The article was prepared with the participation of DOZATECH specialists

Despite the fact that our country is one of the largest exporters of blue fuel, there is no need to talk about widespread gasification. For many consumers both in Moscow and Siberia, the cheapest heating method is unattainable now, and it is not a fact that it will be available in the future. Therefore, we have to look for alternative heating sources; fortunately, the choice in this area is impressive. And in recent years, the range of heating equipment has been replenished with an interesting unit - a pellet boiler. Let us dwell in more detail on this type of equipment, for which we will consider the following aspects:

- What is a pellet heating boiler and what fuel does it use?

- Unit design.

- Advantages and disadvantages of a pellet boiler.

- What to look for when choosing a unit.

What is a pellet boiler

In essence, this is a type of solid fuel boiler, but designed for a specific type of fuel (pellets) and with the possibility of full or partial automation of the work process.

It is the ability to function autonomously with minimal intervention from the owners that makes pellet boilers radically different from conventional solid fuel boilers.

They have a higher efficiency (efficiency factor) - both due to the characteristics of the pellets and due to the design features. Pellet boilers can be either highly specialized - intended only for pellets, or combined (universal) - capable of running on wood or coal, some models operate on almost any biomass; husks, wood waste and the like can be used as fuel.

Alexander DimitrevRepresentative of DOZATECH, a manufacturer of pellet boilers

With a certain boiler design, it can burn any biomass of very low calorie content - wood chips, bark, wood waste, agricultural waste, sunflower husks and more.

Pellets, or wood pellets, are environmentally neutral fuel, obtained mainly from waste from the wood processing industry (chips, shavings, bark), but they can also be from agricultural waste. Pellets appeared in the thirties of the last century, when the first installation for pressing waste from local sawmills into pellets was invented and tested in the state of Idaho. Under strong pressure, the raw material mass is heated, which provokes the formation of lignin, which binds the smallest particles into dense, smooth granules. This allows you to abandon the use of chemicals - pellets are a completely natural, environmentally safe fuel. The diameter of the granules varies between 6-8 mm, length – up to 50 mm. In European countries, pellets are classified as standardized fuels and are produced according to the DIN plus standard.

In our country, their production is not so developed and supervised; the quality of the granules, on which both the efficiency of the boiler and its performance will depend, is determined visually - white ones are better than gray ones. Unlike wood, pellets have low humidity and high density, which is why when burning, more heat is released and a minimal amount of carbon dioxide is released. If we translate this property into numbers, for comparison, we get the following ratio: when burning a ton of pellets, the same amount of heat will be released as when burning 1.6 tons of firewood. The ash content will be only 0.5% of the burned volume, and the emitted flue gases will be colorless.

The approximate calorific value of pellets is 5 kW/hour per kilogram, but how close the actual efficiency will be to the theoretical data depends on the quality of the pellets themselves and on the performance of the boiler in which they will be burned.

How to determine quality fuel pellets?

Let's talk about the cost of fuel right away. It depends on the quality and class of pellets, but on average, wood pellets (for example, from pine) cost about 6 thousand rubles per ton, and from peat - about 5.5. Prices may vary in one direction or another, but the general figures are clear.

The efficiency of heating with pellets depends mainly on their quality. And this quality, in turn, is completely determined visually. Read the instructions below to learn how to determine product quality.

- Dust. If there is a lot of dust in the package of pellets, it means that the product is of low quality and you have every reason to return it to the seller.

- The surface of the granules must be smooth and free of any defects (bumps or cracks). If such defects exist, it means that there were violations in the production process.

- Color. If pellets for heating have a grayish tint, this indicates that they are stale. And the quality of such fuel will certainly be low.

- Length. Often this is 2.5 centimeters, but, frankly, this figure only indicates European production standards.

- Smell. Good granules should smell slightly sweet - this indicates that all requirements were met during production.

Unit design

The pellet boiler itself consists of three main components:

- Furnace - equipped with a special burner (retort or torch) and two doors (control, cleaning).

- Convective zone - a heat exchanger is located in it: it can be vertical, horizontal or combined, tubular or plate type. In the convective zone, the coolant in the heat exchanger is heated by gases released during the combustion of pellets. Most units are designed only for heating and have one circuit, but some models have two circuits: heating and water heating.

- Ash pan - it receives combustion waste (insignificant during normal afterburning), which is periodically removed through the cleaning door.

However, the listed components are, although the main part, but only a part, the operation of which requires the APT attachment (automatic fuel supply). This attachment includes the following components:

- A hopper is a container for pellets of a certain volume, from which the pellets enter the combustion chamber; it can be built-in or external.

- Auger - portions feed granules to the burner as needed, driven by a gearbox.

- A fan is necessary to maintain the combustion process, since the boiler design does not provide for natural draft.

Since the pellet boiler is an automated system, its device also includes a control unit with a display, which displays information about the current state, and through which the main operating parameters are set. The controller regulates the ignition of the burner, the supply of pellets and air, and stops when the desired temperature is reached, maintaining the heating mode selected by the owner.

