. Welding with electric couplings is used in large country houses. The cost of such a device is quite high, so it is often rented.

Polyvinyl chloride

Not everyone knows how to connect PVC pipes. Most often, polyvinyl chloride products are joined using a special composition that melts the plastic. When applying glue, make sure that no dirt or dust accumulates on the surface of the pipe. Perform all actions quickly: 25 seconds after applying the adhesive, the pipes must be connected, otherwise the glue will dry. When working with such materials, you should not use couplings.

Polypropylene

Below we describe the algorithm of actions on how to correctly connect polypropylene pipes:

- Heat up the soldering iron. Unplug the device and heat it up again.

- While the soldering iron is heating, the reinforced layer is removed from the pipe.

- Clean surfaces from dirt.

- Insert the fitting and pipe into the nozzle. The most important thing is to withstand the heating time, which depends on the diameter. If overheated, products may become deformed. If the heating is poor, the connection will be weak.

- Then, the parts are pulled out of the nozzles and connected as quickly as possible.

Metal-plastic

The easiest way is to use push fittings when connecting metal-plastic pipes. The tube is inserted all the way, when performing these steps you do not need to perform any effort, the tube fits in easily. Once the plumbing system is turned on, run the water, the flow will push the wedge, preventing leakage. This is the easiest and fastest way to assemble pipes.

Polyvinyl chloride

Below we describe how PVC pipes are connected correctly:

- The surfaces are cleaned and chamfered.

- The depth of the fitting is measured. The location is marked with a simple pencil.

- Two parts of the pipe are treated with an adhesive composition using a brush.

- The parts will connect and rotate 25 degrees at different angles from each other.

What is galvanizing

A galvanized water supply pipe is a steel pipe, the inner and outer surfaces of which are coated with a thin layer of zinc, a metal that is not subject to corrosion. The longevity of the pipeline directly depends on the quality, strength and thickness of the applied coating. Galvanization is carried out in several ways:

- electrogalvanic - a method based on electrolysis (under the influence of electric current, zinc from the electrolyte is deposited on a steel surface), allows you to obtain an even layer of zinc 10-25 microns thick, but not the highest adhesion and the presence of porosity;

- hot galvanizing - a steel pipe with a carefully polished, cleaned surface is immersed in a container with molten zinc (450°C), which envelops it, forming a dense coating 40-200 microns thick. The surface may have sagging, thread filling;

- thermal diffusion - a method of obtaining the highest quality coating by treating a steel pipe with zinc vapor under high temperature in a closed container. Zinc particles are “embedded” in the structure of the steel surface, providing reliable adhesion. The layer turns out dense, uniform, durable.

Galvanized pipes for water supply have a number of advantages:

- strength, resistance to loads, water hammer, mechanical damage, wear resistance;

- the roughness of the internal surface is reduced, which increases throughput and significantly slows down the overgrowth of the pipe section;

- corrosion resistance;

- operating temperature 20°C – 140°C;

- working pressure 1.6 MPa;

- minimal thermal expansion, stability of the pipeline design;

- average service life 20 years.

As a rule, in domestic and industrial indoor water supply, a galvanized round pipe with a diameter of 20-160 mm is used, made of ordinary quality carbon steel or high-quality carbon structural steel, seamless or straight-seam electric welded.

The wall thicknesses are standard (2.5-4.5 mm), light (2-4 mm) and reinforced (4-5 mm). The weight of the pipe product after galvanizing increases by 3%. Length is measured, multiple measured (4-12 m).

Galvanized pipes for cold water supply with an uninterrupted supply of drinking water are safe for human health, since the maximum permissible concentration of zinc does not exceed 5 mg/l (the daily norm of zinc is 10-15 mg).

Galvanized pipes are used to organize autonomous water supply when constructing wells, but this is not provided for by SNiP and GOST. There is no sufficient water exchange inside the well; due to the influence of carbon dioxide, the composition of the water due to chemical reactions deteriorates significantly. The soil environment does not exclude electrochemical corrosion at the joints.

Determining the optimal diameter

The installation of the main line is always preceded by a preliminary calculation of polypropylene pipes. It is carried out to determine the quantity and optimal diameter of products for a specific pipeline system, based on its purpose.

A correctly selected diameter ensures minimal losses and the required pressure in the system even during hours of maximum (peak) water consumption. Calculation is especially important when designing a water supply system for an apartment building with a large number of plumbing fixtures.

You can independently calculate the internal diameter of the pipe using the formula:

- where Qtot is the maximum (total) water flow,

- V is the speed at which water is transported through pipes.