Depending on the capacity of the bunker and the selected mode, one filling can be enough for several days, a week or even more.

To make the heating process fully automatic, the boiler can be connected directly to the storage - a pneumatic pipe will supply granules to the bunker as it is emptied.

Advantages and disadvantages of a pellet boiler

One of the main advantages of pellet boilers is their efficiency; in this indicator they are second only to gas main heating. This is due to the high efficiency of the equipment, the high calorific value of pellets, and their affordable cost. The second aspect that attracts consumers is process automation. Unlike other solid fuel boilers, pellet boilers do not require constant monitoring and regular manual fuel supply. It also wins over units running on diesel fuel in terms of environmental friendliness - no odors or black smoke.

The main disadvantage of these units is their substantial price - these are the most expensive solid fuel units, the cost of an automated station made in Europe is measured in hundreds of thousands, domestic ones are slightly cheaper. Not every private owner can afford such investments into the heating system of their home. However, with equipment longevity now approaching two decades, it is a wise investment in the long term.

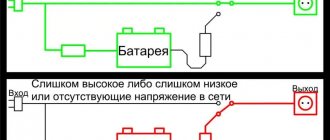

In addition to the high cost, the disadvantages include energy dependence - the automation requires electricity, and if a shutdown of several hours (on average up to 10) is acceptable and will not disrupt the settings, then a longer shutdown will stop the operation of the boiler. The station must be equipped with an independent energy source, which will further increase the cost of the system.

Consumption of pellets for heating a house 150m2

In a not very severe winter, 50W is needed to heat 1m2 per hour. For the whole day this is 1200 W.

The amount of pellets burned to produce heat of 1 m2 per day will be 1200 W/4.25 kW/kg = 280 g.

- per day: 0.28kg*150m2=42kg.

- per month: 42kg*30days=1260kg.

But these figures also turn out to be overestimated if the house is well insulated. Many homeowners with a well-insulated home spend much less kg. On average, the amount needed is reduced by 35%. Then the cost of heating a 150 sq. m house with pellets is also reduced by this amount. Similarly, the amount of raw materials required per month is reduced to 825 kg.

What to look for when choosing a unit

Despite the relative “youth” of this type of solid fuel, there is a large selection of boilers of foreign and domestic production on the market. To choose the optimal unit for your conditions, you should pay attention to several important parameters.

Power - each manufacturer has a fairly wide range of models, including both household and industrial units. As with any heating equipment, power is measured in kilowatts (kW), the power of household models starts from 15 kW. Since heating a room with average heat loss requires about 1 kW per 10 m², such a boiler is capable of heating a house of 150 m². However, it is worth considering that the boiler is needed with a small margin.

Efficiency - the higher this indicator, the more economical the heating process. For pellet burners, the efficiency varies between 85-95% and depends both on the quality of the pellets and on the design features.

Alexander Dimitrev

The five-pass heat exchanger ensures high efficiency of the boiler - it allows you to obtain maximum heat removal when gases pass through the convective zone to the chimney.

The specialist advises paying attention to the material from which the boiler is made and the type of heat exchanger.

Alexander Dimitrev

Boilers made of thick metal (6 mm and 8 mm, depending on power) are more durable. The thickness of the metal affects the service life of the boiler; this is also important - how many years the unit will operate. A plate heat exchanger has advantages over a tubular one - it is more convenient to clean.

Installation of a heating system includes several stages:

1. Preparatory - visit of a specialist to agree with the client on the heating system. selection of components for the project, drawing up the estimated cost of installation and consultation on related work.

2. Design - at this stage, taking into account the structural features of the object, climatic conditions, and the financial wishes of the customer, the heating of a country house is calculated according to the parameters of the thermal regime, calculation of external fences (from the shade). determination of thermal loads (heat loss of premises); boiler equipment operating on the selected type of fuel is selected, the placement of equipment, risers, and mains is determined, and equipment connection diagrams are agreed upon.

3. Installation - heating a country house at the installation stage includes the installation of a boiler room and heating radiators. water or electric heated floors, as well as commissioning work; The heating system is carried out according to the terms agreed with the customer.

From the moment the installation of the system is completed, the heating of a country house

enters the stage of warranty service, which is carried out by qualified personnel in accordance with the warranty obligations specified in the coupon. Service maintenance includes carrying out repair work after the manufacturer’s warranty period has expired for the equipment.

Conclusion

Pellet boilers are modern, environmentally friendly and cost-effective heating equipment. At the moment, they are less in demand than conventional solid fuel units, but in the future they may well conquer the market due to the high quality of heating and decent performance.

On our portal, in the forum section about boiler equipment, an entire thread is devoted to pellet boilers. No less useful and interesting is the article on how to prepare for the heating season. Another option for autonomous heating is heat pumps. In the video, a portal participant shares his experience of installing a pellet burner with his own hands.

Subscribe to our Telegram channel Exclusive posts every week