For thick pipes, the speed value is taken to be 2 m/s, and for thinner pipes - 0.8 - 1.2 m/s.

But owners of apartments and small country houses should not waste time on complex calculations. Considering that the overall permeability of the pipeline system depends on the throughput of the narrowest point, it is enough to purchase pipes with a diameter of 20.0 mm, provided that the length of the water pipeline does not exceed 10 meters. With a standard number of sanitary fixtures (sinks, toilets, washbasins), the throughput of pipes of this diameter will be sufficient.

For a total pipeline length of up to 30 meters, it is necessary to use 25 mm diameter products, and for a length of more than 30 meters - 32 mm.

Which soldering iron for polypropylene pipes is better to buy?

All machines for welding plastic pipes have heating elements and matrices where the ends of the pipe and fitting are placed. In them, the workpieces are heated and connected to each other, creating a sealed circular seam in a matter of seconds.

The main parameters for choosing a tool are:

- Power. It varies from 600 to 2000 W and affects the heating rate of the plastic and productivity - the higher the figure, the faster the work will be done.

- Number of nozzles and their diameter. This determines what diameter pipes can be connected using a welding machine.

- Temperature adjustment. Facilitates adjustment when working with polypropylene from different manufacturers, whose melting temperature ranges from 220 to 260 degrees. Improves the use of a soldering iron depending on the time of year - especially in winter, when the plastic is colder.

But for different types of work it is important to choose the right soldering iron shape. There are only two of them

Ensiform apparatus

They have an elongated plate, in the shape of a wide sword, on which attachments are bolted. The temperature from the plate is transferred to the dies. These soldering irons are also called irons due to the shape of the heating element.

Such models are more designed for stationary work on a table. The welding machine is good for working in uncluttered places where it is convenient to crawl with a sword-shaped structure. Also, due to the ability to install several pairs of dies at once, it is convenient for welding polypropylene pipes of different diameters.

Cylindrical devices

This type of soldering iron for polypropylene pipes has a heating element in the form of a cylinder. The nozzles are put on it from the end and pressed with bolts along the edges included in their design. The distance of the matrix from the edge of the cylinder is not limited in any way (there is no specific mounting hole), so you can set any distance for soldering pipes near the wall. The body of the instrument continues its cylindrical shape, which makes it much more compact than other models.

Such welding machines for plastic pipes are best in the case of complex communications separation: branching in a boiler room, connecting heated floors to a collector, soldering in narrow niches, etc. Thanks to the thin shape of the device, it is convenient to get to limited places and turn it in different directions to perform a junction of pipes already connected on one side to the system. But if desired, they can also be used stationary, for which the manufacturer provides a small folding plate-stand.

Stage two. Welding of polypropylene pipes

Welding of polypropylene pipes

This procedure will require an electric jigsaw (cutting polypropylene) and special welding equipment.

Welding machine

Step one. While the apparatus is warming up, the necessary measurements are taken, the pipes are marked and cut.

Scissors for cutting polypropylene pipes

Step two. The ends of the products that are planned to be connected to each other are thoroughly cleaned and degreased.

Step three. Using a pencil, mark the depth of insertion of each product into the sleeve. It is typical that at least a millimeter gap should remain, so the pipes do not rest against the fitting coupling.

Errors when butt welding polypropylene pipes

Step four. The PP pipe with fitting is put on the sleeve in accordance with the marks made, and heating of all elements must occur simultaneously.

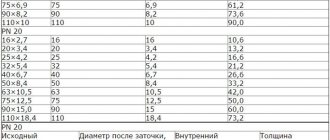

The heating duration depends not only on the diameter of the products, but also on the depth of welding (this can be found in the table below).

Technological pause table

Step five. After a certain period of time, the products are removed and connected, pressing onto each other with little effort. It is prohibited to rotate the elements along the center line.

Welding process of polypropylene pipes

Step six. Within a few seconds after the connection, an initial adjustment is made, then the elements are finally fixed.

Welding of polypropylene pipesWelding of polypropylene pipes

If there are no gaps left at the connection point, then it (the connection) can be considered high quality.

A large number of joints

Another disadvantage in organizing heating with polypropylene pipes is the large number of joints. The average house can sometimes have 200-300 joints and most of them are hidden in the screed and walls. And every junction is a human factor that can play a cruel joke. At any moment, any joint can leak. It's good if he's outside. But as practice shows, quite often the joint begins to leak inside.

And taking into account the constant linear expansion of the pipe, the joint may also lose its tightness. It would be correct to note that such situations do not always occur.